Space engineering

Cleanliness requirements for spacecraft propulsion hardware

Foreword

This Standard is one of the series of ECSS Standards intended to be applied together for the management, engineering and product assurance in space projects and applications. ECSS is a cooperative effort of the European Space Agency, national space agencies and European industry associations for the purpose of developing and maintaining common standards. Requirements in this Standard are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards.

This Standard has been prepared by the ECSS-E-ST-35-06C Working Group, reviewed by the ECSS Executive Secretariat and approved by the ECSS Technical Authority.

Disclaimer

ECSS does not provide any warranty whatsoever, whether expressed, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item are error-free. In no respect shall ECSS incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this Standard, whether or not based upon warranty, business agreement, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by ECSS.

Published by: ESA Requirements and Standards Division

ESTEC, P.O. Box 299,

2200 AG Noordwijk

The

Copyright: 2008 © by the European Space Agency for the members of ECSS

Change log

|

ECSS-E-ST-35-06A

|

Never issued

|

|

ECSS-E-ST-35-06B

|

Never issued

|

|

ECSS-E-ST-35-06C

|

First issue

|

|

ECSS-E-ST-35-06C rev.1

|

First issue revision 1

|

Scope

ECSS-E-ST-35-06 belongs to the Propulsion field of the mechanical discipline, and concerns itself with the cleanliness of propulsion components, sub-systems and systems

The standard

defines design requirements which allow for cleaning of propulsion components sub-systems and systems and which avoid generation or unwanted collection of contamination,

identifies cleanliness requirements (e.g. which particle / impurity / wetness level can be tolerated),

defines requirements on cleaning to comply with the cleanliness level requirements, and the requirements on verification,

identifies the cleanliness approach, cleaning requirements, (e.g. what needs to be done to ensure the tolerable level is not exceeded, compatibility requirements),

identifies, specifies and defines the requirements regarding conditions under which cleaning or cleanliness verification takes place (e.g. compatibility, check after environmental test).

The standard is applicable to the most commonly used propulsion systems and their related storable propellant combinations: Hydrazine (N2H4), Mono Methyl Hydrazine (CH3N2H3), MON (Mixed Oxides of Nitrogen), Nitrogen (N2), Helium (He), Propane (C3H8), Butane (C4H10) and Xenon (Xe).

This standard is the basis for the European spacecraft and spacecraft propulsion industry to define, achieve and verify the required cleanliness levels in spacecraft propulsion systems.

This standard is particularly applicable to spacecraft propulsion as used for satellites and (manned) spacecraft and any of such projects including its ground support equipment.

External cleanliness requirements, e.g. outside of tanks, piping and aspects such as fungus and outgassing are covered by ECSS-Q-ST-70-01.

This standard may be tailored for the specific characteristic and constraints of a space project in conformance with ECSS-S-ST-00.

Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this ECSS Standard. For dated references, subsequent amendments to, or revisions of any of these publications, do not apply. However, parties to agreements based on this ECSS Standard are encouraged to investigate the possibility of applying the most recent editions of the normative documents indicated below. For undated references the latest edition of the publication referred to applies.

|

ECSS-S-ST-00-01

|

ECSS system — Glossary of terms

|

|

ECSS-E-ST-35

|

Space engineering — Propulsion general requirements

|

|

ECSS-Q-ST-40

|

Space product assurance — Safety

|

|

ECSS-Q-ST-70-01

|

Space product assurance — Cleanliness and contamination control.

|

|

ECSS-Q-ST-70

|

Space product assurance — Materials, mechanical parts and processes

|

|

ISO 2210:1972

|

Liquid halogenated hydrocarbons for industrial use-Determination of residue on evaporation

|

|

ISO 5789:1979

|

Fluorinated hydrocarbons for industrial use — Determination of non-volatile residue

|

|

ISO 5884:1978

|

Aerospace — Fluid systems and components — Methods for system sampling and measuring the solid particle contamination of hydraulic fluids

|

|

ISO 14951-3:2000

|

Space systems —Fluid characteristics —Part 3: Nitrogen

|

|

ISO 14951-4:2000

|

Space systems — Fluid characteristics —Part 4: Helium

|

|

ISO 14951-10:2000

|

Space systems — Fluid characteristics —Part 10: Water

|

|

ISO 14952-3:2003

|

Space systems — Surface cleanliness of fluid systems — Part 3: Analytical procedures for the determination of non-volatile residues and particulate contamination

|

|

ASTM D257(99) 2005

|

Standard Test Method for DC Resistance or Conductance of Insulating Materials

|

|

ASTM D329 10 Dec 2002

|

Standard specification for Acetone

|

|

ASTM D740 15 May 2005

|

Standard specification for Methyl Ethyl Ketone

|

|

ASTM D770-05 15 May 2005

|

Standard specification for Isopropyl Alcohol

|

|

ASTM D1152 1 Apr 2006

|

Standard specification for Methanol (Methyl Alcohol)

|

|

ASTM D1293 10 Dec 1999

|

Standard test methods for pH of water

|

|

ASTM D4376

|

Standard specification for vapor-degreasing grade Perchloroethylene

|

|

MIL-PRF-27415B 8 Feb 2007

|

Performance specification, propellant pressurizing agent, Argon

|

|

O-E-760D28 May 1987

|

Federal specification

|

|

SEMI C47-0699 May 1999

|

Guideline for Trans 1,2 Dichloroethylene

|

Terms, definitions and abbreviated terms

Terms from other standards

For the purpose of this Standard, the terms and definitions from ECSS-S-ST-00-01 and ECSS-E-ST-35 apply.

Terms specific to the present standard

accuracy

measure of how close a value is to the “true” value

blank

result for an analytical sample of the virgin test fluid prior to use in performing a cleanliness verification test

cleanliness verification

activity intended to verify that the actual cleanliness conditions of an item are in conformance with the applicable specification

condensable hydrocarbon

hydrocarbon capable of going from a gaseous to a liquid or solid state at ambient temperature and pressure

crazing

creating microvoids in glassy thermoplastic polymers preceding the formation of cracks

critical surface

any surface of an item that contacts the service medium

Examples of service media are propellants and pressurants.

dewar

double-walled vessel with the annular space between the walls evacuated to provide insulation

dew point

temperature at which condensation of water vapour takes place at prevailing pressure

The prevailing pressure is usually atmospheric pressure.

fibre

flexible structure having a length-to-width ratio of 10 to 1 or greater

- 1 A fibre is considered to be a particle, see clause 3.2.14.

- 2 The size of a fibre is its maximum length.

field cleaning

processes of pre-cleaning and precision cleaning of components, subsystems and systems which cannot be processed in a controlled environment such as a clean room

generally clean

free from manufacturing residue, dirt, oil, grease, processing debris, or other extraneous contamination based on visual examination

high-efficiency particulate air filter

filter that is at least 99,97 % efficient by volume on 0,3 μm particles

non-volatile residue

soluble or suspended material and insoluble particulate matter remaining after temperature-controlled evaporation of a volatile liquid

See also clause 6.2.4.3

particle

unit of solid matter with observable size

- 1 Various methods for defining its size may be used and are dependant upon the measurement technique.

- 2 For the manual method the apparent maximum linear dimension of a particle in the plane of observation as observed with instruments such as optical, electron, or atomic force microscopes is the particle size.

- 3 For the automatic method, the equivalent diameter of a particle detected by automatic instrumentation is the particle size.

- 4 The equivalent diameter is the diameter of a reference sphere having known properties and producing the same response in the sensing instrument as the particle being measured.

- 5 A fibre is considered a particle, see clause 3.2.9.

passivation

process by which a corrosion-resistant layer is formed on a metal surface by submersing the surface in an acid solution

pickling

chemical or electrochemical process by which surface oxides are removed from metals

precision cleaning

cleaning process used to achieve cleanliness levels more stringent than visibly clean

pre-cleaning

cleaning process normally used to achieve the visibly clean cleanliness level

reversion

decrease in viscosity, strength, or in rubber modulus due to heating or overworking, resulting in a tacky and soft material

silting

accumulation of particles of sufficient quantity to cause a haze or obscuring of any portion of a filter membrane when viewed visually or under 40-power maximum magnification

test fluid

specified fluid that is utilized to determine the fluid system wetted-surface cleanliness level

threshold limit value

maximum average daily dosage, based on an 8-h day, 5-day week, to which an average worker may be exposed to hazardous chemicals without harmful effect

- 1 The TLV is a time-weighted average concentration.

- 2 The TLV is normally expressed in parts of the gas or vapour in micro litres per litre.

visibly clean

absence of surface contamination when examined with a specific light source, angle of incidence, and viewing distance using normal or magnified vision up to ×20

visibly clean plus ultraviolet

cleaning level that is visibly clean and also meets the requirements for inspection with the aid of an ultraviolet light of wavelength 250 nm to 395 nm

volatile hydrocarbon

hydrocarbon capable of going from liquid or solid to a gaseous state at ambient temperature and pressure

Abbreviated terms

For the purpose of this Standard, the abbreviated terms from ECSS-S-ST-00-01 and the following apply:

|

Abbreviation

|

Meaning

|

|

CC

|

cleanliness certificate

|

|

CRA

|

cleaning requirement analysis

|

|

CTS

|

cleaning technique selection

|

|

GC

|

generally clean

|

|

HEPA

|

high-efficiency particulate air filter

|

|

HFE

|

hydro fluor ether (Per fluoro-n-butyl methyl ether)

|

|

IPA

|

isopropanol

|

|

MAIT

|

manufacturing, assembly, integration and test

|

|

MEK

|

methyl ethyl keton

|

|

MS

|

mass spectroscopy

|

|

NVR

|

non-volatile residue

|

|

ppmv

|

parts per million, volumetric

|

|

TLV

|

threshold limit value

|

|

US

|

ultra sonic

|

|

VC

|

visibly clean

|

|

VC + UV

|

visibly clean plus ultraviolet

|

Symbols

|

Symbol

|

Meaning

|

|

dp

|

mean pore diameter of a filter

|

Cleanliness requirements

General

This standard shall only apply to propulsion systems using Hydrazines, MON, Propane, Butane, Nitrogen, Helium, Xenon as propellants.

Cleanliness assurance precautions and features shall be specified and incorporated in the hardware at the design phase.

In propulsion systems cleanliness is a major requirement to avoid loss of function and performance.

Cleanliness verification shall be applied at progressive MAIT stages in the process.

The hardware shall be designed to enable post-build cleaning and cleanliness verification.

Operation and use shall not generate or release contamination.

A cleanliness verification should be performed successively at component, sub-system and system level prior to a blind-end close-out.

Cleanliness Particle Count levels shall be to a lower required class or subclass at the early hardware build and verification stages, than the final product.

- 1 This allows final system-level cleanliness to be achieved.

- 2 See Table 41: for cleanliness classes and subclasses.

During the design phase the necessity of cleanliness verification shall be assessed. - 1 This applies from components to the design of systems, and to operations as not to generate contamination and to enable cleaning.

- 2 Figure B-1 of ECSS-Q-ST-70-01 gives an overview of space system cleanliness requirements organized in a cleanliness control flow chart.

Compatibility of cleaning fluids with the propulsion system materials and propellants shall be established in conformance with Annex A. - 1 For efficient cleaning chemical compounds like alkaline and acid cleaners are required.

- 2 Related requirements are specified in ECSS-E-ST-35-10, ‘Known incompatibilities’ concerning compatibility testing for liquid propulsion components, subsystems and systems.

All components, subsystems, systems or related equipment for use in ground support equipment and spacecraft requiring cleaning shall be - cleaned to the specified cleanliness level, in conformance with the CRA produced in conformance with Annex A,

- inspected in conformance with Annex B.

The results of 4.1j shall be reported in conformance with Annex C.

Any component, subsystem or system that can be damaged during cleaning shall be: - protected or removed before cleaning;

- cleaned as a separate item in conformance with the CTS produced in conformance with Annex B. Cleaning or disassembly operations on precision components shall be performed only by personnel who have been trained and certified to perform these functions.

Design requirements

General

Designs shall be such that the product

- avoids contamination and

- allows for cleaning and drying. Cleanliness classes shall be established in conformance with Annex A, to apply to propulsion components, subsystems and systems.

Components

Tanks

Tank internal structures shall not shed particles during operation.

Tank internal structures shall allow for draining and cleaning.

Examples of such structures are diaphragms, bladders, baffles, and surface tension screens.

Tubing and manifolds

Tubings and manifolds should avoid stepped diameter transitions that create turbulence or flow separation.

Turbulent flows and wakes can cause particle deposition.

Tubings and manifolds should avoid blind holes and dead ends,

Tubings and manifolds shall avoid internal threads.

The risk of contamination is increased with the number of screw joints.

Valves and regulators

Solenoid valves should use flexure guided armatures.

Sliding surfaces can jam or generate particles.

Valve or regulator function and performance shall be independent from lubrication on critical surfaces.

Fluid paths should be smooth, avoiding stepped transitions.

This is to avoid entrapment of contamination.

Valve or regulator parts and assembled parts should allow for ultrasonic cleaning, in conformance with the CTS produced in conformance with Annex B.

Protective filters shall be dimensioned in conformance with the CRA produced in conformance with Annex A, such that the selected filtration rate does not allow particles exceeding a specified size, to pass, thereby degrading function and performance.

Reference ports on regulators shall be protected by filters.

In conformance with the CRA produced in conformance with Annex A, protective filters shall be dimensioned such that the specified accumulated contamination causes no pressure drop exceeding the requirement.

Valve- or regulator-poppet design shall avoid entrapment of contamination.

A valve or regulator assembly should allow for the integration of protective filters after the final cleaning of the unit has been performed and verified in conformance with the CTS produced in conformance with Annex B.

Valves and regulators subject to reverse flow shall incorporate an outlet filter.

Valves and regulators shall avoid cavities, if not functionally required.

Valves and regulators shall not generate contamination, exceeding the specified level, when exposed to the specified environmental and functional tests.

- 1 E.g. during dry cycles.

- 2 Sliding armatures can generate contamination.

- 3 Sliding armatures are susceptible to jamming and wear.

Filters

Filters shall not shed particles, exceeding the specified level, during operation and environmental testing.

Instrumentation

Sensors introducing cavities shall allow for cleaning by a flushing lance.

See Annex B.

Cavities or dead end tubing shall allow for thermal and vacuum drying.

See Annex B.

Injectors

The deposition of NVR in capillary tubes and injector bores during operation shall be analysed and reported.

- 1 E.g. during pulse mode.

- 2 See Annex A.

Thrust chambers

The deposition of NVR on catalyst beds shall be analysed and reported.

See Annex A.

System

The system shall allow for ground draining of simulation fluids and of propellants.

Systems requiring cleaning and cleanliness verification shall have no protective filters at fill and drain valves or test ports.

Filtration rate and capacity requirements shall include the flight operation and the contamination introduced by integration and testing at higher build level.

See Annex A.

The integration of filters should be performed after final cleaning and verification of the related subsystems.

See Annex B.

Line replaceable components shall be protected by built-in filters.

The system design should enable flow-down cleanliness verification (see clause 4.1g).

Ground support equipment (GSE)

Connect/disconnect interfaces shall be protected from contamination by filters or by procedures

E.g. purge flow during connection / disconnection.

GSE protective filters shall be at the interfacing point to the flight hardware.

The GSE shall provide for draining and drying interfaces

E.g. back flush.

The GSE shall provide sampling interfaces and sampling equipment to verify cleanliness.

Filtration of simulation fluids or propellants shall be performed to a cleanliness class equal or better than the propulsion system requirements.

See Annex A.

Manufacturing

General

Manufacturing aspects that affect the selection of cleaning techniques shall be reported in conformance with Annex B.

Manufacturing processes

ECSS-Q-ST-70-01 requirements for ‘Manufacturing’ and ‘Assembly and integration’ shall apply.

The required proof pressure testing shall be performed after cleaning processes that affect material properties

E.g. after acid treatment.

Machined parts

Machined parts shall be cleaned as specified for the subsequent manufacturing operations.

This is also to achieve the final cleanliness level.

Machined parts shall be free of burrs.

For large items such as diaphragms and bladders, special cleaning procedures can be necessary.

Tubing and manifolds

Tubing, manifolds and transition joints shall be free of burrs, maintaining sharp edges for welding.

Tubing, manifolds and transition joints shall have passed all contaminating handling steps before final cleaning, e.g. bending, flaring, cutting to length and contaminating inspections.

Light oxide films, shall be removed by validated processes, e.g. brushing with a clean stainless steel wire brush, glass blasting (except for flow paths), draw filing, acid pickling.

Grinding shall not be performed on tube end interface surfaces that are subject to welding.

Debris from the grinding wheel can get embedded in the metal surface. This has been known to cause weld problems due to contamination embedded at the interface during welding.

The area to be treated by acid pickling shall be degreased with non-halogenated solvents.

Component interiors shall be protected by internally plugging the tubing stud in case of acid pickling.

For example, valves.

Water flushing shall be used to neutralize the pickling solution.

Tubing and manifolds shall be dried by gas purging.

Tubing shall be protected from contamination by oxidation during welding.

Welding shall avoid generating weld sputter in components, subsystems and system.

To protect stainless steel against external corrosion (e.g. after welding) pickling and passivation shall be performed.

Titanium tubing and manifolds can be pickled in a suitable acid and flushed with de-mineralised water to allow surface natural re-passivation.

Installation of a seal shall not introduce contamination into the system.

E.g. installation of O-rings.

Abrasion and surface damage of a seal during integration shall be avoided.

E.g. by using application compatible lubricants, masking of sharp edges.

The lubricant of mechanical joints shall not be introduced into the critical surface area or come into contact with propellants, pressurants or simulation fluids.

The joining process shall not introduce contamination into the critical surface area or bring contaminants into contact with propellants, pressurants or simulation fluids.

For repair and trimming-to-length clause 6.3.4 shall apply

Components

Components with liquid retaining cavities or capillary structures used for gas applications shall be

- flushed with liquids only at component level,

- verified to be dry.

E.g. pressure regulators, non return and relief valves.

Joining components to cleaning facilities shall not cause damage to interfaces.

Assembly of components (e.g. orifices, valve seats) shall be performed under a controlled environment in conformance with the requirements for “Cleanrooms” in ECSS-Q-ST-70-01F, and the cleanliness requirements of the component.

Hardware shall not be exposed to environments causing chemical contamination.

This can give rise to corrosion or chemical reactions in a later stage of life.

If not protected by specific means to avoid internal contamination, assembled components shall be tested in a controlled environment in conformance with the requirements for cleanrooms in ECSS-Q-ST-70-01 and the cleanliness requirements of the component.

It shall be determined which environmental classes apply to 4.3.5c and 4.3.5e.

See Annex A.

Procedures shall ensure that components that can be damaged or contaminated by reverse flow are not flushed or purged in opposite direction, neither during component operation, nor during subsystem or system operation.

For filters, procedures shall ensure that the last flushing operation at component level is performed in the nominal direction.

Tanks with built in propellant management devices shall have undergone all individually required precision cleaning processes and verification prior to final welding.

No introduction or formation of contaminants during subsequent assembly and operations shall take place.

E.g. introduction or formation of weld sputter.

Valves and regulators that cannot be dried after liquid flushing shall be cleaned with either:

- Nitrogen in conformance with ISO 14951-3 Type A, filtered through a filter with dp 2 μm, or

- Helium in conformance with ISO 14951-4 Type A, filtered through a filter with dp 2 μm, or

- Argon in conformance with MIL-PRF-27415B grade B, filtered through a filter with dp 2 μm.

For the purpose of cleaning, the non-single-use valve or regulator shall be operated during flushing or purging.

Purging or flushing of thrusters shall take the thrusters characteristics into account. - 1 Monopropellant thrusters with catalytic beds have limitations regarding flushing liquids, gas flow rates and pressure differentials.

- 2 Actuation of a flow control valve with gas flow is subject to limitations to avoid overheating of the valve.

Subsystems and systems

Subsystems incorporating components that constrain flushing or purging shall be built up allowing for in-process cleaning in accordance with clause 4.1c.

Subsystems with limited access and requiring flushing or purging shall be fitted with test ports.

Closed or protected subsystems and systems shall be handled in conformance with the ECSS-Q-ST-70-01, class M6.5 environment.

Open subsystems and systems shall be handled in a specified environment equal to or better than ECSS-Q-ST-70-01 class M6.5.

It shall be determined which environmental class applies to requirement 4.3.6d.

See Annex A.

Procedures shall be established to avoid contamination of the subsystem or system in case of component exchange.

Final rinsing solutions

The final rinsing solution shall meet or exceed the cleanliness requirements for which they are intended.

The rinsing liquid shall meet the requirements of clauses 4.4.4a, 4.4.4b, 4.4.4c, and 4.4.4h.

If the final rinsing is not compatible with the operational fluid in the system being cleaned, it shall be demonstrated that subsequent operations remove any residual rinsing solutions.

E.g. if IPA or ethanol only for the fuel system, not for the oxidizer system.

Cleanliness classes definition

Particulate

The particulate cleanliness class required shall be defined and selected, meeting program and system requirements.

The results of 4.4.1a shall be reported in Annex A and Annex C.

Practical experience with standard hydraulic and pneumatic systems has shown that particles below 5 µm are not critical.

The distribution and maximum amount of particles per class, as given in Table 41, shall not be exceeded.

Particles smaller than 5 µm shall not cause silting.

For systems, subsystems and components allowing the presence of particulate matter up to and including 5 m, the particulate cleanliness requirements shall be based on the following three classes, the basis of each being a range of flow system external tube sizes:

- Class 1, which applies for propulsion systems, or sections thereof with external tube sizes up to 20 mm (¾”).

- Class 2, which applies for propulsion systems, or sections thereof with external tube sizes between 20 mm and 50 mm (¾” – 2”).

- Class 3, which applies for propulsion systems, or sections thereof with external tube sizes exceeding 50 mm (>2”).

Different cleanliness classes may be assigned to different sections of a propulsion subsystem or system provided these sections are separated from each other by filters such that the lower class section cannot be contaminated to a level that does not conform to its cleanliness requirements.

In cases where the flow systems, or sections thereof (propellant or pressurant), consist of more than one line size, the smallest flow system size shall specify the selection.

In cases where a component or subsystem was originally dimensioned for a smaller size system, but incorporated into a larger one, the smaller size system shall determine the class selection.

The classes 1 through 3 specified in 4.4.1e shall be subdivided in subclasses A through I as follows: - Subclass A applies for single part components (piece part, e.g. spring, valve seat, plunger, single tube and fitting).

- Subclass B applies for multi part components (e.g. valves, tanks, engines).

- Subclass C applies for subsystems (e.g. sub-assembly of multipart components and tubing).

- Subclass D applies for systems.

- Subclass E applies for test fluids.

- Subclass F-1 applies for components with moving parts having clearances of 25 m – 40 m.

- Subclass F-2 applies for components with moving parts having clearances of 40 m – 65 m.

- Subclass F-3 applies for components with moving parts having clearances of 65 m – 90 m.

- Subclass G applies for liquid propellants.

- Subclass H applies for gases.

- Subclass I applies for precision packaging material. For systems, subsystems and components that do not allow the presence of particulate matter up to and including 5 m the user shall define specific requirements.

See Annex A.

TableTable 41: Cleanliness classes

|

Hardware, propellant, gases, packaging

|

Class 1

|

Class 2

|

Class 3

| ||||||||||||||||||||

|

Range of particle sizes (μm) a

|

Range of particle sizes (μm) a

|

Range of particle sizes (μm) a

| |||||||||||||||||||||

|

sub-class

|

0-5

|

6-10

|

11-25

|

26-50

|

51-100

|

101-200

|

sub-class

|

0-5

|

6-10

|

11-25

|

26-50

|

51-100

|

101-200

|

sub-class

|

0-5

|

6-10

|

11-25

|

26-50

|

51-100

|

101-200

|

201-500

|

501-1000

| |

|

Single part components

|

A

|

Do not count

|

60

|

9

|

2

|

0

|

0

|

A

|

Do not count

|

140

|

20

|

5

|

1

|

0

|

A

|

Do not count

|

500

|

80

|

20

|

5

|

1

|

0

|

0

|

|

Multi part components

|

B

|

140

|

20

|

5

|

1

|

0

|

B

|

600

|

80

|

20

|

4

|

0

|

B

|

1200

|

200

|

50

|

12

|

3

|

0

|

0

| |||

|

Subsystems

|

C

|

600

|

80

|

20

|

4

|

0

|

C

|

1200

|

200

|

50

|

12

|

3

|

C

|

|

1000

|

250

|

60

|

15

|

0

|

0

| |||

|

Systems

|

D

|

1200

|

200

|

50

|

12

|

3

|

D

|

|

1000

|

250

|

60

|

15

|

D

|

|

|

800

|

200

|

40

|

6

|

1

| |||

|

Test fluid

|

E

|

6

|

1

|

0

|

0

|

0

|

E

|

14

|

2

|

1

|

0

|

0

|

E

|

50

|

8

|

2

|

1

|

0

|

0

|

0

| |||

|

Components with moving parts having clearances of:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

25 m–40 m

|

F-1

|

5

|

0

|

0

|

0

|

0

|

F-1

|

10

|

0

|

0

|

0

|

0

|

F-1

|

50

|

1

|

0

|

0

|

0

|

0

|

0

| |||

|

40 m–65 m

|

F-2

|

20

|

2

|

0

|

0

|

0

|

F-2

|

30

|

3

|

0

|

0

|

0

|

F-2

|

100

|

10

|

0

|

0

|

0

|

0

|

0

| |||

|

65 m–90 m

|

F-3

|

80

|

40

|

5

|

0

|

0

|

F-3

|

100

|

50

|

10

|

0

|

0

|

F-3

|

500

|

100

|

20

|

0

|

0

|

0

|

0

| |||

|

Propellant or reference liquid

|

G

|

140

|

20

|

5

|

1

|

0

|

G

|

600

|

80

|

20

|

4

|

0

|

G

|

1200

|

200

|

50

|

12

|

3

|

0

|

0

| |||

|

Gas b

|

H

|

60

|

9

|

2

|

0

|

0

|

H

|

140

|

20

|

5

|

1

|

0

|

H

|

500

|

80

|

20

|

5

|

1

|

0

|

0

| |||

|

Precision packaging material

|

I

|

10

|

3

|

1

|

0

|

0

|

I

|

20

|

10

|

1

|

0

|

0

|

I

|

50

|

20

|

5

|

1

|

0

|

0

|

0

| |||

|

a The particle count is related to a sample of 100 cm3 of liquid or 1 m3 of gas in conformance with clause 6.2.3, no metallic particles > 50 μm are allowed

| |||||||||||||||||||||||

Non-volatile residues (NVR)

The NVR cleanliness class required shall be defined and selected, meeting program and system requirements.

The results of 4.4.2a shall be reported in Annex A and Annex C.

It does not contribute to the proper functioning of the propulsion system to specify a very small NVR level to components or subsystems with small critical areas. This can even lead to immeasurable quantities of NVR. In general, the smaller the component or subsystem, the larger the allowable NVR per surface area.

The maximum allowable NVR levels shall be classified in conformance with Table 42.

TableTable 42: NVR contamination levels

|

NVR level

|

NVR limit critical surface

|

|

A/100

|

0,1

|

|

A/50

|

0,2

|

|

A/20

|

0,5

|

|

A/10

|

1,0

|

|

A/5

|

2,0

|

|

A/2

|

5,0

|

|

A

|

10

|

|

B

|

20

|

|

C

|

30

|

|

D

|

40

|

|

E

|

50

|

|

F

|

70

|

|

G

|

100

|

|

H

|

150

|

|

J

|

250

|

Dryness and liquid residuals

The dryness or liquid residual levels shall be defined and selected, based on specific program and system requirements, referred to in Annex A and reported in Annex C.

If not otherwise specified, dryness from water shall correspond to a dew point of purge gas:

- for chemical propulsion systems the effluent gas moisture content to be less than 21 μl/l (dew point -55 °C) for individual components, or less than 127 μl/l (dew point -40 °C) for systems,

- for electrical propulsion systems using Xenon the effluent gas moisture content to be less than 5 μl/l (dew point –66 C) for individual components, or less than 11 μl/l (dew point –60 C) for systems. Dryness from other liquids (e.g. IPA, HFE) shall correspond to a vapour concentration in the purge gas

- For chemical propulsion systems the effluent gas liquid vapour content to be less than 10 μl/l for individual components and systems,

- For electrical propulsion systems using Xenon the effluent gas moisture content to be less than 10 μl/l for individual components and systems.

Requirements on process fluids to meet cleanliness classes

Fluids to be used for filtration for particle count or NVR determination shall be filtered through a filter with dp 1 m.

Fluids for other purposes than specified in 4.4.4a shall be filtered through a filter with dp 2 m.

Fluids shall have not more non-volatile residue than 10 % of the NVR concentration specified for the purpose of NVR determination.

Fluids shall have not more than 50 mg/l NVR for the purpose of requirement 4.4.4b.

Nitrogen shall be equivalent to ISO 14951-3:2000.

Helium shall be equivalent to ISO 14951-4:2000.

Argon shall be equivalent to MIL-PRF-27415B, Grade A.

Water shall be equivalent to ISO 14951-10:2000.

Cleaning and test liquids should be selected from Annex D.

It shall be verified that the cleaning fluids meet their specifications.

A verification shall be performed by taking samples from the container, the distribution system or the cleaning bench to be used.

The selection of fluids used in processing shall be approved by the customer.

The following compatibility issues, as applicable, shall be considered and evaluated in the selection of processing fluids:

- corrosion;

- stress corrosion cracking;

- embrittlement;

- leaching;

- masking of crack-like indications;

- residue;

- crazing (nonmetallic);

- reversion (nonmetallic);

- hydrolysis (nonmetallic) or water absorption;

- chemical activity.

Test methods

Cleanliness test methods shall be selected and justified.

Cleanliness test methods shall be reported in Annex A.

Cleanliness test methods shall be performed in conformance with the CTS produced in conformance with Annex B.

Code usage

The required level of cleanliness shall be established based on clause 4.4 and reported in conformance with Annex C.

The cleanliness code shall be derived from Table 43 through.

The cleanliness code and the established particulate class, sub-class and level shall be used to specify to the cleaning facility the desired level of cleanliness.

After cleaning, analysis and verification have been completed by the cleaning facility, the cleaned part or component shall be sealed in a package and marked with the cleanliness code attached to the package.

Particulate class: 2, subclass B NVR level: AVisual contamination level: VCCode: 2B/A/VC

Hardware cleaned to a more stringent cleanliness level than is required may be used.

TableTable 43: Visible contamination levels

|

Level

|

Definition

|

|

GC

|

Generally clean, see 3.2.11

|

|

VC

|

Visibly clean, see 3.2.23

|

|

VC+UV

|

Visibly clean and inspected with ultraviolet light, see 3.2.24

|

Cleaning techniques

General

The selection of the cleaning agents and the processes shall be reported in conformance with Annex B and approved by the customer.

For ‘Process control’, requirements shall be in conformance with ECSS-Q-ST-70 with the exception of ‘Associated materials and mechanical parts’, ‘Selection’, and ‘Packaging, storage, removal from storage’.

It shall be verified before processing that the cleaning facilities and agents meet the specified requirements.

Surfaces that are being degraded during fabrication or pre-cleaning shall be processed to restore the original protective coating.

Cleaning should be done by liquids.

Liquids have a large dirt carrying capacity

Ultrasonic agitation should be used.

This facilitates removing contamination from cavities.

As an alternative to 5.1f, gas-saturated liquids should be used for cleaning.

Cavitation of gas and gas bubbles helps to lift contaminants.

The cleaning fluids shall be compatible with the components being cleaned.

- 1 See ECSS-E-ST-35-10.

- 2 Solvents identified in Annex D as having low threshold limit values are not suitable for cleaning processes conducted in enclosed environments, such as clean rooms, due to their toxicity unless the facility is especially designed for their use.

Temporary installed hardware shall: - be compatible with the cleaning process

- be pre-cleaned

- not compromise the hardware to be cleaned

- be marked as temporarily installed

Environment, health and safety

General

The cleaning organization shall determine and establish the appropriate environmental, health and safety practices that are in conformance with applicable regulations and safety programme plan of ECSS-Q-ST-40.

- 1 This standard does not purport to address all of the environmental, health or safety problems associated with cleaning processes.

- 2 Cleaning requires the use of materials, processes, and equipment that can be hazardous, toxic or detrimental to the environment and personnel.

The cleaning organization shall store all hazardous substances in accordance with the prevailing safety regulations.

The cleaning organization shall inform the local emergency planning organization as to the quantity on hand and the storage location of hazardous substances.

Hardware configuration requirements

Hardware that has been exposed to propellant shall be decontaminated before precision cleaning.

Example of such a hardware is propellant loading equipment.

Decontamination shall take place in an approved facility.

A safety certificate shall confirm that the hardware has been decontaminated to a safe level.

Fluid ground support systems shall be:

- sampled before use to ensure that the GSE does not contaminate the fluids;

- cleaned before use to ensure cleanliness and dryness;

- Inspected to ensure that filters are operational.

Example of such system is propellant loading equipment.

Components obstructing precision cleaning due to blocking portions of a system causing the following, shall be removed and replaced:

- entrapment of liquids,

- incompatibility with the required cleaning process.

Cleaning process approval

Cleaning processes shall be proposed by the cleaning organization.

Only qualified cleaning processes shall be used.

The process shall not be detrimental to the hardware being cleaned.

Process approval shall be obtained from the customer prior to cleaning and handling.

To obtain approval, the cleaning organization shall submit to the customer the proof that the qualified cleaning process satisfies the need.

Pre-cleaning

General

All critical surfaces of system hardware shall be pre-cleaned to remove contaminants, e.g. dirt, grit, scale, corrosion, grease, oil and other foreign matter prior to any precision-cleaning process.

Assembled items that do not lend themselves to this type of treatment shall have been treated prior to assembly.

Annex E shows the typical pre-cleaning sequence for common materials.

Mechanical pre-cleaning

General

Mechanical pre-cleaning shall be performed only if the process of abrasion does not lead to unacceptable damage of the item being cleaned.

Mechanical pre-cleaning shall be performed before or during chemical cleaning.

If there are foreign deposits due to mechanical pre-cleaning, these shall be removed.

Mechanical pre-cleaning includes e.g. wire brushing, shot blasting (wet and dry), grinding, abrasive blasting (wet or dry), the use of aluminium oxide-abrasive-coated papers and cloths.

Compatibility of dissimilar metals shall be considered when selecting a mechanical cleaning method.

Mechanical pre-cleaning shall be verified by visual inspection

E.g. boroscope in pipes.

The conditions of cleaning baths, flushing and purging equipment shall be controlled.

Ultra-sonic cleaning

The process of ultrasonic cleaning shall be qualified for the individual components to be cleaned, e.g. power level, frequency, temperature, duration.

Dry lubrication coatings (MoS2) is destroyed by US cleaning.

For aluminium parts the allowable contact duration of the cleaning process shall be defined.

The equipment shall be compatible with the fluids used.

Chemical pre-cleaning

General

Acid cleaners shall be used to remove contamination not removable by other solutions.

Acid cleaners include nitric acid, chromic acid inhibited hydrochloric acid, inhibited sulphuric acid, inhibited phosphoric acid, mixed acid de-oxidisers and alcoholic phosphoric acid.

Alkaline cleaners and organic or water-based solvents shall be used for degreasing and removal of organic and inorganic contamination, e.g. scale and soluble metal oxides, see Annex D.

To avoid corrosion and etching, passivation and neutralising solutions shall be used as a supplementary process to mechanical, acid and alkaline cleaning.

Neutralisation process

The neutralization process shall be verified by test to ensure that all acids, alkalis and detergents have been removed from the item.

The neutralization process shall be based on tests performed per ASTM D1293:1999.

The neutralization process shall compare a sample of the rinsing fluid effluent (e.g. 200ml) with the rinse fluid source to show that the pH value is between 5 and 8.

The neutralization process shall use water complying with ISO 14951-10, Type HP, as final rinsing fluid.

Precision cleaning

General

Critical surfaces of components, subsystems and systems hardware that have been pre-cleaned shall be visually clean prior to proceeding to any precision-cleaning operation.

Scale-free discoloration due to welding or passivation need not be cleaned.

Detailed acceptance criteria are part of the welding and passivation acceptance procedures.

Precision-cleaning operations shall be performed in an environment compatible with the component cleanliness requirement.

For precision cleaning, clause 4.6 shall apply.

If 5.4.1c cannot be met, it shall be assured that equipment is securely packed and that entry of contamination is avoided.

Example of situation when 5.4.1c cannot be met is due to the size or the equipment. Example of operations when contamination can enter are connect and disconnect activities.

Precision cleaned articles shall be packaged immediately after verification and drying operations, or suitably protected prior to leaving the controlled environment.

See also clause 4.6d.

Assembled items that do not lend themselves to this type of treatment shall have been treated prior to assembly.

Metallic items shall have been surface treated (cleaned, passivated or coated), as applicable, to prevent latent corrosion and contamination.

All critical surfaces of hardware shall be precision cleaned to meet the agreed requirements.

Cleaning of hardware which, due to size or other considerations, cannot meet the requirement 5.4.1i, shall be agreed with the customer.

Subsystems and systems may require disassembly to permit cleaning.

Re-cleaning operational systems

Systems that have successfully passed the specified quality assurance tests for initial acceptance and have been placed in operation shall be re-cleaned if analysis shows that the delivered fluid does not meet specified requirements or to allow for safe transport and handling.

Examples of such systems are propulsion systems, test stands, and GSE.

Drying methods

General

The selected drying methods shall be justified and reported in conformance with Annex B.

The hardware shall be dried by removing traces of cleaning liquids from the outside and from the inside.

The drying process shall remove liquids from trapped areas (e.g. valves open).

The temperature used during drying shall not exceed the component or system allowable temperature ranges.

The selected temperature for drying from liquids shall be within the operational temperature range of the liquid.

The hardware shall be protected against re-contamination during the drying process.

The hardware temperature shall be monitored.

- 1 To efficiently remove traces of water from cleaning the hardware is rinsed with a small amount of alcohol (e.g. IPA) before drying.

- 2 For drying of complex piping and tank systems, gas filling and evacuation cycles are used.

Gaseous purge-drying

Gases used for dry purging and dryness verification of chemical propulsion shall be in conformance with:

- Nitrogen: ISO 14951-3, Type I, Grade A,

- Helium: ISO 14951-4, Type I, Grade A. Gases used for dry purging and dryness verification of electrical propulsion systems shall conform to:

- Nitrogen: ISO 14951-3 Type I, grade A for purging and grade C for verification,

- Helium: ISO-14951-4 Type I, grade A for purging and grade F for verification,

- Argon: MIL-PRF-27415B; Grade A for verification, Grade B for purging.

Gas specified in 5.5.2a and 5.5.2b shall be filtered through a filter with dp 2 μm.

The dew point or condensation point of the purge gas shall be below 60 C (11 μl/l).

Drying sample

General

The reliability of the dryness shall be verified by clause 5.5.3.2 or 5.5.3.3.

Reliability sample

The quantitative analysis reliability sample shall consist of a minimum of 5 % of the items dried but not less than one sample from each group of items dried.

The sample shall be selected such that it reflects the composition of the lot containing production items that have been cleaned, verified and dried.

A lot does not necessarily mean identical parts but does include all hardware processed in one operation.

The reliability sample and the segment of production that it represents shall be identified, as specified by the customer.

Procedure reliability

After qualification of the procedure and equipment for a specific hardware configuration, reliability sampling shall be left to the discretion of the customer.

Samples for qualification of the drying process shall be selected as follows:

- Select a minimum of five cleaned, verified and dried items from each of the hardware configuration to be qualified,

- Evaluate samples in accordance with 5.5.3.4.

Upon qualification of the drying procedure for each hardware configuration, the established drying cycle requirements shall be implemented.

The supplier shall define at what intervals periodic spot tests are made to ensure that drying procedures continue to be effective.

The reliability of the drying procedure can be established for each hardware configuration and drying process.

Drying test

Pre-filtered drying gas shall be flowed through or over the affected surfaces of the item being tested.

For hardware processed with aqueous media, the dew point of the drying gas entering and leaving the affected item shall be monitored to determine the presence of moisture on cleaned and dried surfaces.

An increase in the moisture content of the drying gas of 5 μl/l or greater shall necessitate additional drying prior to packaging or the application of protective coverings.

For hardware processed with halogenated solvents, alcohols or hydrocarbons, the effluent drying gas shall be monitored with a halogen, alcohol or hydrocarbon detector, respectively, to determine if affected surfaces are free from residual solvent.

An increase in the halogen, alcohol or hydrocarbon concentration of 5 μl/l or more in the drying gas shall necessitate additional drying prior to packaging or of the application of protective coatings.

- 1 Due to the time for evaporation of liquids in a closed volume, the measurements of dryness need be timed properly.

- 2 The reliability of the drying procedure for items subjected to liquids during cleaning or drying procedures can be established.

Flow rates during purging

Flow rates and pressures during dry purging and verification shall not exceed the specified operational limits of components, subsystems or systems.

Vacuum drying procedure

General

The vacuum pressure shall be monitored.

Re-pressurization gas shall be filtered through a 2 μm filter.

Vacuum pumping systems shall prevent oil back-migration into the vacuum facility.

Apparatus and reagents

The following items shall accomplish the vacuum drying processes:

- Clean vacuum oven, with temperature control.

Typically, temperature ranging from 45 °C to 130 °C.

- (Vent) gas, in conformance with clauses 5.5.2a, 5.5.2b and 5.5.2c or HEPA filtered air.

- Thermocouple, for independent temperature monitoring of parts during procedure qualification.

Heating

Hardware shall be placed in the vacuum oven.

The drying time, vacuum level and temperature for the hardware shall be specified.

During the procedure qualification, the thermocouple shall be attached, e.g. by clamping, to the largest part placed in the oven.

The oven shall be closed, purged and filled with inert test gas if required for the specific application.

Subsequently, the oven shall be heated to the desired vacuum drying temperature.

Vacuum drying

Once the temperature monitor indicates that the hardware in the oven has reached the desired temperature, a vacuum shall be drawn on the parts and maintained for the period specified in 5.5.5.3b.

Once the liquids have been evaporated from the hardware, the heating shall be discontinued and the oven is slowly filled with a filtered gas in conformance with 5.5.5.2a.2.

Drying by internal evacuation

Hardware to be dried by internal evacuation shall allow for exposure to internal vacuum.

To ensure that the applied drying method by evacuation is applied to all sections of the hardware, an analysis of the hardware shall be made.

E.g. non-return valve, shut-off valve.

Excepted components, subsystems and systems

Components, subsystems and systems that cannot be cleaned, certified and processed per the requirements of 5.1 through 5.5 (because of e.g. the size, construction, or materials of construction), may be processed as excepted components, subsystems and systems as specified in 5.6b and 5.6c.

Excepted components, subsystems and systems shall require a request for approval in conformance with ECSS-Q-ST-70 ‘Request for approval (RFA)’.

These items shall be cleaned as to the intent of this part of ECSSEST3506, as far as is practical.

Cleanliness verification requirements

Surface

Visual and UV inspection

The surfaces of all items that come into contact with the service medium shall be visually inspected for the presence of moisture, corrosion, scale, dirt, grease and other foreign matter.

An external light source or boroscope shall be used to examine internal surfaces.

Light source, angle of incidence, viewing distance and magnification shall be specified.

Items having limited accessibility for visual inspection shall be accepted or rejected on the basis of the quality assurance inspections of 6.1.2, 6.2 and 4.5.

- 1 Visual inspection can be done with the unaided eye or a magnification up to 20 to be agreed between the supplier and the customer.

- 2 The unaided eye is able to discern particles down to 50 m.

The VC+UV inspection shall be performed on precision cleaned items to assure these are free of polymers, cleaning agents or oils.

The UV light source shall have a wave length between 250 nm and 395 nm.

The minimum power of the UV source shall be 100 W.

The results of visual inspection shall be reported in conformance with Annex C.

pH-test

All surfaces that have been in contact with acid or basic liquids shall be tested with pH paper while the surfaces are wet from the final water rinse.

Dry surfaces of completed items shall be wetted with a few drops of high purity water, with a pH range of 5,0 to 8,0, meeting the requirements of ISO 1495110:2000, to permit testing as required.

When tested, the pH shall range from 5,0 to 8,0 and reported in conformance with Annex C.

Acceptance inspection of items cleaned in a controlled environment

General

Items cleaned in a controlled environment, except those processed to level visually clean (VC) or level visually clean and inspected with the aid of an ultraviolet (UV) light, shall be tested for conformance to the applicable cleanliness level by the test liquid-flush procedure given in 6.2.2 to 6.2.4.

Test fluids

The test fluids shall not react with, combine with, etch, or otherwise cause immediate or latent degradation of the item being tested, and can be selected from those specified in Annex D.

The test fluid shall meet the following requirements:

- The test liquid is filtered through a filter with dp 1 m and has less than 10 % of the allowed nonvolatile residue concentration (NVR) for the application.

- The maximum allowable NVR level of the test solvent does not exceed 50 mg/l.

- The quality of the test liquids is assured during use.

Some test fluids can have low threshold limit values; chemical hazard sheets can be consulted.

The test fluids shall be compatible with the fluid used in the system or components being tested.

Halogenated solvents shall not be used on titanium alloys.

Polymer components for oxidiser systems shall be cleaned with a water-based process and blown dry with type A nitrogen conforming to ISO 14951-3:2000.

If the polymer components are cleaned with isopropanol or ethanol, the polymer components shall be purged with type A nitrogen conforming to ISO14951-3:2000, until the methane hydrocarbon equivalent of the effluent gas does not exceed that of the source gas.

Alternatively to 6.2.2f, the polymer components may be vacuum dried as described in 6.2.6 and 6.2.7.

Test fluid volume for analysis

The test fluid volume required for analysis shall depend upon the analytical methods employed.

The standard test sample shall be 1 l of test liquid per m2 of critical surface area.

This is to ensure that all critical surfaces are being flushed.

In cases where all critical surfaces are less than 0,1 m2 a minimum of a 100 ml sample of test liquid shall be used.

The standard test sample shall be 1000 l of test gas per m2 of critical surface area (see clause 11.1.4).

Analysis of test fluid-flush sample (solvent)

General

If a solvent is used as test liquid, the test sample shall be analysed for particle population and NVR by the following recognized analytical methods in conformance with clauses 6.2.4.2 and 6.2.4.3.

The test liquid blank particle count shall not be subtracted from the test sample particle count.

If the supplier uses other analytical methods these shall:

- have demonstrated accuracy and repeatability,

- be approved by the customer.

Particle population analysis (solvent-flush)

Liquids used for a filtration for particle count shall be filtered through a filter with 1μm dp 5 μm.

The solvent-flush sample shall be analysed for particle population by one of the following methods:

- Microscopic particle counting in conformance with clause 12.

- Particle population analysis (automatic particle counters) using automatic liquid-borne particle counters for final verification of cleanliness of the end product under the conditions that:

- the individual counters have demonstrated accuracy and repeatability in the range of application;

- their accuracy and repeatability correlate with accepted analytical methods in the range of application.

NVR analysis (solvent-flush)

Liquids used for a filtration NVR shall be filtered through a filter with 1μm dp 5 μm, while the pore size used for this filtration has the same size as, or is larger than the one used for particle count.

If no filtration is used in determining the NVR, the requirements on the maximum allowed NVR level shall be the same as when filtration is used.

The solvent-flush samples that have been filtered in conformance with 6.2.4.3a shall be analysed for NVR by one or more of the following methods.

- Gravimetric NVR analysis method in conformance with clause 12.

The filtered solvent sample is evaporated to determine the NVR content.

- Solvent purity meter for final verification of cleanliness of the end product under the following conditions:

- the individual meter has demonstrated accuracy and repeatability;

- the accuracy and repeatability correlate with accepted analytical methods.

- Infrared spectrometric NVR analysis method of solvent samples under the following conditions:

- the method quantifies hydrocarbons and other contaminants that are reactive with hypergolic fluids used in the particular application;

- the analysis method has demonstrated accuracy and repeatability.

- Mass spectroscopy (MS) NVR analysis method under the following conditions:

- the method quantifies hydrocarbons and other contaminants that are reactive with hypergolic fluids used in the particular application;

- the analysis method has demonstrated accuracy and repeatability.

- Gas chromatography/mass spectroscopy NVR analysis method under the following conditions:

- the method quantifies hydrocarbons and other contaminants that are reactive with liquid oxygen or hypergolic fluids used in the particular application;

- the analysis method has demonstrated accuracy and repeatability.

Analysis of aqueous-based, liquid-flush sample

With agreement of the customer, the aqueous-based, fluid-flush samples shall be analysed for particle population and NVR as follows:

- Particle population analysis (aqueous) using the particle analyses of 6.2.4.2 for final verification of cleanliness of the end product under the following conditions:

- the sampling and analysis methods have demonstrated accuracy and repeatability,

- The accuracy and repeatability correlate with accepted analytical methods,

- NVR analysis (aqueous) for the final verification of cleanliness of the end product under the following conditions:

- the sampling and analysis methods have demonstrated accuracy and repeatability,

- The accuracy and repeatability correlate with accepted analytical methods,

Drying

General

After testing for particle population and NVR, all components and parts shall be thoroughly dried to remove residual cleaning, rinsing, or verification media.

Purge drying

All rinsed components and critical internal surfaces of small vessels, hoses and tube assemblies shall be dried by a purge of:

- Nitrogen, filtered to remove particulates greater than 2 μm (in accordance with ISO 14951-3, Type A), or

- Helium, filtered to remove particulates greater than 2 μm (in accordance with ISO 14951-4, Type 1, Grade A).

- Parts of components may be dried with HEPA filtered air to remove particulates greater than 2 μm.

Inspection after purge drying

If the critical internal surfaces cannot be inspected visually, analyses shall be performed in conformance with clause 4.4.3.

All items rinsed with reagent water which cannot be visually inspected (100 %) shall be tested by the method of clause 6.4.2 or 6.4.3 for surface moisture.

All items shall meet the dryness requirements of clause 4.4.3.

Vacuum drying

Components or subsystems with intricate features (e.g. wire mesh filter elements, fine threaded holes) shall be placed in a clean vacuum oven, purged with test gas, heated, and then evacuated until dry in conformance with clause 4.4.3.

Maintaining cleanliness

Pressurant gas purge

Fluid containing components (e.g. vessels, pipe and tubing systems, pipe, tubing and flex hose subsystems) shall be maintained under the pressurant gas purge overpressure until all ports, orifices and fittings are sealed.

Typical over-pressures range from 0,01 MPa to 0,05 MPa

The pressurant gas shall be either:

nitrogen in conformance with ISO 14951-3, Grade A, filtered to remove particulates greater than 2 μm , or

helium in conformance with ISO 14951-4, Type 1, Grade A, filtered to remove particulates greater than 2 μm.

Installation and marking of temporary hardware

All temporary hardware necessary to perform or validate the cleaning process shall be compatible with the processing materials and the subsystem, system or other related field equipment that is to be cleaned.

Temporary hardware and all surfaces near openings resulting from the removal of components shall be visibly clean of contamination, such as dirt, scale and grease, prior to the installation of temporary hardware.

All temporary hardware installed in, on, or attached to, an item to be cleaned shall be legibly marked or otherwise identified as temporary hardware.

This is to ensure its removal from the item prior to final acceptance by the customer.

The marking system shall not compromise the cleanliness of the item to be cleaned.

Temporary hardware replacement

After that the system, subsystem or related field equipment has been verified to be clean, temporary hardware installed in systems, subsystems, and related field equipment for cleaning shall be replaced with clean functional components.

Hardware replacement shall take place under pressurant gas purge.

Typical over-pressures range from 0,01 MPa to 0,05 MPa.

Prior to replacement adjacent, external system and structural surfaces shall be cleaned to level GC.

The hardware replacement shall be performed in a controlled environment.

A portable clean room (tent) or similar structure.

Procedures and practices shall be established to maintain system cleanliness.

Component replacement

Replacement of functional components in clean systems shall be in conformance with 6.3.3b through 6.3.3e.

Dryness verification

General

The results of the dryness verification shall be reported in conformance with Annex C.

After testing for particle population and NVR, all hardware shall be dried in conformance with clauses 4.4.3 and 5.5 to remove residual cleaning, rinsing, or other verification media.

Purge dryness

For hardware processed with water the moisture content of the gas effluent through or over the dried components, parts or system at ambient temperature, shall be measured.

The dew point of the exiting gas shall be less than or equal to the source gas which conforms to clause 5.5.2.

For hardware that has been exposed to hydrocarbons, alcohol or haloginated solvents, the contamination of the effluent gas shall be measured using a suitable calibrated instrument.

Any increase of the solvent content of 5 μl/l above the source gas content shall require additional drying of the hardware.

Vacuum dryness

For evacuated hardware the dryness can be verified by:

- reaching the related vacuum pressure,

- verifying that the vacuum pressure is lower than the lowest liquid vapour pressure,

- pressurisation and a measurement of the effluent gas during depressurisation.

The success criteria of 6.4.2d shall apply.

It shall be ensured that no condensation, sublimation or freezing occurs during the dryness verification, to be defined in Annex B.

Sample test and qualified procedure

For batches of hardware processed together (e.g. manifolds or component parts) a representative sample of a minimum of 5% shall be tested.

The selected sample shall be representative for the hardware under test.

For repeated dryness verification of a hardware configuration a procedure shall be qualified and implemented in conformance with Annex B.

The supplier shall define in the deliverable in conformance with Annex B at what intervals periodic tests are made to ensure that the qualified procedure remains effective.

Acceptance inspection of packaging materials

Environmental control

All quality assurance operations shall be accomplished within a clean room that is consistent with, or cleaner than the packaging material being inspected.

See ECSS-Q-ST-70-01 on ‘Cleanroom requirements’.

The packaging materials shall be clean room compatible and visibly clean.

The packaging materials shall be stored in an area with proper cleanliness ratings.

The packaging materials shall be handled with visibly clean lint-free clean room gloves.

Sampling

Packaging materials shall be examined and tested to determine compliance with the cleanliness requirements of 7.1.

Verification of the absence of the release film can be difficult

All the plastic film of one type, e.g. one size and one configuration, tubing, flat roll stock, sheet and fabricated bags, offered by one manufacturer at one time, shall be considered to be one lot.

Thickness of packaging film

The plastic films used for precision packaging shall conform to the thickness and service requirements as given in Table 71.

TableTable 71: Packaging materials

|

Plastic film

|

Typical thickness range μm

|

Use

|

|

Polyethylene (anti-static)

|

100 to 150

|

Over wrap (outer bag)

|

|

Polyamide (trade name Nylon 6) or equivalent (anti-static)

|

40 to 60

|

Precision packaging (inner bag)

|

Static electricity

Anti-static wrapping material shall have a surface resistivity of less than 1012 measured in conformance with ASTM Method D-257.

Verification of cleanliness level

General

All plastic films of one lot shall have the cleanliness level verified prior to use.

Minimum surface area for test

The minimum interior surface area for verification of cleanliness level shall be 0,1 m2.

Sampling shall be in conformance with 7.2, except that additional sample material from the offered lot is used when necessary to make 0,1 m2.

Sample preparation

Fabricated bags shall be sealed across the open end.

Tubular packaging material shall be fabricated into a bag by cutting off, with properly cleaned tools, a length conforming to the requirements of 7.5.2 and sealing both ends.

Flat roll sheet and stock shall be fabricated into a bag by cutting out a section with an area in conformance with the requirements of clause 7.5.2, folding the section and sealing the section as necessary.

The cutting, purging and sealing techniques shall be as follows.

- The cutting does not generate particles.

- Prior to final sealing of the plastic film bag containing the clean component, the plastic film bag is purged with filtered gaseous nitrogen, filtered to remove particulates greater than 2 μm (in conformance with ISO 14951-3, Grade A).

- Sealing under the following conditions:

- An all-purpose impulse sealer is used to produce effective seals with plastic films.

- All items are handled in a manner that avoids exposure of the interior critical surfaces to airborne particles.

- One corner of the completely sealed test bag is cut off so that an opening of a maximum of 20 mm in length is created.

Rinsing procedures

Liquids filtered through a 2 m filter shall be used as the test liquid in the ratio of 1 l of liquid per m2 of surface area.

The following rinsing procedure shall be used:

- introduce the test liquid into the sealed bag through the previously cut opening;

- close the bag by folding over the cut corner;

- agitate the test liquid within the bag for a minimum of 15 s, wetting all surfaces;

- pour the used test liquid into a precision-cleaned beaker, taking care to exclude airborne contamination;

- analyse the test fluid for particulate population in conformance with Table 41 sub-class I.

Packaging and protection

Approved coverings

All critical surfaces or openings to critical surfaces shall be protected from contamination by sealing the surfaces or openings with approved coverings, and securing with tape or other approved methods.

Protected components shall be placed in clean bags.

Clean bags shall have been fabricated from packaging materials listed in Table 71.

Clean bags shall have been cleaned internally and verified in conformance with clause 7.5.

The interior of the clean bags shall be purged with dry nitrogen meeting the requirements of ISO 14951-3, Grade A filtered through a 2 μm filter.

The bags shall be completely sealed to ensure the storage environment is inert.

The item shall be double-bagged and packed to prevent damage during storage and handling.

Other packaging materials compatible with the applicable service media may be used with the approval of the customer.

If desiccants or humidity indicators are required for additional corrosion protection, they shall be placed in the outer bag.

Provisions shall be made for monitoring humidity indicators or desiccants, such as status indicators.

Packaging operations

Packaging operations involving cleaned and verified components shall be accomplished within the same environmentally controlled area in which verification was performed.

Where packaging cannot be performed in the same environment, the environment shall not compromise the cleanliness of the hardware.

Certification labels

Appropriate certification labels shall be placed between the inner and outer bags or layers of protective packaging film.

If the label cannot be placed between the inner and outer packaging film, the label shall be enclosed in a plastic bag or between layers of plastic film and secured to the outside of the package.

Labels shall be of sufficient size to contain at least the following information:

- Component name and identification number.

- Manufacturer’s name and serial number.

- Customer identification.

- Project identification.

- Order number.

- Date of cleaning.

- Cleanliness code, and number and revision of ECSS-E-ST-35-06.

- Service medium or intended use of component.

- Acceptance stamps.

Deliverables

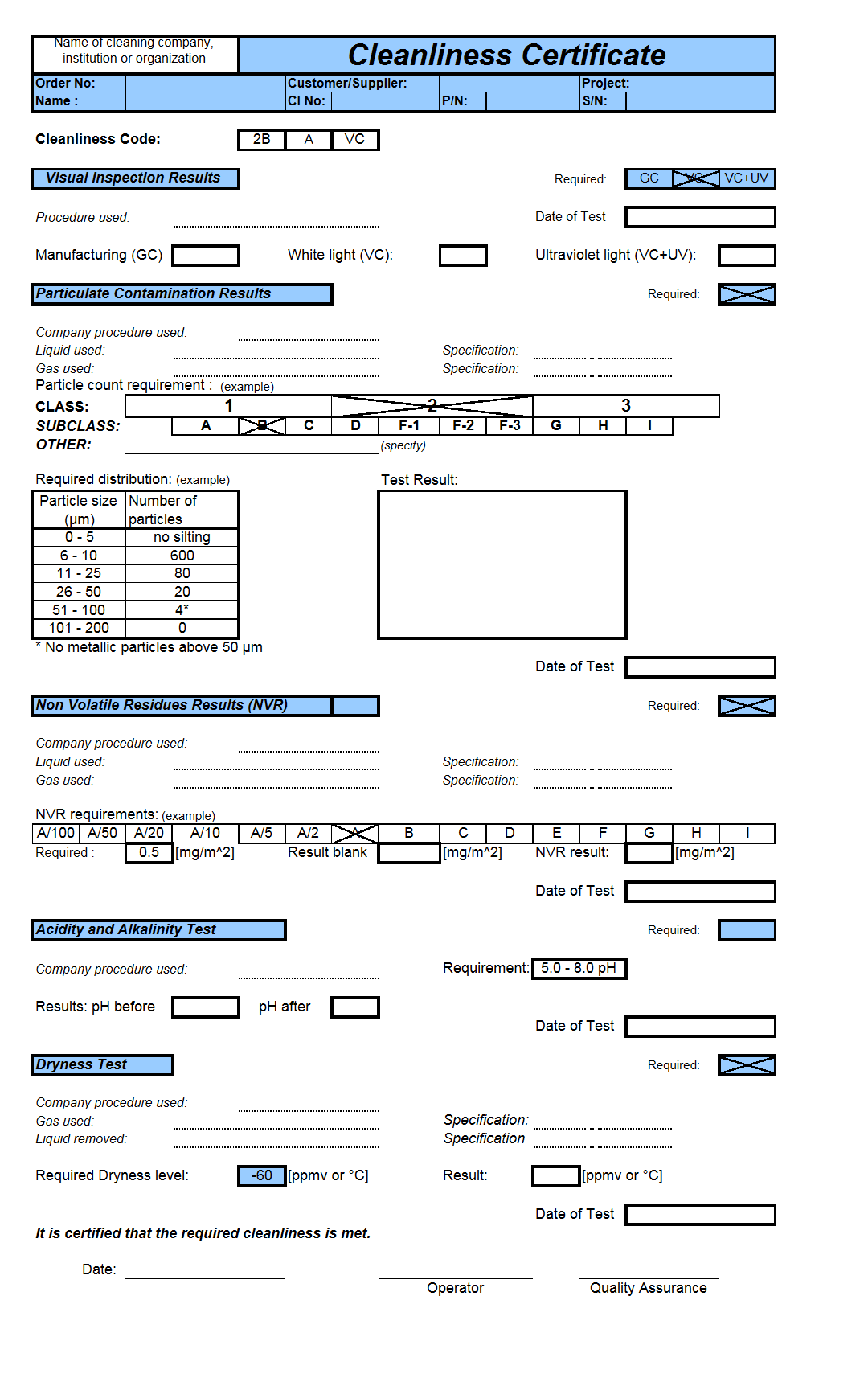

The following documents specific to the cleaning of a propulsion system shall be delivered:

- The Propulsion Cleanliness Requirements Analysis in conformance with Annex A.

- The Propulsion Cleaning Techniques Selection in conformance with Annex B.

- The Cleanliness Certificate in conformance with Annex C.

Test procedures

Test liquid-flush procedure (solvent)

The test procedure and total volume of test fluid necessary to flush the cleansed item or items shall be ascertained in accordance with Method I (clause 11.1.2 Method I “Liquid Flush Test”).

All critical surfaces shall be flushed uniformly with the test liquid.

Tubing, piping and hoses are flushed in accordance with either Method I or Method II (see 11.1.2 Method I “Liquid Flush Test” and 11.1.3 Method II “Liquid Flow Test”).

The test liquid shall be collected in a precision-cleaned container.

Immediately upon the completion of step c, the tested items shall be dried in conformance with the applicable drying method, see clause 5.5.

Gas flow test procedure

The gas flow test shall be performed in conformance with Method III, 11, 11.1.4 Method III “Gas Flow Test”.

The test procedure and total volume of gas necessary to purge the cleaned item or items shall be ascertained in conformance with Method III

All critical surfaces shall be purged uniformly with the purge gas.

Immediately upon completion of step c, dryness shall be verified to meet clause 4.4.3.

Sampling and analytical practices

Cleanliness level test methods

General

For liquids, clause 6.2.3 shall apply.