ECSS system

Glossary of terms

Foreword

The ECSS Glossary is part of the series of ECSS Standards intended to be applied together for the management, engineering and product assurance in space projects and applications. ECSS is a cooperative effort of the European Space Agency, national space agencies and European industry associations for the purpose of developing and maintaining common standards.

Requirements in ECSS Standards are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards.

This document has been prepared by the ECSS Glossary Task Force, reviewed and approved by the ECSS Technical Authority.

Traceability to the previous ECSS Glossary “ECSS-P-001B” is ensured through the matrix given in Annex A.

Disclaimer

ECSS does not provide any warranty whatsoever, whether expressed, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item are error-free. In no respect shall ECSS incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this Standard, whether or not based upon warranty, business agreement, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by ECSS.

Published by: ESA Requirements and Standards Division

ESTEC, P.O. Box 299,

2200 AG Noordwijk

The Netherlands

Copyright: 2012© by the European Space Agency for the members of ECSS

Change log

|

ECSS-P-001A

|

First issue

|

|

ECSS-P-001A Rev.1

|

First issue, Revision 1

|

|

ECSS-P-001B

|

Second issue

|

|

ECSS-S-ST-00-01C

|

Third issue

|

Scope

This document controls the definition of all common terms used in the European Cooperation for Space Standardization (ECSS) Standards System. Terms specific to a particular ECSS Standard are defined in that standard.

This document does not include the definition of terms used with their common meaning. In this case, the definition from the Oxford English Dictionary applies.

Terms, definitions and abbreviated terms

Terms and definitions

When using the ECSS standards, the following is the order of precedence of documents as the source of definition of terms:

-

the standard in question

-

the present Glossary of terms

-

the Oxford English dictionary.

A term used within a definition, which is defined elsewhere in this document is shown in boldface. A boldface term may be replaced within the definition by its own definition.

A concept that has a special meaning in a particular context is indicated by designating the context in angle brackets, < >, before the definition.

A document reference shown after a definition in square brackets, [ ], indicates that this definition is reproduced from the referenced document.

For example:

All terms and their definitions appear in alphabetic order in clause 2.3 of this Glossary. However, wherever it is considered important to present together a set of terms that are interrelated (i.e. constitute a particular “view”), these terms and their definitions are repeated in standalone sections of this Glossary or in Annexes. For example, clause 2.2 collects together all terms that relate to the breakdown of the overall Space System.

Space system breakdown

Introduction

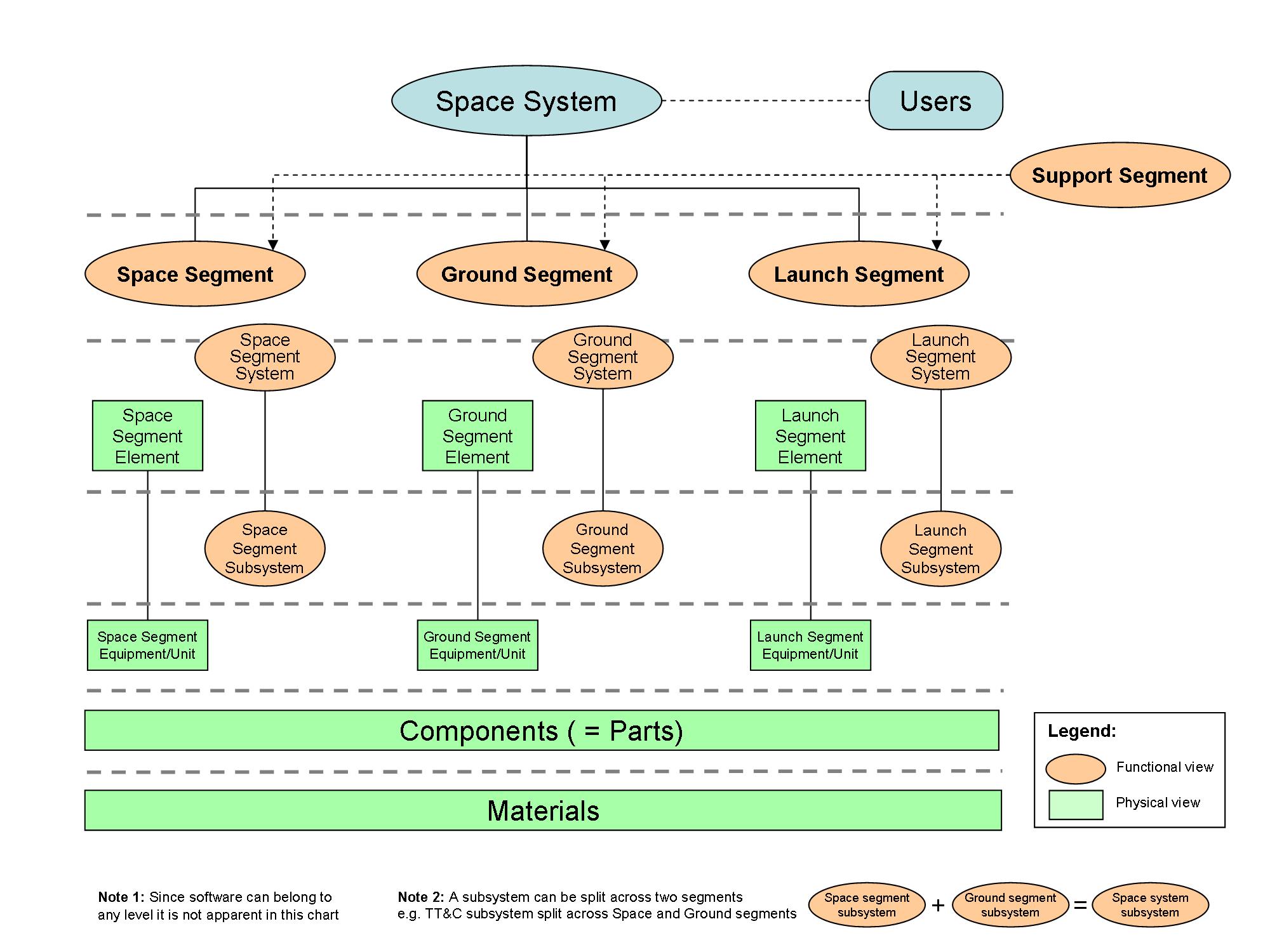

ECSS-S-ST-00C defines the highest-level system within a space project – i.e. the one at the mission-level - as the “Space System”. The purpose of the present clause is to identify the breakdown of a typical space system and to define a set of standard terms for the constituent levels within the breakdown (see Figure 21).

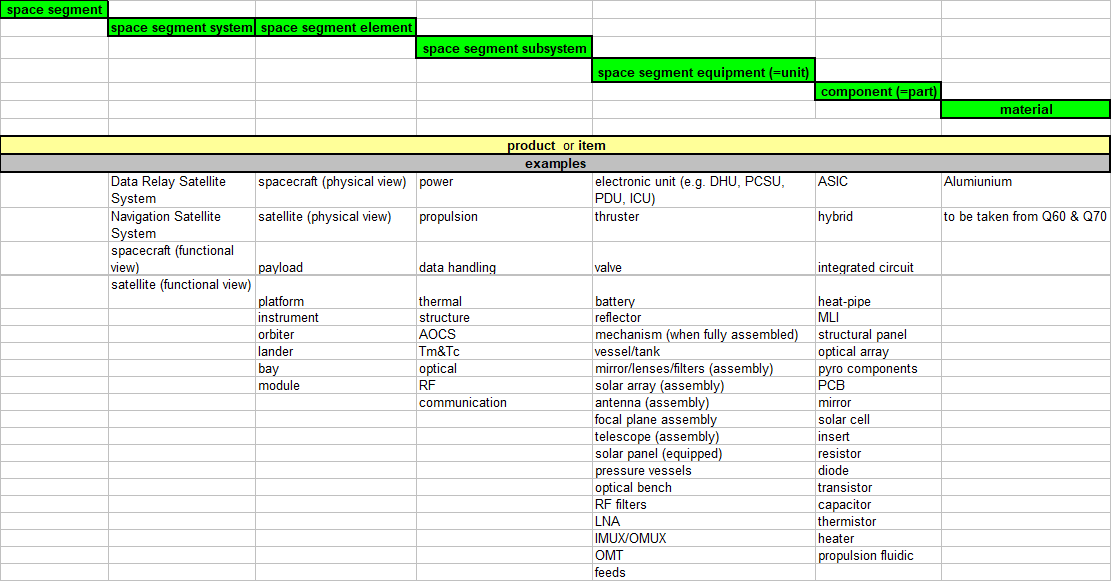

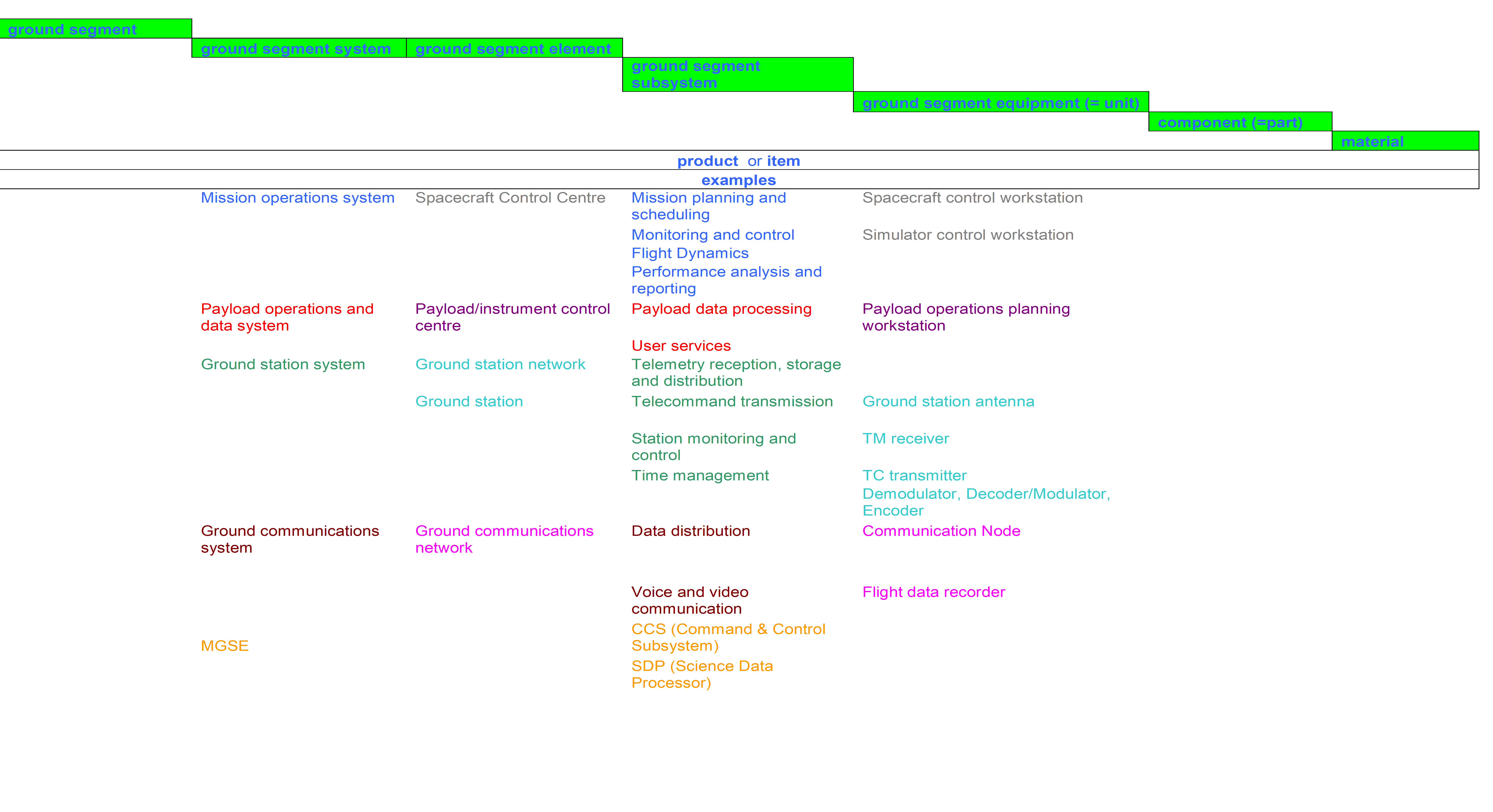

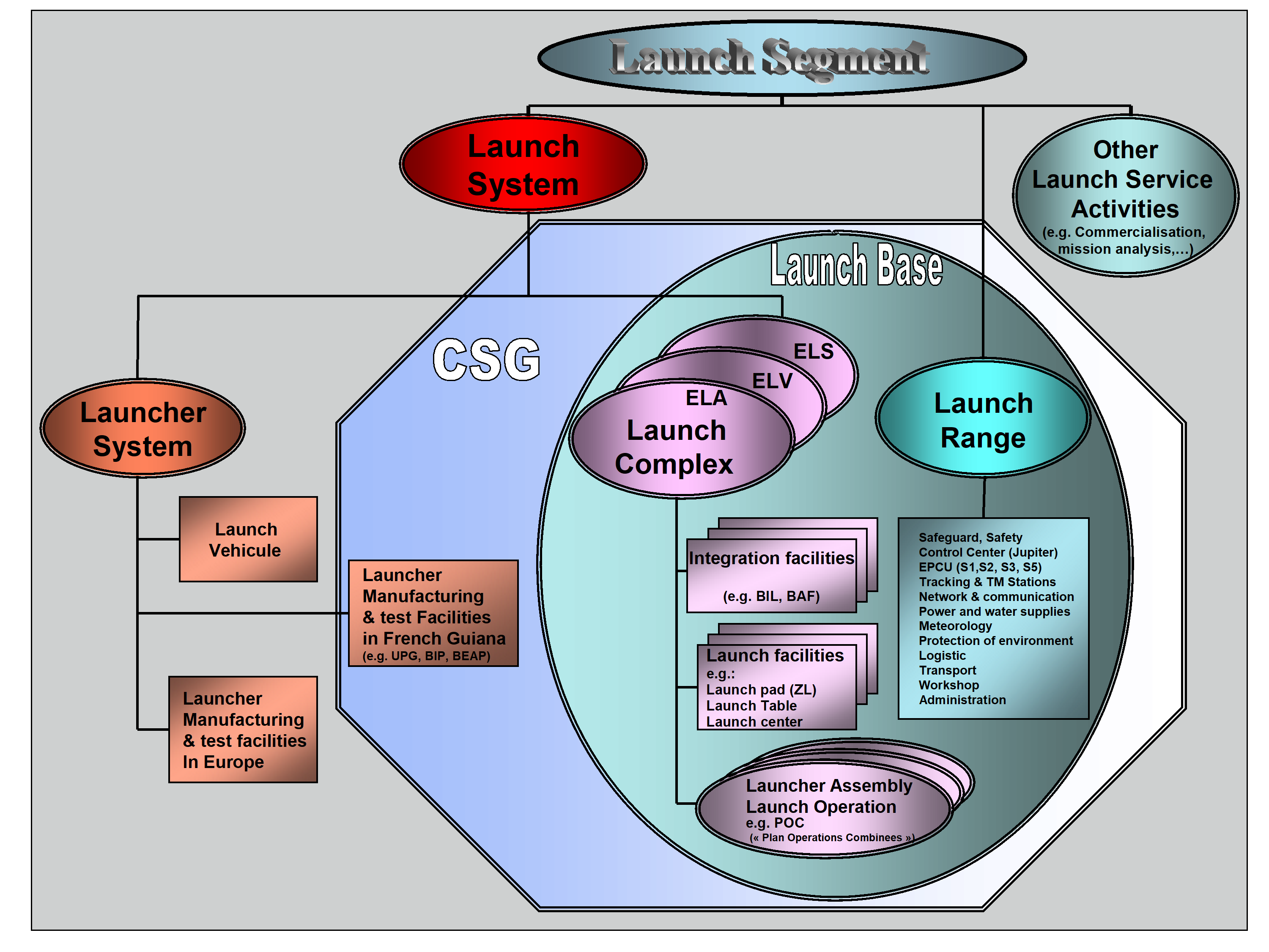

In so doing, it is acknowledged that each distinct domain (i.e. space, ground and launcher) already has its own domain-specific terminology for its internal entities e.g. elements and systems. In the case of the launcher domain, this terminology has been formally defined and agreed at programme-level. It is not the intention to define new terms in this Glossary to supersede those already in universal use. Rather, the intention is to define a standard set of terms for the levels of the space system breakdown and then to show where the domain-specific entities fit into these levels. To this end, Annex B contains examples of entities from the three principal space system segments, mapped to the space system breakdown levels defined below.

The terms are defined in clause 2.2.2 to 2.2.7 and are listed not in alphabetic order but according to the hierarchy defined in Figure 21: Space system breakdown below.

2.2.2 defines generic terms

2.2.3 defines the space system

2.2.4 defines terms relating to the space segment

2.2.5 defines terms relating to the ground segment

2.2.6 defines terms relating to the launch segment

2.2.7 defines terms relating to the support segment

Figure 21: Space system breakdown

Figure 21: Space system breakdown

Definitions for generic terms

system

set of interrelated or interacting functions constituted to achieve a specified objective

segment

set of elements or combination of systems that fulfils a major, self-contained, subset of the space mission objectives

Examples are space segment, ground segment, launch segment and support segment.

element

combination of integrated equipment, components and parts

An element fulfils a major, self-contained, subset of a segment's objectives.

subsystem

part of a system fulfilling one or more of its functions

equipment

integrated set of parts and components

- 1 An equipment accomplishes a specific function.

- 2 An equipment is self-contained and classified as such for the purposes of separate manufacture, procurement, drawings, specification, storage, issue, maintenance or use.

- 3 The term "unit" is synonymous with the term "equipment"

component

set of materials, assembled according to defined and controlled processes, which cannot be disassembled without destroying its capability and which performs a simple function that can be evaluated against expected performance requirements

- 1 The term "part" is synonymous.

- 2 The term "part" is preferred when referring to purely mechanical devices.

- 3 The term "component" is preferred for EEE devices.

part

see "component"

material

raw, semi–finished or finished substance (gaseous, liquid, solid) of given characteristics from which processing into a component or part is undertaken

Definitions for space system

space system

system that contains at least a space, a ground or a launch segment

Generally a space system is composed of all three segments and is supported by a support segment.

Definitions for space segment

space segment

part of a space system, placed in space, to fulfil the space mission objectives

space segment system

system within a space segment

Examples are given in Annex B.1.

space segment element

element within a space segment

- 1 A space segment element can be composed of several space segment elements, e.g. a spacecraft is composed of instruments, a payload module and a service module.

- 2 Examples are given in Annex B.1.

stand-alone space segment element

space segment element that performs its mission autonomously

For example: satellite, rover, lander.

embedded space segment element

space segment element that performs its mission as part of another space segment element

For example: platform, module, instrument, payload.

space segment subsystem

subsystem within a space segment

Examples are given in Annex B.1.

space segment equipment

equipment within a space segment

Examples are given in Annex B.1.

Definitions for ground segment

ground segment

part of a space system, located on ground, which monitors and controls space segment element(s)

A ground segment is composed of one or more ground segment elements.

ground segment system

system within a ground segment

Examples are given in Annex B.2.

ground segment element

element within a ground segment

- 1 A ground segment element can be composed of several ground segment elements, e.g. a ground station network is a ground segment element that can be composed of a set of ground stations and a communication network.

- 2 Examples are given in Annex B.2.

ground segment subsystem

subsystem within a ground segment

Examples are given in Annex B.2.

ground segment equipment

equipment within a ground segment

Examples are given in Annex B.2.

Definitions for launch segment

launch segment

part of a space system which is used to transport space segment element(s) into space

- 1 A launch segment is composed of one or more launch segment elements.

- 2 A launch segment is composed of the integrated launcher and the facilities needed for manufacturing, testing and delivering launcher elements.

launch segment system

system within a launch segment

Examples are given in Annex B.3

launch segment element

element within a launch segment

- 1 A launch segment element can be composed of several launch segment elements, e.g. a launcher is a launch segment element that is composed of several launch segment elements, such as stage, engine and upper part.

- 2 Examples are given in Annex B.3.

launch segment subsystem

subsystem within a launch segment

Examples are given in Annex B.3.

launch segment equipment

equipment within a launch segment

Examples are given in Annex B.3.

Definitions for support segment

support segment

generic infrastructure and services used to support the development and operation of space system elements

- 1 Examples are ground stations and associated networks, orbit computing facilities, test centres, astronaut centre, launch facilities (e.g. Plestek, Baikonour, Guiana Space Centre).

- 2 Items can be part of other segments during their development and later become part of the support segment when used (e.g. a tracking network).

Terms and definitions

acceptance

<act> act by which the customer agrees that the product is designed and produced according to its specifications and the agreed deviations and waivers, and it is free of defects when delivered by the supplier

acceptance

<process> that part of the verification process which demonstrates that the product meets specified acceptance margins

accident

undesired event arising from operation of any project-specific item that results in

human death or injury,

loss of, or damage to, project hardware, software or facilities that can then affect the accomplishment of the mission,

loss of, or damage to, public or private property, or

detrimental effects on the environment.

Accident and mishap are synonymous.

active redundancy

redundancy where all entities are operating and the system can continue to operate without downtime or defects despite the loss of one or more entities

actuator

device that transforms an input signal into motion

alert

formal notification to users, informing them of failures or nonconformance of items, already released for use or not, which could also be present on other items already delivered [e.g. items with identical design concept, materials, components or processes]

An alert can also be raised when a deficiency in the specified requirements, which can affect the fitness for purpose in the defined application, has been identified.

allowable load

maximum load that can be permitted in a structural part for a given operating environment to prevent rupture, collapse, detrimental deformation or unacceptable crack growth

Adapted from ISO 14623:2003.

analysis

<verification> verification method utilizing techniques and tools to confirm that verification requirements have been satisfied

- 1 Examples of techniques and tools are mathematical models, compilation similarity assessments and validation of records.

- 2 Adapted from ISO 10795:2011.

anomaly

any deviation from the expected situation

An anomaly justifies an investigation that might lead to the discovery of a nonconformance or a defect.

applicable document

document that contains provisions which, through reference in the source document, constitute additional provisions of the source document

Adapted from ISO 10795:2011.

approval

formal agreement by a designated management official to use or apply an item or proceed with a proposed course of action

- 1 Approvals must be documented.

- 2 Approval implies that the approving authority has verified that the item conforms to its requirements.

assembly

<act> physically combining parts, components, equipment or segment elements to form a larger entity

assurance

planned and systematic activities implemented, and demonstrated as needed, to provide adequate confidence that an entity fulfils its requirements

audit

systematic, independent and documented process for obtaining audit evidence and evaluating it objectively to determine the extent to which audit criteria are fulfilled

- 1 Internal audits, sometimes called first-party audits, are conducted by, or on behalf of, the organization itself for management review and other internal purposes, and may form the basis for an organization’s declaration of conformity. In many cases, particularly in smaller organizations, independence can be demonstrated by the freedom from responsibility for the activity being audited.

- 2 External audits include those generally termed second- and third-party audits. Second-party audits are conducted by parties having an interest in the organization, such as customers, or by other persons on their behalf. Third-party audits are conducted by external, independent auditing organizations, such as those providing certification/registration of conformity to ISO 9001 or ISO 14001.

- 3 When quality and environmental management systems are audited together, this is termed “combined audit”.

- 4 When two or more auditing organizations cooperate to audit a single auditee jointly, this is termed “joint audit”.

[ISO 9000:2005]

audit criteria

set of policies, procedures or requirements

Audit criteria are used as a reference against which audit evidence is compared.

[ISO 9000:2005]

audit evidence

records, statements of fact or other information which are relevant to the audit criteria and verifiable

Audit evidence can be qualitative or quantitative.

[ISO 9000:2005]

auditee

organization being audited

[ISO 9000:2005]

auditor

person with the demonstrated personal attributes and competence to conduct an audit

Adapted from ISO 9000:2005.

availability

ability of an item to be in a state to perform a required function under given conditions at a given instant of time or over a given time interval, assuming that the required external resources are provided

- 1 This ability depends on the combined aspects of the reliability performance, the maintainability performance and the maintenance support performance.

- 2 Required external resources, other than maintenance resources do not affect the availability performance of the item.

- 3 When referring to the measure for availability, the preferred term is “instantaneous availability”.

- 4 Adapted from IEC Multilingual Dictionary: 2001 edition.

backward contamination

contamination of the terrestrial biosphere by extra-terrestrial life forms in the course of spaceflight missions

bakeout

activity of increasing the temperature of hardware to accelerate its outgassing rates with the intent of reducing the content of molecular contaminants within the hardware

Bakeout is usually performed in a vacuum environment, but may be done in a controlled atmosphere.

baseline

set of information which describes exhaustively a situation at a given instant of time or over a given time interval

A baseline is generally used as a reference for comparison with and analysis of subsequent evolutions of the information.

batch

quantity produced at one operation

black box

representation of an item whereby knowledge of its internal composition is not available to the user, only its function and interface characteristics are known

business agreement

legally binding agreement, for the supply of goods or services, between two or more actors in the customer–supplier chain

Business agreements are recorded in a variety of forms, such as:

- Contracts,

- Memoranda of understanding,

- Inter-governmental agreements,

- Inter-agency agreements,

- Partnerships,

- Bartering agreements, and

- Purchase orders.

calibration

all the operations for the purpose of determining the values of the errors and, if necessary, other metrological properties of a measuring instrument

The metrological use of the term “calibration” is often extended to include operations such as adjustments, scale graduation, etc. This use is deprecated.

[IEC Multilingual Dictionary: 2001 edition]

capability

ability of an organization, system or process to realize a product that will fulfil the requirements for that product

Process capability terms in the field of statistics are defined in ISO 3534-2.

[ISO 9000:2005]

catastrophic

<safety> resulting in loss of life, life-threatening, permanently disabling injury or occupational illness, loss of system, loss of an interfacing manned flight system, loss of launch site facilities or severe detrimental environmental effects

certification

procedure by which a party gives formal assurance that a person or an organization acts, or a product is, in compliance with specified requirements

Certification can be carried out by a first, second or third party.

clean area

area under contamination control

Examples of clean areas are cleanrooms, integration tent, gloves box.

cleanliness

level of particulate or molecular contamination

cleanroom

clean area controlled according to specified levels

Specified levels are humidity, temperature, particulates number versus size and volume and chemical contamination.

cold redundancy

redundancy where one entity is operating and the others are powered off

commissioning

verification and validation activities conducted after the launch and before the entry into operational service either on the space segment elements only or on the overall system (including the ground segment elements)

common cause failure

failure of multiple items occurring from a single cause that is common to all of them

common mode failure

failure of multiple identical items that fail in the same mode

Common mode failures are a particular case of common cause failures.

component

set of materials, assembled according to defined and controlled processes, which cannot be disassembled without destroying its capability and which performs a simple function that can be evaluated against expected performance requirements

-

1 The term "part" is synonymous.

-

2 The term "part" is preferred when referring to purely mechanical devices.

-

3 The term "component" is preferred for EEE devices.

composite

building block of a launcher composed of one or several pre-integrated stages and structural parts (fairing, payload adaptor, dual launch structure, etc.) -

1 Example-1: A5 Upper Composite includes the cryogenic upper stage (ESC), the vehicle equipment bay (VEB), fairing and payload adaptor.

-

2 Example-2: A5 Lower Composite includes two solid booster stages (EAP) and the main cryogenic stage (EPC).

configuration

interrelated functional and/or physical characteristics of a product defined in configuration documents subject to configuration management

Adapted from ISO 10007:2003.

configuration baseline

approved status of requirements and design of a product at a project key milestone that serves as a reference for activities throughout the life cycle of the product

Adapted from ISO 10007:2003.

configuration control

coordinated activities for controlling modifications to a configuration baseline

Requests for deviation are also considered modifications to a baseline.

configuration document

document that defines the requirements for function, design, build, production, and verification for a configuration item

For space standards, configuration documents can include documents relating to operation and disposal of the configuration item.

configuration identification

coordinated activities to establish rules for configuration item selection, configuration baseline content definition, and product and document identifiers definition

configuration item

aggregation of hardware, software, processed materials, services or any of its discrete portions, that is designated for configuration management and treated as a single entity in the configuration management process

A configuration item can contain other configuration item(s).

configuration management

activity for establishing and maintaining consistent records of the performance parameters of a product and its functional and physical attributes compared to product design and operational requirements

- 1 Configuration management is applied throughout the entire life cycle of the product (i.e. development, production, deployment, operation and disposal).

- 2 Adapted from ISO 10007:2003.

configuration status accounting

formalized recording and reporting of product characteristics and configuration information, the status of applicable changes and the status of their implementation

Adapted from ISO 10007:2003.

configuration verification

coordinated activities to determine the conformance of the configuration item to its configuration document(s)

conformance

fulfilment of a requirement

The term “conformity” is synonymous.

conformity

see “conformance”

* The term “conformance” is strongly recommended for use in the ECSS system.

contaminant

undesirable molecular or particulate matter

This includes microbiological matter.

contamination

introduction of contaminant to an item or to the environment of interest

contract

legally enforceable business agreement in which payment is part of the conditions

corrective action

action to eliminate the cause of a detected nonconformance, or other undesirable situation

- 1 There can be more than one cause for a non-conformance.

- 2 Corrective action is taken to prevent recurrence whereas preventive action is taken to prevent occurrence.

COTS

commercial electronic component readily available and not manufactured, inspected or tested in accordance with military or space standards

critical

<general> characteristic of a process, process condition, parameter, requirement or item that deserves control and special attention in order to meet the objectives (e.g. of a mission) within given constraints

critical

<safety> resulting in temporarily disabling but not life threatening injury, temporary occupational illness, major detrimental environmental effects, major damage to public or private properties, major damage to interfacing flight systems or major damage to ground facilities

critical item

potential threat to the schedule, cost, performance and quality of a project or programme that is controlled by a specific action plan in order to mitigate emanating risks and to prevent undesirable consequences

Examples of critical items are:

- item not qualified or validated for the application in question (or has caused problems previously which remained unresolved).

- item for which it is difficult to demonstrate design performance.

- item highly sensitive to the conditions under which it is produced or used (e.g. contamination, radiation).

- item having the potential to degrade the quality of the product significantly, and hence the ability of the end-product to accomplish defined mission objectives.

- item for which major difficulties or uncertainties are expected in the procurement, manufacturing, assembly, inspection, test, handling, storage and transportation, that have the potential to lead to a major degradation in the quality of the product.

critical path

chain of activities that determines the earliest completion of the project

As a consequence, any delay of one task belonging to the critical path extends the project duration.

customer

organization or person that receives a product as part of a business agreement

A customer can be internal or external to the supplier organization.

defect

non-fulfilment of a requirement related to an intended or specified use

-

1 The distinction between the concepts defect and nonconformance is important as it has legal connotations, particularly those associated with product liability issues. Consequently the term “defect” should be used with extreme caution.

-

2 The intended use as intended by the customer can be affected by the nature of the information, such as operating or maintenance instructions, provided by the supplier.

dependability

the extent to which the fulfilment of a required function can be justifiably trusted -

1 Its main components are reliability, availability and maintainability.

-

2 Dependability shall be considered in conjunction with safety.

derating

action when designing a product to limit the component stresses to specified levels that are below their ratings in order to increase its reliability

design

<result> set of information that defines the characteristics of a product

design

<activity> process used to generate the set of information defining the characteristics of a product

The design is completed at CDR closure.

development

complete process of elaborating a product from concept to manufacturing including its qualification and final acceptance

Technology development and design production are part of the process (i.e. from phase 0 to phase D).

deviation

formal authorization to depart from the originally specified requirements for a product, prior to its production

Waiver is an a posteriori decision whereas deviation is an a priori decision with respect to the production phase.

discipline

specific area of expertise within a general subject

The name of the discipline normally indicates the type of expertise (e.g. in the ECSS system, system engineering, mechanical engineering, software and communications are disciplines within the engineering domain).

discrepancy

departure from expected performance

- 1 A discrepancy can be the result of nonconforming hardware or software, or conditions occurring in test set-up.

- 2 A discrepancy can be momentary, non-repeatable, or permanent.

- 3 Adapted from ISO 10795:2011.

disposal

actions performed by a spacecraft or launch vehicle orbital stage to permanently reduce its chance of accidental break-up and to achieve its required long-term clearance of the protected regions

[ISO 24113:2011]

effectiveness

extent to which planned activities are realized and planned results achieved

[ISO 9000:2005]

efficiency

relationship between the result achieved and the resources used

[ISO 9000:2005]

element

combination of integrated equipment, components and parts

An element fulfils a major, self-contained, subset of a segment's objectives.

emergency

situation where hazardous events have occurred with potentially catastrophic or critical consequences requiring an immediate action

embedded space segment element

space segment element that performs its mission as part of another space segment element

For example: platform, module, instrument, payload.

end item

product that is deliverable under a business agreement

engineering model

flight representative model in terms of form, fit and function used for functional and failure effect verification

-

1 The engineering model is usually not equipped with high reliability parts or full redundancy.

-

2 The engineering model is also used for final validation of test facilities, GSE and associated procedures.

-

3 More detailed information on the build standard and the use of this model is given in ECSS-E-HB-10-02.

engineering qualification model

model, which fully reflects the design of the flight model except for the parts standard, used for functional performance and EMC verification and possibly for qualification -

1 Military grade or lower-level parts can be used instead of high reliability parts, provided they are procured from the same manufacturer with the same packaging.

-

2 Functional performance qualification includes verification of procedures for failure detection, isolation and recovery and for redundancy management.

-

3 The engineering qualification model may also be used for environmental testing if the customer accepts the risk, in which case the qualification model rules apply.

-

4 More detailed information on the build standard and the use of this model is given in ECSS-E-HB-10-02.

environment

natural conditions and induced conditions that constrain the design definitions or operations of a product -

1 Examples of natural conditions are weather, climate, ocean conditions, terrain, vegetation, dust, light and radiation.

-

2 Examples of induced conditions are electromagnetic interference, heat, vibration, pollution and contamination.

equipment

integrated set of parts and components -

1 An equipment accomplishes a specific function.

-

2 An equipment is self-contained and classified as such for the purposes of separate manufacture, procurement, drawings, specification, storage, issue, maintenance or use.

-

3 The term "unit" is synonymous with the term "equipment".

fail-safe

preventing the failure of an item from resulting in catastrophic or critical consequences

failure

the event resulting in an item being no longer able to perform its required function

"Failure" is an event, as distinguished from "fault" which is a state.

failure mode

mechanism through which a failure occurs

- 1 For example,. short-circuit, open-circuit, fracture, or excessive wear.

- 2 This term is equivalent to the term “fault mode” in IEC Multilingual Dictionary: 2001 edition.

failure tolerance

attribute of an item that makes it able to perform a required function in the presence of certain given sub-item failures

fault

state of an item characterized by inability to perform as required

- 1 A fault can be the result of a failure of the item itself or can exist without prior failure.

- 2 A fault can generate a failure.

fault tolerance

attribute of an item that makes it able to perform a required function in the presence of certain given sub-item faults

firmware

hardware that contains a computer program or data that cannot be changed in its user environment

The computer program and data contained in firmware are classified as software; the circuitry containing the computer program and data is classified as hardware.

flammability

measure of the ease with which a material is set on fire

flight model

end product that is intended for flight

- 1 The flight model is subjected to formal functional and environmental acceptance testing.

- 2 More detailed information on the build standard and the use of this model is given in ECSS-E-HB-10-02.

flight operations

all activities related to the planning, execution and evaluation of the control of the space segment when in orbit

flight spare

spare flight model that could be used in place of the flight model

- 1 Exceptionally, a refurbished qualification model can be used as a flight spare.

- 2 More detailed information on the build standard and the use of this model is given in ECSS-E-HB-10-02.

forward contamination

contamination of celestial bodies other than the Earth by terrestrial life forms in the course of spaceflight missions

function

intended effect of a product

function tree

hierarchical breakdown of a function into successive levels of function

functional analysis

process that describes completely the functions and their relationships, which are systematically characterised, classified and evaluated

ground segment

part of a space system, located on ground, which monitors and controls space segment element(s)

A ground segment is composed of one or more ground segment elements.

ground segment element

element within a ground segment

- 1 A ground segment element can be composed of several ground segment elements, e.g. a ground station network is a ground segment element that can be composed of a set of ground stations and a communication network.

- 2 Examples are given in Annex B.2.

ground segment equipment

equipment within a ground segment

Examples are given in Annex B.2.

ground segment subsystem

subsystem within a ground segment

Examples are given in Annex B.2.

ground segment system

system within a ground segment

Examples are given in Annex B.2.

ground support equipment

non flight product (hardware/software) used on ground to assemble, integrate, test, transport, access, handle, maintain, measure, calibrate, verify, protect or service a flight product (hardware/software)

handbook

<ECSS> non-normative document providing background information, orientation, advice or recommendations related to one specific discipline or to a specific technique, technology, process or activity

hazard

existing or potential condition that can result in a mishap

- 1 This condition can be associated with the design, manufacturing, operation or environment.

- 2 Hazards are not events but potential threats to safety.

hazardous event

mishap resulting from a hazard

hot redundancy

redundancy where all entities are powered on with only one operating

human factors

model of observed human physical and psycho-physiological behaviour in relation to environment and product

implementation document

formal response from the supplier to the customer’s Project Requirements Document describing how all requirements will be met

incident

unexpected event that might be, or could lead to, an operational interruption, disruption, loss, emergency, crisis or accident

Incidents are recorded for further assessment.

informative

providing non-normative information intended to assist the understanding or use of requirements

inhibit

<noun> design feature that prevents a function from undesirable execution

An inhibit can be software or hardware.

inspection

conformance evaluation by observation and judgement accompanied as appropriate by measurement, testing or gauging

[ISO 9000:2005]

integration

functionally combining lower-level functional entities (hardware or software) so they operate together to constitute a higher-level functional entity

Assembly is a pre-requisite for integration.

interchangeability

ability of a product to be used in place of another to fulfil the same requirements

interface

boundary where two or more products meet and interact

launch base

composed of launch range and launch complexes

launch campaign

launch activities which include:

Launcher preparation and final integration

Payload processing and integration on the launcher

Launch Operations including Flight Data Gathering

launch complex

integration and facilities necessary to carry out the final integration of the launcher elements as well as the launch operations

A Launch System is associated with its specific Launch Complex, which may include facilities shared with other Launch Systems (e.g.: Lox plant at CSG).

launch operations

all launch related activities taking place after completion of the activities necessary to deliver a fully integrated launcher up to reception of post flight data

launch range

systems, facilities and means, not part of the launch segment, required to provide the necessary service and support for carrying out a launch campaign and to ensure safety and security of persons, assets and protection of the environment

The Launch Range includes in particular the CNES/CSG technical centre, the payload Preparation Facilities as well as the downrange stations for launcher tracking and flight data acquisition.

launch segment

part of a space system which is used to transport space segment element(s) into space

-

1 A launch segment is composed of one or more launch segment elements.

-

2 A launch segment is composed of the integrated launcher and the facilities needed for manufacturing, testing and delivering launcher elements.

launch segment element

element within a launch segment -

1 A launch segment element can be composed of several launch segment elements, e.g. a launcher is a launch segment element that is composed of several launch segment elements, such as stage, engine and upper part.

-

2 Examples are given in Annex B.3.

launch segment equipment

equipment within a launch segment

Examples are given in Annex B.3.

launch segment subsystem

subsystem within a launch segment

Examples are given in Annex B.3.

launch segment system

system within a launch segment

Examples are given in Annex B.3

launch service

activities required to conclude a launch service contract and to place a payload in the orbit, at the time, and under the payload environment conditions required by the customer

Launch Service activities cover in particular: Commercialisation, Mission analysis, Procurement of a fully integrated launcher, Procurement of flight programme(s), Procurement of launcher adaptations to meet specific mission requirements, Payload processing and integration on the launcher, Launch Operations including Flight Data Gathering, Launch Range Operations, Post Flight Analysis.

launch system

system comprising the fully integrated launcher, the launch complex and the needed facilities for manufacturing, testing and delivering the launcher elements

"Fully integrated launcher" means the integrated launcher, including payload, and ready to be launched i.e. all launch control lights on green.

launch vehicle

see "launcher"

launcher

vehicle designed to transport payloads to space

The term “launch vehicle” is synonymous.

launcher element

building block of a launcher

[launcher] production facilities

launcher element manufacturing facilities and related launch complex

The launcher element manufacturing facilities include the test facilities specific to the launcher elements’ manufacturing.

launcher stage

complete element of a launcher that delivers the defined thrust during dedicated phase of the launcher mission

- 1 A launcher stage typically consists of a main propulsion system, a reaction controlled system (sometimes integrated to some extend with the main propulsion system), supporting structure, forward and aft skirts, aerodynamic control and/or stabilized surfaces, a separation system and a destruction system.

- 2 Some of the upper stages are also equipped with an avionics system.

- 3 The Ariane 5 upper stage is made of cryogenic main stage (ESC) and vehicle equipment bay (VEB).

launcher system

fully integrated launcher and the needed facilities for manufacturing, testing and delivering the launcher elements

"Fully integrated launcher" means the integrated launcher, including payload, and ready to be launched i.e. all launch control lights on green.

life cycle

all phases in the life of a product from needs identification through disposal

life profile

conditions to which a product is chronologically submitted from its manufacturing to its disposal

lifetime

period, or number of cycles, over which a product is required to perform according to its specification

lot

batch or portion of a batch

maintainability

ease of performing maintenance on a product

- Maintainability can be expressed as the probability that a maintenance action on a product can be carried out within a defined time interval, using stated procedures and resources.

maintenance

actions needed to retain a product in, or restore it to, a state in which it can perform its required function

Actions may include tuning, control, inspection, repair, replacement or redesign.

material

raw, semi–finished or finished substance (gaseous, liquid, solid) of given characteristics from which processing into a component or part is undertaken

mission

set of tasks, duties or functions to be accomplished by an element

model

physical or abstract representation used for calculations, predictions or further assessment

Model can also be used to identify particular instances of the product e.g. flight model.

multipaction

resonant back and forth flow of secondary electrons in a vacuum between two surfaces separated by a distance such that the electron transit time is an odd integral multiple of one half the period of the alternating voltage impressed on the surface

The effects of multipaction can be loss of output power up to reaching the multipaction breakdown voltage leading to the generation of spark.

nonconformance

non-fulfilment of a requirement

The term “nonconformity” is synonymous but deprecated.

nonconformity

see “nonconformance”

The term “nonconformity” is deprecated.

normative

providing requirements for activities or their results

- 1 A “normative document” covers documents such as standards, technical specifications, codes of practice and regulations.

- 2 A “normative reference" incorporates requirements from a cited publication into a normative document.

offgassing

outgassing under atmospheric or near-atmospheric pressure

Examples are manned and biological missions.

off-the-shelf

procured from the market, even if not developed for space application

orbital debris

see “space debris”

The term “orbital debris” is deprecated.

outage

state of a product being unable to perform its required function

outgassing

gaseous release from a material

Outgassing occurs in vacuum as well as in higher-pressure environments.

part

see "component"

payload

set of space segment elements

- 1 A spacecraft payload is a set of instruments or equipment which performs the user mission.

- 2 A launcher payload is a set of space segment elements carried into space in accordance with agreed position, time and environmental conditions.

performance

quantifiable characteristics of a function

planetary protection

policy and the technical implementations to prevent to prevent forward contamination and backward contamination

preventive action

action to eliminate the cause of a potential nonconformance or other undesirable potential situation

- 1 There can be more than one cause for a potential non-conformance.

- 2 Preventive action is taken to prevent occurrence whereas corrective action is taken to prevent recurrence.

procedure

documented way to carry out an activity or process in a controlled manner

process

set of interrelated or interacting activities which transform inputs into outputs

Inputs to a process are generally outputs of other processes.

product

result of a process

- 1 There are four generic product categories:

- services

- software

- hardware

- processed materials.

- 2 Adapted from ISO 9000:2005.

product assurance

discipline devoted to the study, planning and implementation of activities intended to assure that the design, controls, methods and techniques in a project result in a satisfactory degree of quality in a product

product tree

hierarchical breakdown of a product into successive levels of product

project

set of coordinated and controlled activities with start and finish dates, undertaken to achieve an objective conforming to specific requirements, including constraints of time, cost and resources

project requirements document

integral part of an ITT, RFP, or RFQ prepared and released by a customer to potential suppliers, addressing technical and programmatic requirements, as well as political, commercial, and industrial constraints

The response to a PRD is an ID.

protoflight model

flight model on which a partial or complete protoflight qualification test campaign is performed before flight

More detailed information on the build standard and the use of this model is given in ECSS-E-HB-10-02.

provision

expression in the content of a normative document, that takes the form of a statement, an instruction, a recommendation or a requirement

These types of provision are distinguished by the form of wording they employ, e.g. instructions are expressed in the imperative mood, recommendations by the use of the auxiliary “should” and requirements by the use of the auxiliary “shall”.

[EN 45020:2006]

qualification

that part of verification which demonstrates that the product meets specified qualification margins

This can apply to personnel, products, manufacturing and assembly processes.

qualification model

model, which fully reflects all aspects of the flight model design, used for complete functional and environmental qualification testing

- 1 A qualification model is only necessary for newly-designed hardware or when a delta qualification is performed for adaptation to the project.

- 2 The qualification model is not intended to be used for flight, since it is overtested.

- 3 More detailed information on the build standard and the use of this model is given in ECSS-E-HB-10-02.

quality

degree to which a set of characteristics of a product or process fulfils requirements

quality assurance

part of quality management focused on providing confidence that quality requirements will be fulfilled

[ISO 9000:2005]

quality control

part of quality management focused on fulfilling quality requirements

[ISO 9000:2005]

redundancy

existence of more than one means for performing a given function with the intention of increasing reliability

See also definitions for “active redundancy”, “hot redundancy” and “cold redundancy”.

reliability

the ability of an item to perform a required function under given conditions for a given time interval

- 1 It is generally assumed that the item is in a state to perform this required function at the beginning of the time interval.

- 2 Generally, reliability performance is quantified using appropriate measures. In some applications these measures include an expression of reliability performance as a probability, which is also called reliability.

relifing

quality control activity for the extension of the expiry datecode of a EEE component which is intended to be used for space application

repair

action to correct a defect of a product that leads to a configuration item change

- 1 Unlike rework, repair affects or modifies parts of the defective product.

- 2 An NCR needs to be raised for the CI change.

requirement

documented demand to be complied with

residual risk

risk remaining after implementation of risk reduction measures

[ISO 17666:2003]

review

activity undertaken to determine the suitability, adequacy and effectiveness of the subject matter to achieve established objectives

- 1 Review can also include the determination of efficiency.

- 2 Examples are: management review, design and development review, review of customer requirements and nonconformity review.

[ISO 9000:2005]

rework

action to correct a defect of a product that does not lead to a configuration item change

-

1 Unlike repair, rework does not affect or modify parts of the defective product.

-

2 No NCR needs to be raised.

risk

undesirable situation or circumstance that has both a likelihood of occurring and a potential negative consequence on a project -

1 Risks are inherent to any project, and can arise at any time during the project life cycle.

-

2 Predictability and control of events facilitate risk reduction.

-

3 The terms “risk assessment”, “risk mitigation” and “risk control” are in common use in ECSS.

-

4 Adapted from ISO 17666:2003.

safety

state where an acceptable level of risk is not exceeded

Risk relates to:

- fatality,

- injury or occupational illness,

- damage to launcher hardware or launch site facilities,

- damage to an element of an interfacing manned flight system,

- the main functions of a flight system itself,

- pollution of the environment, atmosphere or outer space, and

- damage to public or private property.

safety critical function

function that, if lost or degraded, or as a result of incorrect or inadvertent operation, can result in catastrophic or critical consequences

safing

action of containment or control of emergency and warning situations, or placing a system (or part thereof), in a predetermined safe condition

scrap

action on a nonconforming product to preclude its originally intended use

- 1 The scrapped product is not recoverable by rework or repair for technical or economic reasons. As a consequence, it will be recycled or destroyed.

- 2 A service is scrapped by being discontinued.

security

state where an acceptable level of risk arising from malevolent action is not exceeded

segment

set of elements or combination of systems that fulfils a major, self-contained, subset of the space mission objectives

Examples are space segment, ground segment, launch segment and support segment.

severity

classification of a failure or undesired event according to the magnitude of its possible consequences

single point failure

part of a product that, if it fails, will result in the unrecoverable failure of that product

solar array

assembly of solar panels on a supporting structure with associated hardware

The associated hardware includes mounting features, cables and, in the case of a deployable solar array, a deployment mechanism.

solar cell

photovoltaic component that converts solar radiation to electricity

solar cell assembly

solar cell together with interconnector, coverglass and, if used, by-pass diode

solar panel

interconnected solar cell assemblies mounted on a substrate

space debris

non-functional fragments of, or residue from, a space segment element, or launch segment element, in Earth orbit or re-entering the Earth’s atmosphere

The term “orbital debris” is synonymous, but deprecated.

space mission

user-defined mission to be achieved by a space system

space programme

set of related space projects managed in a coordinated way to contribute to an overall objective

space segment

part of a space system, placed in space, to fulfil the space mission objectives

space segment element

element within a space segment

- 1 A space segment element can be composed of several space segment elements, e.g. a spacecraft is composed of instruments, a payload module and a service module.

- 2 Examples are given in Annex B.1.

space segment equipment

equipment within a space segment

Examples are given in Annex B.1.

space segment subsystem

subsystem within a space segment

Examples are given in Annex B.1.

space segment system

system within a space segment

Examples are given in Annex B.1.

space system

system that contains at least a space, a ground or a launch segment

Generally a space system is composed of all three segments and is supported by a support segment.

spacecraft

manned or unmanned vehicle designed to orbit or travel in space

A spacecraft is a space segment element.

special process

process where the quality cannot be completely ensured by inspection of the end article only

specification

document stating requirements

A specification can be related to activities (e.g. procedure document, process specification and test specification), or products (e.g. product specification, performance specification and drawing).

[ISO 9000:2005]

stand-alone space segment element

space segment element that performs its mission autonomously

For example: satellite, rover, lander.

standard

<ECSS> normative document for use in invitations to tender and business agreements for implementing space related activities

- 1 A standard states verifiable requirements, supported by the minimum descriptive text necessary to understand their context. Each requirement has a unique identification, allowing full traceability and easy verification of compliance.

- 2 A standard is established by consensus amongst all ECSS stakeholders.

- 3 Other Standards Development Organisations (SDOs) use a different definition.

statement of work

contractual document that describes and plans deliverables and activities required to complete a project

The statement of work is issued by the customer at the start of a project for implementation by the supplier.

stress-corrosion

combined action of sustained tensile stress and corrosion that can lead to premature failure of materials

structural model

structurally representative model of the flight model used for qualification of the structural design and for correlation with structural mathematical models

- 1 The system structural model usually consists of a representative structure, with structural dummies of the flight equipment, and also includes representative mechanical parts of other subsystems (e.g. mechanisms and solar panels).

- 2 The system structural model is also used for final validation of test facilities, GSE, and associated procedures.

- 3 More detailed information on the build standard and the use of this model is given in ECSS-E-HB-10-02.

structuralthermal model

structurally and thermally representative model of the flight model that combines the objectives of the structural model and the thermal model

More detailed information on the build standard and the use of this model is given in ECSS-E-HB-10-02.

subsystem

part of a system fulfilling one or more of its functions

supplier

organization or person that provides a product as part of a business agreement

A supplier can be internal or external to the customer organization.

support segment

generic infrastructure and services used to support the development and operation of space system elements

- 1 Examples are ground stations and associated networks, orbit computing facilities, test centres, astronaut centre, launch facilities (e.g. Plestek, Baikonour, Guiana Space Centre).

- 2 Items can be part of other segments during their development and later become part of the support segment when used (e.g. a tracking network).

support system

see "support segment"

The term "support system" is deprecated.

system

set of interrelated or interacting functions constituted to achieve a specified objective

tailoring

process by which standards are made applicable to a specific project by selection of existing requirements, with or without modification, or addition of new ones

technical memorandum

<ECSS> non-normative document providing useful information to the space community on a specific subject

Technical Memoranda are prepared to record and present data which are not the subject for a standard or for a handbook or not yet mature enough to be published as standard or handbook.

test

measurement of product characteristics, performance or functions under representative environments

thermal ambient test

test conducted at ambient pressure and under predefined temperature conditions to demonstrate the capability of the test item to operate according to requirements

- 1 Temperature conditions can be expressed as temperature level, gradient and variation.

- 2 The ambient pressure can be mission dependent.

thermal balance test

test conducted under steady state conditions to correlate and adjust the thermal mathematical model and verify the thermal design

thermal model

thermally representative model of the flight model used for verification of the thermal design and for correlation with thermal mathematical models

- 1 The system thermal model usually consists of a representative structure, with thermal dummies of the flight equipment, and also includes representative thermal parts of other subsystems.

- 2 More detailed information on the build standard and the use of this model is given in ECSS-E-HB-10-02.

thermal vacuum test

test conducted in vacuum under predefined temperature conditions to demonstrate the capability of the test item to operate according to requirements

Temperature conditions can be expressed as temperature level, gradient and variation.

third party

person or body that is recognized as being independent of the parties involved, as concerns the issue in question

Parties involved are usually supplier (“first party”) and purchaser (“second party”).

[EN 45020:1998]

toxic

characteristic of a substance causing serious, acute or chronic effects, even death, when inhaled, swallowed or absorbed through the skin

traceability

ability to track the history, location or application by means of documented records

When considering a product, traceability can relate to:

- the origin of materials and parts,

- the processing history, or

- the distribution and location of the product after delivery.

uncertainty

lack of certitude resulting from inaccuracies of input parameters, analysis process, or both

unit

see "equipment"

The term “equipment” is strongly recommended for use in the ECSS system.

upper part [A5]

made of all the payload adaptor's (ACU), SYLDA or Speltra and Fairing [Ariane 5 launcher]

upper stage [A5]

made of cryogenic main stage (ESC) and vehicle equipment bay (VEB), ending at 1780 diameter interface [Ariane 5 launcher]

validation

process which demonstrates that the product is able to accomplish its intended use in the intended operational environment

-

1 The status of the product following validation is “validated”.

-

2 Verification is a pre-requisite for validation.

verification

process which demonstrates through the provision of objective evidence that the product is designed and produced according to its specifications and the agreed deviations and waivers, and is free of defects -

1 A waiver can arise as an output of the verification process.

-

2 Verification can be accomplished by one or more of the following methods: analysis (including similarity), test, inspection, review of design.

-

3 The status of the product following verification is “verified”.

waiver

formal authorization to accept products which during production, or after having been submitted to inspection or tests, are found to depart from specified requirements -

1 Deviation is an a priori decision whereas waiver is an a posteriori decision with respect to the production phase.

-

2 The term “concession” is synonymous and may be used for materials as per Q-ST-70C.

work breakdown structure

hierarchical representation of the activities necessary to complete a project

work package

group of related tasks that are defined down to the lowest level within a work breakdown structure

Abbreviated terms

|

Abbreviation

|

Meaning

|

|

A/D

|

analogue-to-digital

|

|

ABM

|

apogee boost motor

|

|

AC

|

alternating current

|

|

ADC

|

analogue-to-digital converter

|

|

AIT

|

assembly, integration and test

|

|

AIV

|

assembly, integration and verification

|

|

AOCS

|

attitude and orbit control subsystem

|

|

APS

|

active pixel sensor

|

|

AQL

|

acceptance quality level

|

|

AR

|

acceptance review

|

|

ASIC

|

application specific integrated circuit

|

|

ASTM

|

American Society for Testing and Materials

|

|

ATOX

|

atomic oxygen

|

|

AWG

|

American wire gauge

|

|

BOL

|

beginning-of-life

|

|

CAD

|

computer aided design

|

|

CCB

|

configuration control board

|

|

CCD

|

charge coupled device

|

|

CCSDS

|

Consultative Committee for Space Data Systems

|

|

CDR

|

critical design review

|

|

CIDL

|

configuration item data list

|

|

CIL

|

critical items list

|

|

CoG

|

centre of gravity

|

|

CoM

|

centre of mass

|

|

COTS

|

commercial off-the-shelf

|

|

CVCM

|

collected volatile condensable material

|

|

DC

|

direct current

|

|

DDF

|

design definition file

|

|

DDR

|

detailed design review

|

|

DJF

|

design justification file

|

|

DML

|

declared materials list

|

|

DMPL

|

declared mechanical parts list

|

|

DPL

|

declared processes list

|

|

DRB

|

delivery review board

|

|

DRD

|

document requirements definition

|

|

DRL

|

document requirements list

|

|

ECLS

|

environmental control and life support

|

|

ECSS

|

European Cooperation for Space Standardization

|

|

EED

|

electro-explosive device

|

|

EEE

|

electrical, electronic and electromechanical

|

|

EGSE

|

electrical ground support equipment

|

|

EIDP

|

end item data package

|

|

ELR

|

end-of-life review

|

|

EM

|

engineering model

|

|

EMC

|

electromagnetic compatibility

|

|

EMI

|

electromagnetic interference

|

|

EN

|

European Standard

|

|

EOL

|

end-of-life

|

|

ESA

|

European Space Agency

|

|

ESCC

|

European Space Components Coordination

|

|

ESD

|

electrostatic discharge

|

|

FDIR

|

failure detection isolation and recovery

|

|

FM

|

flight model

|

|

FMEA

|

failure modes and effects analysis

|

|

FMECA

|

failure modes, effects and criticality analysis

|

|

FOS

|

factor of safety

|

|

FRR

|

flight readiness review

|

|

FTA

|

fault tree analysis

|

|

GEO

|

geostationary orbit

|

|

GS

|

ground segment

|

|

GSE

|

ground support equipment

|

|

HMI

|

human-machine interface

|

|

HSIA

|

hardware-software interaction analysis

|

|

HW

|

hardware

|

|

ICD

|

interface control document

|

|

ILS

|

integrated logistic support

|

|

IRD

|

interface requirements document

|

|

ISO

|

International Organization for Standardization

|

|

ISS

|

International Space Station

|

|

I/F

|

interface

|

|

I/O

|

input/output

|

|

LEO

|

low Earth orbit

|

|

LEOP

|

launch and early orbit phase

|

|

LRR

|

launch readiness review

|

|

MCR

|

mission close-out review

|

|

MDD

|

mission description document

|

|

MDP

|

maximum design pressure

|

|

MDR

|

mission definition review

|

|

MEOP

|

maximum expected operating pressure

|

|

MGSE

|

mechanical ground support equipment

|

|

MIP

|

mandatory inspection point

|

|

MLI

|

multi-layer insulation

|

|

MMIC

|

monolithic microwave integrated circuit

|

|

MOI

|

moment of inertia

|

|

NASA

|

National Aeronautics and Space Administration

|

|

NCR

|

nonconformance report

|

|

NDI

|

non-destructive inspection

|

|

NDT

|

non-destructive test

|

|

NRB

|

nonconformance review board

|

|

N/A

|

not applicable

|

|

OBDH

|

on-board data handling

|

|

ORR

|

operational readiness review

|

|

OTS

|

off-the-shelf

|

|

PA

|

product assurance

|

|

PCB

|

printed circuit board

|

|

PDR

|

preliminary design review

|

|

PFM

|

protoflight model

|

|

PID

|

process identification document

|

|

PMP

|

parts, materials and processes

|

|

PRR

|

preliminary requirements review

|

|

PTR

|

post test review

|

|

QA

|

quality assurance

|

|

QM

|

qualification model

|

|

QR

|

qualification review

|

|

RAMS

|

reliability, availability, maintainability and safety

|

|

RB

|

requirements baseline

|

|

RF

|

radio frequency

|

|

RFA

|

request for approval

|

|

RFD

|

request for deviation

|

|

RFW

|

request for waiver

|

|

RH

|

relative humidity

|

|

RID

|

review item discrepancy

|

|

ROD

|

review of design

|

|

r.m.s.

|

root-mean-square

|

|

SCC

|

stress-corrosion cracking

|

|

SEE

|

single event effect

|

|

SEP

|

system engineering plan

|

|

SRR

|

system requirements review

|

|

STM

|

structural-thermal model

|

|

SVT

|

system validation test

|

|

S/C

|

spacecraft

|

|

SW

|

software

|

|

TC

|

telecommand

|

|

TCS

|

thermal control subsystem

|

|

TM

|

telemetry

|

|

TM/TC

|

telemetry/telecommand

|

|

TML

|

total mass loss

|

|

TRB

|

test review board

|

|

TRL

|

technology readiness level

|

|

TRR

|

test readiness review

|

|

TS

|

technical specification

|

|

TT&C

|

telemetry, tracking and command

|

|

UTC

|

coordinated universal time

|

|

UV

|

ultraviolet

|

|

VCD

|

verification control document

|

|

VP

|

verification plan

|

|

WBS

|

work breakdown structure

|

ANNEXTraceability with respect to ECSS-P-001B

The following table shows the differences between ECSS-P-001B and this document.

Deleted terms (terms that appeared in ECSS-P-001B but do not appear in the current document) are listed after this table.

|

Term

|

Type of modification

|

|

2.3.1 acceptance <act>

|

Modified

|

|

2.3.2 acceptance <process>

|

Added

|

|

2.3.3 accident

|

No change

|

|

2.3.4 active redundancy

|

Added

|

|

2.3.5 actuator

|

Added

|

|

2.3.6 alert

|

Modified

|

|

2.3.7 allowable load

|

No change

|

|

2.3.8 analysis

|

Added

|

|

2.3.9 anomaly

|

No change

|

|

2.3.10 applicable document

|

Modified

|

|

2.3.11 approval

|

Modified

|

|

2.3.12 assembly <act>

|

Added

|

|

2.3.13 assurance

|

No change

|

|

2.3.14 audit

|

Modified

|

|

2.3.15 audit criteria

|

Modified

|

|

2.3.16 audit evidence

|

No change

|

|

2.3.17 auditee

|

No change

|

|

2.3.18 auditor

|

Modified

|

|

2.3.19 availability

|

No change

|

|

2.3.20 backward contamination

|

Added

|

|

2.3.21 bakeout

|

No change

|

|

2.3.22 baseline

|

No change

|

|

2.3.23 batch

|

Added

|

|

2.3.24 black box

|

Modified

|

|

2.3.25 business agreement

|

Modified

|

|

2.3.26 calibration

|

No change

|

|

2.3.27 capability

|

No change

|

|

2.3.28 catastrophic

|

Added

|

|

2.3.29 certification

|

Modified

|

|

2.3.30 clean area

|

Modified

|

|

2.3.31 cleanliness

|

Added

|

|

2.3.32� cleanroom

|

Added

|

|

2.3.33 cold redundancy

|

Added

|

|

2.3.34 commissioning

|

Added

|

|

2.3.35 common cause failure

|

No change

|

|

2.3.36 common mode failure

|

No change

|

|

2.3.37 component

|

Added

|

|

2.3.38 composite

|

Added

|

|

2.3.39 configuration

|

Modified

|

|

2.3.40 configuration baseline

|

No change

|

|

2.3.41 configuration control

|

No change

|

|

2.3.42 configuration document

|

No change

|

|

2.3.43 configuration identification

|

No change

|

|

2.3.44 configuration item

|

No change

|

|

2.3.45 configuration management

|

No change

|

|

2.3.46 configuration status accounting

|

No change

|

|

2.3.47 configuration verification

|

Modified

|

|

2.3.48 conformance

|

Added

|

|

2.3.49 conformity

|

Modified

|

|

2.3.50 contaminant

|

Added

|

|

2.3.51 contamination

|

No change

|

|

2.3.52 contract

|

Modified

|

|

2.3.53 corrective action

|

Modified

|

|

2.3.54 COTS

|

Added

|

|

2.3.55 critical <general>

|

Added

|

|

2.3.56 critical <safety>

|

Added

|

|

2.3.57 critical item

|

Modified

|

|

2.3.58 critical path

|

Modified

|

|

2.3.59 customer

|

Modified

|

|

2.3.60 defect

|

Modified

|

|

2.3.61 dependability

|

Modified

|

|

2.3.62 derating

|

Modified

|

|

2.3.63 design <result>

|

No change

|

|

2.3.64 design <activity>

|

No change

|

|

2.3.65 development

|

Modified

|

|

2.3.66 deviation

|

Added

|

|

2.3.67 discipline

|

Added

|

|

2.3.68 discrepancy

|

Added

|

|

2.3.69 disposal

|

Added

|

|

2.3.70 effectiveness

|

No change

|

|

2.3.71 efficiency

|

No change

|

|

2.3.72 element

|

Added

|

|

2.3.73 emergency

|

Modified

|

|

2.3.74 embedded space segment element

|

Added

|

|

2.3.75 end item

|

Added

|

|

2.3.76 engineering model

|

Added

|

|

2.3.77 engineering qualification model

|

Added

|

|

2.3.78 environment

|

Modified

|

|

2.3.79 equipment

|

Modified

|

|

2.3.80 fail-safe

|

Modified

|

|

2.3.81 failure

|

Modified

|

|

2.3.82 failure mode

|

Modified

|

|

2.3.83 failure tolerance

|

No change

|

|

2.3.84 fault

|

Modified

|

|

2.3.85 fault tolerance

|

No change

|

|

2.3.86 firmware

|

No change

|

|

2.3.87 flammability

|

No change

|

|

2.3.88 flight model

|

Added

|

|

2.3.89 flight operations

|

Modified

|

|

2.3.90 flight spare

|

Added

|

|

2.3.91 forward contamination

|

Added

|

|

2.3.92 function

|

Modified

|

|

2.3.93 function tree

|

Modified

|

|

2.3.94 functional analysis

|

Modified

|

|

2.3.95 ground segment

|

Added

|

|

2.3.96 ground segment element

|

Added

|

|

2.3.97 ground segment equipment

|

Added

|

|

2.3.98 ground segment subsystem

|

Added

|

|

2.3.99 ground segment system

|

Added

|

|

2.3.100 ground support equipment

|

Added

|

|

2.3.101 handbook <ECSS>

|

Added

|

|

2.3.102 hazard

|

Modified

|

|