Space product assurance

Radiation hardness assurance - EEE components

Foreword

This Standard is one of the series of ECSS Standards intended to be applied together for the management, engineering and product assurance in space projects and applications. ECSS is a cooperative effort of the European Space Agency, national space agencies and European industry associations for the purpose of developing and maintaining common standards. Requirements in this Standard are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards.

This Standard has been prepared by the Radiation Hardness Assurance Working Group, reviewed by the ECSS Executive Secretariat and approved by the ECSS Technical Authority.

Disclaimer

ECSS does not provide any warranty whatsoever, whether expressed, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item are error-free. In no respect shall ECSS incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this Standard, whether or not based upon warranty, business agreement, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by ECSS.

Published by: ESA Requirements and Standards Division

ESTEC, P.O. Box 299,

2200 AG Noordwijk

The Netherlands

Copyright: 2012© by the European Space Agency for the members of ECSS

Change log

|

ECSS-Q-ST-60-15A

|

Never issued

|

|

ECSS-Q-ST-60-15B

|

Never issued

|

|

ECSS-Q-ST-60-15C

|

First issue

|

Scope

This standard specifies the requirements for ensuring radiation hardness assurance (RHA) of space projects. These requirements form the basis for a RHA program that is required for all space projects in conformance to ECSS-Q-ST-60. RHA program is project specific. This standard addresses the three main radiation effects on electronic components: Total Ionizing Dose (TID), Displacement Damage or Total Non-Ionizing Dose (TNID), and Single event Effects (SEE).

Spacecraft charging effects are out of the scope of this standard.

In this standard the word “component” refers to Electrical, Electronic, and Electromechanical (EEE) components only. Other fundamental constituents of space hardware units and sub-systems such as solar cells, optical materials, adhesives, polymers, and any other material are not covered by this standard.

This standard may be tailored for the specific characteristic and constrains of a space project in conformance with ECSS-S-ST-00.

Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this ECSS Standard. For dated references, subsequent amendments to, or revision of any of these publications do not apply. However, parties to agreements based on this ECSS Standard are encouraged to investigate the possibility of applying the more recent editions of the normative documents indicated below. For undated references, the latest edition of the publication referred to applies.

|

ECSS-S-ST-00-01

|

ECSS system - Glossary of terms

|

|

ECSS-Q-ST-10-09

|

Space product assurance - Nonconformance control system

|

|

ECSS-Q-ST-30

|

Space product assurance - Dependability

|

|

ECSS-Q-ST-30-11

|

Space product assurance - Derating - EEE components

|

|

ECSS-Q-ST-60

|

Space product assurance - Electrical, electronic, and electromechanical (EEE) components

|

|

ECSS-E-ST-10-04

|

Space engineering - Space environment

|

|

ECSS-E-ST-10-12

|

Space engineering - Methods for the calculation of radiation received and its erects, and a policy for design margins

|

|

ESCC 22900

|

ESCC Basic Specification: Total dose steady state irradiation test method

|

|

ESCC 25100

|

ESCC Basic Specification: Single Event Effect Test Method and Guidelines

|

|

MIL-STD-750E

|

Test methods for semiconductor devices - Single event burnout and single event gate rupture test

|

|

MIL-STD-750E

|

Test methods for semiconductor devices - Steady-state total dose irradiation procedure

|

|

MIL-STD-883G

|

Microcircuits - Ionizing radiation (total dose) test procedure

|

|

MIL-HDBK-814

|

Military Handbook: Ionizing dose and neutron hardness Assurance guidelines for microcircuits and semiconductor devices

|

Terms, definitions and abbreviated terms

Terms from other standards

For the purpose of this Standard, the terms and definitions from ECSS-S-ST-00-01 apply, in particular for the following terms:

applicable document

approval

assurance

derating

EEE component

environment

equipment

failure

information

outage

recommendation

required function

requirement

review

risk

specification

standard

subsystem

system

test

traceability

validation

verification

For the purpose of this Standard, the terms and definitions from ECSS-Q-ST-60 apply, in particular for the following terms:

characterization

commercial component

screening

space qualified parts

For the purpose of this Standard, the terms and definitions from ECSS-E-ST-10-04 apply, in particular for the following terms:

dose

equivalent fluence

fluence

flux

linear energy transfer (let)

For the purpose of this Standard, the terms and definitions from ECSS-E-ST-10-12 apply, in particular for the following terms:

cross-section

displacement damage

LET threshold

multiple cell upset (MCU)

(total) non-ionizing dose, (T)NID, or non-ionizing energy loss (NIEL) dose

NIEL

projected range

radiation design margin (RDM)

sensitive volume (SV)

single event burnout (SEB)

single event dielectric rupture (SEDR)

single event effect (SEE)

single event functional interrupt (SEFI)

single event gate rupture (SEGR)

single event latch-up (SEL)

single event transient (SET)

single event upset (SEU)

solar energetic particle event (SEPE)

total ionizing dose (TID)

Terms specific to the present standard

component type TIDS

TID level at which the part exceeds its parametric/functional requirements

component type TNIDS

TNID level at which the part exceeds its parametric/functional requirements

enhanced low dose rate sensitivity (ELDRS)

increased electrical parameter degradation of a part when it is irradiated with a lower dose rate

equivalent LET

averaged value of the LET curve inside a sensitive volume

one sided tolerance limit

limit that will not be exceeded with a probability P and a confidence level C, assuming that TID degradation of electrical parameters follow a normal distribution law

If <delta x> is the mean shift among tested population of n samples, is the standard deviation of the shift, and K is the one sided tolerance limit factor, then:

- Delta XL = <delta x > + K σ, for increasing total dose shift

- Delta XL = <delta x > - K σ, for decreasing total dose shift

- K depends on the number of tested samples n, the probability of success P and the confidence limit C. K values are available in MIL-HDBK-814. A 3 sigma (K=3) approach is often used. With 10 samples tested it gives a probability of success P of 90% with a confidence level C of 99%. Table 31 gives the values of K as a function of the number of tested samples n for P=0,9 and C=0,9

Table 31: K values for P=0,9 and C=0,9 as function of the number of tested samples n

|

n

|

K

|

|

3

|

4,259

|

|

4

|

3,188

|

|

5

|

2,742

|

|

6

|

2,493

|

|

7

|

2,332

|

|

8

|

2,218

|

|

9

|

2,133

|

|

10

|

2,065

|

radiation design margin (RDM)

ratio of TIDS over TIDL for TID and ratio of TNIDS over TNIDL for TNID

radiation lot acceptance test (RADLAT)

see “radiation verification test”

radiation verification test (RVT)

radiation test performed on sample coming from the same diffusion lot as the flight parts

This test is also known as “radiation lot acceptance test (RADLAT)”.

total ionizing dose level (TIDL)

calculated TID level received by the part at the end of the mission

total non-ionizing dose level (TNIDL)

calculated TNID level received by the part at the end of the mission

Abbreviated terms

For the purpose of this Standard, the abbreviated terms from ECSS-S-ST-00-01 and the following apply:

|

Abbreviation

|

Meaning

|

|

APS

|

active pixel sensor

|

|

ASIC

|

application specific integrated circuit

|

|

CCD

|

charge coupled device

|

|

CDR

|

critical design review

|

|

DCL

|

declared part list

|

|

ELDRS

|

enhanced low dose rate sensitivity

|

|

EOL

|

end of lifetime

|

|

FMECA

|

failure mode effects and criticality analysis

|

|

GEO

|

geostationary Earth orbit

|

|

LET

|

linear energy transfer

|

|

MCU

|

multiple cell upset

|

|

MOS

|

metal oxide semiconductor

|

|

NCR

|

nonconformance report

|

|

NIEL

|

non-ionizing energy loss

|

|

PDR

|

preliminary design review

|

|

QR

|

qualification review

|

|

RADLAT

|

radiation lot acceptance test

|

|

RDM

|

radiation design margin

|

|

RHA

|

radiation hardness assurance

|

|

RVT

|

radiation verification test

|

|

SEB

|

single event burnout

|

|

SEDR

|

single event dielectric rupture

|

|

SEE

|

single event effect

|

|

SEFI

|

single event functional interrupt

|

|

SEGR

|

single event gate rupture

|

|

SEL

|

single event latch-up

|

|

SET

|

single event transient

|

|

SEU

|

single event upset

|

|

SRR

|

system requirement review

|

|

TID

|

total ionizing dose

|

|

TIDL

|

total ionizing dose level

|

|

TIDS

|

total ionizing dose sensitivity

|

|

TNIDL

|

total non-ionizing dose level

|

|

TNIDS

|

total non-ionizing dose sensitivity

|

|

TNID

|

total non-ionizing dose

|

|

TNIDL

|

total non-ionizing dose level

|

|

TNIDS

|

total non-ionizing dose sensitivity

|

|

WCA

|

worst case analysis

|

Principles

Overview of RHA process

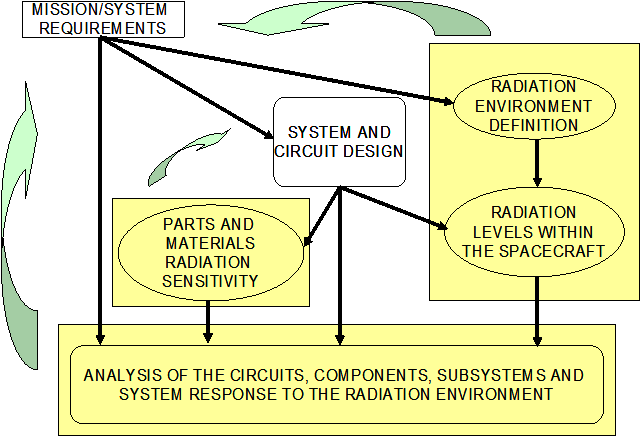

Survival and successful operation of space systems in the space radiation environment cannot be ensured without careful consideration of the effects of radiation. RHA consists of all those activities undertaken to ensure that the electronics of a space system perform to their specification after exposure to the space radiation environment. A key element of RHA is the selection of components having a sufficient tolerance to radiation effects for their application. However, RHA process is not confined to the part level. It has implications with system requirements and operations, system and subsystems circuit design, and spacecraft layout. Figure 41 shows an overview of the process. The RHA process follows an iterative and top-down approach where mission radiation environment is calculated from mission requirements and the radiation environments models and rules defined in ECSS-E-ST-10-04. Top level requirements derived from mission radiation environment specification are employed as the starting point. Then, when necessary, radiation environment is transferred to component level via sector analysis or Monte Carlo analysis according to the methods described in ECSS-E-ST-10-12. Then, radiation analysis is performed at equipment level. Radiation sensitivity of each component is defined and its impact on equipment performance is analyzed. An equipment electronic design is validated when the equipment can fulfil its requirement under exposure to the mission space environment with a sufficient RDM.

Figure 41: RHA process overview

Figure 41: RHA process overview

Radiation effects on components

A comprehensive compendium of radiation effects is provided in ECSS-E-HB-10-12A section 3. Radiation effects that are important to be considered for instrument and spacecraft design fall roughly into three categories: degradation from TID, degradation from TNID, or NIEL or DDD, and SEE.

Degradation from TID in electronics is a cumulative, long term degradation mechanism due to ionizing radiation—mainly primary protons and electrons and secondary particles arising from interactions between these primary particles and spacecraft materials. It causes threshold shifts, leakage current and timing skews. The effect first appears as parametric degradation of the device and ultimately results in functional failure. It is possible to reduce TID with shielding material that absorbs most electrons and lower energy protons. As shielding is increased, shielding effectiveness decreases because of the difficulty in slowing down the higher energy protons. When a manufacturer advertises a part as “rad-hard”, he is almost always referring to its total ionizing dose characteristics. Rad-hard does not usually imply that the part is hard to non-ionizing dose or single event effects. In some cases, a “rad-hard” part can perform significantly worse in the space radiation environment if unrepresentative ground irradiation tests were performed by the manufacturer in the qualification process (e.g. Enhanced Low Dose Rate Sensitivity in linear bipolar devices).

Degradation form TNID or displacement damage is cumulative, long-term non-ionizing damage due to protons, electrons, and neutrons. These particles produce defects mainly in optoelectronics components such as APS, CCDs, and optocouplers. Displacement damage also affects the performance of linear bipolar devices but to a lesser extent. The effectiveness of shielding depends on the location of the device. Increasing shielding beyond a critical threshold, however, is not usually effective for optoelectronic components because the high-energy protons are capable of penetrating most spacecraft electronic enclosures. For detectors in instruments it is necessary to understand the instrument technology and geometry to determine the vulnerability to the environment.

SEEs result from ionization by a single charged particle as it passes through a sensitive junction of an electronic device. SEEs are caused by heavier ions, but for some devices, protons can also contribute. In some cases SEEs are induced through direct ionization by the proton, but in most instances, proton induced effects result from secondary particles produced when the proton scatters off of a nucleus in the device material. Some SEEs are non-destructive, as in the case of SEU, SET, MCU, and SEFI. Single event effects can also be destructive as in the case of single event SEL, SEGR, and SEB. The severity of the effect can range from noisy data to loss of the mission, depending on the type of effect and the criticality of the system in which it occurs. Shielding is not an effective mitigator for SEEs because they are induced by very penetrating high energy particles. The preferred method for dealing with destructive failures is to use SEE-hard parts. When SEE-hard parts are not available, latch-up protection circuitry is sometimes used in conjunction with failure mode analysis. (Note: Care is necessary when using SEL protection circuitry, because SEL can damage a microcircuit and reduce its reliability even when it does not cause outright failure.) For non-destructive effects, mitigation takes the form of, for example, error-detection and correction codes (EDAC), and filtering circuitry.

Knowledge of parts radiation sensitivity is an essential part of the overall RHA program. For the total dose environment, the damage is caused by the ionization energy absorbed by the sensitive materials, measured in rad or in gray (1 gray = 100 rad). This implies that a number of ionization sources can be used for simulation of space environment at ground level. However, the total dose response is also a strong function of the dose rate. Displacement damage can be simulated for any particle by using the value of NIEL. This implies that the effects of the displacement are to a first approximation, only proportional to the total energy loss through displacements and not dependant on the nature of the displacements. The single particle environment is usually simulated by the particle LET. For heavy ions this seems to be a reasonable measure of the environment as long as the particle type and energy are adjusted to produce the appropriate range of the ionization track. For protons, however, the LET is not the primary parameter since the upsets result primarily from secondary particles resulting from the interaction of proton with device’s atoms. Thus for the proton environment, the simulations should be conducted with protons of the appropriate energy.

Evaluation of radiation effects

For assessing TID and TNID damages, electrical parameter drift values of each single individual component are derived from TID levels and TNID levels with an appropriate RDM. These drifts are used as input for WCA as defined in ECSS-Q-ST-30 clause 6.4.2.7. Rationale for establishing RDM for TID and TNID is provided in ECSS-E-ST-10-12.

SEE are generally analyzed during Failure Mode Effects and Criticality Analysis (FMECA) as defined in ECSS-Q-ST-30 clause 6.4.2.2. Operational impact of each single individual component SEE is analyzed and its criticality is assessed based on the SEE rate of occurrence with an appropriate RDM. Rationale for establishing RDM for SEE is provided in ECSS-E-ST-10-12.

Phasing of RHA with the different phases of a space project

Phase 0: Mission analysis, Phase A: Feasibility

Mission environment is defined and top level radiation requirements can be derived. RHA requirements (e.g. RDM) are tailored to the specific project needs. Preliminary radiation characterization studies can be started to help technology selection and design trade-off activities.

Phase B: Preliminary definition

For SRR, Mission environment and RHA requirements are finalized. Electronic design and spacecraft layout are defined. Preliminary shielding analyses can be started as well as radiation characterization activities.

Phase C: Detailed definition

Radiation characterization tests are performed. Equipment shielding analyses , equipment circuit design analyses (e.g. WCA, SEE analysis) are performed.. Radiation analysis and WCA reports are provided in equipment CDR data package. When necessary, impact of radiation effect at equipment level is analysed at upper (subsystem and system) levels and document in upper levels CDR data packages. At the end of phase C, most of the RHA work is completed.

Phase D: Qualification and production

Remaining RHA activities are radiation tests on flight lots (e.g. RVT). At this stage of program development, radiation effects issues resulting in redesign activities are very costly.

Radiation reviews

Equipment, subsystem, and system radiation analysis reports are part of project reviews data packages (from PDRs (all levels) to CDRs (all levels), QRs (all levels), and, finally, SAR. Radiation data on parts and part radiation testing are also reviewed during PAD review process. However, PAD approval for a part is only a provisional approval. As far as radiation effects are concerned, use of a part in a specific application is only validated when corresponding equipment radiation analysis and WCA reports are approved.

Equipment radiation reviews held in association with equipment PDR, may also be performed at customer request. These reviews are useful to review available radiation test data, define the radiation tests to perform, define or review the test plans, review shielding strategy and preliminary shielding analysis.

Requirements

TID hardness assurance

Mission TID radiation environment shall be defined according to ECSS-E-ST-10-04 and documented in a Mission Radiation Environment Specification in conformance with the DRD in Annex A.

A draft mission environment specification shall be available at SRR.

A final version of mission environment specification shall be available latest at system PDR.

No effect due to TID shall cause permanent damage to a system or subsystem, or degrade its performances outside its specification limits.

Each EEE part belonging to families and sub-families listed in Table 51 shall be assessed for sensitivity to TID effects to the level specified in this table.

Hybrids can also be treated as an electronic box. In this case, RHA requirements, as listed in this document, are applicable to every die used in the hybrid.

Table 51: EEE part families potentially sensitive to TID

|

EEE part family

|

Sub family

|

TIDL

|

|

Diodes

|

Voltage reference, Zener

|

all

|

|

|

Switching, rectifier, Schottky

|

> 300 krad-Si eq.

|

|

Diodes microwave

|

|

> 300 krad-Si eq.

|

|

Integrated Circuits

|

|

all

|

|

GaAs Integrated Circuits

|

|

> 300 krad-Si eq.

|

|

Oscillators (hybrids)

|

|

all

|

|

Charge Coupled devices (CCD)

|

|

all

|

|

Opto discrete devices, Photodiodes, LED, Phototransistors, Opto couplers

|

|

all

|

|

Transistors (MOS and bipolar)

|

|

all

|

|

GaAs Transistors

|

|

> 300 krad-Si eq.

|

|

Hybrids containing active parts

|

|

all

|

TID test data used to assess TIDS shall comply with the following rules to be acceptable:

- tests are performed in conformance to ESCC 22900, MIL-STD 883 method 1019, or MIL-STD-750 method 1019, and

- devices that contain bipolar transistors are tested at a dose rate of 36 rad/h to 360 rad/h, and

- tested parts are manufactured with technology identical to the technology of flight parts: same process, same diffusion mask, and same wafer fabrication facility, and

- test bias conditions are worse or equivalent to the application.

If acceptable component TID test data does not exist, ground testing shall be performed in conformance to ESCC 22900 and requirements 5.1f.2 to 5.1f.4.

Acceptable component TID test data shall be available latest at CDR.

Component type TIDS shall be based on the parametric and functional limits given in component detail specification or manufacturer data sheet, or on the maximum parameter degradation acceptable to ensure equipment operation in compliance with equipment performance specification at the end of overall lifetime (EOL).

TIDS is defined by comparing part parametric/functional requirements with TID test data.

Component type TIDS shall be calculated either as

- Total Dose level at which the worst case part of the worst case lot exceeds its limits as defined in requirement 5.1i (worst case approach), or

- Total Dose level at which the one sided tolerance limit, as defined in MIL-HDBK-814, exceeds its limits as defined in requirement 5.1i (statistical approach).

Component received TID level (TIDL) shall be calculated using 3D Monte Carlo analysis or ray tracing analysis in conformance with ECSS-E-ST-10-12.

Minimum RDM shall be as follows: - for geostationary orbits 1,2;

- greater than 1 if worst case models were used to define the environment and then TIDL, and if TIDS is based on statistical analysis of test data to guarantee a probability of survival Ps of at least 90 % with a confidence level of at least 90 %;

- in any other cases, if not defined by the customer, to be defined by the supplier and submitted to customer for approval.

For any component that is estimated to have on-orbit performance degradation due to TID, a WCA of the function shall be performed in accordance with requirements of ECSS-Q-ST-30 to demonstrate that the function performs within specification despite radiation induced drifts in its constituent part parameters at EOL.

If requirements 5.1l and 5.1m are not met, mitigation shall be implemented to eliminate the possibility of damage to equipment or degradation of its performance outside its specification limits.

Mitigation shall be verified by analysis or test.

The supplier shall document the TID analysis in the equipment radiation analysis report in conformance to Annex B – DRD for customer approval.

A draft radiation analysis report shall be part of equipment PDR data package.

A final version of radiation analysis report shall be issued for equipment CDR.

At that stage all RHA activities except RVTs are completed.

For geostationary orbit, radiation verification test (RVT) on flight lot shall be performed if the component meets following condition: 1,2xTIDL < component type TIDS < 2xTIDL

Components can be classified into three groups as follows:

- Group 1, if 2xTIDL < component type TIDS, for which the above test is not necessary.

- Group 2, if 1,2xTIDL < component type TIDS < 2xTIDL, where testing is required in accordance with the above requirement.

- Group 3, if component type TIDS < 1,2xTIDL, which use is prevented by requirement 5.1l.1.

For geostationary orbit, RVT on flight lot shall be performed if flight model part diffusion lot number is different from tested part diffusion lot number and tested parts date code is 4 years older than flight model part date code.

For other orbits, the criteria for performing RVT on flight lot, if not defined by the customer, shall be defined by the supplier and submitted to customer for approval.

It is part of hardness assurance to perform RVT on flight lot based on the following criteria: age of available test data, part type and technology, and RDM.

Conformity of RVT results with as designed radiation analysis shall be checked.

As designed radiation analysis includes TIDL based on shielding, TIDS based on existing data and radiation drifts considered in WCA.

Nonconformities of RVT results with as designed radiation analysis shall be reported in a NCR in conformance with ECSS-Q-ST-10-09.

All radiation test reports, including RVT reports, shall be available for customer review.

TNID hardness assurance

Mission TNID radiation environment shall be defined according to ECSS-E-ST-10-04 and documented in Mission Radiation Environment Specification in conformance to Annex A.

A draft mission environment specification shall be available at SRR.

A final version of mission environment specification shall be available latest at system PDR.

No effect due to TNID shall cause permanent damage to a system or subsystem, or degrade its performances outside its specification limits.

Each EEE part belonging to families and sub-families listed in Table 52 shall be assessed for sensitivity to TNID, to the levels specified in this table.

Guidelines and NIEL rates for calculating monoenergetic equivalent proton fluences are provided in ECSS-E-HB-10-12 section 7.5.

Table 52: List of EEE part families potentially sensitive to TNID

|

Family

|

Sub-Family

|

TNIDL

|

|

CCD, CMOS APS, opto discrete devices

|

all

|

all

|

|

Integrated circuits

|

Silicon monolithic bipolar

|

> 2x1011 p/cm2 50 MeV equivalent proton fluence

|

|

Diodes

|

Zener

|

> 2x1011 p/cm2 50 MeV equivalent proton fluence

|

|

Transistor

|

Low power NPN

|

> 2x1011 p/cm2 50 MeV equivalent proton fluence

|

TNID data used to assess TNIDS shall satisfy the following criteria to be acceptable:

- Tests are performed with protons or neutrons and tested levels encompass the specified mission environment;

- Tested parts are manufactured with technology identical to the technology of flight parts: same process, same diffusion mask, and same wafer fabrication facility.

If acceptable component TNID test data does not exist, ground testing shall be performed in conformance to requirement 5.2f.2.

TNID irradiation test plans shall be submitted to customer for approval.

This is because no standard method exists for TNID testing.

TNID irradiations should be performed with protons at several proton energies encompassing the specified mission radiation environment.

This is because of the limitations of NIEL calculations for some technologies and component families.

Acceptable TNID test data shall be available latest at CDR.

Component type TNIDS shall be based on the parametric and functional limits given in detail specification or manufacturer data sheet, or on the maximum parameter degradation acceptable to ensure equipment operation in compliance with equipment performance specification at the end of overall lifetime (EOL).

TNIDS is defined by comparing part parametric/functional requirements with TNID test data

Component type TNIDS shall be calculated either as

- Total non-ionizing dose level at which the worst case part of the worst case lot exceeds its limits as defined in requirement 5.2k (worst case approach), or

- Total dose level at which the one sided tolerance limit as defined in MIL-HDBK-814 exceeds its limits as defined in requirement 5.2k (statistical approach)

Component TNID level (TNIDL) shall be calculated using 3D Monte Carlo or ray tracing analysis in conformance to ECSS-E-ST-10-12.

Minimum RDM shall be as follows: - for geostationary orbits 1,2;

- greater than 1 if worst case models were used to define the environment and then TNIDL, and if TNIDS is based on statistical analysis of test data to guarantee a probability of survival Ps of at least 90 % with a confidence level of at least 90 %;

- In any other cases, if not defined by the customer, to be defined by the supplier and submitted to customer for approval.

For any component that is estimated to have on-orbit performance degradation due to TNID, a WCA of the function shall be performed in accordance with requirements of ECSS-Q-ST-30 to demonstrate that the function performs within specification despite radiation induced drifts in its constituent part parameters at EOL.

Both TNID and TID degradations shall be combined to define the component parameter drifts for WCA.

If combined TNID and TID tests are used to get the combined TID/TNID sensitivity, such test plans shall be submitted to customer for approval.

Generally, TNID sensitive parts are also sensitive to TID.

If requirements 5.2n, 5.2n.1, and 5.2p cannot be met, mitigation shall be implemented to eliminate the possibility of damage to equipment or degradation of its performance outside its specification limits.

Mitigation shall be verified by analysis or test.

TNID analysis shall be documented in the equipment radiation analysis report in conformance with the DRD in Annex B.

A draft radiation analysis report shall be part of equipment PDR data package.

A final version of radiation analysis report shall be issued for equipment CDR.

At that stage all RHA activities except RVTs are completed.

For geostationary orbit, radiation verification testing (RVT) on flight lot shall be performed if the component meets following condition: 1,2xTNIDL < component type TNIDS < 2xTIDL

Components can be classified into three groups as follows:

- Group 1, if 2xTNIDL < component type TNIDS, for which the above test is not necessary.

- Group 2, if 1,2xTNIDL < component type TNIDS < 2xTIDL, where testing is required in accordance with the above requirement.

- Group 3, if component type TNIDS < 1,2xTNIDL, which use is prevented by requirement 5.2n.1.

For geostationary orbit, RVT on flight lot shall be performed if flight model part diffusion lot number is different from tested part diffusion lot number and tested parts date code is 4 years older than flight model part date code.

For other orbits, the criteria for performing RVT on flight lot, if not defined by the customer, shall be defined by the supplier and submitted to customer for approval.

It is part of hardness assurance to perform RVT on flight lot based on the following criteria: age of available test data, part type and technology, and RDM.

Conformity of RVT results with as designed radiation analysis shall be checked.

As designed radiation analysis includes TIDL based on shielding, TIDS based on existing data and radiation drift considered in WCA

Nonconformities of RVT results with as designed radiation analysis shall be reported in a NCR in conformance with ECSS-Q-ST-10-09.

All radiation test reports, including RVT reports, shall be available for customer review.

SEE hardness assurance

Mission SEE radiation environment shall be defined according to ECSS-E-ST-10-04 and documented in a Mission Radiation Environment Specification in conformance with the DRD in Annex A.

A draft mission environment specification shall be available at SRR.

A final version of mission environment specification shall be available latest at system PDR.

No SEE shall cause damage to a system or a subsystem or induce performance anomalies or outages not compliant with mission specifications.

Each EEE part belonging to families and sub-families listed in Table 53 shall be assessed for sensitivity to SEE.

A description of different types of SEE can be found in ECSS-E-ST-10-12.

Table 53: List of EEE part families potentially sensitive to SEE

|

Family

|

Sub-family

|

|

Integrated Circuits

|

all

|

|

Integrated Circuits Microwave

|

all

|

|

Transistors

|

FET N channel

|

|

Transistors Microwave

|

all

|

|

CCD, CMOS APS, opto discrete devices

|

all

|

SEE test data shall meet the following criteria to be acceptable:

- Test are performed in conformance to

- MIL-STD-750 method 1080 for power MOSFET,

- ESCC 25100 for all other parts.

Useful information about SEE testing is also provided in EIA/JESD 57.

- Tested parts are manufactured with technology identical to the technology of flight parts: same process and same diffusion mask.

- Test conditions are worse or equivalent to the application.

Test conditions include, but are not limited to, bias conditions, clock frequency, test pattern, and temperature.

If acceptable component test data does not exist, heavy ion ground testing shall be performed.

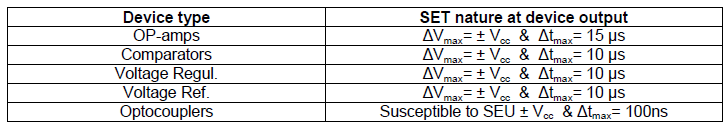

For the SET criticality analysis of SET in analog ICs, worst case SET templates in Table 54 may be used in the absence of acceptable test data.

Table 54: Worst case SET templates

All SEE testing shall be performed in conformance to requirements of clause 5.3f.

All SEE testing shall be performed in conformance to requirements of clause 5.3f.

SEE analysis proton testing shall take place based on LET threshold (LETth) of the candidate devices as specified in Table 55.

In accordance with this table, no further analysis is necessary above a LETth of 60 MeVcm2/mg, because parts are commonly considered immune to SEE in the space environment.

Table 55: Environment to be assessed based on LETth

|

Device LETth (MeVcm2/mg)

|

Environment to be assessed

|

|

LETth < 15

|

Heavy ions (GCR, solar event ions)

|

|

LETth= 15-60

|

Heavy ions (GCR, solar event ions)

|

|

LETth>60

|

No analysis required

|

Below a LETth level of 60 MeVcm2/mg, SEE analysis shall be performed.

Below a LETth of 15 MeVcm2/mg proton induced sensitivity analysis shall be analyzed.

Proton SEE sensitivity of SEE hardened parts shall be assessed.

The LETth of 15 MeVcm2/mg for performing proton SEE tests is not an absolute value. For VLSI hardened IC employing high-Z material in the vicinity of sensitive volumes, the LET of secondaries can be higher than 15 MeVcm2/mg.

The LETth levels as described in the requirements 5.3k, 5.3l and 5.3m shall be recalculated for parts made of other material than Silicon (i.e. GaAs).

Proton SEE test data shall satisfy requirement 5.3f to be acceptable.

If acceptable proton SEE data is not available, proton ground testing shall be performed.

Proton SEE testing shall be performed according to requirement 5.3f.

Acceptance of simulation tools to obtain proton SEU cross-section curves on digital devices shall be approved by customer.

For SEUs, proton cross-section curve can be obtained from heavy ion cross-section curve with simulation tools such as SIMPA or PROFIT.

For any component that is not immune to destructive SEE analysis, it shall be demonstrated that the probability of occurrence in the mission environment is more than 10 times lower than component intrinsic failure rate.

Examples of destructive SEE are: SEL, SEB, SEGR and SEDR.

One of the following two power MOSFET SEB/SEGR assessment methods shall be applied:

- SEB/SEGR failure rates based on SEB/SEGR cross-section versus equivalent LET curves;

- VDSmax, VGSoff max derating based on VDS versus VGS SOA.

Power MOSFET have a deep sensitive volume. Therefore, LET can vary significantly along ion path in sensitive volume.

Practical implementation of the method used to assess power MOSFET SEB/SEGR sensitivity, as specified in the requirement 5.3t, if not specified by the customer shall be defined by the supplier and submitted to customer for approval.

For non-destructive SEEs the criticality of a component in its specific application shall be defined including impacts at higher level, i.e. subsystem and system.

Examples of non-destructive SEE are: SEU, SET, MCU, and SEFI.

For the criticality analysis of SET in analog ICs, the analysis method, electrical simulations or hardware electrical injection, shall be submitted to customer for approval.

The mission event rate shall be calculated when a SEE on a given component for a given application is considered critical or potentially critical.

The mission event rate shall be calculated for the mission background environment and a solar event environment as defined in mission radiation environment specification in conformance to ECSS-E-ST-10-12.

The following RDM shall be applied on calculated error rate:

- 10, when proton error rate is based on simulation from heavy ion data;

- No RDM, when proton error rate is based on actual proton test data.

The calculated event rates shall be such that the application meets the projected availability, performance and reliability requirements.

If requirements 5.3s and 5.3aa are not met, mitigation shall be implemented to eliminate the possibility of damage to equipment or degradation of its performance outside its specification limits.

Mitigation shall be verified by analysis or test.

All data and analysis shall be documented in Radiation Analysis report in conformance with the DRD in Annex B.

A draft radiation analysis report shall be part of equipment PDR data package.

A final version of radiation analysis report shall be issued for equipment CDR.

All radiation test reports shall be available for customer review.

ANNEX(normative)Mission radiation environment specification – DRD

DRD identification

Requirement identification and source document

This DRD is called from ECSS-Q-ST-60-15, requirements 5.1a, 5.2a, and 5.3a.

Purpose and objective

The purpose of mission environment specification is to document in a single place the particle fluxes (shielded and unshielded), the TID and TNID versus shielding dose curves, and the LET spectra.

Expected Response

Contents

Mission definition

Mission orbit, duration, and, possibly, launch date shall be documented.

TID and TNID environment

High energy electrons and protons spacecraft incident fluence versus energy spectra shall be presented with figures and tables.

High energy electrons and protons can be trapped and solar.

Total dose curve in Silicon versus Aluminium shield thickness for a solid sphere geometry shall be presented with figure and table.

Total non-ionizing dose curves for Silicon and GaAs materials versus Aluminium shield thickness for a solid sphere geometry shall be presented with figure and table.

SEE environment

GCR fluxes versus LET spectrum calculated for a given Aluminium shield thickness (e.g. 1 g/cm2) shall be presented with figure and table.

Solar particle event fluxes versus LET spectrum for a given Aluminium shield thickness (e.g. 1 g/cm2) shall be presented with figure and table.

Trapped and solar protons shielded (e.g. behind 1 g/cm2 of Al) fluxes versus energy spectra shall be presented with figures and tables.

Special remarks

None.

ANNEX(normative)Radiation analysis report - DRD

DRD identification

Requirement identification and source document

This DRD is called from ECSS-Q-ST-60-15, requirements 5.1p, 5.2t and 5.3dd.

Purpose and objective

The purpose of the equipment Radiation Analysis report is to document in a single place all baseline information (data, assumptions, methods and techniques) used for the radiation analyses, and the results obtained.

Expected response

Contents

Identification of parts sensitive to radiation effects

The radiation analysis report shall list all radiation sensitive parts, as defined in ECSS-Q-ST-60-15 Table 51, Table 52, and Table 53, extracted from the DCL.

The list shall include the full part number and manufacturer information.

TID analysis

The radiation analysis report shall provide TID tolerance of each sensitive component with reference of test report and date code of tested parts.

The radiation analysis report shall identify the parts submitted to RVT.

The radiation analysis report shall include the description of mechanical model, assumption, method and tools used for ray trace or Monte Carlo analysis, and results obtained.

The radiation analysis report shall present TIDL and TIDS for each part as well as RDM.

TNID analysis

The radiation analysis report shall provide TNID tolerance of each sensitive component with reference of test report and date code of tested parts.

The radiation analysis report shall identify the parts submitted to RVT.

The radiation analysis report shall include the description of mechanical model, assumption, method and tools used for ray trace or Monte Carlo analysis, and results obtained.

The radiation analysis report shall present TNIDL and TNIDS for each part as well as RDM.

SEE analysis

The radiation analysis report shall provide SEE tolerance of each sensitive component with reference of test report.

The radiation analysis report shall describe the assumptions, methods and tools used for SEE rate predictions as well as SEE rates.

The radiation analysis report shall present SEE criticality analysis results.

Special remarks

None.

Bibliography

|

ECSS-S-ST-00

|

ECSS system – Description, implementation and general requirements

|

|

ECSS-E-HB-10-12

|

Space engineering - Methods for the calculation of radiation received and its effects and a policy for the design margin

|

|

EIA/JESD 57

|

Test Procedure For The Management Of Single-event Effects In Semiconductor Devices From Heavy Ion Irradiation

|