Space engineering

Electrical design and interface requirements for power supply

Foreword

This Standard is one of the series of ECSS Standards intended to be applied together for the management, engineering and product assurance in space projects and applications. ECSS is a cooperative effort of the European Space Agency, national space agencies and European industry associations for the purpose of developing and maintaining common standards. Requirements in this Standard are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards.

This Standard has been prepared by the ECSS-E-ST-20-20 Working Group, reviewed by the ECSS Executive Secretariat and approved by the ECSS Technical Authority.

Disclaimer

ECSS does not provide any warranty whatsoever, whether expressed, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item are error-free. In no respect shall ECSS incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this Standard, whether or not based upon warranty, business agreement, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by ECSS.

Published by: ESA Requirements ,Standards and Engineering Knowledge Office ESTEC, P.O. Box 299, 2200 AG Noordwijk The NetherlandsCopyright: 2016© by the European Space Agency for the members of ECSS## Change log

|

ECSS-E-ST-20-20C

|

First issue

|

Introduction

This standard identifies the requirements needed to specify, procure or develop a space power distribution based on Latching Current Limiters, both from source and load perspective.

For a reference architecture description, it is possible to refer to ECSS-E-HB-20-20.

ECSS-E-HB-20-20 includes a clarification of the principles of operation of a power distribution based on LCLs, identifies important issues related to LCLs and explains the requirements of the present standard.

Note that the present issue of the standard covers electrical design and interface requirements for power distribution based on Latching Current Limiters only. Future issues of the present standard will cover additional power interfaces.

Scope

The target applications covered by this standard are all missions traditionally provided with power distribution and protection by LCLs/RLCLs (science, earth observation, navigation) with exclusion of applications for which the power distribution and protection is provided by fuses (e.g. most of the GEO telecom satellites).

The present standard applies to power distribution by LCLs/RLCLs for power systems, and in general for satellites, required to be Single Point Failure Free.

The present standard document applies exclusively to the main bus power distribution by LCLs/RLCLs to external satellite loads.

A particular case of LCLs (Heater LCLs, or HLCLs) is also treated. The HLCLs are the protections elements of the power distribution to the thermal heaters in a spacecraft.

Internal power system protections of LCLs/RLCLs are not covered.

Paralleling of LCLs to increase power supply line reliability is not covered by the present standard, since this choice does not appreciably change the reliability of the overall function (i.e. LCL plus load).

In fact, a typical reliability figure of the LCL (limited to the loss of its switch-on capability) is 20 FIT or less.

If the load to be connected to the LCL line has a substantial higher failure rate than this, it is not necessary to duplicate the LCL to supply that load.

This standard may be tailored for the specific characteristic and constrains of a space project in conformance with ECSS-S-ST-00.

Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this ECSS Standard. For dated references, subsequent amendments to, or revision of any of these publications do not apply. However, parties to agreements based on this ECSS Standard are encouraged to investigate the possibility of applying the more recent editions of the normative documents indicated below. For undated references, the latest edition of the publication referred to applies.

|

ECSS-S-ST-00-01

|

ECSS system - Glossary of terms

|

|

ECSS-E-ST-20

|

Space engineering - Electrical and electronic

|

Terms, definitions and abbreviated terms

Terms from other standards

For the purpose of this Standard, the terms and definitions from ECSS-S-ST-00-01 apply, in particular for the following terms:

redundancy

active redundancy

hot redundancy

cold redundancy

fault

fault tolerance

Terms specific to the present standard

centralised

feature that serves a number of elementary functions in a system

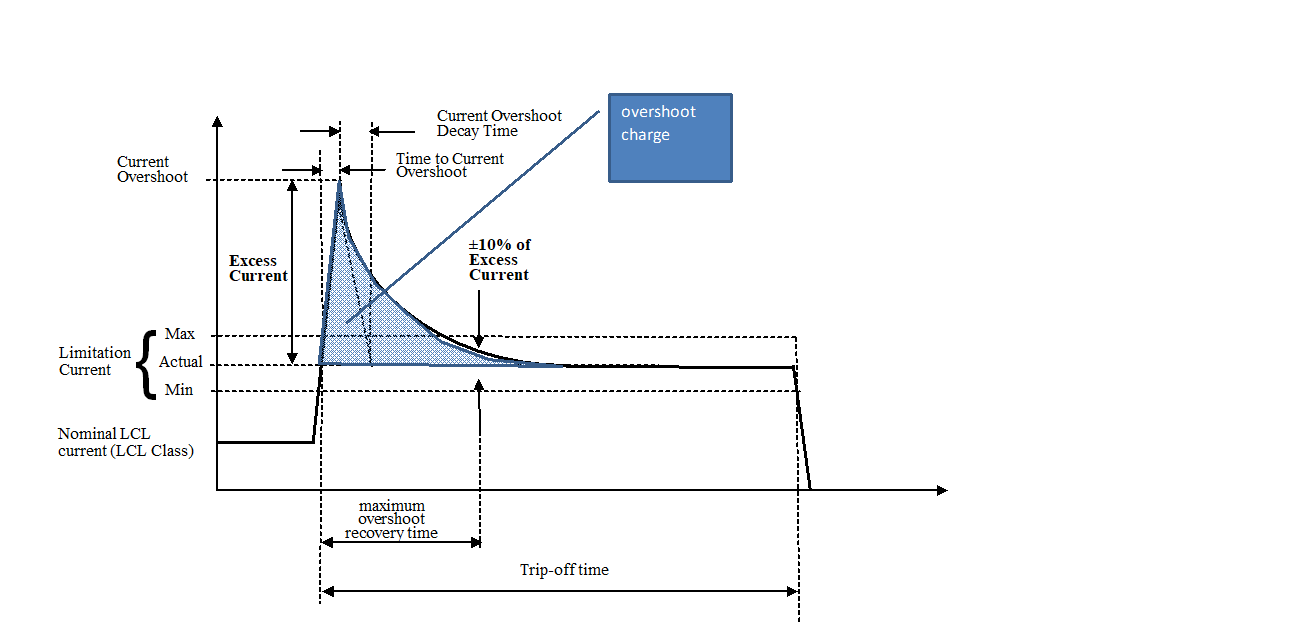

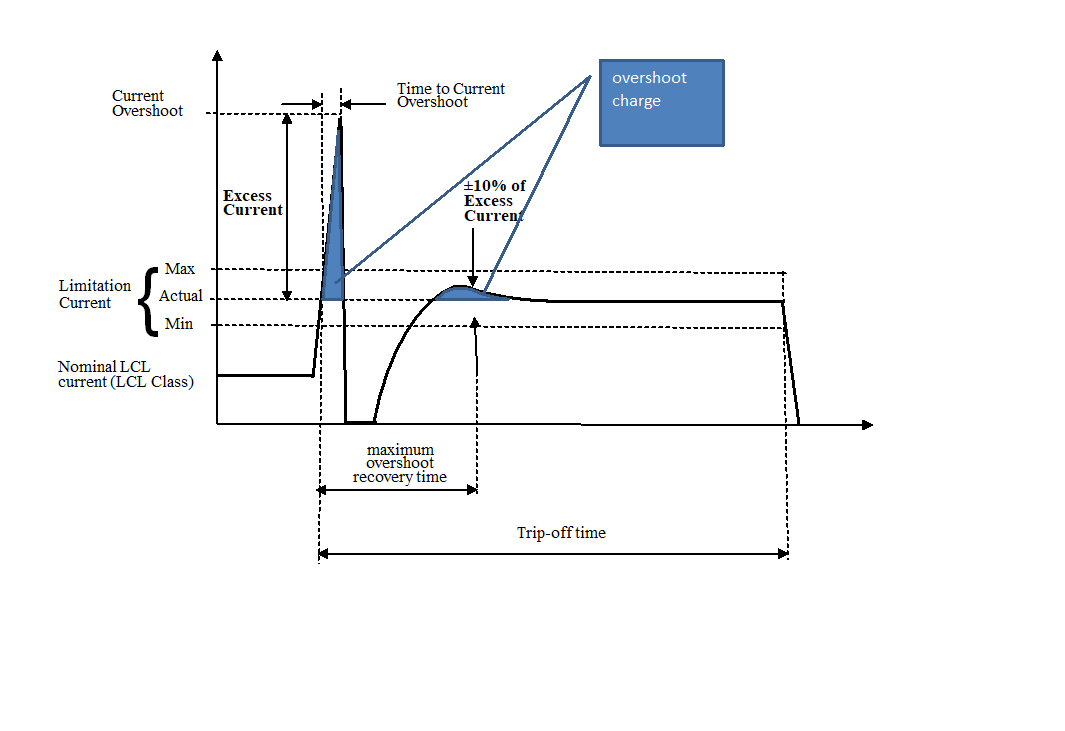

current overshoot decay time

maximum time constant decay time from current overshoot peak to actual limitation current after an overcurrent event, under the assumption that the decay time is modelled by an exponential law

current overshoot recovery time

time needed for the to reduce from its maximum value to ±10% of the excess current, at the application of an overload to the LCL/RLCL/HLCL

- 1 See Figure 31 and Figure 32.

- 2 Excess current is intended as overshoot peak minus actual limitation current value.

fault condition

internal failure of one of the following devices: LCL, RLCL or HLCL

This definition is aimed at clarifying that the fault condition is not the one relevant to the load.

fault current emission

maximum current emission of a given circuit at external interface under abnormal conditions

Abnormal in this context can cover fault condition or operator error.

fault current tolerance

minimum abnormal interface current that a circuit can sustain without being damaged

fault voltage emission

maximum voltage emission of a given circuit at external interface under abnormal conditions

Abnormal condition can cover fault condition or operator error.

fault voltage tolerance

minimum abnormal interface voltage that a circuit can sustain without being damaged

feature

part of a function to which a specific requirement refers

heater latching current limiter (HLCL)

LCL used as protection element in a power distribution to satellite thermal heaters

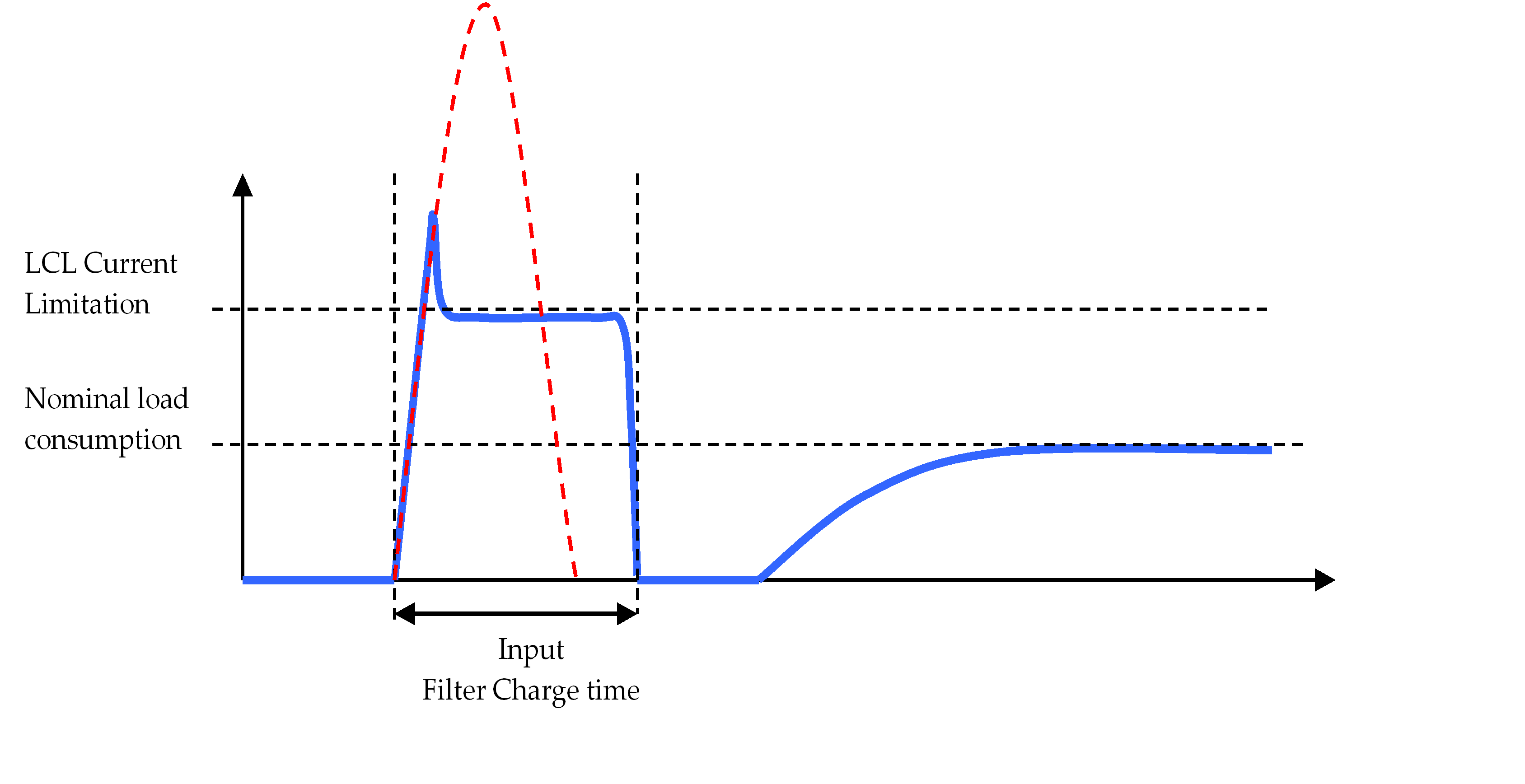

input filter charge time

time required for the LCL to charge the load input filter

See Figure 33.

input overshoot charge

charge requested at the LCL/RLCL/HLCL input at the application of an overload, for current in excess of the actual limitation current

See Figure 31 and Figure 32.

latching current limiter (LCL)

switchable and latching protection placed between a power source and the relevant load, causing a trip-off after having achieved at its output an overcurrent limitation for a definite trip-off time

LCL class

maximum allowable current that can flow through the LCL itself, under given standard conditions

LCL classes are defined in Table 31.

LCL switch dissipative failure

failure corresponding to an equivalent gate to drain short circuit on a MOSFET

The voltage across is approximately 4V to 5V maximum.

nominal condition

operative condition of the LCL/RLCL/HLCL, with no internal failure

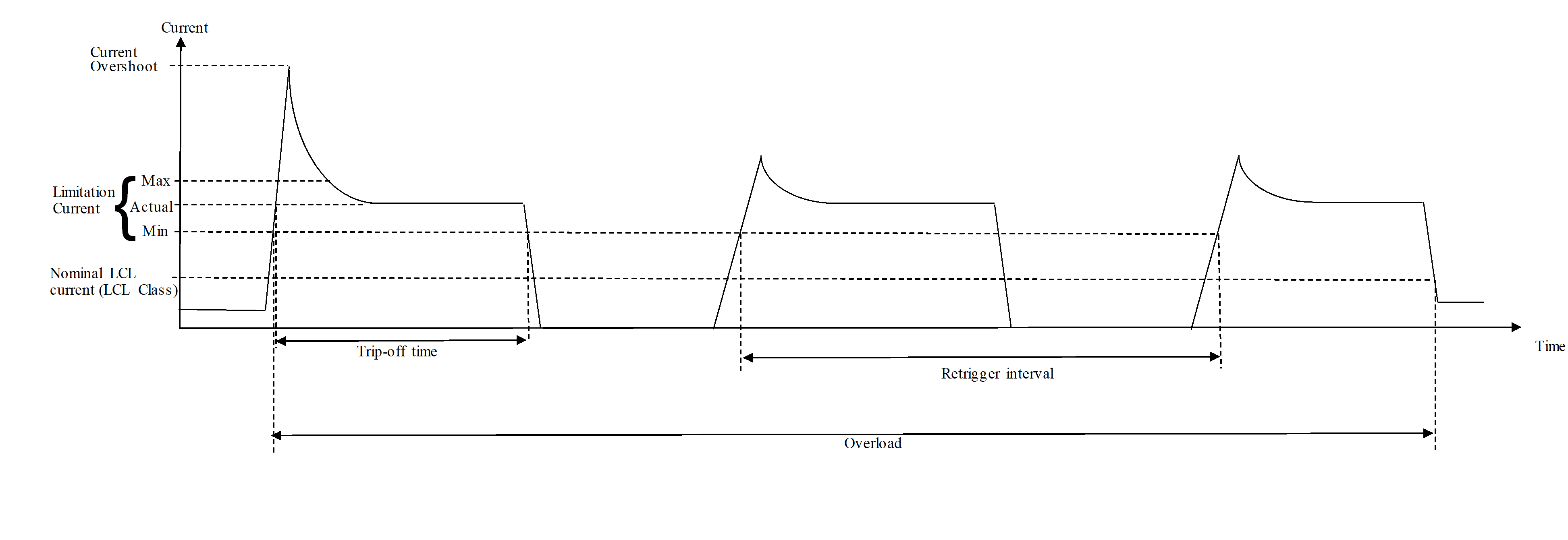

repetitive overload

overcurrent event that repeats for a number of cycles or indefinitely

retriggerable latching current limiter (RLCL)

LCL that automatically attempts to switch ON when powered or after a retrigger interval when a trip-off event occurred

retriggerability

characteristic of an RLCL protection to be able to restart automatically after being triggered

retrigger interval

time duration in high impedance state of a RLCL after a permanent overcurrent event occurred and the relevant trip-off time elapsed

- 1 See Figure 34.

- 2 High impedance state is equivalent to OFF condition.

RLCL class

maximum allowable current that can flow through the RLCL itself, under given standard conditions

RLCL classes are defined in Table 32.

sub-feature

sub-part of a function to which a specific requirement refers

switch-on capability

See “Switch-on response time”.

switch-on response time

time needed to enable actual ON command reception, under specified conditions

UVP switch-off response time

time to achieve UVP action in dynamical conditions, when under voltage excitation is achieved under standard conditions

The UVP action is the OFF of the relevant function.

time to current overshoot

maximum time from max limitation current to actual current overshoot peak after an overcurrent event

See Figure 31 and Figure 32.

trip-off

event occurring when a current protection latch flips and opens the protected distribution line after an overcurrent condition

To open a distribution line means to set the distribution line in high impedance status.

trip-off time

time in between LCL crossing actual current limitation value and the trip-off event, in permanent overcurrent condition.

See Figure 31 and Figure 32.

undervoltage protection (UVP)

protection that is triggered when the voltage provided to a function falls below a predefined threshold

LCL and RLCL are examples of functions for which UVP is activated.

Figure 31: LCL overload timing diagram (case 1)

Figure 31: LCL overload timing diagram (case 1)

Figure 32: LCL overload timing diagram (case 2)

Figure 32: LCL overload timing diagram (case 2)

Figure 31 and Figure 32 show typical current diagrams expected when an LCL/RLCL/HLCL are subject to an overload. They can represent either the LCL/RLCL/HLCL input or output current.

Figure 33: Typical start-up current profile of a DC/DC converter attached to a LCL

Figure 33: Typical start-up current profile of a DC/DC converter attached to a LCL

Figure 34: RLCL overload timing diagram

Figure 34: RLCL overload timing diagram

Table 31: LCL classes

|

|

|

LCL class

|

|

LCL class

| |||||||||||||||

|

Characteristic

|

|

1

|

2

|

3

|

4

|

5

|

6

|

8

|

10

|

|

1

|

2

|

3

|

4A

|

4B

|

5

|

6

|

8

|

10

|

|

Regulated Bus voltage [V]

|

|

28

|

|

50

| |||||||||||||||

|

Unregulated Bus voltage [V]

|

|

22 to 38

|

|

32 to 52

| |||||||||||||||

|

Class current [A]

|

|

1

|

2

|

3

|

4

|

5

|

6

|

8

|

10

|

|

1

|

2

|

3

|

4

|

4

|

5

|

6

|

8

|

10

|

|

Min limitation current [A]

|

|

1,1

|

2,2

|

3,3

|

4,4

|

5,5

|

6,6

|

8,8

|

11

|

|

1,1

|

2,2

|

3,3

|

4,4

|

4,4

|

5,5

|

6,6

|

8,8

|

11

|

|

Max limitation current [A]

|

|

1,4

|

2,8

|

4,2

|

5,6

|

7

|

8,4

|

11,2

|

14

|

|

1,4

|

2,8

|

4,2

|

5,6

|

5,6

|

7

|

8,4

|

11,2

|

14

|

|

Trip-off min [ms]

|

|

10

|

10

|

6

|

6

|

4

|

2

|

2

|

1,5

|

|

10

|

6

|

4

|

2

|

4

|

2

|

2

|

2

|

1,5

|

|

Trip-off max [ms]

|

|

20

|

20

|

12

|

12

|

8

|

4

|

4

|

3

|

|

20

|

12

|

8

|

4

|

8

|

4

|

4

|

4

|

3

|

|

Max load capacitance [µF] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Regulated bus

|

|

272

|

545

|

490

|

653

|

545

|

327

|

436

|

408

|

|

152

|

183

|

183

|

122

|

244

|

152

|

183

|

244

|

229

|

|

Unregulated bus

|

|

203

|

405

|

365

|

486

|

405

|

243

|

324

|

304

|

|

148

|

178

|

178

|

118

|

237

|

148

|

178

|

237

|

222

|

Table 32: RLCL classes

|

Characteristic

|

|

LCL class

|

|

LCL class

| ||||||

|

|

0,5

|

1

|

2A

|

2B

|

|

0,5

|

1A

|

1B

|

2

| |

|

Regulated Bus voltage [V]

|

|

28

|

|

50

| ||||||

|

Unregulated Bus voltage [V]

|

|

22 to 38

|

|

32 to 52

| ||||||

|

Class current [A]

|

|

0,5

|

1

|

2

|

2

|

|

0,5

|

1

|

1

|

2

|

|

Min limitation current [A]

|

|

0,55

|

1,1

|

2,2

|

2,2

|

|

0,55

|

1,1

|

1,1

|

2,2

|

|

Max limitation current [A]

|

|

0,7

|

1,4

|

2,8

|

2,8

|

|

0,7

|

1,4

|

1,4

|

2,8

|

|

Trip-off min [ms]

|

|

10

|

10

|

4

|

10

|

|

10

|

4

|

6

|

4

|

|

Trip-off max [ms]

|

|

20

|

20

|

8

|

20

|

|

20

|

8

|

12

|

8

|

|

Max load capacitance [µF] |

|

|

|

|

|

|

|

|

|

|

|

Regulated bus

|

|

136

|

272

|

218

|

545

|

|

76

|

61

|

91

|

122

|

|

Unregulated bus

|

|

101

|

203

|

162

|

405

|

|

74

|

59

|

89

|

118

|

Table 33: HLCL classes

|

|

|

LCL class

|

|

LCL class

| |||||||||||||||

|

Characteristic

|

|

1

|

2

|

3

|

4

|

5

|

6

|

8

|

10

|

|

1

|

2

|

3

|

4

|

|

5

|

6

|

8

|

10

|

|

Regulated Bus voltage [V]

|

|

28

|

|

50

| |||||||||||||||

|

Unregulated Bus voltage [V]

|

|

22 to 38

|

|

32 to 52

| |||||||||||||||

|

Class current [A]

|

|

1

|

2

|

3

|

4

|

5

|

6

|

8

|

10

|

|

1

|

2

|

3

|

4

|

|

5

|

6

|

8

|

10

|

|

Min limitation current [A]

|

|

1,1

|

2,2

|

3,3

|

4,4

|

5,5

|

6,6

|

8,8

|

11

|

|

1,1

|

2,2

|

3,3

|

4,4

|

|

5,5

|

6,6

|

8,8

|

11

|

|

Max limitation current [A]

|

|

1,4

|

2,8

|

4,2

|

5,6

|

7

|

8,4

|

11,2

|

14

|

|

1,4

|

2,8

|

4,2

|

5,6

|

|

7

|

8,4

|

11,2

|

14

|

|

Trip-off min [ms]

|

|

0,5

|

0,5

|

0,5

|

0,5

|

0,5

|

0,5

|

0,5

|

0,5

|

|

0,5

|

0,5

|

0,5

|

0,5

|

|

0,5

|

0,5

|

0,5

|

0,5

|

|

Trip-off max [ms]

|

|

2

|

2

|

2

|

2

|

2

|

2

|

2

|

2

|

|

2

|

2

|

2

|

2

|

|

2

|

2

|

2

|

2

|

|

Max parasitic capacitance [µF] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Regulated bus

|

|

1

|

1

|

1

|

1

|

1

|

1

|

1

|

1

|

|

1

|

1

|

1

|

1

|

|

1

|

1

|

1

|

1

|

|

Unregulated bus

|

|

1

|

1

|

1

|

1

|

1

|

1

|

1

|

1

|

|

1

|

1

|

1

|

1

|

|

1

|

1

|

1

|

1

|

Abbreviated terms

For the purpose of this Standard, the abbreviated terms from ECSS-S-ST-00-01 and the following apply:

|

Abbreviation

|

Meaning

|

|

EMC

|

electromagnetic compatibility

|

|

ESD

|

electrostatic discharge

|

|

FDIR

|

failure detection, isolation and recovery

|

|

FIT

|

failure in time

|

|

FMECA

|

failure modes, effects, and criticality analysis

|

|

HLCL

|

heater latching current limiter

|

|

LCL

|

latching current limiter

|

|

MB

|

main bus

|

|

PCDU

|

power conditioning and distribution unit

|

|

RLCL

|

retriggerable latching current limiter

|

|

SC

|

short circuit

|

|

SEE

|

single event effect

|

|

SSE

|

space segment element

|

|

SSS

|

space segment subsystem

|

|

UVP

|

undervoltage protection

|

Nomenclature

The following nomenclature applies throughout this document:

The word “shall” is used in this Standard to express requirements. All the requirements are expressed with the word “shall”.

The word “should” is used in this Standard to express recommendations. All the recommendations are expressed with the word “should”.

It is expected that, during tailoring, recommendations in this document are either converted into requirements or tailored out.

The words “may” and “need not” are used in this Standard to express positive and negative permissions, respectively. All the positive permissions are expressed with the word “may”. All the negative permissions are expressed with the words “need not”.

The word “can” is used in this Standard to express capabilities or possibilities, and therefore, if not accompanied by one of the previous words, it implies descriptive text.

In ECSS “may” and “can” have completely different meanings: “may” is normative (permission), and “can” is descriptive.

The present and past tenses are used in this Standard to express statements of fact, and therefore they imply descriptive text.

Principles

General

The indicated requirements verification (see clause 5) identifies the overall applicable methods to confirm compliance to the requirements, without explicitly explaining how the verification is split at applicability level (equipment, SSE/SSS or SSE/SSS/equipment). The verification methods suggested for the verification of the requirements are listed in Annex A.

Standard assumptions

The assumption for the maximum qualification temperature of the unit hosting the power distribution LCLs/RLCLs/HLCLs is 70 °C.

The bus voltage time derivative at bus application or removal varies from 0 V/µs to 0,1 V/ µs.

Requirements

Reference power bus specifications

The power distribution by LCLs/RLCLs shall work nominally for applicable nominal DC bus voltage range, nominal bus ripple voltage and voltage transients according to Table 51.

Nominally means “within the nominal functional and performance requirements”.

The power distribution by LCLs/RLCLs shall survive for applicable abnormal DC bus voltage range and abnormal bus voltage transients according to Table 51.

A component is meant to survive if its rating is respected.

The power distribution by LCLs/RLCLs for unregulated 28V and 50V bus cases shall work nominally for applicable abnormal DC bus voltage range according to Table 51.

- 1 The requirement 5.1c is explained by the same applicable minimum and maximum voltage limits both for nominal and abnormal (emission) DC bus voltage range for unregulated 28 V and 50 V bus cases.

- 2 Nominally means “within the nominal functional and performance requirements”.

LCLs/RLCLs shall not trip off up to maximum abnormal DC bus voltage limits as per to Table 51, unless the application of such limits result in an overload.

The load short circuit in presence of abnormal DC bus voltage (fault tolerance) is not taken into account.

Table 51: Reference Power Bus Specifications

|

Power Bus type :

|

28V regulated bus [V]

|

50V regulated bus [V]

|

28V unregulated bus [V]

|

50V unregulated bus [V]

| |

|

Nominal DC Bus Voltage Range at regulation point

|

Min

|

28 -1%

|

50 -1%

|

22

|

32

|

|

Max

|

28 +1%

|

50 +1%

|

38

|

52

| |

|

Nominal DC Bus Voltage Range at load side

|

Min

|

28 -5%

|

50 -5%

|

22

|

38

|

|

Max

|

28 +1%

|

50 +1%

|

38

|

52

| |

|

Abnormal DC Bus voltage range

|

Min

|

0

|

0

|

0

|

0

|

|

Max

|

N/A

|

N/A

|

40

|

55

| |

|

Max

|

38

|

52

| |||

|

Nominal Bus ripple voltage

|

Max

|

According to

|

Up to ± 500 mVpp in the range of 30 Hz to 50 MHz

|

Up to ± 500 mVpp in the range of 30 Hz to 50 MHz

| |

|

Nominal Bus voltage transients

|

Max

|

According to

|

±1,4V for load steps of 50%, with dI/dt=1A/µs

|

±2,5V for load steps of 50%, with dI/dt=1A/µs

| |

|

Abnormal Bus voltage transients

|

Max

|

0 to 34 max

|

0 to 60 max

|

Within Power Bus abnormal DC limits

| |

Functional/Source interface requirements

LCL/HLCL class

LCL/HLCL class

Nominal condition

The LCL class shall be selected among one shown in Table 31 and comply with related class performance.

The performance of the LCL classes can be achieved by using several MOSFETs in parallel.

The HLCL class shall be selected among one shown in Table 33 and comply with related class performance.

RLCL class

RLCL class

Nominal condition

The RLCL class shall be selected among one shown in Table 32 and comply with related class performance.

The performance of the LCL classes are typically achieved by using several MOSFET switches.

Current limitation section

Range

Nominal condition

The LCL/RLCL/HLCL shall limit the output current between the minimum and maximum limitation values.

Switch element, position

Nominal condition

For LCL/RLCL/HLCL, the switch element shall be on the hot main bus side.

Current sensing element, position

Nominal condition

For LCL/RLCL/HLCL, the current sensor element shall be on the hot main bus side.

Current limitation, LCL rating

Nominal condition

In current limitation mode, the LCL/HLCL components application shall respect the relevant rating limits.

Current limitation, RLCL derating

Nominal condition

In current limitation mode, the RLCL components application shall respect the relevant derating limits.

Trip-off section

Range

Nominal condition

In case the load current exceeds the relevant limit, the LCL/RLCL/HLCL shall switch-off within its trip-off time min to max range defined in Table 31, Table 32 and Table 33

UVP section

Provision

Nominal condition

The LCL/RLCL/HLCL shall be provided with an input UVP.

Unregulated bus case

Nominal condition

For RLCL, UVP shall be provided with hysteresis.

For LCL/HLCL, UVP should be provided with hysteresis.

Centralised protection

Nominal condition

In case of centralised protection for several LCLs/RLCLs/HLCLs, UVP shall be implemented as Single Point Failure Free.

Telecommand section features

Commandability

Nominal condition

The LCL/HLCL shall be ON/OFF commandable.

Retrigger function

Nominal condition

It shall be possible to enable or disable the retriggering function of the RLCL.

Retrigger ENABLE

Nominal condition

The retrigger function of an RLCL shall be enabled by default.

Retrigger DISABLE

Nominal condition

The disable command to a retrigger function of an RLCL feeding an essential load shall only be provided by ground.

- 1 Provision by ground command does not imply necessarily a discrete direct command or similar, but just that the command is not issued as a result of an automatic procedure (e.g. FDIR).

- 2 Examples of essential loads are the receiver and the decoder.

Conditions at start-up/ switch-off

Auto ON

Nominal condition

An RLCL shall always start in ON condition.

Auto OFF

Nominal condition

An LCL/HLCL should always start in OFF conditions.

LCL start-up with an internal failure

Fault condition

After a failure, no propagation outside the failed LCL/RLCL/HLCL shall occur. For this purpose in this case, LCL/RLCL/HLCL components blocking failure propagation shall meet their applicable derating.

When an internal failure of the LCL caused the trip-off of the LCL, the power bus needs to be protected if the operator or an automatic restart circuit or routine attempts to turn it on again, or at the next occurrence of bus power-up.

LCL status at start-up

Nominal condition

The actual LCL/RLCL/HLCL status shall not deviate from the programmed/intended one during MB start-up or recovery from zero volt.

LCL start-up on SC 1

Nominal condition

The LCL/RLCL/HLCL shall start up correctly, and within applicable rating/derating limits, when an overload or short circuit is already present at its output.

LCL start-up on SC 2

Nominal condition

Requirement 5.2.7.5.1a shall apply both in case of the LCL/HLCL being commanded ON by telecommand and when the bus voltage rises for the RLCL.

Switch-off

Nominal condition

The LCL/RLCL/HLCL shall contain a provision to free wheel the current circulating in the load or harness inductance, when the LCL/RLCL is either commanded OFF or when it opens the line after an overload.

Telemetry section

LCL status

Nominal condition

The LCL/HLCL/RLCL ON/OFF status shall confirm that the LCL/RLCL/HLCL output voltage is within its nominal range.

Current telemetry

Nominal condition

An LCL/RLCL/HLCL shall provide current telemetry.

Current telemetry, full scale reading

Nominal condition

Full scale of current TM shall be at least equal to the maximum LCL/RLCL/HLCL limitation current.

Current telemetry, linearity and accuracy

Nominal condition

For LCL/RLCL/HLCL, the current TM shall be linear and have an absolute accuracy referred to the class current and applicable on the full range of the TM.

Telemetry accuracy is detailed in 5.4.7.1.1a.

Current telemetry, offset

Nominal condition

For LCL/RLCL/HLCL, the current TM offset shall be referred to the class current.

Offset performance is defined in 5.4.8.1.1a.

Current telemetry, reading at zero current

Nominal condition

For LCL/RLCL/HLCL, the current TM should be able to read down to zero current within the specified accuracy.

Telemetry accuracy is detailed in requirement 5.4.7.1.1a.

Current telemetry, verification

Nominal condition

For LCL/RLCL/HLCL, if requirement 5.2.8.6.1a is met, then the accuracy shall be verified at 0%, 50% and 100% of the class current, else the accuracy shall be verified at 0%, 10%, 50% and 100% of the class current.

Status section

LCL status under failed conditions

Fault condition

The capability of reading the correct LCL/RLCL/HLCL status shall not be impacted by any failure in the command interface of the LCL/RLCL/HLCL itself.

Repetitive overload

LCL case

Nominal case

The LCL shall correctly operate the application of repetitive overload conditions within the applicable rating/derating limits.

For instance hiccup between LCL and UVP of the function supplied by the LCL. In absence of specific needs, the approach described in ECSS-E-HB-20-20 section 5.7.2.6 can conveniently be used (e.g. ensuring a ratio of 30 between the countdown and count up time constant of the LCL trip-off counter).

RLCL case

Nominal case

The RLCL shall correctly operate the application of repetitive overload conditions within the applicable derating limits.

For instance hiccup between RLCL and UVP of the function supplied by the RLCL. In absence of specific needs, the approach described in ECSS-E-HB-20-20 section 5.7.2.6 can conveniently be used (e.g. ensuring a ratio of 30 between the count down and count up time constant of the RLCL trip-off counter).

Reverse current tolerance

Reverse current tolerance

Nominal case

The LCL design should be capable to withstand the application of reverse current by the load, both in ON and in OFF conditions.

Parallel connection

LCLs in parallel

Nominal case

It should be possible to put LCLs/HLCLs in parallel.

LCLs in parallel and current sharing

Nominal case

When two or more LCLs/RLCLs/HLCLs are put in parallel, the current sharing accuracy shall be correctly assessed to avoid unwanted tripping-off of the LCLs themselves.

The overall limitation current of two or more LCLs in parallel is usually smaller than the sum of the individual LCLs limitation currents.

LCLs in parallel and trip-off

Nominal case

When two or more LCLs/RLCLs/HLCLs are put in parallel, the overall trip-off time shall be correctly assessed to avoid unwanted tripping-off of the LCLs/RLCLs/HLCLs themselves.

LCLs in parallel and ON/OFF command

Nominal case

When two or more LCLs/HLCLs are put in parallel, the ON/OFF command shall be made common to all of them.

LCLs in parallel and current telemetry

Nominal case

When two or more LCLs/RLCLs/HLCLs are put in parallel, the current telemetry shall provide the overall current flowing through them.

Switching options

No additional switching capability

Fault case

For LCL/HLCL, if no additional switching capability is provided as per 5.2.13.3.1a, the power budget shall cover the LCL/HLCL switch failure by considering the actual MB maximum load, plus eventually the unwanted load connected to the failed LCL/HLCL, in the following cases:

- all the load operational modes imply a non-negligible power consumption;

- the load operational modes cannot be directly commanded by an autonomous, on board load shedding routine to be triggered by abnormal bus load consumption.

- 1 In case the load power consumption is negligible, refer to requirement 5.2.13.2.1a.

- 2 The LCL switch is the only switch in the relevant distribution line.

No additional switching capability, negligible load power consumption mode

Nominal case

For LCL/HLCL, the load power consumption considered as negligible in terms of power budget shall be specified by the system integrator.

The "negligible" power consumption is intended as the one that can be drawn from the power bus without the system integrator or system responsible being forced to disconnect it.Such power level is indeed added to the power budget.

Additional switching capability

Nominal and fault cases

For LCL/HLCL, in case that there is an additional switch that can be commanded open in any case when the LCL/HLCL switch is in ON state or fails ON or in short circuit, requirements 5.2.13.4.1a and 5.2.13.5.1a should be fulfilled.

It shall be possible to command the LCL/HLCL and the relevant additional switch in series by a different, individual command, or a different commanding path.

Additional switching capability, location of additional switch

Nominal and fault cases

For LCL, the additional switch should be put on power system LCL side.

Additional switching capability, UVP acting on additional switch

Nominal and fault cases

For LCL, the UVP should act both on the LCL switch and on the additional switch provided by an independent memory cell.

Each switch which is supposed to maintain its ON (or OFF) status is provided with a memory cell (a flip-flop or other). See Figures 5-29 and 5-30 of ECSS-E-HB-20-20.

LCL Switch dissipative failure

Steady state condition

Fault case

In case the LCL/RLCL/HLCL switch fails in a dissipative failure and in case no other protection removes the failure, all the surrounding components shall be within derating.

Surrounding components are the ones not relevant to the failed LCL.

Transient condition

Fault case

In case the LCL/RLCL/HLCL switch fails in a dissipative failure and in case the "on board system" removes the failure by reducing the load or commanding OFF an additional switch, all the surrounding components shall be within rating during the on board system reaction time.

Local protection

Fault case

In case the LCL/RLCL/HLCL switch fails in a dissipative failure and in case requirements 5.2.14.1.1a and 5.2.14.2.1a cannot be fulfilled, a protection shall be embedded in the LCL or in the Distribution Unit to avoid a failure propagation due to the abnormal heat dissipation.

Loss of LCL lines

Loss of LCL lines

Fault case

In case of a single failure, no more than one LCL/RLCL/HLCL line shall be lost.

Noise immunity

General

Nominal case

The LCL/RLCL/HLCL state shall not change from the commanded one due to spurious perturbations, including:

- EM emissions, both conducted and radiated,

- SEE,

- ESD,

- ON/OFF commands to other LCL/RLCL lines, and

- Overcurrent events to other LCL/RLCL lines.

Verification

Nominal case

Requirement 5.2.16.1.1a shall be verified at unit level and/or at system level: points 1, 3, 4, 5 at unit level and points 1, 4 at system level.

Requirement 5.2.16.1.1a point 2 shall be verified by analysis.

Output impedance envelope, when in limitation

Value

Nominal case

The LCL/RLCL/HLCL output impedance in terms of both gain and phase shall be provided per LCL/RLCL/HLCL class, between 100 Hz and 1 MHz.

Tests cases are described in ECSS-E-HB-20-20.

Verification

Nominal case

The LCL/RLCL/HLCL output impedance shall be provided for a voltage across the LCL/RLCL/HLCL equal to (4 ±1) V.

Tests cases are defined in ECSS-E-HB-20-20.

Noise immunity feature

RLCL spurious switch-off

Nominal case

The RLCL state shall automatically be recovered to ON conditions after a spurious switch-off.

The status recovery can be implemented by hardware or software means, at system, subsystem or unit level.

RLCL spurious effects

Nominal case

Spurious disable of RLCL retriggering memory cell and of RLCL ON/OFF status memory cell shall not result in the loss of the relevant load.

Output LCL load (Input load characteristic)

Load inductance

Nominal case

The LCL/RLCL/HLCL shall work nominally for any load inductance from zero to the maximum specified in 5.5.2.1.1a for LCL/RLCL or in 5.5.2.1.1b for HLCL.

Test verification is made with some inductance values (e.g. min/avg/max) and not for all values from 0 to max.

Load capacitance

Nominal case

The LCL/RLCL/HLCL shall work nominally for any load capacitance from zero to the maximum specified in Table 31, Table 32 and Table 33 respectively.

Test verification is made with some capacitance values (e.g. min/avg/max) and not for all values from 0 to max.

Functional/Load interface requirements

Nominal feature

Load behaviour

Nominal case

During nominal operation after switch-on, the load current for LCL/RLCL/HLCL shall always be smaller than the correspondent class current.

Requirement 5.3.1.1.1a shall be valid also in the following conditions:

- the bus voltage transients are applied, and

- the MB voltage ripple is considered, and

- there are load-conducted emissions as per the EMC specification.

Further details can be found in ECSS-E-HB-20-20 section 5.7.3.4.1.

Switch-on

Load behaviour 1

Nominal case

During Switch-on, the load current shall not exceed the LCL/RLCL class current except for charging the relevant input filter.

Load behaviour 2

Nominal case

Converters contained in the load shall start up without the load current to exceed the LCL/RLCL class current.

Input filter charging

Nominal case

If the LCL/RLCL current limit is reached, the load input filter shall be completely charged within the relevant LCL/RLCL maximum charge time defined in requirement 5.4.2.3.1a.

LCL switch dissipative failure

Steady state condition, load

Fault case

In case the LCL/RLCL switch fails in a dissipative failure mode, the load shall perform one of the following actions:

- work nominally,

- enter autonomously a safe operating condition, or

- survive the condition without abnormal conducted or radiated emissions.

The issue in an LCL/RLCL switch failing in dissipative mode is the additional power line voltage drop.

Load test condition

Load test condition

Nominal case

A representative LCL/RLCL interface should be used during the standalone tests of any load connected to it.

The specific LCL/RLCL load compatibility tests are defined on a case-by-case basis.

User UVP at bus input side

User UVP at bus input side

Nominal case

In case an UVP at load side is present, the repetitive overload pattern that can result from the interaction with the LCL/RLCL shall be studied as part of the FMECA.

Performance/Source interface requirements

Overall requirements

Current overshoot

Nominal case

The input or output current overshoot when an overload is applied to the LCL/RLCL/HLCL shall be lower than 50 A, when evaluated in the conditions specified in req. 5.4.1.1.1b.

Refer to Figure 31 and/or Figure 32.

The worst case overload condition applied for the verification shall be a sudden short-circuit applied at the LCL Distribution Unit connector interface.

The time to current overshoot for LCL/RLCL/HLCL shall be 5 µs maximum, when evaluated in the conditions specified in req. 5.4.1.1.1b.

Refer to Figure 31 and/or Figure 32.

The current overshoot recovery time for LCL/RLCL/HLCL shall be 300 µs maximum, when evaluated in the conditions specified in req. 5.4.1.1.1b.

Refer to Figure 31 and/or Figure 32.

The maximum LCL/RLCL input overshoot charge due to any overload shall be limited to 1 mC maximum.

Refer to Figure 31 and/or Figure 32.

The maximum input overshoot charge due to an overload, as per 5.4.1.1.1e., shall be complied for any load inductance value from zero to the maximum specified in 5.5.2.1.1a for LCL/RLCL, or in 5.5.2.1.1b for HLCL.

Test verification is made with some inductance values (e.g. min/avg/max) and not for all values from 0 to max.

Reverse current tolerance

Nominal case

In case the reverse current functional requirement 5.2.11.1.1a is applied, the reverse current peak tolerance shall be equal to the LCL class current, with linear decay of 10 minutes maximum.

Linear decay time is indicative, the thermal situation for the LCL is close to the steady state during this transient.

Leakage current

Nominal case

Maximum leakage current for LCL/RLCL/HLCL shall be 100 µA.

The voltage appearing at the LCL/RLCL/HLCL output in OFF state shall be lower than 1V.

Time interval between successive ON commands

Nominal case

The minimum time between two successive external LCL/HLCL ON commands shall be 1 s.

Start-up/Switch-off requirements

Start-up current rate

Nominal case

Maximum LCL/RLCL/HLCL start-up current rate dI/dt shall be 1A/µs.

Switch-off current rate

Nominal case

Maximum LCL/RLCL/HLCL switch-off current rate dI/dt shall be 1A/µs.

Load input filter charge time

Nominal case

The load input filter charge time shall be maximum 80 % of LCL/RLCL class minimum trip-off time when:

operating in worst-case conditions;

the minimum LCL/RLCL class limitation current is chosen.

Output, auto start OFF, amplitude

Nominal case

The amplitude of the pulse appearing at LCL/HLCL output during main bus start-up shall not exceed 5 V.

Requirement 5.4.2.4.1a shall be valid for any applicable main bus voltage derivative at start-up and when minimum load is applied.

See clause 4.2 to have an insight into the standard assumptions.

Output, auto start OFF, duration

Nominal case

The duration of the pulse appearing at LCL/HLCL output during main bus start-up shall not exceed 1 ms.

Requirement 5.4.2.5.1a shall be valid for any applicable main bus voltage derivative at start-up and when minimum load is applied.

See clause 4.2 to have an insight into the standard assumptions.

UVP

Switch-off threshold, regulated bus

Nominal case

The LCL/RLCL/HLCL switch-off threshold shall be configurable on ground from 80 % of the nominal bus voltage value.

Switch-off threshold, unregulated bus

Nominal case

The LCL/RLCL/HLCL switch-off threshold shall be configurable on ground from 50 % of the nominal DC maximum bus voltage value.

UVP noise immunity

Nominal case

For LCL/RLCL/HLCL, the UVP shall not react for an undervoltage event lasting less than 500 µs.

UVP noise immunity, verification

Nominal case

For LCL/RLCL/HLCL, the UVP noise immunity shall be verified by applying a voltage step from nominal bus voltage to 80 % of nominal DC switch-off threshold with a fall time equal or smaller than 1 % of the actual UVP reaction time.

The test point is selected taking into account that the reaction time does not include the delay between the UVP output and the OFF command issuing the LCL output voltage cut-off.

UVP hysteresis

Nominal case

If UVP hysteresis is implemented, the difference between the actual UVP switch-off threshold, and relevant enabled ON threshold, shall be higher than 0,5 V.

Switch-on capability

Enable ON threshold Voltage, regulated bus

Nominal case

The LCL/RLCL/HLCL enable ON threshold shall be configurable up to 95 % of the nominal main bus voltage.

Enable ON threshold Voltage, unregulated bus

Nominal case

The LCL/RLCL/HLCL enable ON threshold shall be configurable up to 90 % of the nominal DC maximum bus voltage value.

Switch-on response time, value

Nominal case

The RLCL shall not switch ON when relevant threshold is reached for less than 500 µs.

Switch-on response time, verification

Nominal case

The RLCL Switch-on response time shall be verified by the application of a voltage step from 80 % of nominal DC switch-off threshold to nominal bus voltage with a rise time equal or smaller than 1 % of the actual Switch-on response time.

The test point is selected taking into account that the reaction time does not include the delay between the switch-on circuitry signal output and the actual RLCL output voltage increase.

Voltage drop

Voltage drop

Nominal case

The voltage drop of LCL/RLCL line shall not exceed 1 % of the nominal main bus voltage at the relevant class current.

The voltage drop of an HLCL/LCL with an additional switch shall not exceed 2 % of the nominal main bus voltage at the relevant class current.

The LCL/RLCL/HLCL voltage drop shall be measured from central regulation point to the output connector.

Stability

Frequency domain, phase margin

Nominal case

Minimum phase margin for LCL/RLCL/HLCL shall be 50°, under the following conditions:

- a zero Ohm impedance load is applied, and

- the DC voltage across the LCL/RLCL/HLCL equals (4 ±1) V.

The zero Ohm impedance is implemented by a voltage source with current sink capability.

Frequency domain, gain margin

Nominal case

Minimum gain margin for LCL/RLCL/HLCL shall be 10 dB under the following conditions:

- a zero Ohm impedance load is applied, and

- the DC voltage across the LCL/RLCL/HLCL equals (4 ±1) V.

The zero Ohm impedance is implemented by a voltage source with current sink capability.

Time domain, transient from non-limiting mode to current limitation mode

Nominal case

For any specified inductive load, no persistent voltage or current oscillation shall occur when the LCL/RLCL/HLCL is applied a sudden overload.

Requirements on inductive load are detailed in 5.2.19.1.1a , 5.5.2.1.1a and 5.5.2.1.1b.

The period of observed oscillation as per requirement 5.4.6.3.1a shall be greater or equal to the envelope decay time.

Test verification for 5.4.6.3.1a and 5.4.6.3.1b is done on the basis of the analysis, which is used to identify the worst case inductance to be applied.

Time domain, start-up transient to current limitation mode

Nominal case

For any specified inductive or capacitive load, no persistent voltage or current oscillation shall occur when the LCL/RLCL/HLCL is starting up in current limitation.

Requirements on inductive and capacitive loads are detailed in 5.2.19.1.1a, 5.5.2.1.1a, 5.5.2.1.1b, 5.2.19.2.1a and 5.5.2.2.1a.

The period of observed oscillation as per requirement 5.4.6.4.1a shall be greater or equal to the envelope decay time.

Test verification for 5.4.6.4.1a and 5.4.6.4.1b is done on the basis of the analysis, which is used to identify the worst case capacitance and inductance to be applied

Current Telemetry, accuracy

Current Telemetry, accuracy

Nominal case

For LCL/RLCL/HLCL, the accuracy of the current telemetry shall be equal or better than ±4 % of the full scale value in worst case.

Current Telemetry, offset

Current Telemetry, offset

Nominal case

If functional requirement 5.2.8.6.1a is not met, for LCL/RLCL/HLCL the offset of the current telemetry shall be equal or better than ±4 % of the full scale value in worst case.

Retrigger interval

Retrigger interval

Nominal case

For RLCL, the minimum retrigger interval shall be 20 s unless a specific RLCL memory cell for latched trip-off status is provided.

dI/dt limit on retrigger ON edge

dI/dt limit on retrigger ON edge

Nominal case

For RLCL, the maximum value of dI/dt rate on retrigger ON edge shall be 1 A/µs.

dI/dt limit on retrigger OFF edge

dI/dt limit on retrigger OFF edge

Nominal case

For RLCL, the maximum value of dI/dt rate on retrigger OFF edge shall be 1 A/µs.

Status, accuracy

Nominal condition

The LCL/RLCL/HLCL ON/OFF status shall confirm that the LCL/RLCL/HLCL output voltage is within its nominal range with an accuracy of ±10 %.

Performance/Load interface requirements

Load reverse current

Avoidance

Nominal case

For LCL/RLCL, a load should not reinject current into the bus.

Reinjection current

Nominal case

In case requirement 5.2.11.1.1a is complied, the maximum current reinjected to the LCL shall be equal to the LCL class current, with linear decay of 10 minutes maximum.

Linear decay time is indicative, the thermal situation for the LCL is close to the steady state during this transient.

Load characteristic

Maximum inductance

Nominal case

The maximum inductance, including the harness between LCL/RLCL and load, and including the input load filter, shall be 300 µH.

The maximum inductance, including the harness between HLCL and load, and including the input load filter, shall be 50 µH.

Maximum capacitance

Nominal case

The maximum capacitance for LCL and RLCL shall be compatible with the one shown in Table 31 and Table 32 respectively.

The maximum capacitance for HLCL shall be compatible with the one shown in Table 33.

Load impedance envelope

Nominal case

For LCL/RLCL, the supplier shall provide to the customer the load impedance envelope, expressed in terms of magnitude and phase, for a frequency range from 100 Hz to 1 MHz.

Source-load characteristic

Source-load impedance phase margin

Nominal case

For LCL/RLCL, at those frequencies in which the load and the source impedance are equal in magnitude, the difference between the load impedance phase and the source impedance phase shall be greater than abs(±150°±n*360°).

n is a positive integer including 0,

abs is the absolute value operator.

Source-load impedance gain margin

Nominal case

For LCL/RLCL, at those frequencies in which the difference between the load impedance phase and the source impedance phase is equal to -180°±n*360°, the difference between the load impedance gain and the LCL impedance gain shall be greater than 5 dB.

n is a positive integer including 0.

Start-up surge input current

Start-up surge input current

Fault case

In case of an LCL/RLCL failure causing a sudden application of nominal voltage to the load, the relevant peak current shall be lower than 20 A or 5 times the class current, whichever is greater.

The peak current shall be compatible with the electrical and thermal stress of:

- the LCL/RLCL,

- the load input filter components, and

- the relevant main bus disturbance.

Internal load Input current limitation

Internal load Input current limitation

Nominal case

If an internal current limitation is used in the load, the relevant overall current limit shall be at maximum equal to the class current of the relevant LCL/RLCL.

ANNEX(informative)Requirements mapping

Table A-1 to Table A-4 provide a compact view of the requirements of the present standard, including the verification method suggested for each of them. According to ECSS-E-ST-10-02, the verification is accomplished by one or more of the following verification methods:

Test (T),

Analysis (A),

Review-of-design (RoD), and

Inspection (I).

In addition to the methods of verification specified in ECSS-E-ST-10-02, the present annex includes the test verification at design qualification level (T*).

The test verification at design qualification level (T*) is intended to be performed on an electrical representative version of the hardware, on a set up not necessarily equal to the final flight one, to be established for the LCL distribution product line by the relevant manufacturer.

If not stated otherwise, any reference to the handbook inside the tables, is a reference to ECSS-E-HB-20-20.

Level 3 heading in this standard (for example, 5.2.14 “LCL Switch dissipative failure”) is reported as “feature” in Table A-1 to Table A-4.

Level 4 heading in this standard (for example, 5.2.14.1 “Steady state condition”) is reported as “sub-feature” in Table A-1 to Table A-4.

The suggested applicability level indicated in Table A-1 to Table A-4 (SSE/SSS/Equipment) is intended in and/or-option (SSE and/or SSS and/or Equipment).

Table: Functional/Source requirements list

|

Reference

|

Text of the requirement

|

Feature

|

Sub-feature

|

Conditions

|

Applicability

|

Applicability level

|

Verification

|

|

5.2.1.1.1a

|

The LCL class shall be selected among one shown in Table 31 and comply with related class performance.

|

LCL/HLCL class

|

LCL/HLCL class

|

Nominal

|

LCL

|

SSE/SSS

|

RoD

|

|

5.2.1.1.1b

|

The HLCL class shall be selected among one shown in Table 33 and comply with related class performance.

|

LCL/HLCL class

|

LCL/HLCL class

|

Nominal

|

HLCL

|

SSE/SSS

|

RoD

|

|

5.2.2.1.1a

|

The RLCL class shall be selected among one shown in Table 32 and comply with related class performance.

|

RLCL class

|

RLCL class

|

Nominal

|

RLCL

|

SSE/SSS

|

RoD

|

|

5.2.3.1.1a

|

The LCL/RLCL/HLCL shall limit the output current between the minimum and maximum limitation values.

|

Current limitation section

|

Range

|

Nominal

|

LCL/RLCL/HLCL

|

SSE/SSS/Equipment

|

RoD, A, T

|

|

5.2.3.2.1a

|

For LCL/RLCL/HLCL, the switch element shall be on the hot main bus side.

|

Switch element, position

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

RoD

| |

|

5.2.3.3.1a

|

For LCL/RLCL/HLCL, the current sensor element shall be on the hot main bus side.

|

Current sensing element, position

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

RoD

| |

|

5.2.3.4.1a

|

In current limitation mode, the LCL/HLCL components application shall respect the relevant rating limits.

|

Current limitation, LCL rating

|

Nominal

|

LCL/HLCL

|

Equipment

|

A

| |

|

5.2.3.5.1a

|

In current limitation mode, the RLCL components application shall respect the relevant derating limits.

|

Current limitation, RLCL derating

|

Nominal

|

RLCL

|

Equipment

|

A

| |

|

5.2.4.1.1a

|

In case the load current exceeds the relevant limit, the LCL/RLCL/HLCL shall switch-off within its trip-off time min to max range defined in Table 31, Table 32 and Table 33

|

Trip –off section

|

Range

|

Nominal

|

LCL/RLCL/HLCL

|

SSE/SSS/Equipment

|

RoD, A, T

|

|

5.2.5.1.1a

|

The LCL/RLCL/HLCL shall be provided with an input UVP.

|

UVP section

|

Provision

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

RoD

|

|

5.2.5.2.1a

|

For RLCL, UVP shall be provided with hysteresis.

|

Unregulated bus case

|

Nominal

|

RLCL

|

Equipment

|

RoD

| |

|

5.2.5.2.1b

|

For LCL/HLCL, UVP should be provided with hysteresis.

|

Unregulated bus case

|

Nominal

|

LCL/HLCL

|

Equipment

|

RoD

| |

|

5.2.5.3.1a

|

In case of centralised protection for several LCLs/RLCLs/HLCLs, UVP shall be implemented as Single Point Failure Free.

|

Centralised protection

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

RoD, A

| |

|

5.2.6.1.1a

|

The LCL/HLCL shall be ON/OFF commandable.

|

Telecommand section features

|

Commandability

|

Nominal

|

LCL/HLCL

|

SSE/SSS/Equipment

|

RoD

|

|

5.2.6.2.1a

|

It shall be possible to enable or disable the retriggering function of the RLCL.

|

Retrigger function

|

Nominal

|

RLCL

|

SSE/SSS/Equipment

|

RoD, T

| |

|

5.2.6.3.1a

|

The retrigger function of an RLCL shall be enabled by default.

|

Retrigger ENABLE

|

Nominal

|

RLCL

|

SSE/SSS/Equipment

|

RoD, T

| |

|

5.2.6.4.1a

|

The disable command to a retrigger function of an RLCL feeding an essential load shall only be provided by ground.

|

Retrigger DISABLE

|

Nominal

|

RLCL

|

SSE/SSS

|

RoD, T

| |

|

5.2.7.1.1a

|

An RLCL shall always start in ON condition.

|

Conditions at start-up / switch-off

|

Auto ON

|

Nominal

|

RLCL

|

SSE/SSS/Equipment

|

RoD, T

|

|

5.2.7.2.1a

|

An LCL/HLCL should always start in OFF conditions.

|

Auto OFF

|

Nominal

|

LCL/HLCL

|

SSE/SSS/Equipment

|

RoD, T

| |

|

5.2.7.3.1a

|

After a failure, no propagation outside the failed LCL/RLCL/HLCL shall occur. For this purpose in this case, LCL/RLCL/HLCL components blocking failure propagation shall meet their applicable derating.

|

LCL start-up with an internal failure

|

Fault

|

LCL/RLCL/HLCL

|

Equipment

|

A

| |

|

5.2.7.4.1a

|

The actual LCL/RLCL/HLCL status shall not deviate from the programmed/intended one during MB start-up or recovery from zero volt.

|

LCL status at start-up

|

Nominal

|

LCL/RLCL/HLCL

|

SSE/SSS/Equipment

|

A,T

| |

|

5.2.7.5.1a

|

The LCL/RLCL/HLCL shall start up correctly, and within applicable rating/derating limits, when an overload or short circuit is already present at its output.

|

Start-up on short circuit 1

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

A,T

| |

|

5.2.7.6.1a

|

Requirement 5.2.7.5.1a shall apply both in case of the LCL/HLCL being commanded ON by telecommand and when the bus voltage rises for the RLCL.

|

Start-up on short circuit 2

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

A,T

| |

|

5.2.7.7.1a

|

The LCL/RLCL/HLCL shall contain a provision to free wheel the current circulating in the load or harness inductance, when the LCL/RLCL is either commanded OFF or when it opens the line after an overload

|

Switch-off

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

RoD

| |

|

5.2.8.1.1a

|

The LCL/HLCL/RLCL ON/OFF status shall confirm that the LCL/RLCL/HLCL output voltage is within its nominal range.

|

Telemetry Section

|

LCL status

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

T

|

|

5.2.8.2.1a

|

An LCL/RLCL/HLCL shall provide current telemetry.

|

Current telemetry

|

Nominal

|

LCL/RLCL/HLCL

|

SSE/SSS/Equipment

|

RoD

| |

|

5.2.8.3.1a

|

Full scale of current TM shall be at least equal to the maximum LCL/RLCL/HLCL limitation current.

|

Current telemetry, full scale reading

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

RoD

| |

|

5.2.8.4.1a

|

For LCL/RLCL/HLCL, the current TM shall be linear and have an absolute accuracy referred to the class current and applicable on the full range of the TM.

|

Current telemetry, linearity and accuracy

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

A,T

| |

|

5.2.8.5.1a

|

For LCL/RLCL/HLCL, the current TM offset shall be referred to the class current.

|

Current telemetry, offset

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

A,T

| |

|

5.2.8.6.1a

|

For LCL/RLCL/HLCL, the current TM should be able to read down to zero current within the specified accuracy.

|

Current telemetry, reading at zero current

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

A,T

| |

|

5.2.8.7.1a

|

For LCL/RLCL/HLCL, if requirement 5.2.8.6.1a is met, then the accuracy shall be verified at 0%, 50% and 100% of the class current, else the accuracy shall be verified at 0%, 10%, 50% and 100% of the class current.

|

Current telemetry, verification

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

A, T

| |

|

5.2.9.1.1a

|

The capability of reading the correct LCL/RLCL/HLCL status shall not be impacted by any failure in the command interface of the LCL/RLCL/HLCL itself.

|

Status section

|

LCL status under failed conditions

|

Fault

|

LCL/RLCL/HLCL

|

Equipment

|

A

|

|

5.2.10.1.1a

|

The LCL shall correctly operate the application of repetitive overload conditions within the applicable rating/derating limits.

|

Repetitive overload

|

LCL case

|

Nominal

|

LCL

|

Equipment

|

A,T*

|

|

5.2.10.2.1a

|

The RLCL shall correctly operate the application of repetitive overload conditions within the applicable derating limits.

|

RLCL case

|

Nominal

|

RLCL

|

Equipment

|

A,T*

| |

|

5.2.11.1.1a

|

The LCL design should be capable to withstand the application of reverse current by the load, both in ON and in OFF conditions.

|

Reverse Current Tolerance

|

Reverse Current Tolerance

|

Nominal

|

LCL

|

Equipment

|

RoD

|

|

5.2.12.1.1a

|

It should be possible to put LCLs/HLCLs in parallel.

|

Parallel connection

|

LCLs in parallel

|

Nominal

|

LCL/HLCL

|

Equipment

|

RoD

|

|

5.2.12.2.1a

|

When two or more LCLs/RLCLs/HLCLs are put in parallel, the current sharing accuracy shall be correctly assessed to avoid unwanted tripping-off of the LCLs themselves.

|

LCLs in parallel and current sharing

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

A,T

| |

|

5.2.12.3.1a

|

When two or more LCLs/RLCLs/HLCLs are put in parallel, the overall trip-off time shall be correctly assessed to avoid unwanted tripping-off of the LCLs/RLCLs/HLCLs themselves.

|

LCLs in parallel and trip-off

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

A,T

| |

|

5.2.12.4.1a

|

When two or more LCLs/HLCLs are put in parallel, the ON/OFF command shall be made common to all of them.

|

LCLs in parallel and ON/OFF command

|

Nominal

|

LCL/HLCL

|

Equipment

|

A,T

| |

|

5.2.12.5.1a

|

When two or more LCLs/RLCLs/HLCLs are put in parallel, the current telemetry shall provide the overall current flowing through them.

|

LCLs in parallel and current telemetry

|

Nominal

|

LCL / RLCL/HLCL

|

Equipment

|

A,T

| |

|

5.2.13.1.1a

|

For LCL/HLCL, if no additional switching capability is provided as per 5.2.13.3.1a, the power budget shall cover the LCL/HLCL switch failure by considering the actual MB maximum load, plus eventually the unwanted load connected to the failed LCL/HLCL, in the following cases:

|

Switching options

|

No additional switching capability

|

Fault

|

LCL/HLCL

|

SSE/SSS

|

RoD

|

|

5.2.13.2.1a

|

For LCL/HLCL, the load power consumption considered as negligible in terms of power budget shall be specified by the system integrator.

|

No additional switching capability, negligible load power consumption mode

|

Nominal

|

LCL/HLCL

|

SSE/SSS

|

RoD, A

| |

|

5.2.13.3.1a

|

For LCL/HLCL, in case that there is an additional switch that can be commanded open in any case when the LCL/HLCL switch is in ON state or fails ON or in short circuit, requirements 5.2.13.4.1a and 5.2.13.5.1a should be fulfilled.

|

Additional switching capability

|

Nominal/ Fault

|

LCL/HLCL

|

SSE/SSS/Equipment

|

RoD

| |

|

5.2.13.3.1b

|

It shall be possible to command the LCL/HLCL and the relevant additional switch in series by a different, individual command, or a different commanding path.

|

Additional switching capability

|

Nominal/ Fault

|

LCL/HLCL

|

SSE/SSS/Equipment

|

RoD

| |

|

5.2.13.4.1a

|

For LCL, the additional switch should be put on power system LCL side.

|

Additional switching capability, location of additional switch

|

Nominal/ Fault

|

LCL

|

Equipment

|

RoD

| |

|

5.2.13.5.1a

|

For LCL, the UVP should act both on the LCL switch and on the additional switch provided by an independent memory cell.

|

Additional switching capability, UVP acting on additional switch

|

Nominal/ Fault

|

LCL

|

Equipment

|

RoD

| |

|

5.2.14.1.1a

|

In case the LCL/RLCL/HLCL switch fails in a dissipative failure and in case no other protection removes the failure, all the surrounding components shall be within derating.

|

LCL Switch Dissipative failure

|

Steady state condition

|

Fault

|

LCL/RLCL/HLCL

|

Equipment

|

A

|

|

5.2.14.2.1a

|

In case the LCL/RLCL/HLCL switch fails in a dissipative failure and in case the "on board system" removes the failure by reducing the load or commanding OFF an additional switch, all the surrounding components shall be within rating during the on board system reaction time.

|

Transient condition

|

Fault

|

LCL/RLCL/HLCL

|

Equipment

|

A

| |

|

5.2.14.3.1a

|

In case the LCL/RLCL/HLCL switch fails in a dissipative failure and in case requirements 5.2.14.1.1a and 5.2.14.2.1a cannot be fulfilled, a protection shall be embedded in the LCL or in the Distribution Unit to avoid a failure propagation due to the abnormal heat dissipation.

|

Local protection

|

Fault

|

LCL/RLCL/HLCL

|

Equipment

|

A,T*

| |

|

5.2.15.1.1a

|

In case of a single failure, no more than one LCL/RLCL/HLCL line shall be lost.

|

Loss of LCL lines

|

Loss of LCL lines

|

Fault

|

LCL/RLCL/HLCL

|

Equipment

|

RoD, A

|

|

5.2.16.1.1a

|

The LCL/RLCL/HLCL state shall not change from the commanded one due to spurious perturbations, including:

|

Noise immunity

|

General

|

Nominal

|

LCL/RLCL/HLCL

|

SSE/SSS/Equipment

|

see 5.2.16.2.1a and 5.2.16.2.1b

|

|

5.2.16.2.1a

|

Requirement 5.2.16.1.1a shall be verified at unit level and/or at system level: points 1, 3, 4, 5 at unit level and points 1, 4 at system level.

|

Verification

|

Nominal

|

LCL/RLCL/HLCL

|

SSE/SSS/Equipment

|

T

| |

|

5.2.16.2.1b

|

Requirement 5.2.16.1.1a point 2 shall be verified by analysis.

|

Verification

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

A

| |

|

5.2.17.1.1a

|

The LCL/RLCL/HLCL output impedance in terms of both gain and phase shall be provided per LCL/RLCL/HLCL class, between 100 Hz and 1 MHz.

|

Output impedance envelope (when in limitation)

|

Value

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

T*

|

|

5.2.17.2.1a

|

The LCL/RLCL/HLCL output impedance shall be provided for a voltage across the LCL/RLCL/HLCL equal to (4 ±1) V.

|

Verification

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

T*

| |

|

5.2.18.1.1a

|

The RLCL state shall automatically be recovered to ON conditions after a spurious switch-off.

|

Noise immunity

|

RLCL spurious switch-off

|

Nominal

|

RLCL

|

Equipment

|

RoD, A, T*

|

|

5.2.18.2.1a

|

Spurious disable of RLCL retriggering memory cell and of RLCL ON/OFF status memory cell shall not result in the loss of the relevant load.

|

RLCL spurious effects

|

Nominal

|

RLCL

|

Equipment

|

RoD, A, T*

| |

|

5.2.19.1.1a

|

The LCL/RLCL/HLCL shall work nominally for any load inductance from zero to the maximum specified in 5.5.2.1.1a for LCL/RLCL or in 5.5.2.1.1b for HLCL

|

Output LCL Load (Input load characteristic)

|

Load inductance

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

A,T*

|

|

5.2.19.2.1a

|

The LCL/RLCL/HLCL shall work nominally for any load capacitance from zero to the maximum specified in Table 31, Table 32 and Table 33 respectively.

|

Load capacitance

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

A

|

Table: Functional/Load requirements list

|

Reference

|

Text of the requirement

|

Feature

|

Sub-feature

|

Conditions

|

Applicability

|

Applicability level

|

Verification

|

|

5.3.1.1.1a

|

During nominal operation after switch-on, the load current for LCL/RLCL/HLCL shall always be smaller than the correspondent class current.

|

Nominal

|

Load behaviour

|

Nominal

|

LCL/RLCL/HLCL

|

SSE/SSS/Equipment

|

A,T

|

|

5.3.1.1.1b

|

Requirement 5.3.1.1.1a shall be valid also in the following conditions:

| ||||||

|

5.3.2.1.1a

|

During Switch-on, the load current shall not exceed the LCL/RLCL class current except for charging the relevant input filter.

|

Switch-on

|

Load behaviour 1

|

Nominal

|

LCL/RLCL

|

SSE/SSS/Equipment

|

A,T

|

|

5.3.2.2.1a

|

Converters contained in the load shall start up without the load current to exceed the LCL/RLCL class current.

|

Load behaviour 2

|

Nominal

|

LCL/RLCL

|

SSE/SSS/Equipment

|

A,T

| |

|

5.3.2.3.1a

|

If the LCL/RLCL current limit is reached, the load input filter shall be completely charged within the relevant LCL/RLCL maximum charge time defined in requirement 5.4.2.3.1a.

|

Input filter charging

|

Nominal

|

LCL/RLCL

|

SSE/SSS/Equipment

|

A,T

| |

|

5.3.3.1.1a

|

In case the LCL/RLCL switch fails in a dissipative failure mode, the load shall perform one of the following actions:

|

LCL switch dissipativefailure

|

Steady state condition, load

|

Fault

|

LCL/RLCL

|

Equipment

|

A,T

|

|

5.3.4.1.1a

|

A representative LCL/RLCL interface should be used during the standalone tests of any load connected to it.

|

Load test condition

|

Load test condition

|

Nominal

|

LCL/RLCL

|

Equipment

|

T

|

|

5.3.5.1.1a

|

In case an UVP at load side is present, the repetitive overload pattern that can result from the interaction with the LCL/RLCL shall be studied as part of the FMECA.

|

User UVP at bus input side

|

User UVP at bus input side

|

Nominal

|

LCL/RLCL

|

SSE/SSS/Equipment

|

A

|

Table: Performance/Source requirement list

|

Reference

|

Text of the requirement

|

Feature

|

Sub-feature

|

Conditions

|

Applicability

|

Applicability level

|

Verification

|

|

5.4.1.1.1a

|

The input or output current overshoot when an overload is applied to the LCL/RLCL/HLCL shall be lower than 50 A, when evaluated in the conditions specified in req. 5.4.1.1.1b.

|

Overall requirements

|

Current overshoot when an overload is applied to the LCL.

|

Nominal

|

LCL/RLCL/HLCL

|

Equipment

|

A,T*

|

|

5.4.1.1.1b

|

The worst case overload condition applied for the verification shall be a sudden short-circuit applied at the LCL Distribution Unit connector interface.

| ||||||

|