Space engineering

Structural general requirements

Foreword

This Standard is one of the series of ECSS Standards intended to be applied together for the management, engineering and product assurance in space projects and applications. ECSS is a cooperative effort of the European Space Agency, national space agencies and European industry associations for the purpose of developing and maintaining common standards. Requirements in this Standard are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards.

This Standard has been prepared by the ECSS-E-ST-32C Working Group, reviewed by the ECSS Executive Secretariat and approved by the ECSS Technical Authority.

Disclaimer

ECSS does not provide any warranty whatsoever, whether expressed, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item are error-free. In no respect shall ECSS incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this Standard, whether or not based upon warranty, business agreement, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by ECSS.

Published by: ESA Requirements and Standards Division

ESTEC, ,

2200 AG Noordwijk

The

Copyright: 2008 © by the European Space Agency for the members of ECSS

Change log

|

ECSS-E-30 Part 2A

|

First issue

|

|

ECSS-E-30 Part 2B

|

Never issued

|

|

ECSS-E-ST-32C

|

Second issue

|

|

ECSS-E-ST-32C Rev. 1

|

Second issue revision 1

|

Scope

ECSS-E-ST-32C (Space engineering – Structural) defines the mechanical engineering requirements for structural engineering.

This Standard specifies the requirements to be considered in all engineering aspects of structures: requirement definition and specification, design, development, verification, production, inservice and eventual disposal.

The Standard applies to all general structural subsystem aspects of space products including: launch vehicles, transfer vehicles, reentry vehicles, spacecraft, landing probes and rovers, sounding rockets, payloads and instruments, and structural parts of all subsystems.

This Standard may be tailored for the specific characteristics and constraints of a space project in conformance with ECSSSST-00.

Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this ECSS Standard. For dated references, subsequent amendments to, or revisions of any of these publications, do not apply. However, parties to agreements based on this ECSS Standard are encouraged to investigate the possibility of applying the most recent editions of the normative documents indicated below. For undated references the latest edition of the publication referred to applies.

|

ECSSSST0001

|

ECSS system– Glossary of terms

|

|

ECSS-E-ST-32-01

|

Space engineering – Fracture control

|

|

ECSS-E-ST-32-02

|

Space engineering – Structural design and verification of pressurized hardware

|

|

ECSS-E-ST-32-10

|

Space engineering – Reliability based mechanical factors of safety

|

|

ECSS-Q-ST-70-36

|

Space product assurance – Material selection for controlling stress-corrosion cracking

|

|

ECSS-Q-ST-70-37

|

Space product assurance – Determination of the susceptibility of metals to stress-corrosion cracking

|

Terms, definitions and abbreviated terms

Terms from other standards

For the purpose of this Standard, the terms and definitions from ECSSSST0001 apply.

Terms specific to the present standard

A-basis design allowable (A-value)

mechanical property value above which at least 99 % of the population of values is expected to fall, with a confidence level of 95 %

B-basis design allowable (B-value)

mechanical property value above which at least 90 % of the population of values is expected to fall, with a confidence level of 95 %

buckling

not stable equilibrium of a structure under loads applied statically or dynamically

Buckling include snapping of slender beams, buckling of flat plates, buckling of cylindrical panels, three dimensionally curved shells, rib crippling, and skin buckling of a sandwich.composite material

combination of materials different in composition or form on a macro scale

- 1 Composite materials provide improved characteristics not obtainable by any of the original components acting alone

- 2 The constituents retain their identities in the composite.

- 3 Normally the constituents can be physically identified, and there is an interface between them.

- 4 Composites include

- fibrous (composed of fibres, usually in a matrix),

- laminar (layers of materials), and

- hybrid (combinations of any of the above).

- 5 Composites material can be metallic, non-metallic or a combination thereof.

composite structure

structure fully or partially made of composite materials

contributing loads

loads which decrease the margin of safety.

damage tolerance

capability of a structure to resist failure due to the presence of flaws, cracks, or other damage for a specified period of usage without inspection or repair.

design allowable

statistically based strength capability with respect to a failure mode

For example in terms of load resistance, stress resistance, or strain limit with respect to rupture, collapse, detrimental deformation.design factor

factor used in the determination of DLL to account for uncertainties

Design factor accounts for uncertainties related to loads, models and project programmatic aspects (i.e. protoflight approach, uncertainty in launcher environment, maturity of design, growth potential and other design considerations).design limit load (DLL)

limit load multiplied by a design factor

Design factors are defined in ECSS-E-ST-32-10.design load (DL)

design limit load or design yield load or design ultimate load

design parameters

physical features which influence the design performances

According to the nature of the design variables, different design problems can be identified such as: * structural sizing for the dimensioning of beams, shells;

- shape optimization;

- material selection;

- structural topology.

design ultimate load (DUL)

design limit load multiplied by the ultimate safety factor

design ultimate stress

stress caused by the design ultimate load

With this definition no relation exists with ultimate strength.design yield load (DYL)

design limit load multiplied by the yield safety factor

design yield stress

stress caused by the design yield load

With this definition no relation exists with yield strength.detrimental deformation

structural deformation, deflection or displacement that prevents any portion of the structure or other system from performing its intended function or that reduces the probability of successful completion of the mission

dynamic load

time varying load with deterministic or stochastic distribution

effective mass

measure of the mass portion associated to the mode shape with respect to a reference support point

factor of safety (FOS)

factor by which design limit loads are multiplied in order to account for uncertainties of the verification methods, and uncertainties in manufacturing process and material properties

- 1 Factor of safety is synonym of safety factor.

- 2 FS and SF are also recognized abbreviations used for factor of safety

- 3 The factor of safety is a combination of factors according to various sources of uncertainties. Its magnitude is based on proven processes and verification methods for analyses, tests and manufacturing. To account for uncertainties of analysis, higher values of factor of safety are normally used for verification by analysis only. Higher values of factors of safety are also used if higher reliability is desired than was taken in the limit load determination.

failure

rupture, collapse, degradation, excessive wear or any other phenomenon resulting in an inability to sustain design limit loads, pressures (e.g. MDP) and environments

fail-safe structure

structure designed with sufficient redundancy to ensure that the failure of one structural element does not cause failure of the entire structure

No factor of safety is applied to design limit loads in the failure analysis.flaw

local discontinuity in a structural material

For example: scratch, notch, crack, void or pores in case of metallic and homogenous non metallic material; delamination or porosity in case of composite material.generalized mass

mass transformed by the mode shapes into the modal space (i.e. modal coordinates)

limited service life items

hardware item that requires periodic re-inspection or replacement

limit load (LL)

maximum load(s), which a structure is expected to experience with a given probability, during the performance of specified missions in specified environments

maximum design pressure (MDP)

pressure equal to MEOPKmKp

-

1 MDP correspond to design limit loads

-

2 MDP is equal or larger than MEOP.

-

3 Km is a factor which takes into account the representativity of the mathematical models predicting MEOP and it is defined by the entity defining MEOP (for definition of Km see ECSS-E-ST-32-10 ‘Factors of safety’).

-

4 Kp is the project factor (for definition of Kp see ECSS-E-ST-32-10 ‘Factors of safety’)

maximum expected operating pressure (MEOP)

highest pressure that a system or component is expected to experience during its mission life in association with its applicable environment -

1 For mission life see definition in 3.2.29.

-

2 MEOP corresponds to limit loads.

-

3 MEOP includes effects of temperature and acceleration on pressure, maximum relief pressure, maximum regulator pressure and effects of failures within the system or its components. The effect of pressure transient is assessed for each component of the system and used to define its MEOP.

-

4 MEOP includes effects of failures of an external system (e.g. spacecraft), as specified by the customer ,on systems (e.g. propulsion ) or components.

-

5 MEOP does not include testing factors, which are included in ECSS-E-ST-32-02 ‘Structural design and verification of pressurized hardware’ and ECSS-E-ST-10-03 ‘Verification’.

mission life

life cycle from delivery to disposal

primary structure

part of the structure that carries the main flight loads and defines the overall stiffness

proof load

load applied during a proof test

proof test

test of flight hardware under the proof load or pressure, to give evidence of satisfactory workmanship and material quality or to establish the initial crack sizes in the hardware

random load

vibration load whose instantaneous magnitudes are specified only by probability distribution functions giving the probable fraction of the total time that the instantaneous magnitude lies within a specified range

Random load contains no periodic or quasiperiodic constituents. relieving loads

loads which increase the margin of safety

residual stress

stress that remains in a structure after processing, fabrication, assembly, testing or operation

safe life

fracture control design principle, for which the largest undetected defect that can exist in the part does not grow to failure when subjected to the cyclic and sustained loads and environments encountered in the service life

safe life structure

structure designed according to the safe life design principle

scatter factor

factor by which the number of cycles or life time is multiplied in fatigue analysis, fracture analysis, thermal cycling analysis and test in order to account for uncertainties in the statistical distribution of loads and cycles

service life

interval beginning with the last item inspection or flaw screening proof test after manufacturing, and ending with completion of its specified life

secondary structure

structure attached to the primary structure with negligible participation in the main load transfer and overall stiffness

shock load

special type of transient load, where the load shows significant peaks and the duration of the load is well below the typical response time of the structure

(quasi) static loads

loads independent of time or which vary slowly, so that the dynamic response of the structure is not significant

stiffness

ratio between an applied force and the resulting displacement or between an applied moment and the corresponding rotation

structural design

set of information defining the structure, or the process used to generate it

Structural design is an iterative process. The process starts with the conceptual design of possible alternatives which can be considered to satisfy the general performance requirements and are likely to meet the main mission constraints (e.g. mass, interfaces, operation and cost). The various concepts are then evaluated according to a set of prioritised criteria in order to select the designs to develop in further detail. The main purpose of the evaluation is to identify the main mission requirements and to establish whether the selected concepts meet the requirements. The selected concepts are evolved and evaluated in more detail against a comprehensive set of mechanical requirements and interface constraints which are “flowed down” from the main mission and functional requirements.structure

set of mechanical components or assemblies designed to sustain loads or pressures, provide stiffness or stability, or provide support or containment

The structure is usually split into primary and secondary structures.transient load

deterministic load whose magnitude or direction varies with time and for which the dynamic response of the structure is significant

ultimate strength

the maximum load or stress that a structure or material can withstand without incurring rupture or collapse

It is implied that the condition of stress represents uniaxial tension, uniaxial compression, or pure shear.yield strength

maximum load or stress that a structure or material can withstand without incurring a specified permanent deformation or yield

The yield is usually determined by measuring the departure of the actual stressstrain diagram from an extension of the initial straight proportion. The specified value is often taken as a unit strain of 0,002.### Abbreviated terms

For the purpose of this standard, the abbreviated terms of ECSS-S-ST-00-01 and the following apply:

|

Abbreviation

|

Meaning

|

|

AIT

|

assembly, integration and tests

|

|

AOCS

|

attitude and orbit control system

|

|

BIT

|

builtin testing

|

|

CAD

|

computer aided design

|

|

CAE

|

computer aided engineering

|

|

|

computer aided manufacturing

|

|

COG

|

centre of gravity

|

|

DDF

|

design definition file

|

|

DJF

|

design justification file

|

|

DL

|

design load

|

|

DLL

|

design limit load

|

|

DOF

|

degree of freedom

|

|

DRD

|

document requirement definition

|

|

DUL

|

design ultimate load

|

|

DYL

|

design yield load

|

|

ECLS

|

environment control and life support

|

|

EMC

|

electromagnetic compatibility

|

|

FCI

|

fracture critical item

|

|

FEA

|

finite element analysis

|

|

FE

|

finite element

|

|

FM

|

flight model

|

|

FMECA

|

failure mode, effects and criticality analysis

|

|

FOS

|

factor(s) of safety

|

|

FOSU

|

factor(s) of safety at ultimate

|

|

FOSY

|

factor(s) of safety at yield

|

|

FSI

|

fluid structure interaction

|

|

LCDA

|

launcher coupled dynamic analysis

|

|

LL

|

limit load

|

|

MDP

|

maximum design pressure

|

|

MEOP

|

maximum expected operating pressure

|

|

MOS

|

margin of safety

|

|

NDT

|

nondestructive test

|

|

NDI

|

nondestructive inspection

|

|

OTM

|

Output Transformation Matrix

|

|

PFCI

|

potential fracture critical item

|

|

PFO

|

particle fall out

|

|

POGO

|

propulsion generated oscillations

|

|

r.m.s.

|

root-mean-square

|

|

SEP

|

system engineering plan

|

Requirements

Overview

The structural engineering produces a structural product which conforms to its functional and performance requirements by:

aiming for simple load paths,

maximizing the use of conventional materials,

simplifying interfaces, and

providing easy integration.

Lifetime

Structural assemblies and components shall be designed to withstand applied loads due to the mechanical environments to which they are exposed during the servicelife.

Structural assemblies and components shall fulfil, in operation, the mission objectives for the specified duration.

The servicelife shall include the expected events, with at least:

- transportation, handling, testing and storage, and

- all phases of prelaunch, launch, operation and descent. Usually handling tools are provided such that manufacturing, transportation, assembling, testing and storage are not dimensioning cases of the structure.The phases, applicable loads and duration shall be determined using:

- the requirements of the structure (i.e. single mission, expendable, reusable or longterm deployment),

- the effect of all degradation mechanisms upon materials used in the construction (i.e. both terrestrial and space environments and all expected loading regimes), and

- experience with similar structures (e.g. qualification and problems identified inservice). Servicelife evaluations shall determine:

- the inspection and maintenance requirements,

- the item replacement procedure (preventive maintenance), and

- the inspection and repair procedures and intervals (corrective maintenance).

Natural and induced environment

Components and assemblies for space applications shall be compatible with the natural and induced environments, including:

- the on ground, launch and operational environment conditions,

- the atmospheric conditions on earth in which they are manufactured, stored and tested, including corrosion effects,

- the effects of gravitation, and

- the exposure of sensitive materials to manufacturing and atmospheric environments . Provisions (e.g. gravitational compensation and purging) shall be made for the protection of equipment or components.

- 1 The sensitivity of materials to the environment on earth can determine the requirements for quality control procedures.

- 2 The natural environment generally covers the climatic, thermal, chemical and vacuum conditions, cleanliness, levels of radiation and the meteoroid and space debris environment.

- 3 The induced environments cover the mechanical loads induced by ground handling and prelaunch operations, launch, manoeuvres and disturbances, reentry, descent and landing. Additional induced environments include static pressure within the payload volume, temperature and thermal flux variations and the electromagnetic and humidity environments.

Mechanical environment

The mechanical environment shall be defined by static, thermal and dynamic environment loads.

The static and dynamic environment loads shall be defined in terms of constant acceleration, transient, sinusoidal and random vibration, acoustic noise and shock loads.

Loads shall be used in the worst combinations in which they can occur.

The severest loads are experienced during launch, ascent and separation, and, where relevant during reentry, descent and landing.Definition of the mechanical environment shall include the loads which can affect structural integrity and functional performance.

Microgravity, audible noise and human induced vibration

Structural requirements derived from microgravity, audible noise and human induced vibration system level requirements shall be identified.

Load events

The relevant mechanical and thermal load events expected throughout the service life of the structure shall be identified.

Loads shall be defined according to their nature, (i.e. static or dynamic) and their level, occurrence time and duration.

As a minimum the following load events shall be used:

- Ground and test loads:

- handling, transportation and storage loads,

- assembly and integration loads, and

- ground test loads.

- Launch loads as defined by the launch services supplier and including:

- launch preparation,

- operational pressures,

- engine ignition,

- thrust built-up,

- aborted launch

- lift-off,

- thrust (constant or varying slowly),

- aerodynamic loads,

- heat flux from engine and aerodynamics,

- wind and gust,

- dynamic interaction between the structure and propulsion system,

- thrust decay,

- acoustic noise,

- manoeuvres,

- pyrotechnics,

- separation of parts (e.g. stage, fairing and spacecraft), and

- depressurization.

- Inorbit loads:

- operational pressures,

- static and dynamic loads induced by thrusters,

- shocks due to pyrotechnical operation and deployment of appendages,

- thermoelastic loads induced by temperature variations,

- hygroscopicinduced load due to variations in moisture content,

- microvibrations induced by moving elements (e.g. momentum wheels) and thrusters,

- micrometeoroids and debris,

- docking,

- berthing, and

- crew induced loads (e.g. on handles, rails and by movements).

- Reentry, descent and landing:

- aerodynamic loads and thermal fluxes,

- parachute ejection and deployment shocks,

- operational pressures,

- landing loads, and

- impact loads.

Combined loads

Load combination rules shall be defined according to specified load events by establishing the loads to be combined, their level and mathematical combination procedures

For example mathematical combination procedures like linear superposition or root of the sum of the squares.Load application sequence shall be defined.

For example to account for any non-linear effect depending on load application sequence.Factors of safety for combined loads shall be defined at yield and ultimate level, and for the tests.

Relieving loads which are independent from contributing loads shall be combined at their minimum operating value without any design factor nor FOS.

This requirement aims at avoiding overestimation of relieving effects due to combination of loads.### Limit loads

The limit loads are derived as follows:

- For cases where a representative statistical distribution of the loads is known, the limit load shall be defined as the load level not being exceeded with a probability of 99 % and a confidence level of 90 % during the servicelife.

- For cases where a statistical distribution of the loads is not known the limit loads shall be agreed with the costumer. It is good practice to determine the loads using conservative assumptions.* For pressurised systems, the maximum expected operating pressure (MEOP) shall be part of the limit loads. For Gaussian distributed random loads for verification, with a zero mean value, the limit load contribution shall be derived as standard deviation multiplied by three, i.e. 3 × root-mean-square (r.m.s.).

Design limit loads

The design limit loads shall be derived by multiplication of the limit loads by the design factors.

Design factors shall be system defined.

For pressurised systems, the maximum design pressure (MDP) shall be part of the design limit loads.

Functionality

Overview

For the design, manufacturing, verification, operation and maintenance of metallic and non-metallic pressurized hardware see the requirements of ECSSEST3202. For fracture control programme see ECSS-E-ST-32-01.

Strength

The structure shall withstand the design limit loads without failing or exhibiting permanent deformations that can endanger the mission objectives.

Local yielding

For metal structures or metal structure components local yielding may exist, provided it does not cause overall permanent set, instability or fatigue failure of the structure

Buckling

The stability (i.e. no buckling) of the structure shall be verified for the design loads.

Local buckling shall be prevented unless:

- the buckling is reversible, and

- the resulting stiffness and deformations still conform to the structural and functional requirements, and

- a post-buckling investigation (by analysis or test) demonstrates positive margins against failure.

Stiffness

Stiffness requirements under the specified load and boundary conditions shall be identified.

Stiffness is often expressed in terms of a minimum natural frequency requirement.The stiffness of subassemblies and components and interfaces shall be such that the structural and functional performance requirements are met

For example avoiding deformations leading to violations of specified envelopes, gapping at joints, the creation of inefficient load paths and dynamic coupling with other subsystems e.g. Attitude and Orbital Control System.### Dynamic behaviour

The natural frequencies of a structure shall be within specified bandwidths preventing dynamic coupling with major excitation frequencies

For example launch vehicle fundamental frequencies.### Thermal

Constraints imposed by the thermal design and impacting the structure shall be identified.

The temperatures and temperature variations and gradients during all phases of a mission, including manufacturing and storage, shall be used, both in the material selection and in the design in order to achieve the specified functional and structural performance.

Damage tolerance

Damage tolerance design principles shall be applied.

Design principles can include failsafe design (redundancy) of attachment points, and damage tolerant materials.The resistance of the structure against manufacturing defects and the result of accidental damage (e.g. low energy impact) shall be taken into account in the design.

A structure is considered tolerant to damage if the amount of general degradation or the size and distribution of local defects expected during operation does not lead to structural degradation below specified performance.### Tolerances and alignments

The accuracy of the tolerances applied to the mechanical design shall guarantee conformance to geometrical interface requirements.

The impacts of the assembly alignment and pointing accuracy requirements on the angular and position tolerances shall be identified.

In cases where alignment adjustability is specified, either at assembly level or at spacecraft level, these provisions shall be included in the mechanical design together with the devices (e.g. alignment cubes) for measurement or checking of the alignment.

Electrical conductivity

Structural requirements derived from electrical conductivity requirements shall be identified.

Lightning protection

The structure shall be designed to

- dissipate static electrical charges,

- provide electromagnetic protection, and

- provide means of diverting electrical current arising from lightning strike so as not to endanger the vehicle.

Electromagnetic compatibility

Structural requirements derived from electromagnetic compatibility requirements shall be identified.

Dimensional stability

Impact of system requirements on dimensional stability of the structure shall be identified.

Dimensional stability requirements address the short, medium and long term alignment stability of a space structure under the operational environment.The mechanical design of a structure shall ensure that no loss of alignment caused by the action of applied loads and material stability can jeopardise or degrade the mission objectives.

Structure stability can be affected for example by launch loads, deployment loads, thermal and moisture release.### Interface

The design of structural assemblies shall be compatible with internal and external interfaces, which can affect or be affected by adjacent systems, subsystems or assemblies.

Mechanical subsystem internal interfaces shall include:

- thermal control,

- mechanisms,

- ECLS,

- propulsion,

- pyrotechnics,

- mechanical parts, and

- materials. External interfaces shall include:

- spacecraftlauncher interface,

- human factors and ergonomics

- interfaces with equipment, optics and avionics,

- rendezvous and docking, robotics,

- ground support equipment for pre-flight and post-flight operations, and

- support equipment for in-orbit operations. Interfaces shall be explicitly defined with respect to the following:

- Design requirements. These include areas, volumes, alignments, surface finishing and properties, tolerances, geometry, flatness, fixations, conductibility, constraints imposed by the launcher (e.g. geometric, static and dynamic envelopes) and by design concepts (e.g. thermal and optical design), mass and inertia properties.* External loads applied to the interfaces, including temperature effects and overfluxes caused by adjacent structures.

- Global and local stiffness.

- Electrical, magnetic and radio frequency aspects, where applicable

Design

Inspectability

To ensure structural integrity, the requirement to inspect a component, assembly or structure shall be met during the following:

- at various stages throughout manufacture,

- at various stages during assembly,

- after testing, and

- inservice.

An NDI policy shall be defined and incorporated into the design process using the inspectability of parts and access for inspection equipment and personnel.

For structures subject to fracture control the NDI policy shall be consistent with the assumption made for the fracture control verification, and as specified in ECSS-E-ST-32-01.

Interchangeability

All parts or subassemblies identified by an item number shall be functionally and dimensionally interchangeable with items which are identically numbered.

It is not guaranteed that parts or subassemblies which are match drilled during assembly are interchangeable.### Maintainability

The mechanical design shall be performed in such a way that assembly, integration and repair and maintenance activities can be carried out with tools and test equipment agreed with the customer.

It is good practice to minimize the number of special tools and equipment to minimize cost.The maintenance activity during storage and ground life should be avoided.

The maintenance programme shall

- include a maintenance protocol, and

- define measurable parameters for all operations, and during all project phases, including at least the following:

- meantimetorepair,

- limitedlife,

- fault detection and isolation capability,

- spares requirements, and

- ground storage requirements.

The results of the maintenance programme evaluation shall

- avoid alterations and replacement of parts,

- form the criteria with which various concept designs are evaluated. Structures that are not accessible shall be maintenance free during service-life.

Dismountability

The mechanical design shall enable removal and replacement of:

- secondary structures,

- equipment, and

- payload.

Mass and inertia properties

Mass and inertia properties of the structure shall be determined during all phases of the design

Mass and inertia properties can be estimated, calculated or measured.Mass and inertia properties shall be compliant with the mass budget allocation.

The mass and inertia properties of a structure comprise its mass, the location of its centre of gravity, its moments and products of inertia, and, where applicable, its balancing masses.### Material selection

Overview

For requirements on material selection, see ECSS-Q-ST-70 and ECSS-E-ST-32-08.

Corrosion effects

The material selected for corrosion resistance shall be compatible with:

- the specific environment,

- interaction with contained fluid,

- design, fabrication, storage of individual and assembled components,

- interactions with dissimilar materials, and

- susceptibility to fretting and crack initiation.

Corrosion can be regarded as any deterioration in the physical and chemical properties of a material due to the environment to which they are exposed.In cases where the behaviour of a material in a specific environment is not known, corrosion tests of representative materials (composition and condition) shall be performed, either under the service conditions, or in more severe conditions (accelerated testing).

For alloys, and their weldments, not included in table “Alloys with high resistance to stress–corrosion cracking” of ECSS-Q-ST-70-36, their characteristics on susceptibility to stress-corrosion cracking shall be demonstrated by test in conformance with ECSS-Q-ST-70-37. - 1 These materials have been tested and demonstrated to have a high resistance to stress-corrosion cracking and therefore can be used for this purpose.

- 2 Metals, alloys and weldments not present in table “Alloys with high resistance to stress–corrosion cracking” of ECSS-Q-ST-70-36 can be approved for structural applications by means of the stress-corrosion evaluation form specified in the Annex A of ECSS-Q-ST-70-36.

Mechanical parts selection

For requirements on selection of mechanical parts, see ECSS-Q-ST-70.

Material design allowables

For structural material, design allowables shall be statistically derived covering all operational environments.

The scatter bands of the data shall be derived and design allowables defined in terms of fractions of their statistical distribution with A-basis or B-basis specified levels of reliability and confidence.

For each type of test the minimum number of test specimens shall be:

- ten (10) to establish Avalues, and

- five (5) to establish Bvalues.

If the material is delivered in several batches, the design allowables test programme shall evaluate the variations from batch to batch by performing sample tests at regular intervals during the production sequence.

In the cases specified in d) above, preliminary design allowables may be based on the initially small sample size, and upgraded as the sample size increases by tests of newly arriving batches. - 1 For material testing requirements, see ECSS-E-ST-32-08 and ECSS-E-HB-32-20.

- 2 Probabilistic descriptions of the strength distribution of materials are usually based on the normal, lognormal or the Weibull distribution. Regardless of the kind of distribution, distribution curves and fractiles cannot be uniquely identified due to the data scatter. The values are assumed to lie within an interval bounded by upper and lower confidence limits. When design allowables are deduced from a regression line based on a small number of test specimens the confidence in such allowables is low. Larger numbers of test specimens generally do not change the shape of the regression line, but the confidence in the statistical evaluation increases.

- 3 The test database can be broadened by the inclusion of compatible data from acceptance and development tests.

Metals

All design allowables for metals shall be defined by their Avalues.

For unpressurized metal structures, B-values may be used in redundant structure in which the failure of a component can result in a safe redistribution of applied loads to other load–carrying structures.

All other metal material properties shall be defined by average values.

Nonmetallic materials

Glass and ceramics

Design allowables for glass and ceramics shall be derived through a probabilistic approach, covering all size effects.

For brittle materials such as glass and ceramics the lack of ductility results in very low failure strains. The large scatter observed in component testing is primarily caused by the variable severity of flaws distributed within the material (volume flaws) or flaws extrinsic to the material volume (surface flaws). The different physical nature of the flaws result in dissimilar failure response to identical external loading conditions. Due to the random distribution of flaws the failure of a complex structural part can be initiated not only at the point of highest stress.#### Nonmetallics other than glass and ceramics

Design allowables for other non-metals, (stress or strain) shall be defined by their Avalues.

For unpressurized non-metallic structures, B-values may be used in redundant structure in which the failure of a component can result in a safe redistribution of applied loads to other load–carrying structures.

The material properties other than those specified in 4.5.10.2a and 4.5.10.2b shall be defined by average values.

Composite materials

All design allowables for composite materials (stress or strain) shall be defined by their Avalues.

For unpressurized structures in composite materials, B-values may be used in redundant structure in which the failure of a component can result in a safe redistribution of applied loads to other load–carrying structures.

For structures made in composite materials, a progressive failure analysis methodology can be used to demonstrate that the material is intrinsically redundant, i.e. it maintains the required load carrying capability after initial damage or failure of one component (e.g. after failure of the most critical lamina).All the material properties other than those specified in 4.5.11a and 4.5.11b shall be defined by their average values.

The strength and stiffness of composite fibre reinforced materials are functions of fibre properties, matrix properties, fibre content and orientation of fibres. The properties of composites are determined by both fibres and matrix. By placing fibres in different directions, the material properties can range from highly anisotropic to quasi isotropic.### Adhesive materials in bonded joints

All design allowables for adhesive materials in bonded joints (stress or strain) shall be defined according to standards agreed with the customer.

Ablation and pyrolysis

Impact of material changes due to ablation and pyrolysis shall be identified.

In cases where the behaviour of a material in a specific environment is not known, ablation and pyrolysis tests of representative materials (composition and condition) shall be performed, either under the service conditions, or in more severe conditions (accelerated testing).

Micrometeoroid and debris collision

Pressurised structures, tanks, battery cells, pipes, electronic boxes and other specified equipment shall be protected from micrometeoroid and debris impact in order to prevent loss of functionalities.

The selection and design of material and debris protection systems shall be based on a specified probability of survival.

For a given hardware design and configuration, the probability of survival is influenced by the probability of impact, critical debris size, material response to hypervelocity impacts, impact face; back face (spalling), mission duration, spacecraft orientation and multiple impacts.### Venting

Provision shall be made in the design of the structure for venting.

In order to prevent a buildup of excess pressure and to reduce the time to evacuate the structure, a minimum ratio of venting-area to enclosed-volume is usually needed for venting.In case that provision a. is not made, the structure shall withstand build-up pressure (including safety factors).

The openings for venting shall be compatible with the purging system gas supply pressure and flow rate.

The openings for venting can be used to prevent contamination or risk of explosion.### Margin of safety (MOS)

Margins of safety (MOS) shall be calculated by the following formula:

Loads can be replaced by stresses if the load stress relationship is linear.All margins of safety shall be positive.

The margins of safety for combined loads shall be computed by the following procedure:

- define the load combination applied at a certain design level (limit, yield or ultimate), according to the specified FOS for combined loads;

- calculate the margin of safety as: Equation MOS = -1

where , called reserve factor, is the ratio between design allowable and design load.

MOS shall be computed by accounting for interactions of different types of failures (e.g. failure of a bolt due to shear and tension)

The following “interaction equation” is normally used to compute for interacting failure types:

where , , , and are experimental exponents and Ri are the ratios between the i-th DLL x FOS and the allowable load (which causes the failure if the i-th load is applied alone)### Factors of safety (FOS)

Overview

The selection of appropriate factors of safety for a specific structural element depends on parameters, which are related to loads, design, structural verification approach, model philosophy and manufacturing aspects. Such aspects include the following:

pressurized structures,

human presence,

flight hardware or ground support equipment,

material type,

joints, bearings, welds,

verification by test,

verification by analysis only,

thermal loads,

ageing effects,

emergency loads,

fail-safe structure verification, and

dimensional stability.

FOS requirements

Factors of safety shall be determined considering the uncertainty of loads, design, material, manufacturing and verification parameters

Factors of safety listed in ECSS-E-ST-32-10 and ECSS-E-ST-32-02 shall be applied.

Scatter factors

A scatter factor of four (4) shall be used in fatigue analysis.

- 1 The scatter factor is applied to the number of cycles of a certain load level in order to cover the uncertainties of loads and material properties. Usually for metallic materials a scatter factor of 4 is applied. However, for specific applications (e.g. pressure vessels and low cycle fatigue) higher values are commonly used (e.g. 5 for pressure vessels).

- 2 For composite materials in some cases a factor on the stress (e.g. 1.15) is defined instead of a scatter factor on the load cycles”

- 3 The number of cycles can be based on the number of possible repetitions of tests (e.g. 1 qualification vibration plus 3 possible repetitions) specified by the project.

Verification

Overview

For general requirements on verification, verification programme and verification methods, see ECSS-E-ST-10-02.

Verification by analysis

General

Analysis methods shall be agreed between customer and supplier.

Different state of the art analysis methods are available, such as handbooks, standards or validated numerical solutions.A mathematical model (e.g. finite element model) shall be developed for primary and secondary structure.

A mathematical model shall be developed and delivered for launcher coupled dynamic analysis (LCDA).

It shall be demonstrated that the analysis tools used are adequate for the intended purpose.

A justification of assumptions made in tools, methods, models and input data shall be provided.

The influence of tolerances (including overall dimensions and thickness) shall be assessed whenever potentially critical.

All analysis data shall be traceable, and the organization responsible for the analysis shall provide procedures to ensure data traceability during the life of the product.

Modelling aspects

It shall be demonstrated that the mathematical models is adequate to perform the foreseen analysis.

- 1 Finite element mathematical models meet the requirements detailed in ECSS-E-ST-32-03.

- 2 Analysis is based on mathematical models which are representative of the structural behaviour. These models help the designer to assess how the design fulfils structural requirements and gives an insight on how to improve the design.

- 3 The mathematical models enable preparation of experimental testing and verification of requirements not demonstrable by tests, e.g. through coupled analysis.

- 4 The mathematical models help in defining load cases or combination of load cases.

- 5 The mathematical models can also give designers insight on sensitivity of the design with respect to uncertainties.

Mathematical models shall be validated by correlation with test results for specific needs.

Static analysis

Static analysis shall be performed to verify that the structural responses (e.g. displacements, forces, stresses and internal loads) to (quasi) static loads conform to the structural requirements.

The static analysis shall use representative load introduction, load distribution and boundary conditions.

Provisions shall be made to include the effects of residual stresses due to the manufacturing process (e.g. welding).

Static analysis shall take into account stress concentrations.

Stress concentrations essentially take place in areas with steeply varying shape or section and with notches (macro and micro stress raisers). For metals stress concentrations are known to have a detrimental effect on fatigue lifetime. For fibre reinforced plastics stress concentrations have a detrimental effect on static strength. #### Modal analysis

Modal analysis shall be performed to

- verify that the structure conforms to the natural frequency requirements, and

- determine associated modal characteristics (e.g. natural frequencies, mode shapes, generalized and effective masses).

Pretension and spin effects shall be included.

For large lightweight structures (e.g. solar arrays, antenna reflectors), the effect of the surrounding air shall be included in the analysis.

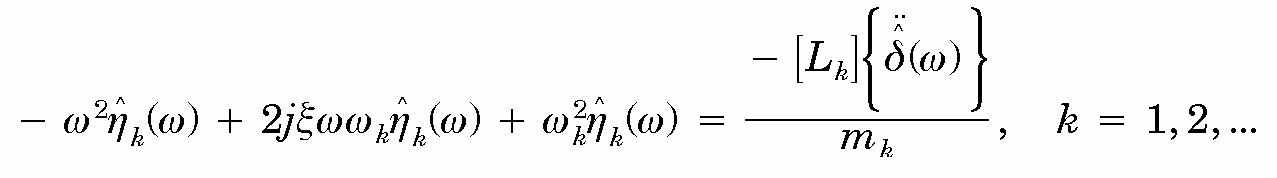

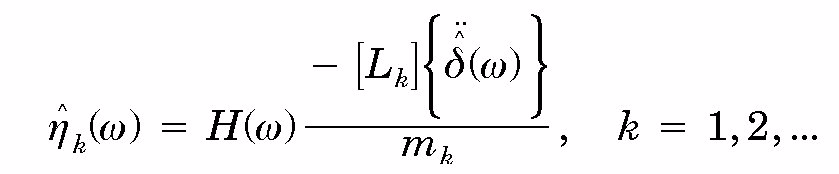

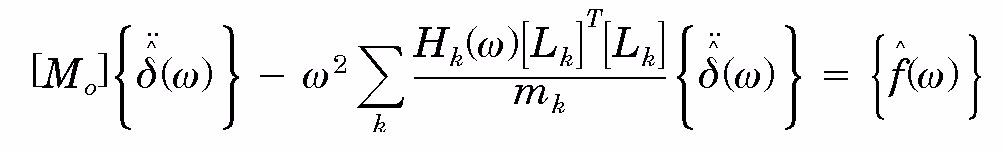

Dynamic response analysis

Dynamic response analysis shall be used to verify the structural response due to excitations (e.g. force or motion inputs via mechanical interfaces, thermal input such as eclipse transitions, spinner centrifugal forces, and possible combination thereof) either in the frequency domain (e.g. sine and random) or time domain (transient) according to the definition of loads.

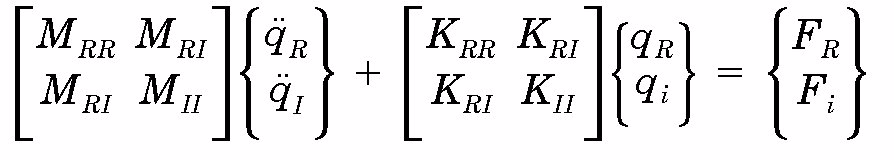

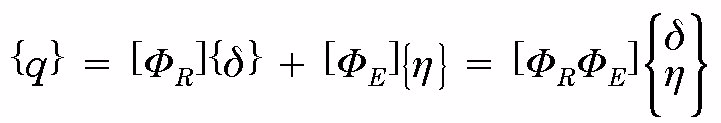

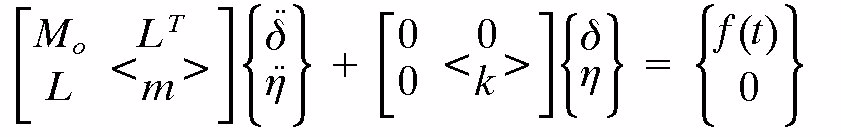

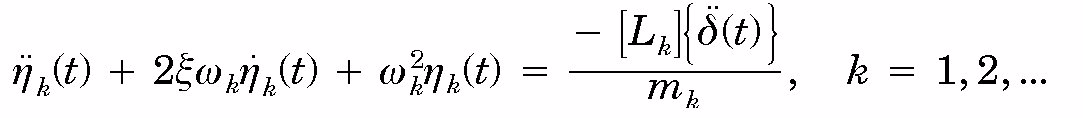

Coupled loads analyses are performed to verify the loads resulting from dynamic behaviour of structural assemblies as follows:

- The mathematical models applied in coupled analyses shall represent the structural assemblies by characterization of the dynamic parameters, namely natural frequencies, mode shapes, associated generalized and effective masses, and damping.

- The characterization of natural frequencies with small effective masses (e.g. multilayer insulation) need not be performed if it can be shown that these modes do not participate to the overall dynamic behaviour.

Acoustics analysis

Acoustic analysis shall be used to calculate the characteristics of the pressure field due to acoustic sources.

Response analysis shall be performed to verify structural response to acoustic fields including acoustic fatigue.

Fluid structure interaction (FSI)

The structure shall be verified against the effects of the interaction with fluids (e.g. sloshing, POGO, cavitation effects and pressure fields).

Fatigue analysis

Fatigue analysis shall be performed to verify that fatigue defect (crack or delamination) initiation or propagation resulting in structural failure or functional degradation cannot occur throughout the service life of the structure.

Effects of stress concentrations shall be included in the analysis.

The life of the structure shall be verified for the specified service life multiplied by the specified scatter factor considering the most unfavourable load sequence within each event.

Design limit loads (multiplied by factors of safety specified by the customer for fatigue) shall be used for fatigue analysis.

Alternate, permanent, and acoustic loads and their combination and sequence shall be used to perform the fatigue analysis.

- 1 Fatigue analysis normally uses a cumulative damage approach which estimates fatigue life from stress spectra and fatigue material allowables (S-N or Wöhler curves).

- 2 The following safety factors are usually applied for fatigue analysis: 1,0 for metallic materials, and 1,15 for composite materials.

Fracture control analysis

For fracture control analysis requirements, see ECSS-E-ST-32-01.

Buckling analysis

Buckling analysis shall be used to predict the loads at which the onset of structural instability occurs.

For cases where elastic fully reversible buckling is accepted, postbuckling behaviour shall be analysed.

Effects on stability of boundary conditions, defects and geometrical imperfections in the structure shall be included in the buckling analysis.

Geometrical imperfections refer to any deviation from the nominal shape including effect due to assembly tolerances.Minimum gauge shall be used for buckling analysis.

Thermo-elastic and Hygro-thermal analysis

Thermo-elastic analysis shall be performed to compute stresses and deformations due to occurring temperatures.

To perform thermo-elastic analysis temperature distributions defined by thermal analysis are usually mapped on the structural model.Hygro-thermal analysis shall be performed to compute deformations due to occurring moisture release or absorbtion.

Bonded joints

The analysis of bonded joints shall be performed in accordance with standards or procedures agreed with the customer.

- 1 For the mechanical characteristics of the bonded joints the following is usually taken into account:

- the influence of the characteristics of the adhesive,

- the material of the adherents

- any surface treatments,

- the dimensions of the bonded areas, and

- the relative stiffness of the parts.

- 2 For bonded joints, see ECSS-E-HB-32-21.

Bolted joints

Bolted joints shall be analysed according to standards or procedures agreed with the customer.

For bolted joints, see ECSS-E-HB-32-23.#### Welded joints

Welded joints shall be analysed according to standards or procedures agreed with the customer.

The analytical verification of welded joints usually takes into account the following:* stress concentrations,

- type and quality of the weld,

- local maximum allowable geometrical defects (e.g. mismatch and peaking), and

- residual stresses and material characteristics changes due to local heating and cooling.

Riveted joints

Riveted joints shall be analysed according to standards or procedures agreed with the customer.

Inserts

Inserts shall be analysed according to standards or procedures agreed with the customer.

- 1 Inserts are generally used in sandwich constructions with cores of low strength.

- 2 For inserts, see ECSS-E-HB-32-22.

Aeroelastic analysis

Aeroelastic analysis shall be used to assess the interaction between the aerodynamic flow and the structure.

Mass and inertia properties

The inertia properties shall be computed according to the specified accuracy using the inertia matrix of individual components.

The inertia properties shall be monitored and presented in a mass budget report issued on a regular basis agreed with the customer.

A breakdown of mass to component level shall be given together with mass contingency estimates based on the design maturity.

The mass and inertia data shall include the following:

- mass,

- co-ordinates of the centre of mass with respect to specified co-ordinate system,

- moments of inertia with respect to specified co-ordinate system, and

- the principal moments of inertia and their orientation with respect to specified coordinate system.

Alignments

It shall be demonstrated by analysis that alignment requirements can be met with the chosen design tolerances.

Dimensional stability

Short, medium and long term effects shall be included in the analysis to determine the dimensional stability of the structure.

A stability budget shall be established and the contributors shall be identified, analysed and allocated.

Examples of contributors affecting dimensional stability are: thermoelastic effects, moisture release, inorbit loads, zerogravity environment, microvibrations, material ageing (material property changes), material dimensional instability, setting effect and spin effect. #### Micro-vibrations, microgravity, audible noise and human induced vibration analysis

The structural responses at the locations of sensitive receivers due to disturbance sources shall be analysed.

Disturbance sources are e.g. reaction wheels, human induced vibrations, microcracking.”### Verification by test

Overview

For general requirements and definitions on verification by test, see ECSS-E-ST-10-02 and ECSS-E-ST-10-03.

General

The test objectives and success criteria shall be specified.

The adequacy of the test procedure with regard to the test objectives shall be verified before the test.

Checking of the test conformance with regard to the test procedure shall be performed after the test.

The impact of deviations on the adequacy of the test with respect to the test objectives shall be evaluated.

Differences between test conditions and expected operating conditions (e.g. boundary conditions, gravity and atmosphere) shall be identified.

Correction factors shall be applied to test loads to correct the effects of the differences identified in clause e. on the operating conditions.

The test results shall be evaluated with respect to the requirements to be verified.

Test data shall be used to validate mathematical models for specific needs.

Model philosophy

One of the following test model philosophies shall be applied:

- prototype approach,

- protoflight approach, or

- hybrid approach

Development tests

For materials, design concepts and expected critical parts not documented in previous applications, development tests shall be performed to:

- evaluate the design choices,

- support and check analysis methods,

- determine the failure modes,

- support qualification and acceptance test definition.

- 1 Development tests can be performed on:

- specimens (e.g. to test material properties),

- structural parts or components, or

- the whole structure.

- 2 Development tests can include static tests and other tests (e.g. fracture mechanics test, thermal distortion test).

Qualification tests

Qualification tests shall be performed to verify that the structure design and manufacturing technique fulfil specification requirements.

Qualification tests can include static tests, dynamic and acoustic tests, and other tests (e.g. thermal stress test).Qualification test shall account for the worst hardware characteristics which can be present in a flight unit but are not present in the test unit (e.g. by means of dedicated correction factors).

Acceptance tests

Acceptance tests shall be performed on the flight hardware.

- 1 Acceptance tests are performed to demonstrate that no workmanship defect prevents a structure item to fulfil specification requirements.

- 2 Acceptance tests can include static tests (including proof pressure tests), dynamic and acoustic tests, and other tests (e.g. dimensional stability tests)

- 3 Acceptance tests can include the following types of tests:

- proof pressure tests of pressurized hardware;

- tests of composite structures (see clause 4.6.4);

- proof tests on sandwich inserts;

- structure related functional tests (e.g. mechanism or leakage tests);

- dynamic tests on equipped sub-assemblies.

Static test

Static test shall be performed to:

- demonstrate that the structure is able to carry a specified load type and level (e.g. qualification load) without failure;

- verify the structural stiffness;

- verify the static mathematical model (at a specified load level).

Failure test (e.g. by rupture or buckling) shall be performed to determine the load-carrying capability of the structure and to confirm type of the real failure mode.

The following requirements apply to static test conditions: - boundary conditions shall be demonstrated to be representative of flight boundary constraints or alternatively test forces on boundary constraints shall be measured;

- dummy structure used in the test shall be demonstrated to be representative as regard the stiffness and the constraints of the replaced flight component.

Modal survey test

Modal survey test shall be performed to verify the modal characteristics.

See ECSS-E-ST-32-11.#### Dynamic tests: sine, random, shock

Dynamic tests (sine, random, shock) shall be performed to verify:

- the dynamic behaviour, in terms of accelerations and interface forces (including units and appendages)

- the compliance to the stiffness requirements, and

- the strength and alignment stability under dynamic loads.

Acoustic test

Acoustic tests shall be performed to verify:

- the ability of the structure and its equipment to withstand the vibrations induced by the specified acoustic field.

- the random dynamic design environment for subsystems and equipment.

Fatigue and fracture test

Fatigue and fracture tests shall verify that the structure can survive, without degradation, at least the predicted service life cycles with the specified scatter factor.

Fatigue tests shall verify that the cyclic loads do not cause cracks or crack-like defects that endanger integrity of the structure or change the behaviour in an unacceptable manner.

Fracture tests shall verify that initial cracks or crack-like defects which can be present in the structure after application of NDI do not propagate, due to cyclic or constant loading, up to a critical value, which causes structural failure.

Micro-vibrations, microgravity, audible noise and human induced vibration tests

The conformance to requirements on micro-vibrations and microgravity disturbances originating from the structure shall be verified by test.

Structural and acoustic to structural transmissibilities shall be validated by test.

Non destructive inspection and test

A nondestructive inspection and test shall be performed on the structure to verify that no defect (e.g. crack, delamination, porosity, impact damage, scratches) larger than the size specified by requirements (e.g. life or leak) are present.

Nondestructive tests evaluate or quantitatively measure properties or detect defects in materials or structural components or whole structures which do not cause a permanent change to the item under test, e.g. visual inspection, ultrasonics, holography, eddy current and leak test.#### Thermo-elastic test

The adequacy of the structure to withstand thermal loads shall be verified by test.

Conformance of thermo-elastic distortion to requirements shall be verified by test.

Thermal cycling test

Thermal cycling tests shall be performed in order to verify that the structure is capable to survive without failure all of the thermal cycling loads expected during its service life.

Thermal cycling temperature range shall be increased to account for uncertainties in the thermal analysis.

The following scatter factor shall be applied on the number of cycles for the thermal cycling tests:

- for launchers, re-entry vehicles and spacecraft subject to a low number of operational thermal cycles:

- a scatter factor of 4, for cycling within flight temperature ranges;

- a scatter factor of 2 for cycling within the qualification temperature ranges;

- for other spacecraft subjected to a large number of operational thermal cycles a scatter factor of 1,5. Thermal cycles for year range from 100 for geostationary orbits to 6000 for low Earth orbits.#### Ageing test

Ageing tests shall be performed to identify variations of the material properties as a function of time and environment.

Variations identified in clause a. shall be used to assess the structural design.

Contamination test

Contamination tests shall determine the particle fall-out (PFO) on specified spacecraft systems.

Mass and Inertia properties measurement

The mass and inertia properties of the structure shall be measured to the specified accuracy.

Alignment checks

Alignment checks shall be performed in order to verify the relative position and movements between parts during manufacturing, assembly and verification.

Dimensional stability tests

The dimensional stability of the structure in the environment of the operational conditions shall be verified by test.

The conformance of long term changes of material properties to specification (e.g. moisture release, ageing and creep) shall be verified by test.

Geometrical control

Dimensions and tolerances shall be controlled during and after manufacturing to conform to the functional requirements.

Interface verification

Interface verification shall be performed by:

- inspection (including geometrical control) of the manufacturing drawings and parts with respect to the interface requirements, and

- with the aid of fit checks of interfacing structural components.

Aerothermodynamic test

Aerodynamic and aerothermodynamic tests shall be performed to verify the behaviour of the vehicle or a part of it during flight in the atmosphere.

Tests performed with subscale models shall be verified for their representativity with respect to the flight item.

Aeroelastic test

Aeroelastic tests shall be performed to verify the analytically predicted behaviour for each flight configuration and to determine application limits.

Aeroelasticity tests are performed on subscale and full scale models and on flight vehicles on ground and in flight.#### Lightning protection verification

Test and inspection according to agreed procedures shall be performed to ensure the functioning of the lightning protection system.

Verification of composite structures

In addition to requirements from 4.6.1 to 4.6.3, the requirements 4.6.4b until 4.6.4e shall be applied to composite structures.

For all composite structures, acceptance tests shall be performed at 1,0 times the limit load.

Except in the case specified in 4.6.4d, composite structure acceptance tests shall be performed at component level or on fully assembled structure.

If tests are performed at assembly level, measurements shall be performed to verify the load paths in the tested composite component.

Composite structure may be exempted from acceptance testing if agreed with the customer.

The acceptance tests are not performed if it can be shown that the manufacturer of the composite component has:* extensive experience and a successful history of manufacturing similar design,

- proven application of the process specifications and trained personnel,

- proven non-destructive techniques to validate the quality and integrity of the finished article.

Acceptance tests shall be performed in case of transfer of manufacturing of composite structure to a new manufacturer.

Production and manufacturing

General

The production engineering of space structures shall ensure that the structure, and all its component parts, can be manufactured in the way intended to conform to the quality, reliability and reproducibility requirements.

The production of space structures includes the following:* procurement, which covers - materials,- components, and - parts,

- manufacturing and fabrication of components,

- assembly of components, and

- the assembly of substructures to form the final structure, either within the factory or at the launch site.

Manufacturing process

The selected manufacturing processes shall be qualified before manufacturing of flight or flight-representative hardware.

For new and unproven manufacturing technology a development and qualification program shall be performed.

Manufacturing drawings

Manufacturing drawings shall be established in conformity to the functional requirements and design drawings.

Quality requirements, manufacturing process, and manufacturing steps shall be input for manufacturing drawings.

For requirements on drawings, see the ISO 128 series of standards.### Tooling

Requirements for tooling, including assembly jigs and fixtures, shall include the following

- materials used in manufacture,

- geometry of the parts,

- number of parts, and

- production rate. Tooling design shall cover the acceptability of the finished components quality, size, shape and surface finish.

Assembly

Overview

The assembly covers both component assembly and major assembly.

Component assembly is the activity of joining together of individual parts to form assemblies or substructures.

Major assembly is the connection of either large substructures, e.g. launcher stage assembly, or final construction of the launch vehicle and its payloads, and the preparation for launch.

Assembly procedures

Component assembly procedures shall include at least:

- specifications of parts and materials,

- inspection and test, and

- assembly instructions including:

- preparation,

- equipment,

- parts and materials,

- method, and

- cleaning.

Major assembly operations shall be accompanied by inspection and tests.

Storage

Storage conditions shall prevent the degradations of the structure.

To avoid all hazards to personnel or equipment, items that contain hazardous materials or those with specific storage requirements shall be marked according to ad-hoc procedures.

For parts or components, which cannot be inspected prior to flight and for which the structural degradation during storage is uncertain, representative specimens (witness specimens) shall be stored together with the flight hardware.

Prior to acceptance for flight, the samples shall be inspected or tested for any structural degradation.

Cleanliness

Conformance to cleanliness requirements shall be controlled during all production phases.

Production phases include manufacture, storage and transportation.### Health and safety

Health and safety aspects of all processes and materials shall be evaluated to ensure that they conform to standards and policies agreed with the customer, and to applicable law.

In-service

Ground inspection

Ground inspection of integrated structures shall be performed prior to launch.

Ground inspection shall be performed after the return of a recoverable structure.

Ground inspection techniques can generally be those which are applied during system integration or during assembly manufacturing stages.### Inorbit inspection

Overview

The role of inorbit inspection is to inspect during use that a structure has not deteriorated such that further operation would render it unsafe.

Inorbit inspection equipment is designed in such a way that:

it is capable to detect damage in a reliable and costeffective way,

it is easy to use, and

it is used without the use of specialist personnel, extensive resources and expert interpretation.

In-orbit inspection system can be either portable or built-in.

Provisions

Builtintesting (BIT) systems shall:

- be developed for continuous monitoring of longterm deployed structures, where access is limited or the area is critical to the integrity and safety of the structure.

- identify damaged areas as they occur

In case damage is identified, other agreed techniques shall be used to investigate local damage sites.

BIT systems monitor the condition of structures.### Evaluation of damage

When a defective or damaged area is located, its criticality with regard to the operations and safety shall be assessed.

The following factors shall be determined:

- defect size,

- location, and

- propagation rate. The factors determined in 4.8.3b shall be used to assess the criticality of the damage with respect to:

- operational conditions (loading and environment),

- maintenance schedules,

- structural requirements and robustness of the actual design, and

- servicelife of the structure. Depending on the outcome of the evaluation of the damage, a decision shall be made and justified to repair, replace or use as is the affected parts of the structure.

Maintenance

General maintenance requirements

All maintenance actions shall be documented, including:

- the specification of inspection methods,

- recording of results,

- category of damage,

- repair methods, and

- compilation of service history documents. The maintenance schedules shall be determined during the design process, and procedures shall be followed.

Preventive maintenance

Preventive maintenance shall be performed on parts which are:

- critical to the safety and function of the structure,

- exposed to temperature which can affect their mechanical properties,

- moving parts experiencing wear,

- access points of structures (doors and hatches),

- surfaces experiencing general “wearandtear”, and “Wear and tear” refers to the gradual deterioration of an asset which results naturally from user age or both.* limited service life items. Preventive maintenance includes the replacement of parts approaching the end of their stated lives, repainting and adequately lubricating moving parts, where relevant.#### Corrective maintenance

Corrective maintenance shall be performed on parts incurring damage and those undergoing higher than expected rates of deterioration.

Expected rates of deterioration are a result of the design.Depending on the criticality of the damage or deterioration, procedures shall be specified for what actions are to be taken for both inorbit or onEarth cases.

Corrective maintenance includes replacing or repairing parts and assemblies which have been damaged, either by accident or as a result of a higher than expected rate of deterioration.Since corrective maintenance involves the repair or replacement of damaged parts, the decision to repair or replace shall be justified using at least:

- evaluation of damage performed in accordance with clause 4.8.3,

- possibility to repair (i.e. to restore the asdesigned mechanical and environmental performance for the remaining designed servicelife, by known and proven techniques),

- capability to replace, and

- remaining servicelife.

Repair

OnEarth and inorbit repair procedures shall be specified.

The following shall be input to repair procedures:

- structural classification,

- damage category,

- accessibility to damaged parts (e.g. one or both sides), and

- availability of equipment (e.g. repair material and services, and qualified personal). The following shall be input to inorbit repair procedures:

- requirements for extravehicular activity,

- transportability of materials to space (e.g. stability and outgassing properties of adhesives, hazardous cleaning and preparation chemicals),

- preparation of surfaces or damage removal (e.g. availability of appropriate handtools, control of dust, vapours and contamination, and avoidance of space debris generation), and

- repair manufacture difficulties. All repair procedures shall be qualified (i.e. w.r.t. their expected application mode and environment)

Data exchange

General

Introduction

For requirements on exchange of product data, see ECSS-E-TM-10-20.

Dataset requirements

The data shall include the delivery of datasets both:

- in the native data format of the software or facility used to produce the data, and

- in neutral data format complying with an open international standard. Refer to ECSS-E-TM-10-26.All data, regardless of the format, shall be accompanied by documentation containing detailed descriptions of the data, including the following:

- native data format, and open international data format (name and version);

- date and time stamp when the data was produced;

- status of data;

- responsible organisation and person who produced the data;

- name and version of the software or facility used to produce the data,

- format of media (e.g. tape, backup, and operating system) During the development process it is important to exchange data safely and quickly within the project. This includes data exchange between all engineering disciplines and sub-disciplines including design, analysis, manufacturing and test, as well as geographically distributed teams and between different subsystems. For management of project information and documentation see ECSSMST40.### System configuration data

Data for the system configuration should be exchanged in a computer sensible format through interfaces complying with open international standards or through direct interfaces agreed with the customer.

Data exchange between design and structural analysis

Geometrical data shall be exchanged between CAD and CAE software tools through interfaces complying with open international standards or through direct interfaces agreed with the customer.

Other data for design and structural analysis (e.g. material definitions and their properties) should be exchanged in a computer sensible format through interfaces complying with open international standards or through direct interfaces agreed with the customer. .

Data exchange between structural design and manufacturing

Data for structural design and manufacturing should be exchanged in a computer sensible format through interfaces complying with open international standards or through direct interfaces agreed with the customer.

Data exchange with other subsystems

The transfer of data and interfacing software between structural and other subsystems (e.g. thermal control and optical) can be achieved by means of standard based or direct electronic interfaces where available or by using applicable documents.

The exchange of data with other subsystems can imply a mapping of entries or results between the different models and the use of extrapolation methods.### Tests and structural analysis

Test and structural analysis data shall be exchanged with electronic format agreed with the customer.

Structural mathematical models

Exchange of structural mathematical model data shall be made at the following three levels:

- physical models (e.g. finite element models and finite difference models),

- mass and stiffness matrices, and

- mode components.

See ECSS-E-ST-32-03.When exchanging structural mathematical model data, for physical models, the same software shall be used.

When exchanging structural mathematical model data, for physical models, the same version of the software should be used.

When exchanging structural mathematical model data, for physical models transfer between different codes, translation problems and differences in capabilities of different software shall be considered.

When exchanging structural mathematical model data, for physical models, accompanying documents shall describe the model, the software, the version or release, any parameters being used and the results of the performed model checks.

When exchanging structural mathematical model data, for mass and stiffness matrices, the model shall be reduced in size and restitution matrices shall be used.

When exchanging structural mathematical model data, for mode components, the definition may depend upon the method used (e.g. clamped or free).

Detailed numbering (nodes and elements) and modelling requirements shall be specified in a finite element model requirements document.

Data traceability

Traceability of design data and relationship between each other shall be provided including CAD, CAE, models, structural analysis and test documentation.

Deliverables