Space product assurance

Material selection for controlling stress-corrosion cracking

Foreword

This Standard is one of the series of ECSS Standards intended to be applied together for the management, engineering and product assurance in space projects and applications. ECSS is a cooperative effort of the European Space Agency, national space agencies and European industry associations for the purpose of developing and maintaining common standards. Requirements in this Standard are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards.

This Standard has been prepared by the ECSS Executive Secretariat, endorsed by the Document and Discipline Focal points, and approved by the ECSS Technical Authority.

Disclaimer

ECSS does not provide any warranty whatsoever, whether expressed, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item are error-free. In no respect shall ECSS incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this Standard, whether or not based upon warranty, business agreement, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by ECSS.

Published by: ESA Requirements and Standards Division

ESTEC, ,

2200 AG Noordwijk

The

Copyright: 2009 © by the European Space Agency for the members of ECSS

Change log

|

ECSS-Q-70-36A

|

First issue

|

|

ECSS-Q-70-36B

|

Never issued

|

|

ECSS-Q-ST-70-36C

|

Second issue

|

Scope

This Standard covers the following processes of the general materials, mechanicals parts and processes (MMPP) flow of ECSS-Q-ST-70:

The selection of metal alloys for which preference is given to approved data sources (Table 51 to Table 53)

The criticality analysis to determine if a stress corrosion cracking (SCC) evaluation is necessary

This Standard sets forth the criteria to be used in the selection of materials for spacecraft and associated equipment and facilities so that failure resulting from stress-corrosion is prevented.

It is intended to provide general criteria to be used in stress-corrosion cracking control, which begins during design thanks to a methodological material selection.

This document does not intend to include all factors and criteria necessary for the total control of stresscorrosion cracking in all alloys.

The criteria established in this Standard are only applicable to designs for service involving exposure conditions similar to testing conditions

As regards weldments, this Standard is applicable to aluminium alloys, selected stainless steels in the 300 series and alloys listed in Table 51.

This Standard is not applicable to listed materials whose behaviour differs at elevated temperature and in specific chemical.

This standard may be tailored for the specific characteristic and constrains of a space project in conformance with ECSS-S-ST-00.

Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this ECSS Standard. For dated references, subsequent amendments to, or revision of any of these publications do not apply, However, parties to agreements based on this ECSS Standard are encouraged to investigate the possibility of applying the more recent editions of the normative documents indicated below. For undated references, the latest edition of the publication referred to applies.

|

ECSS-S-ST-00-01

|

ECSS system - Glossary of terms

|

|

ECSS-Q-ST-70

|

Space product assurance - Materials, mechanical parts and processes.

|

|

ECSS-Q-ST-70-37

|

Space product assurance - Determination of the susceptibility of metals to stress-corrosion cracking.

|

|

NASA-MSFC-SPEC 522B (July 1987)

|

Design criteria for controlling stress-corrosion cracking

|

Terms, definitions and abbreviated terms

Terms from other standards

For the purpose of this Standard, the terms and definitions from ECSS-ST-00-01 and ECSS-Q-ST-70 apply.

Terms specific to the present standard

stress-corrosion

combined action of sustained tensile stress and corrosion that can lead to the premature failure of materials

Abbreviated terms

For the purpose of this Standard, the abbreviated terms from ECSSSST-0001 and the following apply:

|

Abbreviation

|

Meaning

|

|

SCC

|

stress-corrosion cracking

|

|

SCEF

|

stress-corrosion evaluation form

|

Principles

Stress corrosion

Certain materials are more susceptible to stress corrosion cracking (SCC) than others. If a susceptible material is placed in service in a corrosive environment under tension of sufficient magnitude, and the duration of service is sufficient to permit the initiation and growth of cracks, failure occurs at a stress lower than that which the material is normally be expected to withstand. The corrosive environment need not be severe in terms of general corrosive attack.

Service failures due to stress-corrosion are frequently encountered in cases where the surfaces of the failed parts are not visibly corroded in a general sense.

Moreover, stresses are additive and threshold stresses for susceptibility are often low. There have been a number of stresscorrosion failures for which design stresses were intermittent and of short duration, and only of minor significance in contributing to failure. Stresscorrosion cracking in those cases occurred because of a combination of residual and assembly stresses not anticipated in design.

Evaluation of metal alloys

Resistance to stress- corrosion cracking of metal alloys depends mainly on factors:

Grain orientation (see Annex D)

Susceptibility to SCC (see Annex E)

Requirements

Stress corrosion cracking resistance evaluation of metal alloys

Overview

Clause 5.1.2 lists the requirements applicable for applications involving and identified as case 1:

unlisted materials (i.e. materials not listed in tables 1, 2 or 3), or

combinations of materials and environments outside the scope of this Standard

Clause 5.1.3 lists the requirements applicable for application involving listed materials with

moderate SCC resistance,

low SCC resistance, or

moderate or low SCC resistance and coated or plated with materials with a high SCC resistance.

and identified as case 2.

The classes for high, moderated and low resistance to SCC are defined in ECSS-Q-ST-70-37.

Requirements for case 1

A request for evaluation shall be established in conformance with the DRD in Annex A.

As a reply to the customer request for SCC evaluation, the supplier shall provide a work proposal (including test specifications and procedures) in conformance with the DRD in Annex B.

An example of approved test specifications and procedures is ECSS-Q-ST-70-37.

The supplier shall perform a detailed evaluation of susceptibility according to test specifications and procedures approved by the customer

This is often the case for many applications involving unfamiliar materials, or unusual combinations of materials and environments.

The results of stress corrosion cracking resistance evaluation shall be reported in conformance with DRD in Annex A of ECSS-Q-ST-70-37.

The SCC test report shall be submitted for customer’s approval before the material under evaluation is used or incorporated in a design.

Requirements for Case 2

The supplier shall provide the SCEF in conformance with the DRD in Annex C.

Materials selection criteria

General

The supplier shall use in preference high SCC resistance alloys listed in Table 51.

Selecting an alloy from this table avoid the need to perform a stress corrosion evaluation

High SCC resistance alloys

Surface treated materials

Alloys which are surface treated shall be evaluated according to 5.1.3a.

- 1 For example:

- Metals having been treated with surface treatments such as nitriding and carburising.

- A lowstrength plain carbon steel, carburised on the surface to a hardness corresponding to a tensile strength above 1 370 MPa (200 ksi).

- 2 Surface treatment such as nitriding and carburising can make a stress-corrosion evaluation necessary for a material not normally considered susceptible.

Moderate SCC resistance alloys

Coated and plated materials

Alloys with moderate SCC resistance and coated or plated with materials with a high SCC resistance shall be evaluated according to 5.1.3a.

- 1 For example: Even though 2024-T6 aluminium is anodised, this material has moderate resistance to stress corrosion.

- 2 All electroplated, anodised and chemical-conversion coatings on otherwise acceptable materials are excluded from the requirements of this specification

Thin materials (alloy or temper of metal)

Sheet material less than () thick of the aluminium alloys listed in Table 52 do not require a SCEF according to Annex C.

Alloys used for electrical wiring, thermocouple wires, magnet windings and similar non-structural electrical applications do not require a SCEF according to Annex C.

Others

Alloys and tempers listed in Table 52 shall only be considered for use when a suitable alloy cannot be found in Table 51.

Materials listed in Table 52 shall not be used for applications involving high installation stress.

Examples of application involving high stress are springs or fasteners

Low SCC resistance alloys

Alloys and tempers listed in Table 53 shall only be considered for use in applications where the probability of stress-corrosion is remote.

Coated and plated materials

Alloys with low SCC resistance and coated or plated with materials with a high SCC resistance shall be evaluated according to 5.1.3a.

- 1 For example: Even stainless steel is chrome plated, this material has low resistance to stress corrosion.

- 2 All electroplated, anodised and chemical-conversion coatings on otherwise acceptable materials are excluded from the requirements of this specification

Unlisted materials

The stresscorrosion resistance of alloys and weldments not listed in this document shall be ascertained:

- by means of tests conducted in an environment representative of the proposed application, or

- by means of direct comparison with similar alloys and weldments for which susceptibility is known to be low.

Design and assembly

The directional variation of the alloy shall be considered in the design of the manufactured product.

- 1 The directional variation can be appreciable with respect to SCC.

- 2 This is necessary for the evaluation of the susceptibility to stress corrosion cracking.

The supplier shall include both the residual stress distribution and the grain orientation in designing a part to be machined from wrought aluminium.

During design and assembly, the supplier shall avoid tension which is applied in transverse directions.

For example: Figure D-2 and Figure D-3 in Annex D illustrate undesirable situations.

The supplier shall ensure that stress corrosion threshold stresses are not exceeded by the combination of the following sources of stresses:

- residual and assembly stress;

- stresses resulting from operational, transportation and storage loads;

- assembly stresses result from improper tolerances during fitup, overtorquing, press fits, highinterference fasteners and welding;

See for examples Figure D-2 and Figure D-3.

- residual stresses as a result of machining, forming and heattreating operations.

Customer’s approval

The customer shall approve the SCEF before any of the following alloy, temper or weldment can be used or incorporated in a design:

- coated, plated or surface-treated alloys, and weldments listed in Table 51;

- any alloys, tempers and weldments listed in Table 52;

- any alloys, tempers and weldments listed in Table 53;

- any alloys, tempers and weldments not listed in this Standard.

In special cases where specific data are already available on a material under environmental conditions representative of anticipated exposure, a stress-corrosion evaluation form for use of this material within prescribed limits can be submitted for approval.

Table 51: Alloys with high resistance to stresscorrosion cracking

|

(a) Steel

|

Condition

|

|

Carbon steel (1000 series)

|

Below 1 225 MPa (180 ksi) UTS

|

|

Low alloy steel (4130, 4340, etc.)

|

Below 1 225 MPa (180 ksi) UTS1

|

|

(E) D6AC, H-11

|

Below 1 450 MPa (210 ksi) UTS

|

|

Music wire (ASTM 228)

|

Cold drawn

|

|

HY-80 steel

|

Quenched and tempered

|

|

HY-130 steel

|

Quenched and tempered

|

|

HY-140 steel

|

Quenched and tempered

|

|

1095 spring steel

|

Quenched and tempered

|

|

300 series stainless steel (unsensitized)2

|

All

|

|

400 series Ferritec stainless steel (404, 430, 431, 444, etc.)

|

All

|

|

21-6-9 stainless steel

|

All

|

|

Carpenter 20 Cb stainless steel

|

All

|

|

Carpenter 20 Cb-3 stainless steel

|

All

|

|

A286 stainless steel

|

All

|

|

AM350 stainless steel

|

SCT 10004 and above

|

|

AM355 stainless steel

|

SCT 1000 and above

|

|

Almar 362 stainless steel

|

H10005 and above

|

|

Custom 450 stainless steel

|

H1000 and above

|

|

Custom 455 stainless steel

|

H1000 and above

|

|

15-5 PH stainless steel

|

H1000 and above

|

|

PH 14-8 Mo stainless steel

|

CH900 and SRH950 and above6,7

|

|

PH 15-7 Mo stainless steel

|

CH900

|

|

17-7 PH stainless steel

|

CH900

|

|

Nitronic 333

|

All

|

|

(E) Maraging steel MARVAL X12

|

All

|

|

1. A small number of laboratory failures of specimens cut from plate more than thick have been observed at 75 % yield, even within this ultimate strength range. The use of thick plate should therefore be avoided in a corrosive environment when sustained tensile stress in the short transverse direction is expected.

| |

Table 51: Alloys with high resistance to stresscorrosion cracking (cont.)

|

(b) Nickel Alloy

|

Condition

|

|

Hastelloy C

|

All

|

|

Hastelloy X

|

All

|

|

Incoloy 800

|

All

|

|

Incoloy 901

|

All

|

|

Incoloy 903

|

All

|

|

Inconel 6003

|

Annealed

|

|

Inconel 625

|

Annealed

|

|

Inconel 7183

|

All

|

|

Inconel X-750

|

All

|

|

Monel K-500

|

All

|

|

Ni-Span-C 902

|

All

|

|

René 41

|

All

|

|

Unitemp 212

|

All

|

|

Waspaloy

|

All

|

|

3. Including weldments

| |

Table 51: Alloys with high resistance to stresscorrosion cracking (cont.)

|

(c) Aluminium alloys:

| |||

|

Wrought1,2

|

Cast

| ||

|

Alloy

|

Condition

|

Alloy3

|

Condition

|

|

1000 series

|

All

|

355.0, C355.0

|

T6

|

|

2011

|

T8

|

356.0, A356.0

|

All

|

|

2024, rod bar

|

T8

|

357.0

|

All

|

|

2219

|

T6, T8

|

B358.0 (Tens50)

|

All

|

|

(E) 2419

|

T8

|

359.0

|

All

|

|

(E) 2618

|

T6, T8

|

380.0, A380.0

|

As cast

|

|

3000 series

|

All

|

514.0 (214)

|

As cast5

|

|

5000 series

|

All4,5

|

518.0 (218)

|

As cast5

|

|

6000 series

|

All

|

535.0 (Almag 35)

|

As cast5

|

|

(E) 7020

|

T66

|

A712.0, C712.0

|

As cast

|

|

7049

|

T73

|

|

|

|

7149

|

T73

|

|

|

|

7050

|

T73

|

|

|

|

7075

|

T73

|

|

|

|

7475

|

T73

|

|

|

|

1. Mechanical stress relieved (TX5X or TX5XX) where possible.

| |||

Table 51: Alloys with high resistance to stresscorrosion cracking (cont.)

|

(d) Copper Alloy

| |

|

CDA no. 1

|

Condition (% cold rolled) 2

|

|

110

|

37

|

|

170

|

AT, HT 3,4

|

|

172

|

AT, HT 3,4

|

|

194

|

37

|

|

195

|

90

|

|

230

|

40

|

|

422

|

37

|

|

443

|

10

|

|

510

|

37

|

|

521

|

37

|

|

619

|

40 (9 % B phase)

|

|

619

|

40 (95 % B phase)

|

|

688

|

40

|

|

706

|

50

|

|

725

|

50, annealed

|

|

280, 524, 606, 632, 655, 704, 710

|

0

|

|

715, (E) 917, (E) 937

|

0

|

|

1. Copper Development Association alloy number.

| |

Table 51: Alloys with high resistance to stresscorrosion cracking (cont.)

|

(e) Miscellaneous Alloy (wrought)

|

Condition

|

|

Beryllium, S-200C

|

Annealed

|

|

HS 25 (L605)

|

All

|

|

HS 188

|

All

|

|

MP35N

|

All

|

|

Titanium, 3Al-2.5V

|

All

|

|

Titanium, 6AI-4V

|

All

|

|

Titanium, 13V-11Cr-3AI

|

All

|

|

(E) Titanium OMI 685, IMI 829

|

All

|

|

Magnesium, M1A

|

All

|

|

Magnesium, LA141

|

Stabilised

|

|

Magnesium, LAZ933

|

All

|

|

(E) Cast alloy Magnesium ELEKTRON 21

|

T6

|

|

(E) ESA classification not in NASA MSFC-SPEC-522A.

| |

Table 52: Alloys with moderate resistance to stresscorrosion cracking

|

(a) Steel Alloy

|

Condition

|

|

Carbon steel (1000 series)

|

1 225 to 1 370 MPa

|

|

Lowalloy steel (4130, 4340, etc.)

|

1 225 to 1 370 MPa

|

|

Nitronic 32

|

All

|

|

Nitronic 60

|

All

|

|

403, 410, 416, 431 stainless steel

|

(see footnote 1)

|

|

PH 13-8 Mo stainless steel

|

All

|

|

15-5PH stainless steel

|

Below H1000 2

|

|

17-4PH stainless steel

|

All

|

|

1. Tempering between and should be avoided because corrosion and stress-corrosion resistance is lowered.

| |

Table 52: Alloys with moderate resistance to stresscorrosion cracking (cont.)

|

(b) Miscellaneous Alloy

|

Condition

|

|

Magnesium, AZ31B

|

All

|

|

Magnesium, ZK60A

|

All

|

|

Magnesium (E) ZW3

|

|

|

(E) ESA classification not in NASA MSFC-SPEC-522A.

| |

Table 52: Alloys with moderate resistance to stresscorrosion cracking (cont.)

|

(c) Aluminium alloys1,2

| |||

|

Wrought

|

Cast

| ||

|

Alloy

|

Condition

|

Alloy

|

Condition

|

|

2024 rod, bar, extrusion

|

T6, T62

|

319.0, A319.0

|

As cast

|

|

2024 plate, extrusions

|

T8

|

333.0, A333.0

|

As cast

|

|

2124 plate

|

T8

|

|

|

|

2048 plate

|

T8

|

|

|

|

4032

|

T6

|

|

|

|

5083

|

All 3

|

|

|

|

5086

|

All 3

|

|

|

|

5456

|

All 3

|

|

|

|

7001

|

T75, T76

|

|

|

|

(E) 7010

|

T736

|

|

|

|

7049

|

T76

|

|

|

|

7050

|

T736,T76

|

|

|

|

7075

|

T76

|

|

|

|

7175

|

T736,T76

|

|

|

|

7475

|

T76

|

|

|

|

7178

|

T76

|

|

|

|

(E) Russian Al-Li 1420 and 1421

|

soln. treat + age

|

|

|

|

1. Mechanically stress relieved products (TX5X or TX5XX) should be specified where possible.

| |||

Table 53: Alloys with low resistance to stresscorrosion cracking

|

(a) Steel Alloy

|

Condition

|

|

Carbon steel (1000 series)

|

Above 1 370 MPa

|

|

Lowalloy steel (4130, 4340, etc.)

|

Above 1 370 MPa

|

|

(E) D6AC, H-11 steel

|

Above 1 450 MPa

|

|

stainless steel

|

All

|

|

18 Ni Maraging steel, 200 grade

|

Aged at 900 F

|

|

18 Ni Maraging steel, 250 grade

|

Aged at 900 F

|

|

18 Ni Maraging steel, 300 grade

|

Aged at 900 F

|

|

18 Ni Maraging steel, 350 grade

|

Aged at 900 F

|

|

AM 350 stainless steel

|

Below SCT 1000

|

|

AM 355 stainless steel

|

Below SCT 1000

|

|

Custom 455 stainless steel

|

Below H1000

|

|

PH 15-7 Mo stainless steel

|

All except CH900

|

|

17-7 PH stainless steel

|

All except CH900

|

|

(E) Kovar

|

All

|

|

(E) ESA classification not in NASA MSFC-SPEC-522A.

| |

Table 53: Alloys with low resistance to stresscorrosion cracking (cont.)

|

(b) Aluminium Alloys1,2

| |||

|

Wrought

|

Cast

| ||

|

Alloy

|

Condition

|

Alloy

|

Condition

|

|

2011

|

T3, T4

|

295.0 (195)

|

T6

|

|

2014

|

All

|

B295.0 (B195)

|

T6

|

|

2017

|

All

|

520.0 (220)

|

T4

|

|

2024

|

T3, T4

|

707.0 (607, tern-alloy 7)

|

T6

|

|

2024 Forgings

|

T6, T62, T8

|

D712.0 (D612,40E)

|

As cast

|

|

2024 Plate

|

T62

|

|

|

|

(E) Al-Li 2080

|

T8

|

|

|

|

(E) 2618

|

T3, T4

|

|

|

|

7001

|

T6

|

|

|

|

7005

|

All

|

|

|

|

(E) 7020

|

Weldments

|

|

|

|

7039

|

All

|

|

|

|

7075

|

T6

|

|

|

|

7175

|

T6

|

|

|

|

7079

|

T6

|

|

|

|

7178

|

T6

|

|

|

|

7475

|

T6

|

|

|

|

(E) Al-Li 8090

|

All

|

|

|

|

(E) BS L93

|

T6

|

|

|

|

(E) Russian Al-Li 1441 and 1460

|

All

|

|

|

|

1. Mechanically stressrelieved products (TX5X or TX5XX) should be specified where possible

| |||

Table 53: Alloys with low resistance to stresscorrosion cracking (cont.)

|

(c) Copper alloys

| |

|

CDA no.1

|

Condition (% cold rolled)2

|

|

260

|

50

|

|

353

|

50

|

|

443

|

40

|

|

672

|

50, annealed

|

|

687

|

10, 40

|

|

762

|

A, 25, 50

|

|

766

|

38

|

|

770

|

38, 50, annealed

|

|

782

|

50

|

|

1. Copper Development Association alloy number.

| |

Table 53: Alloys with low resistance to stresscorrosion cracking (cont.)

|

(d) Magnesium Alloy

|

Condition

|

|

AZ61A

|

All

|

|

AZ80A

|

All

|

|

WE54

|

All

|

|

ZCM711

|

All

|

ANNEX(normative)Request for SCC resistance evaluation - DRD

DRD identification

Requirement identification and source document

This DRD is called from ECSS-Q-ST-70-36, requirement 5.1.2a.

Purpose and objective

The purpose of the request for SCC resistance evaluation is to confirm that the materials is to be evaluated with respect to the specific SCC resistance test specification of the project and prior to its validation and approval for selection as item of the DML.

Expected response

Scope and content

The Request for SCC resistance evaluation shall include or refer to the following information:

- objective of the test activity,

- background and justification to the test activity,

- material to be investigated,

- description of test activity, and

- deliverables.

Special remarks

None.

ANNEX(normative)SCC resistance test specifications and procedures (Work Proposal) - DRD

DRD identification

Requirement identification and source document

This DRD is called from ECSS-Q-ST-70-36, requirement 5.1.2b.

Purpose and objective

The work proposal is a document that defines the stress corrosion cracking resistance test specification and procedures proposed by the test house. The work proposal for SCC resistance testing of metals alloys is prepared by the test house, which is responsible for the test activity, and it is submitted to the customer for review and approval

Expected response

Scope and content

The WP shall include a proposed work description giving:

- the objectives of the test activity,

- test procedure and reference to standards,

- materials, number and dimensions of samples,

- test conditions,

For example: environment, properties evaluated and measurement techniques.

- expected test output. The WP shall include a proposed settlement describing the test procedures and any deviation from the conditions initially requested by the customer in the Request for SCC resistance evaluation.

Special remarks

None.

ANNEX(normative)Stress-corrosion evaluation form (SCEF) - DRD

DRD identification

Requirement identification and source document

This DRD is called from ECSS-Q-ST-70-36, requirement 5.1.3a

Purpose and objective

The objective of the stress-corrosion evaluation form (SCEF) is to conduct a detailed evaluation of susceptibility in order to ensure adequate stresscorrosion resistance in applications involving unfamiliar materials, or unusual combinations of materials and environments.

Expected response

Scope and content

Originator

The SCEF shall contain the name, organization and address of the originator.

System / Subsystem

The SCEF shall contain the name of the system/subsytem on which the material is used.

Project

The SCEF shall contain the name of the project on which the material is used.

Declared material list identification

The SCEF shall contain the declared material list identification.

Use and location

The SCEF shall contain the use and location planned for the material.

Number of identical parts

The SCEF shall contain the number of identical parts.

Manufacturer

The SCEF shall contain the name of the manufacturer.

Material

The material shall be identified as specified on figure xxx.

Specific alloy and temper designation of raw material from which the part is fabricated shall be given.

Heat treatment

All thermal treatments which the part receives shall be listed.

Size and form

Approximate dimensions of raw material from which the part is fabricated shall be listed.

The raw material form shall be mentioned.

For example: bar, plate, sheet, extrusion, and forging.

Sustained tensile stresses

An estimate of stresses shall be carried out.

Stresses shall be listed according to their source following:

11.a.: Process

11.b.: Assembly

11.c.: Design

Stresses shall be listed according to the basis on which the estimate has been made.

The direction of the resultant stresses shall be indicated with respect to the grain orientation of the material.

Reference shall be made to all instances when machining or other metalremoval operations expose short transverse grain orientation to stress.

For example: Following machining of forged parts; removal of clad surfaces.

Any special precautions taken to control stresses shall be noted.

Special processing

Any processes used for reducing tensile stresses shall be noted, if relevant.

For example: Shot peening or stressrelief treatments.

Weldments

A stresscorrosion cracking evaluation of all weldments shall be made.

All information relevant for the stresscorrosion cracking evaluation shall be submitted:

- alloy, form and temper of the parent metal;

- filler alloy, if any;

- welding process;

- weld bead removed;

- postweld thermal treatment or stress relief. Environment

The corrosive environment to which the part is exposed during its lifetime shall be evaluated.

The evaluation shall include the following elements:

- exposure during fabrication;

- exposure during assembly;

- exposure during component storage;

- environmental conditions during use. Protective finish

Any corrosion-protective finish applied shall be listed.

Any finish that can affect the basic corrosion resistance of the component shall be listed.

Function of part

The basic function of the part shall be listed.

If more pertinent, the basic function of the assembly shall be listed in replacement of the basic function of the part.

Effect of failure

The possible effects of the failure of the part or assembly on the overall function or mission of the major assembly involved shall be listed.

Evaluation of stresscorrosion susceptibility

The SCEF shall contain the rationale underlying the material selection and a short explanation as to why no stress-corrosion problem is expected.

Remarks

The SCEF shall contain any additional information or explanatory notes not included in the preceding sections.

Relevant laboratory reports can be referenced.

Special remarks

Stress-corrosion evaluation form

|

Originator (Name, Organization, Address):

|

|

Used on system/subsystem:

|

|

Project:

|

|

1. Declared material list identification

|

|

2. Use and location

|

|

3. Number of identical parts

|

|

4. Manufacturer

|

|

5. Material

|

|

6. Heat treatment

|

|

7. Size and form

|

|

8. Sustained tensile stresses - magnitude and direction:

|

|

a. Process residual

|

|

b. Assembly

|

|

c. Design, static

|

|

9. Special processing

|

|

10. Weldments:

|

|

a. Alloy form, temper of parent metal

|

|

b. Filler alloy (if none, indicate)

|

|

c. Welding process

|

|

d. Weld bead removed: Yes ( ) No ( )

|

|

e. Post–weld thermal treatment

|

|

f. Post–weld stress relief

|

|

11. Environment

|

|

12. Protective finish

|

|

13. Function of part

|

|

14. Effect of failure

|

|

15. Evaluation of stress–corrosion susceptibility

|

|

16. Remarks

|

Figure: Example of a Stress-corrosion evaluation form

Annexes

Annexes may be supplied with the stress-corrosion evaluation form.

For example: Construction drawings for intended use or laboratory stresscorrosion test report, as per clause xx.xx of Standard_Reference.

ANNEX(informative)Grain orientation

Introduction

Rolling, extrusion and forging are the most common processing operations employed in the production of standard forms of wrought metal. All of these produce a flow of metal in a predominant direction so that when viewed microscopically, is the metal neither isotropic nor homogeneous. As a result, the properties of the metal vary according to the direction in which they are measured. The extent of directional variation depends on the property of interest.

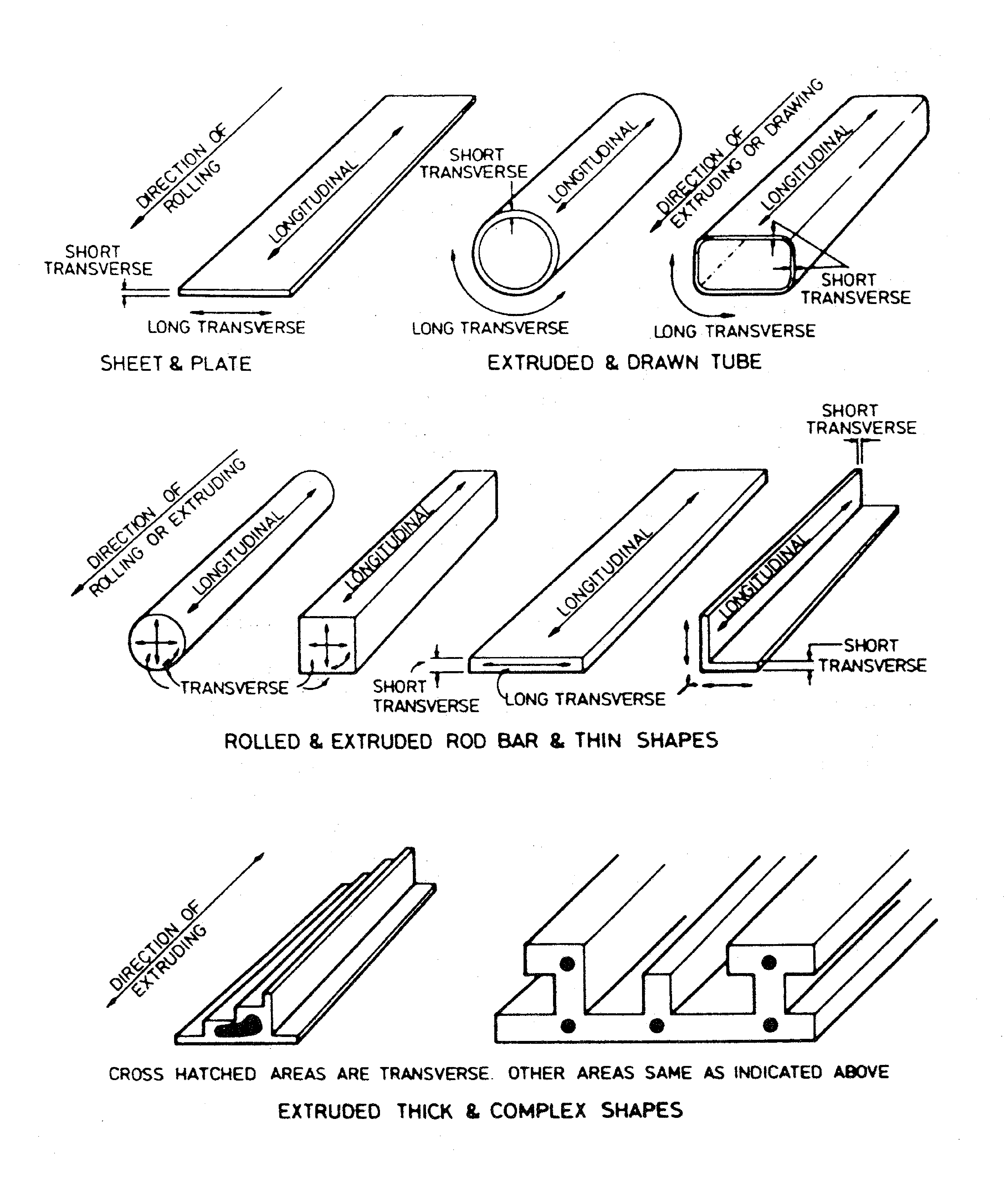

Anisotropy of grain orientation

The anisotropy of grain orientation, produced by rolling and extruding, is illustrated in Figure D-1. Taking the rolled plate as an example, it is conventional to describe the direction of rolling as the longitudinal direction, the direction perpendicular to the longitudinal axis and in the plane of the plate as the long transverse direction, and the direction through the thickness of the plate as the short transverse direction.

Figure: Grain orientations in standard wrought forms

Figure: Grain orientations in standard wrought forms

For certain shapes, it is not possible to distinguish both a long and a short transverse direction on the basis of the simple rules for identifying those directions in a plate.

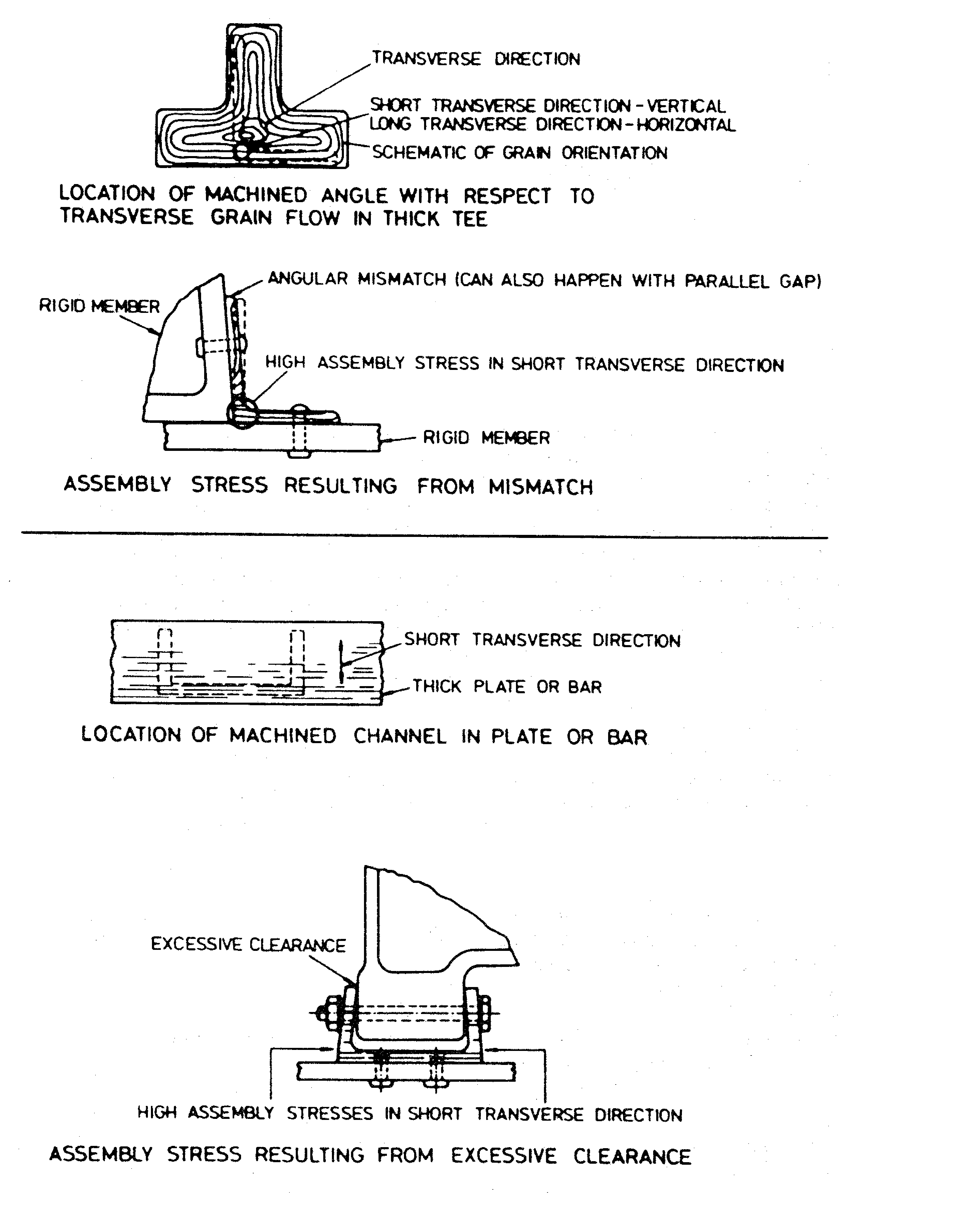

As an example, consider the thick tee illustrated in Figure D-2, where a region with both long and short transverse orientations has been identified on the basis of experience with that particular shape and a knowledge of the forming method.

Figure: Examples of tensile stresses in short transverse direction applied during assembly

Figure: Examples of tensile stresses in short transverse direction applied during assembly

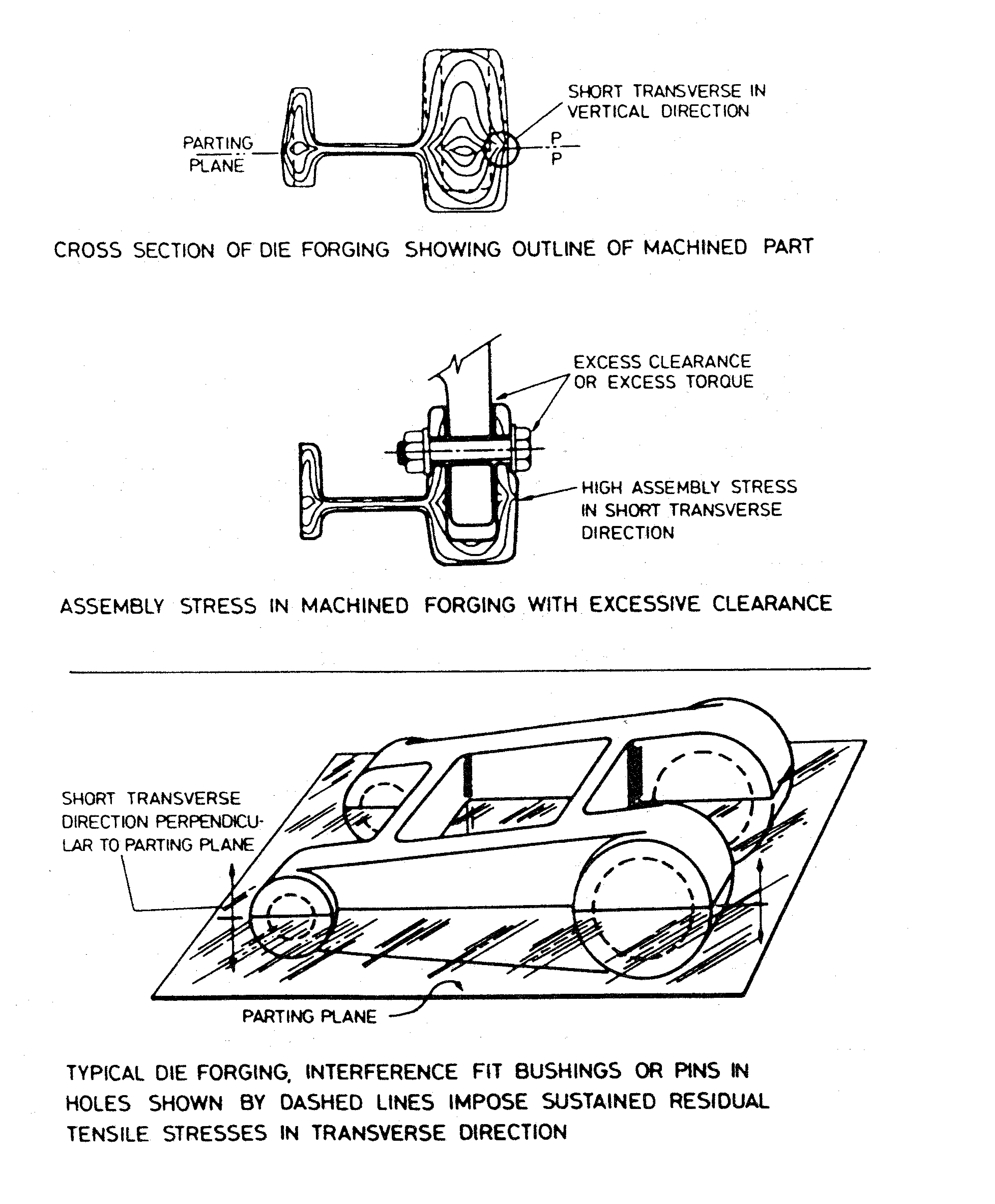

Forgings also require special consideration when identifying the short transverse direction. In a forging operation, the flow of metal is influenced and constrained by the shape of the die cavity. For complex shapes, there may be several regions where a short transverse direction exists. The direction perpendicular to the parting plane of the dies is always short transverse, as illustrated in Figure D-3

Figure: Examples of tensile stresses in short transverse direction resulting from assembly

Figure: Examples of tensile stresses in short transverse direction resulting from assembly

The resistance of metals, particularly alloys of aluminium, to stresscorrosion cracking is always less when tension is applied in a transverse direction. It is least for the short transverse direction. Figure D-2 and Figure D-3 were drawn to illustrate undesirable situations in which tensile stresses due to assembly have been applied in the short transverse direction.

ANNEX(informative)SCC resistance of alloys

Stress corrosion susceptibility

The stresscorrosion susceptibility of alloys included in this document was determined at ambient temperature:

by means of laboratory tests in which specimens were either sprayed with salt water or periodically immersed (every xx days/mn/sec) and withdrawn;

by exposing specimens in sea coast or mild industrial environments;

Example of mild industrial environment;

by subjecting fabricated hardware to service conditions.

- 1 For example: Example of service condition for a given hardware

- 2 Use of the criteria established herein should therefore be limited to designs for service involving similar exposure conditions.

Weldments present specific problems, as described in Document_Reference, in designing for resistance to SCC. In addition to the susceptibility of the parent metals, it is also necessary to consider the filler metal and the microstructural effects of heat introduced by the welding operations and subsequent heat treatments, such as Subsequent_Heat_Treatment_Example. Because of the additional variables to be considered (Additional_Variables_List), susceptibility data are not as extensive for weldments as for alloys in mill form.

In designing for stress-corrosion resistance, it is important to realize that stresses are additive and that threshold stresses for susceptibility are often low. There have been a number of stress-corrosion failures for which design stresses were intermittent and of short duration, and only of minor significance in contributing to failure. Stress-corrosion cracking in those cases occurred because a combination of residual and assembly stresses not even anticipated in design. Unfortunately, for most service environments, accurate threshold stresses are difficult to assess. In addition to stresses resulting from operational, transportation and storage loads that are anticipated during design, assembly and residual stresses also contribute to stress-corrosion failure.

Metal alloys

Aluminium

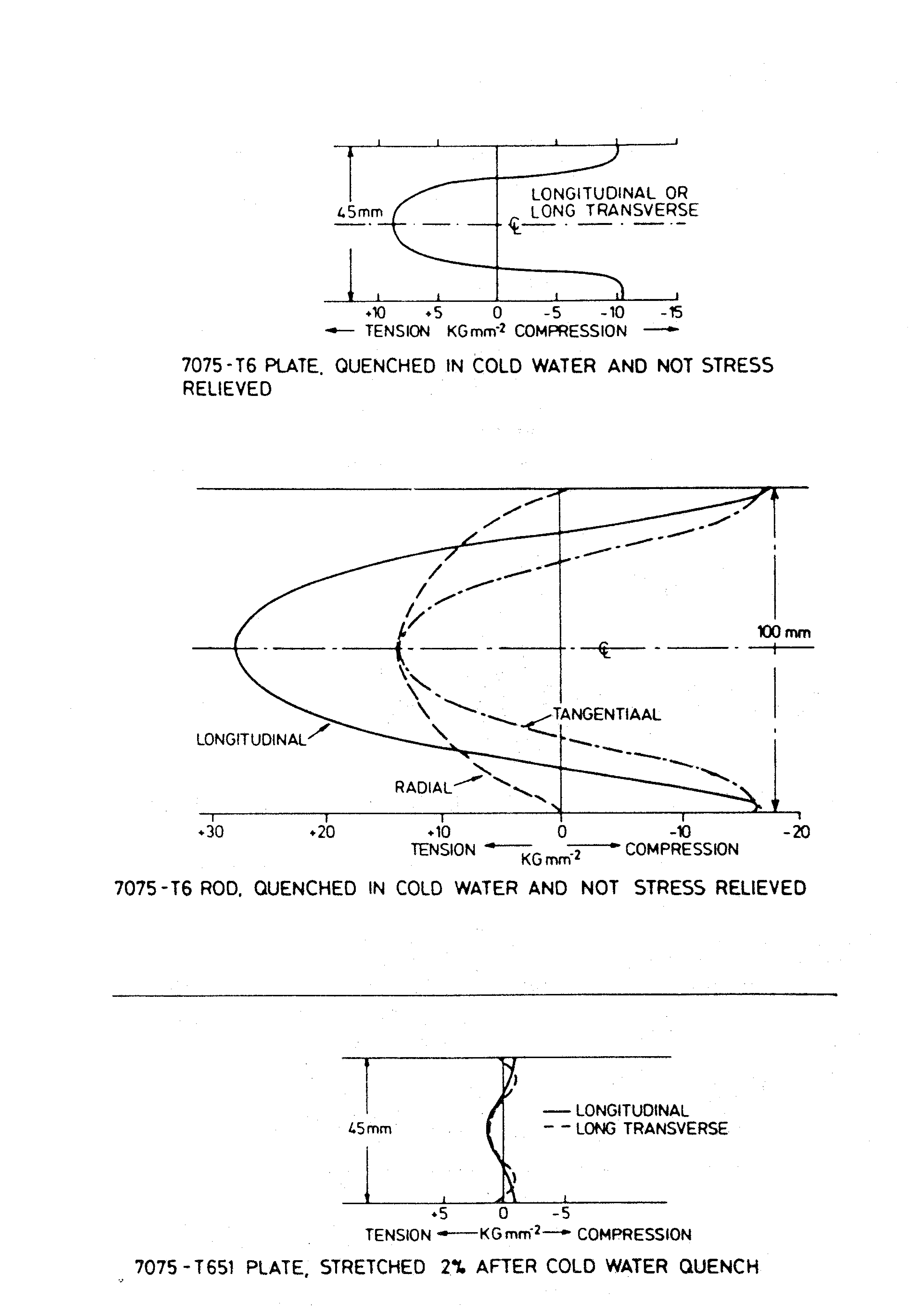

Many aluminium alloys exhibit excellent resistance to stresscorrosion cracking in all standard tempers. The highstrength alloys, however, which are of primary interest in aerospace applications, is approached cautiously. Some are resistant only in the longitudinal grain direction, and the resistance of others varies with the specific temper. Because metallurgical processing of aluminium alloys usually results in a pronounced elongation of grains, the variation of susceptibility with grain orientation is more extensive than for other metals. Also, because conventional processing methods are designed to optimise strength, residual stresses - especially in thick sections - are usually greater in aluminium products than in wrought forms of other metals. For this reason, wrought, heattreatable aluminium products specified for use in the fabrication of hardware should be mechanically stress relieved (the TX5X or TX5XX temper designations) whenever possible.

Both the residual stress distribution and the grain orientation are carefully considered, as specified in clause 5.3, in designing a part to be machined from wrought aluminium. Machining does not only alter the stress distribution but, as indicated in Figure D-2, it can also result in the exposure of a short transverse region on the surface of the finished part which is subjected to tension in service.

Steel

Carbon and lowalloy steels with ultimate tensile strengths below 1 225 MPa (180 ksi) are generally resistant to stresscorrosion cracking. Austenitic stainless steels of the 300 series are generally resistant. Martensitic stainless steels of the 400 series are more or less susceptible, depending on composition and heat treatment. Precipitationhardening stainless steels vary in susceptibility from extremely high to extremely low, depending on composition and heat treatment. The susceptibility of these steels is particularly sensitive to heat treatment, and special vigilance is required to avoid problems due to stresscorrosion cracking.

Nickel

As a class, alloys with high nickel content are resistant to stresscorrosion cracking.

Copper

Natural atmospheres containing the pollutants sulphur dioxide, oxides of nitrogen, and ammonia are reported to cause stresscorrosion cracking of some copper alloys. Chlorides present in marine atmospheres may cause stresscorrosion problems, but to a lesser extent than the previously listed pollutants, which indicates that industrial areas are probably more aggressive than marine sites to copperbase alloys. Many copper alloys containing over 20 % zinc are susceptible to stresscorrosion cracking even in the presence of alloying additions that normally impart resistance to stress-corrosion.

Figure: Typical residual stress distributions in 7075 Aluminium alloys

Figure: Typical residual stress distributions in 7075 Aluminium alloys

ANNEX(informative)Stress sources

Introduction

In addition to stresses resulting from operational, transportation and storage loads that are anticipated during design, assembly and residual stresses also contribute to stress-corrosion, and in many cases are the major contributors to stresscorrosion failure.

Stress sources

Table: Sources of stress

|

Stress type

|

Source

|

|

Assembly

|

improper tolerances during fitup (Figure D-3 and Figure E-1)

|

|

Residual1

|

machining

|

|

Transportation

|

|

|

Storage

|

|

|

Operational

|

|

|

1 Some typical residualstress distributions through plate and rod are illustrated in Figure D-1 to provide an indication of the magnitudes of stress which can be developed as the result of conventional heat treating and forming operations.

| |

Bibliography

|

ECSS-S-ST-00

|

ECSS system – Description, implementation and general requirements

|