Space engineering

Testing

Foreword

This Standard is one of the series of ECSS Standards intended to be applied together for the management, engineering and product assurance in space projects and applications. ECSS is a cooperative effort of the European Space Agency, national space agencies and European industry associations for the purpose of developing and maintaining common standards. Requirements in this Standard are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards.

This Standard has been prepared by the ECSS-E-ST-10-03 TA Task Force, reviewed by the ECSS Executive Secretariat and approved by the ECSS Technical Authority.

Disclaimer

ECSS does not provide any warranty whatsoever, whether expressed, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item are error-free. In no respect shall ECSS incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this Standard, whether or not based upon warranty, business agreement, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by ECSS.

Published by: ESA Requirements and Standards Division

ESTEC, ,

2200 AG Noordwijk

The

Copyright: 2012© by the European Space Agency for the members of ECSS

Change log

|

ECSS-E-10-03A

|

First issue

|

|

ECSS-E-10-03B

|

Never issued

|

|

ECSS-E-ST-10-03C

|

Second issue.

|

Introduction

The requirements on the systems engineering process are gathered in ECSS-E-ST-10; while specific aspects are further elaborated in dedicated standards, in particular: ECSS-E-ST-10-06, ECSS-E-ST-10-02 and the present standard (ECSS-E-ST-10-03)

In the System Engineering branch (ECSS‐E‐10) this standard aims at a consistent application of on ground testing requirements to allow proper qualification and acceptance of space products

Experience has demonstrated that incomplete or improper on ground testing approach significantly increase project risks leading to late discovery of design or workmanship problem(s) or in-orbit failure(s).

Testing is part of the system engineering process as defined in ECSS‐E‐ST‐10. This starts at the early phase of the mission when defining verification process in terms of the model philosophy and test sequence and ends at the last testing phase prior launch.

In the level of decomposition of a space system, this standard addresses the requirements for space segment element and space segment equipment.

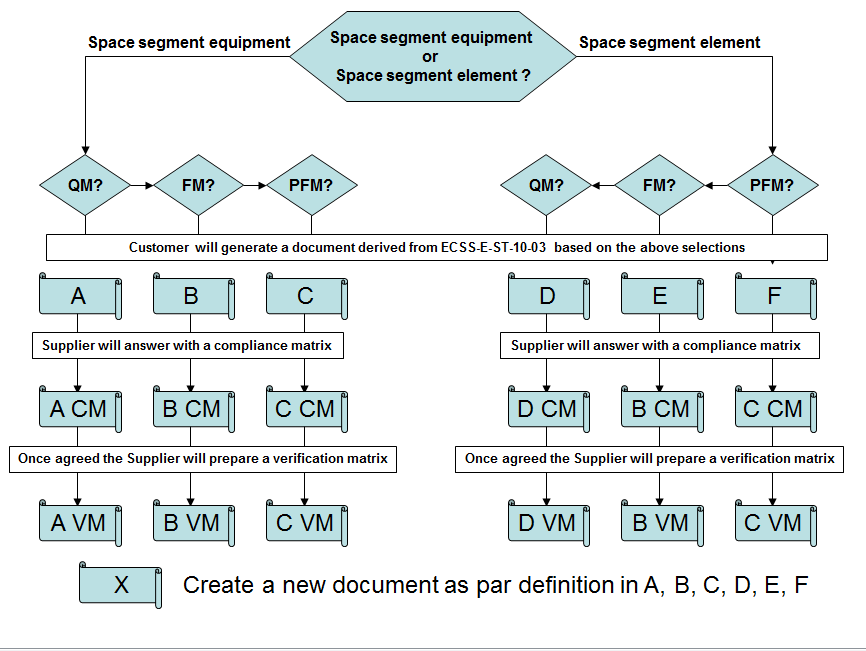

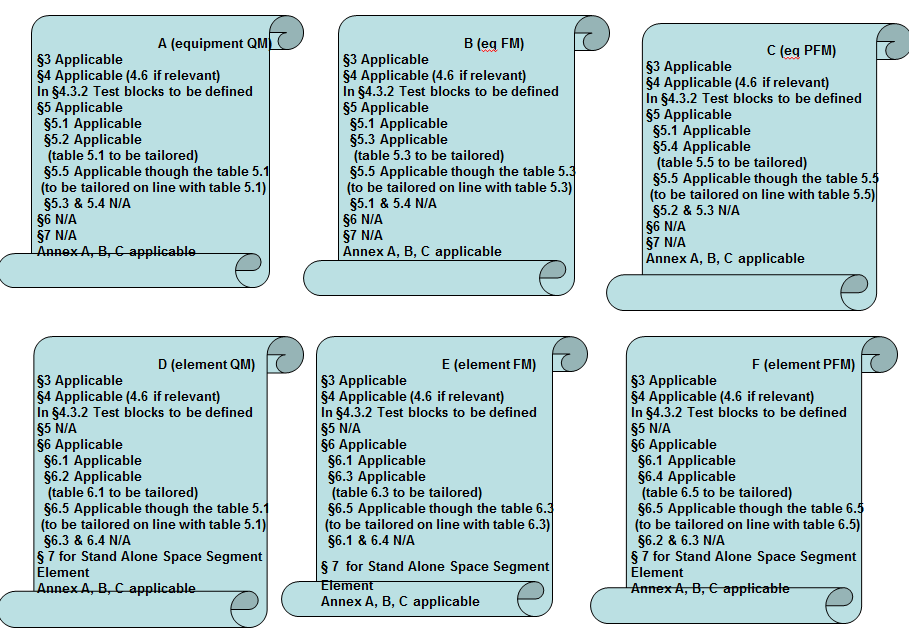

The document is organised such that:

clause 4 provides requirements for overall test programme, test management and test conditions, tolerances and accuracy;

clause 5 provides requirements for Space segment equipment;

clause 6 provides requirements for Space segment element;

clause 7 provides requirements for Pre-launch testing.

Clauses 5 and 6 are organised as follows:

general requirements for the products under test applicable to all models (clause 5.1 or 6.1);

requirements applicable to qualification model (clause 5.2 or 6.2);

requirements applicable to acceptance model (clause 5.3 or 6.3);

requirements applicable to protoflight model (clause 5.4 or 6.4);

detailed implementation requirements (clause 5.5 or 6.5);

In the clause providing requirements for each model (i.e. clauses 5.2, 5.3, 5.4, 6.2, 6.3 and 6.4), the first table of the clause:

lists all types of test and defines their applicability and conditions;

links to the second table of the clause that defines tests level and duration;

provides reference to the clause defining the detailed implementation requirements for the given test (clause 5.5 or 6.5).

For space segment equipment, the required sequence of test, for each model, is defined after the two tables in clause 5.2, 5.3 or 5.4.

Since testing activities are part of the overall verification activities, test documentation to be produced (DRD’s) are either specified in the ECSS-E-ST-10-02 (case of the test report) or in this document.

Annex D gives guidelines for performing the tailoring of this standard as well as the generation of the compliance and verification matrices.

Scope

This standard addresses the requirements for performing verification by testing of space segment elements and space segment equipment on ground prior to launch. The document is applicable for tests performed on qualification models, flight models (tested at acceptance level) and protoflight models.

The standard provides:

Requirements for test programme and test management,

Requirements for retesting,

Requirements for redundancy testing,

Requirements for environmental tests,

General requirements for functional and performance tests,

Specific requirements for functional and performance tests are not part of this standard since they are defined in the specific project documentation.

Requirements for qualification, acceptance, and protoflight testing including qualification, acceptance, and proto-fight models’ test margins and duration,

Requirements for test factors, test condition, test tolerances, and test accuracies,

General requirements for development tests pertinent to the start of the qualification test programme,

Development tests are specific and are addressed in various engineering discipline standards.

Content of the necessary documentation for testing activities (e.g. DRD).

Due to the specific aspects of the following types of test, this Standard does not address:

Space system testing (i.e. testing above space segment element), in particular the system validation test,

In-orbit testing,

Testing of space segment subsystems,

Tests of space segment subsystems are often limited to functional tests that, in some case, are run on dedicated models. If relevant, qualification tests for space segment subsystems are assumed to be covered in the relevant discipline standards.

Testing of hardware below space segment equipment levels (including assembly, parts, and components),

Testing of stand-alone software,

For verification of flight or ground software, ECSS-E-ST-40 and ECSS-Q-ST-80 apply.

Qualification testing of two-phase heat transport equipment,

For qualification testing of two-phase heat transport equipment, ECSS-E-ST-31-02 applies.

Tests of launcher segment, subsystem and equipment, and launch facilities,

Tests of facilities and ground support equipment,

Tests of ground segment.

This standard may be tailored for the specific characteristic and constrains of a space project in conformance with ECSS-S-ST-00. Annex D gives guidelines for performing this tailoring.

Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this ECSS Standard. For dated references, subsequent amendments to, or revision of any of these publications do not apply. However, parties to agreements based on this ECSS Standard are encouraged to investigate the possibility of applying the more recent editions of the normative documents indicated below. For undated references, the latest edition of the publication referred to applies.

|

ECSS-S-ST-00-01

|

ECSS system - Glossary of terms

|

|

ECSS-E-ST-10-02

|

Space engineering - Verification

|

|

ECSS-E-ST-20

|

Space engineering - Electrical and electronic

|

|

ECSS-E-20-01

|

Space engineering - Multipaction design and test

|

|

ECSS-E-ST-20-06

|

Space engineering - Spacecraft charging

|

|

ECSS-E-ST-20-07

|

Space engineering - Electromagnetic compatibility

|

|

ECSS-E-ST-20-08

|

Space engineering - Photovoltaic assemblies and components

|

|

ECSS-E-ST-31

|

Space engineering - Thermal control general requirements

|

|

ECSS-E-ST-32

|

Space engineering - Structural general requirements

|

|

ECSS-E-ST-32-02

|

Space engineering - Structural design and verification of pressurized hardware

|

|

ECSS-E-ST-32-10

|

Space engineering - Structural factors of safety for spaceflight hardware

|

|

ECSS-E-ST-32-11

|

Space engineering - Modal survey assessment

|

|

ECSS-E-ST-33-01

|

Space engineering - Mechanisms

|

|

ECSS-M-ST-40

|

Space project management - Configuration and information management

|

|

ECSS-Q-ST-10-09

|

Space product assurance - Nonconformance control system

|

|

ECSS-Q-ST-20-07

|

Space product assurance - Quality assurance for test centres

|

|

ECSS-Q-ST-40

|

Space product assurance - Safety

|

|

ECSS-Q-ST-70-01

|

Space product assurance - Cleanliness and contamination control

|

|

ISO 3740:2000

|

Acoustics - Determination of sound power levels of noise sources - Guidelines for the use of basic standards

|

Terms, definitions and abbreviated terms

Terms from other standards

For the purpose of this standard, since ECSS-S-ST-00-01 has not been published at the time of the publication of this standard, the introduction part of the ECSS Glossary has been copied here.

For the purpose of this standard; the terms and definitions from ECSS-S-ST-00-01 apply, and in particular the following:

flight model

lifetime

protoflight model

qualification model

space segment element

space segment equipment

space segment subsystem

structural model

system

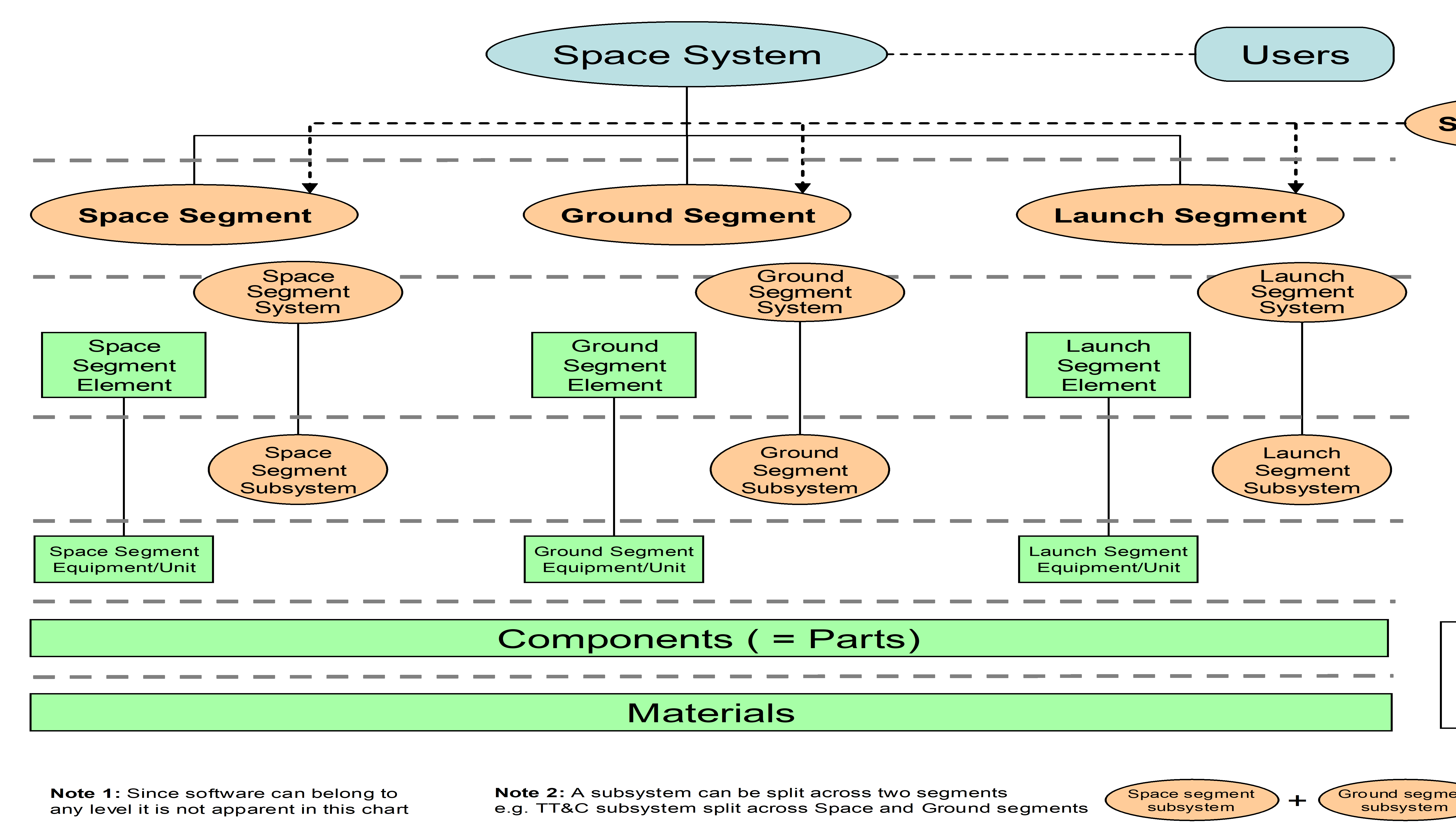

ECSS-S-ST-00-01C defines the highest-level system within a space project - i.e. the one at the mission-level - as the “Space System”. The breakdown of a typical space system and the definition of standard terms for the constituent levels within the breakdown are given below (see Figure 31 and subsequent definitions).

For this standard only, the terms for the Space Segment are defined in 3.1.

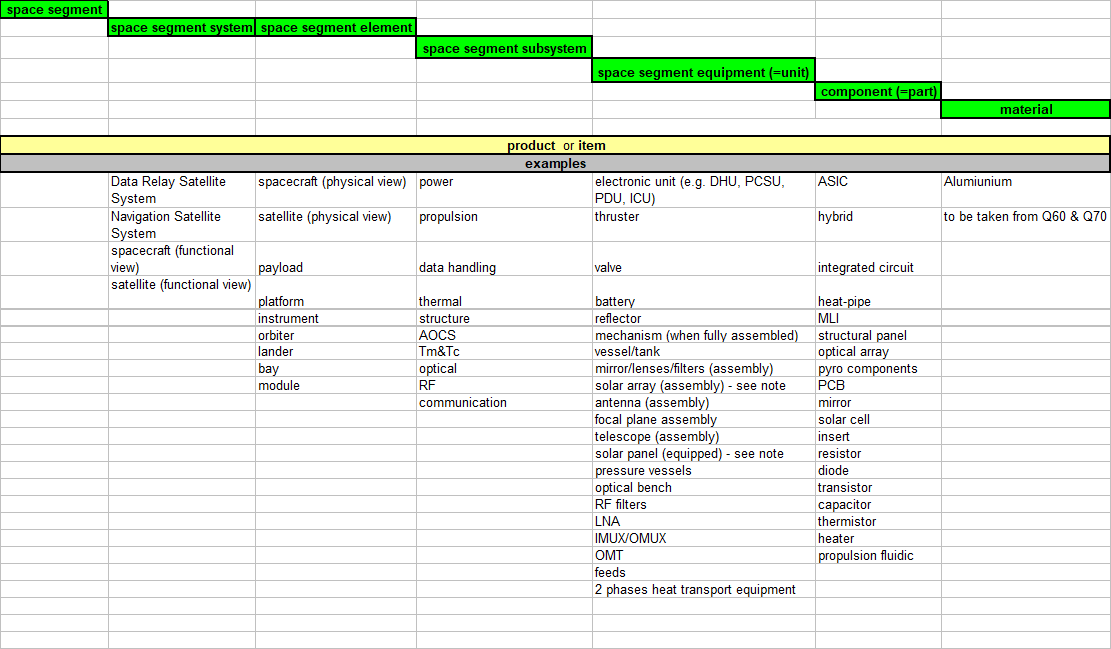

Since any definition always includes some ambiguity and in order to allow the user of the testing standard to clearly classify the item under test in the right category (i.e. Space segment Element, or equipment the table below give a list of example (see Figure 32). This table, however, is not exhaustive

Figure 31: Space system breakdown

Figure 31: Space system breakdown

The following terms are copied from ECSS-S-ST-00-01C Draft 1.1. Cross-references in these terms are within ECSS-S-ST-00-01C Draft 1.1.

systemset of interrelated or interacting functions constituted to achieve a specified objective

space systemsystem that contains at least a space, a ground or a launch segment

Generally a space system is composed of all three segments and is supported by a support segment.

space segmentpart of a space system, placed in space, to fulfil the space mission objectives

space segment systemsystem within a space segment

Examples are given in Annex B.1.

space segment elementelement within a space segment

- 1 A space segment element can be composed of several embedded space segment elements, e.g. a spacecraft is composed of instruments, a payload module and a service module.

- 2 Examples are given in Annex B.1.

stand-alone space segment elementspace segment element that performs its mission autonomously

For example: satellite, rover, lander.

embedded space segment elementspace segment element that performs its mission as part of another space segment element

For example: platform, module, instrument, payload.

space segment subsystemsubsystem within a space segment

Examples are given in Annex B.1.

space segment equipmentequipment within a space segment

Examples are given in Annex B.1.

componentset of materials, assembled according to defined and controlled processes, which cannot be disassembled without destroying its capability and which performs a simple function that can be evaluated against expected performance requirements

- 1 The term "part" is synonymous.

- 2 The term "part" is preferred when referring to purely mechanical devices.

- 3 The term "component" is preferred for EEE devices.

partsee “component”

materialraw, semi-finished or finished substance (gaseous, liquid, solid) of given characteristics from which processing into a component or part is undertaken

flight model (FM)end product that is intended for flight

- 1 The flight model is subjected to formal functional and environmental acceptance testing.

- 2 More detailed information on the build standard and the use of this model is given in ECSS-E-HB-10-02.

lifetimeperiod, or number of cycles, over which a product is required to perform according to its specification

protoflight model (PFM)flight model on which a partial or complete protoflight qualification test campaign is performed before flight

More detailed information on the build standard and the use of this model is given in ECSS-E-HB-10-02.

qualification model (QM)model, which fully reflects all aspects of the flight model design, used for complete functional and environmental qualification testing

-

1 A qualification model is only necessary for newly-designed hardware or when a delta qualification is performed for adaptation to the project.

-

2 The qualification model is not intended to be used for flight, since it is overtested.

-

3 More detailed information on the build standard and the use of this model is given in ECSS-E-HB-10-02.

structural model (SM)structurally representative model of the flight model used for qualification of the structural design and for correlation with structural mathematical models -

1 The system structural model usually consists of a representative structure, with structural dummies of the flight equipment, and also includes representative mechanical parts of other subsystems (e.g. mechanisms and solar panels).

-

2 The system structural model is also used for final validation of test facilities, GSE, and associated procedures.

-

3 More detailed information on the build standard and the use of this model is given in ECSS-E-HB-10-02.

A deployable solar array is an equipment composed of one or several solar panels (panel substrate and photovoltaic assembly), deployment mechanism including hinges, restrain and release mechanism, and yoke.

Figure 32: Space segment examples

For the purpose of this standard, the following terms and definitions from ECSS-E-ST-10-02 apply:

commissioning

model philosophy

test

For the purpose of this Standard, the following terms and definitions from ECSS-E-ST-31 apply:

acceptance temperature range

minimum switch ON temperature

predicted temperature range

qualification temperature range

temperature reference point

For the purpose of this Standard, the following terms and definitions from ECSS-E-ST-32 apply:

burst pressure

design burst pressure

factor of safety

limit load (LL)

maximum design pressure (MDP)

proof factor

proof pressure

proof test

Terms specific to the present standard

24-hour equivalent noise exposure level

equivalent sound pressure level (Leq) to which the crew members are exposed over a 24-hour period; expressed in dBA

0 dBA corresponds to 20 µPa.

a-weighting

adjustments typically made to acoustic measurements to approximate the response of the human ear

abbreviated functional test (AFT)

See "reduced functional test (RFT)"

acceptance level

test level reflecting the maximum level expected to be encountered during the flight product lifetime increased by acceptance margins

acceptance margin

increase of the environmental, mechanical, thermal, electrical, EMC, or operational extremes above the worst case levels predicted over the specified product lifetime for the purpose of workmanship verification

- 1 Margins can include an increase in level or range, an increase in duration or cycles of exposure, as well as any other appropriate increase in severity.

- 2 For thermal acceptance margin refer also to ECSS-E-ST-31.

accuracy of measurement

degree of closeness between a measured quantity value and its true value

The accuracy depends from the measurement process (e.g. instrument or machine, operator, procedure; environmental conditions).

crewed space segment element

space segment design to ensure the safe presence of crew onboard

development test prior qualification

test to support the design feasibility and to assist in the evolution of the design

dwell time

duration necessary to ensure that internal parts or subassembly of a space segment equipment have achieved thermal equilibrium, from the start of temperature stabilisation phase, i.e. when the temperature reaches the targeted test temperature plus or minus the test tolerance

environmental tests

tests applied to a product simulating (together or separately) environmental conditions as encountered during its operational life cycle

Environmental tests cover natural and induced environments.

full functional test (FFT)

comprehensive test that demonstrates the integrity of all functions of the item under test, in all operational modes, including back-up modes and all foreseen transitions

-

1 The main objectives of this test is to demonstrate absence of design manufacturing and integration error.

-

2 FFT exists at the different level of decomposition of a space segment element. For satellite they also called system functional test (SFT) or integrated system test (IST).

maximum expected acceleration

acceleration value determined from the combined effects of the steady state acceleration and the transient response of the item as it will experience during its life time -

1 This term is equivalent to limit load (as defined in E-ST-32).

-

2 Examples of events during life time are transportation, handling, engine ignition, engine burnout, and stage separation.

maximum expected acoustic spectrum

maximum value of the time average root-mean-square (r.m.s.) sound pressure level (SPL) in each frequency band occurring inside the payload fairing, orbiter, or cargo bay, which occurs during flight events -

1 E.g. lift-off, powered flight or re-entry.

-

2 The maximum expected acoustic environment test spectrum is specified in octave or 1/3 octave bands over a frequency range of 31,5 Hz to 10 kHz. The duration of the maximum environment is the total period when the overall amplitude is within 6 dB of the maximum overall amplitude.

maximum expected shock

worst cases of the collection of the shock at their mounting interface due to every possible cause -

1 For example: causes of shocks are stage, shroud or satellite separation pyro elements, non-explosive actuators, mechanisms with energy release, appendage latching, and fuel valves.

-

2 Shocks can be characterized by their time histories, shock response spectrum, or impulse geometry.

-

3 Refer to ECSS-E-HB-32-25 for additional information.

maximum expected random vibration spectrum

maximum expected environment imposed on the space segment element and space segment equipment due to broad band random forcing functions within the launch element or space segment element during flight or from ground transportation and handling -

1 E.g. lift-off acoustic field, aerodynamic excitations, and transmitted structure-borne vibration.

-

2 A different spectrum can exist for different space segment equipment zones or for different axis. The space segment equipment vibration levels are based on vibration response measurements or model prediction made at the space segment equipment attachment points during ground acoustic tests or during flight. The duration of the maximum environment is the total period during flight when the overall level is within 6 dB of the maximum overall level.

-

3 The power spectral density is based on a frequency resolution of 1/6 octave (or narrower) bandwidth analysis, over a frequency range of 20 Hz to 2000 Hz.

maximum expected sinusoidal vibration environment

maximum expected environment imposed on the space segment element and space segment equipment due to sinusoidal and narrow band random forcing functions within the launch element or space segment element during flight or from ground transportation and handling

In flight, sinusoidal excitations are caused by unstable combustion, by coupling of structural resonant frequencies (POGO), or by imbalances in rotating space segment equipment in the launch element or space segment element. Sinusoidal excitations occur also during ground transportation and handling due to resonant responses of tires and suspension systems of the transporters.

multipaction

resonant back and forth flow of secondary electrons in a vacuum between two surfaces separated by a distance such that the electron transit time is an odd integral multiple of one half the period of the alternating voltage impressed on the surface

The effects of multipaction can be loss of output power up to reaching the multipaction breakdown voltage leading to the generation of spark.

notching

reduction of the input level or spectrum to limit structural responses at resonant frequencies according to qualification or acceptance loads during a vibration test

Notching is a general accepted practice in vibration testing to avoid over testing of the item under test. Implementation of notching is subject to customer approval and when relevant to Launcher authority approval

operational modes

combination of operational configurations or conditions that can occur during the product lifetime for space segment equipment or space segment element

For example: Power-on or power-off, command modes, readout modes, attitude control modes, antenna stowed or deployed, and spinning or de-spun.

performance test

test to verify that the item under test performs according to its specifications while respecting its operational requirements

Performance tests are mission specific therefore their details are not specified under this standard.

polarity test

test to verify the correct polarity of the functional chains (mainly AOCS) or equipment of the space segment element from sensors to actuators, through a number of interfaces and processing.

-

1 A polarity error can be generated throughout the development process: interface documentation, design, H/W manufacturing, S/W development, satellite AIT, satellite database.

-

2 A polarity error can be generated by any element of the functional chain: sensor or actuator design, sensor or actuator mounting, harness, interface units, software algorithms.

-

3 Polarity inversion on Safe Mode control loops can cause a satellite loss.

-

4 This term "sign test" is synonymous.

qualification level

test level reflecting the maximum level expected to be encountered during the flight product lifetime increased by qualification margins -

For thermal the qualification margin applies on top of the acceptance margin.

qualification margin

increase of the environmental, mechanical, electrical, EMC, or operational extremes above the worst case levels predicted over the specified product lifetime for the purpose of design margin demonstration -

1 Margins can include an increase in level or range, an increase in duration or cycles of exposure, as well as any other appropriate increase in severity.

-

2 This definition is not applicable for thermal aspects. Refer to ECSS-E-ST-31 for "qualification margin".

reduced functional test (RFT)

sub-set of the full functional test to verify the integrity of the major functions of the item under test, with a sufficiently high degree of confidence, in a relatively short time

* The term "abbreviated functional test (AFT)" is synonymous.

residual life

time left before a product is no longer able to achieve minimum acceptable performance requirements, including availability

Criteria can be estimated in terms of serviceability or structural strength for example.

resolution

minimum readable value of a quantity on a measurement system

The resolution is accounted for in the accuracy.

resonance search

frequency sweep of low level sinusoidal vibrations to characterise main resonant modes for preparing the higher level runs, and to show possible deficiencies in workmanship, as a consequence of high level runs

Resonance search is also known as “signature test”, “low level sinusoidal vibration test”, “low level sine sweep”, “low level sweep” or “low level test”.

reverberation time (T60)

duration necessary for the sound level to decrease by 60 dB after the switch off of the sound source

shock response spectrum (SRS)

graphical representation of a transient waveform determined by the response of a set of single degree of freedom oscillators using a defined amplification factor Q

- 1 The Shock Response Spectrum can be defined for any input or response parameters of interest (displacement, velocity, or acceleration). For aerospace structures it is common to define the input transient in terms of acceleration.

- 2 The acceleration amplification factor Q is conventionally chosen equal to 10, corresponding to a factor of critical damping equal to 5 %. In situations when damping is known, Q can be chosen accordingly.

- 3 The Shock Response Spectrum allows characterizing the shock effect in order to estimate its severity or its damaging potential.

- 4 There are several representations of Shock Response Spectrum, including positive, negative, primary, residual and maximax. The latter SRS envelopes the previous four and is the most commonly used for shock testing.

sign test

see “polarity test”

temperature cycle

transition from an initial temperature to the same temperature, with excursion within a specified range

test block

aggregation of several tests grouped by discipline

tolerance

limiting or permitted range of values of a specified test level without affecting the test objectives

The tolerance is typically specified as deviation from a specified value, or as an explicit range of allowed values. Tolerance can be symmetrical, as in 40 ±0,1, or asymmetrical, such as 40 -0,2/+0,1.

Abbreviated terms

For the purposes of this Standard the following abbreviated terms apply.

|

Abbreviation

|

Meaning

|

|

AFT

|

abbreviated functional test

|

|

AIT

|

assembly, integration and test

|

|

AITP

|

assembly, integration and test plan

|

|

AIV

|

assembly, integration and verification

|

|

AVT

|

acceptance vibration test

|

|

CCB

|

configuration control board

|

|

CoG

|

centre of gravity

|

|

DRD

|

document requirements definition

|

|

EC

|

European Commission

|

|

EGSE

|

electrical ground support equipment

|

|

EM

|

engineering model

|

|

EMC

|

electromagnetic compatibility

|

|

EMCCP

|

electromagnetic compatibility control plan

|

|

EQM

|

engineering qualification model

|

|

ESD

|

electrostatic discharge

|

|

FFT

|

full functional test

|

|

FM

|

flight model

|

|

FOP

|

flight operation plan

|

|

GSE

|

ground support equipment

|

|

HFE

|

human factors engineering

|

|

HMI

|

human-machine interface

|

|

ICD

|

interface control document

|

|

KIP

|

key inspection point

|

|

LCDA

|

launcher coupled dynamic analysis

|

|

LEOP

|

launch and early orbit phase

|

|

MDP

|

maximum design pressure

|

|

MIP

|

mandatory inspection point

|

|

MoI

|

moment of inertia

|

|

NC

|

noise criterion

|

|

NCR

|

nonconformance report

|

|

NRB

|

nonconformance review board

|

|

OSPL

|

overall sound pressure level

|

|

PFM

|

protoflight model

|

|

PIM

|

passive intermodulation

|

|

PSD

|

power spectral density

|

|

PT

|

performance test

|

|

PTR

|

post test review

|

|

QM

|

qualification model

|

|

r.m.s.

|

root-mean-square

|

|

RF

|

radio frequency

|

|

RFT

|

reduced functional test

|

|

SEP

|

system engineering plan

|

|

SFT

|

system functional test

|

|

SPL

|

sound pressure level

|

|

SRS

|

shock response spectrum

|

|

SVT

|

system validation test

|

|

TB

|

thermal balance

|

|

TC

|

telecommand

|

|

TCS

|

thermal control system

|

|

TM

|

telemetry

|

|

TPRO

|

test procedure

|

|

TR

|

test review

|

|

TRB

|

test review board

|

|

TRP

|

temperature reference point

|

|

TRPT

|

test report

|

|

TRR

|

test readiness review

|

|

TV

|

thermal vacuum

|

|

TQ

|

qualification temperature

|

|

TA

|

acceptance temperature

|

|

TD

|

design temperature

|

|

TOp

|

operating temperature

|

|

TNOp

|

non-operating temperature

|

|

TSPE

|

test specification

|

|

TT&C

|

telemetry, tracking and command

|

|

TWT

|

travelling wave tube

|

|

VCD

|

verification control document

|

|

VP

|

verification plan

|

General requirements

Test programme

A coherent test programme shall be established, encompassing each verification stage and level to implement the verification by testing.

- 1 The testing programme is performed incrementally at different product decomposition levels.

- 2 Refer to clause 3.1 for determining the type of item for which the test programme is defined (i.e. space segment equipment or space segment element), in particular the example table.

- 3 The number and type of testing levels depends upon the complexity of the project and on its characteristics in accordance with the Verification programme (see ECSS-E-ST-10-02).

- 4 The test programme documentation is defined in 4.3.3.

The customer and the supplier shall agree the need to treat a space segment element as a space segment equipment.

This is typically the case for small instrument.

AITP and test specifications shall be derived from the product requirements, verification plan and verification control document (VCD).

Verification plan and VCD are defined in ECSS-E-ST-10-02.

Test procedures shall be derived from test specifications and AITP.

Test programme and its implementation shall be in conformance with safety requirements of ECSS-Q-ST-40 and ECSS-Q-ST-20-07.

Development test prior qualification

Development test of a product shall be completed prior to the start of its formal qualification testing.

- Development tests are conducted over a range of operating conditions that can exceed the design range.

Development tests shall not be conducted on qualification or flight models or parts of it.

Records of test configuration, test results and other pertinent data shall be maintained.

This kind of information can be used for investigation when failure occurs during the qualification and acceptance, or for other investigations.

Test management

General

The supplier shall assign clear responsibility for the implementation of the test programme.

The customer, or its duly appointed representative, shall have the right to participate to all test phases.

Test reviews

Test programme

The test programme shall be decomposed in blocks.

The general test programme is reviewed at the CDR as per ECSS-M-ST-10.

The definition of the blocks of requirement 4.3.2.1a shall be agreed between the customer and supplier.

- 1 Test block definition depends mainly on the item under test, the facility and the contractual agreement. A test block can include one or more tests. For equipment, usually one test block covers the full test programme.

- 2 Typical test blocks for space segment elements are:

- Integration

- Alignment

- Leak/proof pressure

- Mechanical (Static load test, sinusoidal, acoustic, random, modal survey, shock)

- EMC conducted

- EMC radiated/auto-compatibility/RF

- Thermal (TB/TV test)

- Functional and performance test

- Final preparation

Each test block shall include the following formal reviews: - test readiness review (TRR);

- post test review(s) (PTR);

- test review board (TRB).

- 1 TRRs from several blocks can be combined, TRRs can also be combined with a PTR of the previous block.

- 2 Depending on the nature of the test, the customer can decide to establish additional key-points between formal reviews. Typical examples are transition between level and axes in vibration tests and transition between test phases in TV/TB tests.

Test readiness review (TRR)

A TRR shall be held before the start of the test activity to verify that all conditions allow to proceed with the test.

The TRR shall address the following topics:

- test documentation availability and suitability, including:

- approved AITP,

- approved test specification,

- test predictions (when relevant),

- approved test procedures (including contingency and emergency procedures),

- approved measurement point plan,

- approved test facility readiness report,

- approved test schedule, and

- acceptance data package of lower level items.

- item under test configuration;

- test configuration/set-up;

- inspection status report of KIP, MIP, or both;

- test facility, environmental conditions, test instrumentations, calibration, maintenance status;

- cleanliness condition, hazard and safety;

- ground support equipment (GSE) and infrastructures;

- status of nonconformances that affect the item under test, its associated GSE, or the test facility;

- waivers status, and deviations;

- personnel qualification and availability;

- results from test rehearsal using the test facility with or without the item under test, when relevant;

- test pass/fail criteria completeness;

- assignment of responsibilities;

- test schedule.

- 1 For 4.3.2.2b.1(f), the content of the facility readiness report is defined in ECSS-Q-ST-20-07.

- 2 The level of details according to which each topic is addressed, is different for the general test programme TRR than for each block test TRR.

The following parties shall participate to the TRR: - the chairperson, who is the product assurance manager of the authority responsible for the test;

- product assurance from all involved parties;

- project engineer from all involved parties;

- AIT from all involved parties;

- specialists, when necessary from all involved parties;

- facility representative;

- other as relevant.

For example launcher authority for tests related to launcher interface or other company representative that will take over the responsibility of the hardware after delivery.

All the open points shall be clearly identified and actions assigned with closure date before the execution of the test.

The output of the TRR shall be a decision to proceed with the test or not.

Post test review (PTR)

A PTR shall be held in order to formally declare the test completed and allow the release of the item under test and test facility for further activity.

The release of the test facility includes the breaking of the test configuration.

The PTR shall address the following topics:

- verification that all test data were acquired, recorded, and archived in conformance with the test specification and test procedure requirements;

- verification that the process for test anomalies and NCRs, raised during the test, was initiated, and all needed inspection, test data and test configuration were acquired;

- confirmation that tests were performed according to the AITP, the test specification and the test procedures, with the exceptions of what is covered by agreed procedure variations or NCRs;

- status of compliance of the item under test to the relevant requirement;

- post test status of GSE;

- post item under test configuration based on inspection and cleanliness report;

- identification of the open points with assignment of actions for their closure, as well as lessons learned drawn. The following parties shall participate to the PTR:

- product assurance;

- project engineer;

- AIT;

- facility representative;

- other, including specialist, as relevant.

For example launcher authority for tests related to launcher interface or other company representative that will take over the responsibility of the hardware after delivery.

Test review board (TRB)

A TRB shall be held to review all results and conclude on the test completeness and achievement of objectives.

The TRB shall address the following topics:

- test documentation availability, including:

- test report as per ECSS-E-ST-10-02 Annex C,

- facility report when relevant,

- inspection report including cleanliness report,

- list of NCRs,

- copy of NCRs raised during test with the related NRB minutes of meeting, and associated request(s) for waiver, and

- list of procedure deviations.

- compliance with the test specification, and variations to the AITP;

- status of compliance of the item under test to the relevant requirement;

- post test status of GSE;

- post item under test configuration based on inspection and cleanliness report;

- review of all still open NCRs raised during test in order to assess that there is no impact on the test objectives achievement;

- lessons learned to be drawn. The following parties shall participate to the TRB:

- product assurance;

- project engineer;

- AIT;

- facility representative;

- other, including specialist, as relevant.

For example launcher authority for tests related to launcher interface or other company representative that will take over the responsibility of the hardware after delivery.

Test documentation

General

Clauses 4.3.3.2 to 4.3.3.5 define the Test programme documentation (AITP, Test specification, Test procedure, and Test report) generated at all product levels.

These documents are derived from the System Engineering Plan (SEP) and from the Verification Plan (VP).

Assembly, integration and test plan (AITP)

The supplier shall establish the AITP in conformance with the DRD in Annex A.

At space segment equipment level, the AITP can be called test plan.

The agreed AITP shall be available, at the latest, for the TRR of the test programme.

The way the requirement 4.3.3.2b is achieved shall be agreed between the customer and the supplier.

Test specification (TSPE)

The supplier shall establish the test specification in conformance with the DRD in Annex B.

The agreed test specification shall be available at the relevant test block TRR and on time to allow procedure preparation.

The way the requirement 4.3.3.3b is achieved shall be agreed between the customer and the supplier.

Test procedure (TPRO)

The supplier shall establish the test procedure in conformance with the DRD in Annex C.

The test procedure, derived from the agreed test specification, shall be available at the relevant test block TRR.

The way the requirement 4.3.3.4b is achieved shall be agreed between the customer and the supplier.

Test report (TRPT)

The supplier shall establish the test report in conformance with the DRD in Annex C of ECSS-E-ST-10-02.

The test report describes test execution, results and conclusions in the light of the test requirements. It contains the test description and the test results including the as-run test procedures, the considerations and conclusions with particular emphasis on the close-out of the relevant verification requirements including any deviation.

The test report shall be available prior to the TRB.

Anomaly or failure during testing

Any failure or anomaly during testing shall be recorded.

All nonconformances shall be managed in conformance with ECSS-Q-ST-10-09.

The NRB shall decide on the necessity and extent of any retest activity in order to demonstrate the correctness of the disposition made.

Test data

Test measurements and the environmental conditions shall be recorded for subsequent evaluation.

A database of parameters shall be established for trend analysis.

Trend analysis shall be performed using test data acquired across test sequences.

Test conditions, tolerances, and accuracies

Test conditions

Test conditions shall be established using predicted environment plus margins.

This can be done using previous mission flight data, relevant ground environments, analytical prediction, relevant previous test results, or a combination thereof.

Tests shall be performed simulating the mission envelope, including operational and non-operational conditions with margins.

For items tested in an environment different from the one it is expected to operate, the possible differences in behaviour shall be accounted for in the test levels and duration.

In this case, the test levels and duration are modified based on analyses. For example to prevent effects of convective heat transfer that reduce thermal gradients.

Cleanliness and contamination control for test programmes shall conform to ECSS-Q-ST-70-01.

The quality and safety management system used to operate and maintain test facility(ies) shall be recognized by the customer.

As example, in accordance to quality and safety management system requirements from ECSS-Q-ST-20-07.

Test facilities, tools and instrumentation shall not prevent to fulfil the tests objectives.

The EGSE or other support systems of the item under test shall:

- not jeopardize the results of tests;

- be immune to signals used for susceptibility tests;

- be designed to comply with the applicable legislation, including safety (e.g. EC Directives). The combination of test set-up, test levels durations, and operational modes shall not create conditions that can:

- induce failures of the item under test,

- lead to rejection of adequate item under test, or

- create hazardous conditions.

Test tolerances

Test tolerances bands shall be specified in test error budgets and agreed by the customer prior to start of test.

For the purpose of 4.4.2a test tolerances shall be justified by reference to the uncertainty budget and confidence level of the measurement instrument(s) used.

- 1 EA-4/16 and EA-4/02 (section 2) guidelines can be used to build up the uncertainty budget.

- 2 The tolerances specified in Table 41 are the allowable ranges within which the test parameters can vary, they include instrumentation accuracy.

Quantitative requirements demonstrated by measured test values shall account for test inaccuracies and tolerances, and be compared with the specified requested values.

The tolerances specified in Table 41 shall be applied to the test values.

Changes to the tolerances specified in Table 41 shall be approved by the customer.

For example, when tolerances of Table 41 are detected to be inconsistent with test accuracy values of Table 42.

Table 41: Allowable tolerances

|

Test parameters

|

Tolerances

|

|

1. Temperature

|

Low High

|

|

above 80K

|

Tmin +0/-4 K Tmax -0/+4 K

|

|

|

|

|

T< 80 K

|

Tolerance to be defined case by case

|

|

2. Relative humidity

|

± 10 %

|

|

3. Pressure (in vacuum chamber)

|

|

|

> 1,3 hPa

|

± 15 %

|

|

1,3 10-3 hPa to 1,3hPa

|

± 30 %

|

|

< 1,3 10-3 hPa

|

± 80 %

|

|

4. Acceleration (steady state) and static load

|

-0 / +10 %

|

|

5. Sinusoidal vibration

|

|

|

Frequency (5 Hz to 2000 Hz)

|

± 2 % (or ±1 Hz whichever is greater)

|

|

Amplitude

|

± 10 %

|

|

Sweep rate (Oct/min)

|

± 5 %

|

|

6. Random vibration

|

|

|

Amplitude (PSD, frequency resolution better than 10Hz)

|

|

|

20 Hz - 1000 Hz

|

-1 dB / +3 dB

|

|

1000 Hz - 2000 Hz

|

± 3 dB

|

|

Random overall g r.m.s.

|

± 10 %

|

|

7. Acoustic noise

|

|

|

Sound pressure level, Octave band centre (Hz)

|

|

|

31,5

|

-2 dB /+4 dB

|

|

63

|

-1 dB /+3 dB

|

|

125

|

-1 dB /+3 dB

|

|

250

|

-1 dB /+3 dB

|

|

500

|

-1 dB /+3 dB

|

|

1000

|

-1 dB /+3 dB

|

|

2000

|

-1 dB /+3 dB

|

|

Overall

|

-1 dB /+3 dB

|

|

Sound pressure level homogeneity per octave band

|

+/- 2 dB

|

|

8. Microvibration

|

|

|

Acceleration

|

±10 %

|

|

Forces or torque

|

±10 %

|

|

9. Audible noise (for Crewed Element only)

|

|

|

Sound-power (1/3 octave band centre frequency)

|

|

|

32,5 Hz - 160 Hz

|

±3 dB

|

|

160 Hz – 16 kHz

|

±2 dB

|

|

9. Shock

|

|

|

Response spectrum amplitude (1/12 octave centre frequency or higher)

|

|

|

Shock level

|

- 3 dB/ + 6 dB

|

|

10. Solar flux

|

|

|

in reference plane

|

± 4 % of the set value

|

|

in reference volume

|

± 6 % of the set value

|

|

11. Infrared flux

|

|

|

Mean value

|

± 3 % on reference plane(s)

|

|

12. Test duration

|

-0/+10 %

|

Test accuracies

Test accuracies shall be specified in test error budgets and agreed by the customer prior to test performance.

EA-4/16 and EA-4/02 (section 2) guidelines can be used to build up the overall test measurement accuracy.

The accuracy of test instrumentation shall be verified in accordance with approved calibration procedures, with traceability to international measurement standards.

All test instrumentation shall be within the normal calibration period at the time of the test.

Any anomaly of test instrumentation, detected at the first calibration sequence after the test, shall be reported.

The accuracy of measurement shall be as follows:

- as per Table 42 for the parameters listed, or

- at least one third of the tolerance of the variable to be measured.

The values of Table 42 are typical from test centre capabilities.

Table 42: Test accuracies

|

Test parameters

|

Accuracy

|

|

1. Mass

|

|

|

Space segment equipment and space segment element

|

± 0,05 % or 1 g whatever is the heavier

|

|

2. Centre of gravity (CoG)

|

|

|

Space segment equipment

|

Within a 1 mm radius sphere

|

|

Space segment element

|

± 2,5 mm along launch axis± 1 mm along the other 2 axes

|

|

3. Moment of inertia (MoI)

|

|

|

Space segment equipment and Space segment element

|

± 3 % for each axis

|

|

4. Leak rate

|

One magnitude lower than the system specification, in Pa m3 s-1 at standard conditions (1013,25 Pa and 288,15 K).

|

|

5. Audible noise (for Crewed Element only)

|

|

|

32,5 Hz to 160 Hz

|

± 3 dB

|

|

160 Hz to 16 kHz

|

± 2 dB

|

|

6. Temperature

|

|

|

above 80 K

|

± 2 K

|

|

T< 80 K

|

Accuracy to be defined case by case

|

|

7. Pressure (in vacuum chamber)

|

|

|

> 1,3 hPa

|

± 15 %

|

|

1,3 10-3 hPa to 1,3 hPa

|

± 30 %

|

|

< 1,3 10-3 hPa

|

± 80 %

|

|

8. Acceleration (steady state) and static load

|

± 10 %

|

|

9. Frequency for mechanical tests

|

± 2 % (or ±1 Hz whichever is greater)

|

|

10. Acoustic noise

|

± 0,1dB

|

|

11. Strain

|

± 10 %

|

|

12. EMC

|

See ECSS-E-ST-20-07 clause 5.2.1.

|

|

13. ESD

|

See ECSS-E-ST-20-06

|

Test objectives

General requirements

The test programme shall be defined taking into account the agreed model philosophy.

The model philosophy, including model definition, is detailed in ECSS-E-HB-10-02.

When preparing the overall test programme of a space segment element tests linked to compatibility with ground and launch segment shall also be included.

This covers in particular the system validation test.

Qualification testing

Qualification testing shall be performed to provide evidence that the space segment element or equipment performs in accordance with its specifications in the intended environments with the specified qualification margins.

- 1 The Qualification test programme requirements are defined in ECSS-E-ST-10-02 requirement 5.2.4.2b. and 5.2.4.2c.

- 2 This evidence is used, further to analysis as relevant, to provide via verification reports (defined in ECSS-E-ST-10-02 Annex F) the elements for the close-out of the VCD (defined in ECSS-E-ST-10-02 Annex B).

Qualification testing shall be conducted on dedicated qualification models except when using protoflight approach.

Qualification testing shall be completed and design improvements or modification incorporated and qualified prior to the authorization for the flight product manufacturing.

Upon achievement of qualification the design files shall not be modified.

In case destructive tests are needed (e.g. Burst test), a representative model different from the QM shall be used or the test shall be performed at the end of the qualification programme.

This model can be simplified but needs to fully represent the function tested.

The qualification test levels and durations shall be as specified in Table 52 for space segment equipment and in Table 62 for space segment element.

The test durations identified in Table 52 and Table 62 are the minimum values.

Acceptance testing

Acceptance testing shall be performed to provide evidence that the space segment element or equipment performs in accordance with the specifications in the intended environments with the specified acceptance margins.

This evidence is used, further to analysis as relevant, to provide via verification reports (defined in ECSS-E-ST-10-02 Annex F) the elements for the close-out of the VCD (defined in ECSS-E-ST-10-02 Annex B).

Acceptance testing shall be performed on each flight product, except the one used as Protoflight, to assure freedom from workmanship defects and flawed materials in conformance with ECSS-E-ST-10-02.

The acceptance programme shall be performed, after a qualification programme has been completed (as per clause 4.5.2 or clause 4.5.4).

The FM is built from the same design file than the QM or the PFM used for qualification, as specified in the ECSS-E-ST-10-02 clause 5.2.4.3.

The acceptance test levels and durations shall be as specified in Table 54 for space segment equipment, and in Table 64 for space segment element levels.

The test durations identified in Table 54 and Table 64 are the minimum values.

Protoflight testing

Overview

Protoflight testing is the combination of the qualification and acceptance testing objectives on the first flight model.

The protoflight approach can be applied at each level of decomposition of space system.

To minimize risk, a space segment elements protoflight approach can include test(s) on dedicated model(s), which can later be refurbished in PFM. An example of this is the development of a Structural Model for early mechanical qualification.

Requirements

Protoflight testing shall be performed on the first flight model to provide evidence that the space segment element or equipment performs in accordance with the specifications in the intended environments with the specified qualification margins and to confirm its readiness for delivery and subsequent usage, being free from workmanship defects and flawed materials.

This evidence is used, in addition to analysis as relevant, to provide via verification reports (defined in ECSS-E-ST-10-02 Annex F) the elements for the close-out of the VCD (defined in ECSS-E-ST-10-02 Annex B).

In case destructive tests are needed (e.g. Burst test), a representative model different from the PFM shall be used.

This model can be simplified but needs to fully represent the function tested.

The protoflight test levels and durations shall be as specified in Table 56 for space segment equipment and in Table 66 for space segment element levels.

- 1 The general approach is to select:

- test levels: as qualification levels;

- test durations: as acceptance durations.

- 2 The test durations identified in Table 56 and Table 66 are the minimum values.

Retesting

Overview

ECSS-E-ST-10-02 identifies several situations, in which re-verification is required. However, as the scope and the nature of retesting differ so much, test requirements are defined on a case-by-case basis. Examples of cases involving retesting are described in clauses 4.6.2 to 4.6.5 below.

Implementation of a design modification after completion of qualification

The configuration control board (CCB), as per ECSS-M-ST-40, shall convene to evaluate and decide the extent of the qualification test sequence to be repeated.

Storage after protoflight or acceptance testing

The supplier shall identify the testing requirements during storage and post-storage.

These requirements can be presented in the user manual.

Periodic tests shall be assessed and performed with a frequency accounting for:

- space segment equipment degradation, and

- specific personnel know-how maintenance. Storage configuration shall be agreed with the customer in particular for the deployable mechanisms.

If deployable mechanisms are stored assembled with the space segment elements, the flight tension can be reduced.

The periodic tests during storage shall cover:

- overall functional test,

- testing of the rotating parts,

- power consumption measurement,

- TT&C space segment subsystem through tests caps (space segment element switched ON),

- testing of the propulsion space segment subsystem pressure through the telemetry,

- visual inspection of the separately stored space segment equipment in a suitable clean work area,

- contamination tests on the contamination probes.

Example of age sensitive space segment equipment: Travelling wave tubes (TWTs), batteries and special lubricated mechanisms valves and motors.

Any additional test to the one listed in 4.6.3d shall be identified for customer approval.

The storage procedure shall be submitted to the customer for approval.

Solar array(s) should be stored in a gaseous Nitrogen environment.

This recommendation is also relevant for the solar panels integrated with the photovoltaic assembly, during any transportation phase, and during any long term storage phase after a successful solar panel DRB (Delivery Review Board).

Space segment element or equipment to be re-flown

Space segment element or equipment to be re-flown shall be re-tested before the new flight in accordance with the verification programme and acceptance criteria defined for the new mission.

High level (system or element) functional testing shall be performed in preference to individual low level tests.

Post-landing testing is performed on space products to be recovered at the end of mission and on products which are re-flown.

Flight use of qualification Space segment element or equipment

Use of qualification space segment element or equipment shall not be allowed unless agreed by the customer.

Additional testing of qualification space segment element or equipment subsequently selected for flight shall be compatible with the residual life.

This is done when the customer considers the risk acceptable.

In case of refurbishment or disassembly the qualification space segment element or equipment shall be subjected to an acceptance re-testing to be agreed with the customer.

The extend of the acceptance testing depends on the item past history and on the extend of the modification.

Space segment equipment test requirements

General requirements

The test baseline and sequencing shall be tailored to the specific space segment equipment type for each project.

The types of space segment equipment are uniformly listed at the end of Table 51, Table 53, and Table 55.

Where space segment equipment falls into two or more types, the combination of all required tests specified for each type shall be applied.

For example: A star sensor can be considered to fit both “electronic space segment equipment” and “optical space segment equipment” types, therefore, an EMC test is conducted since it is applicable for electronic space segment equipment, even though there is no requirement for optical space segment equipment.

The test sequence shall be performed, taking into account tests’ applicability, as defined for qualification in Table 51, for acceptance in Table 53, for protoflight in Table 55.

This sequence reflects the principle “Test as you fly”. It is based on a combination of:

- the order in which the environments are encountered during flight, and

- the capability to identify defects as early as possible in the test sequence.

Any unusual or unexpected behaviour shall be evaluated to determine the existence of any trend potentially leading to anomaly or failure situation.

PT and FFT shall be performed at the beginning and at the end of the test programme under ambient conditions.

Those tests provide the criteria for judging the integrity of the space segment equipment thought the overall test programme. The results of both tests should be identical within the test tolerances.

RFT shall be performed before and after each environmental test block as well as before and after transportation.

This test allows verifying the integrity of the space segment equipment.

PT, FFT or RFT, as relevant, shall be performed:

- during thermal test(s), or

- when the space segment equipment is expected to be operational under another type of imposed environment.

The test definition corresponds to the expected operation of the item when the environment is being imposed.

Space segment equipment, if operated during ascent and descent, shall be powered and configured in the corresponding operating mode during the environmental tests and parameters monitored to detect intermittent or persistent failures during the test.

Any space segment equipment pressurized during ascent shall be tested as specified in ECSS-E-ST-32-02 clause 5.4.4, and verified for internal pressure decay.

Adjustable protection functions shall be tested.

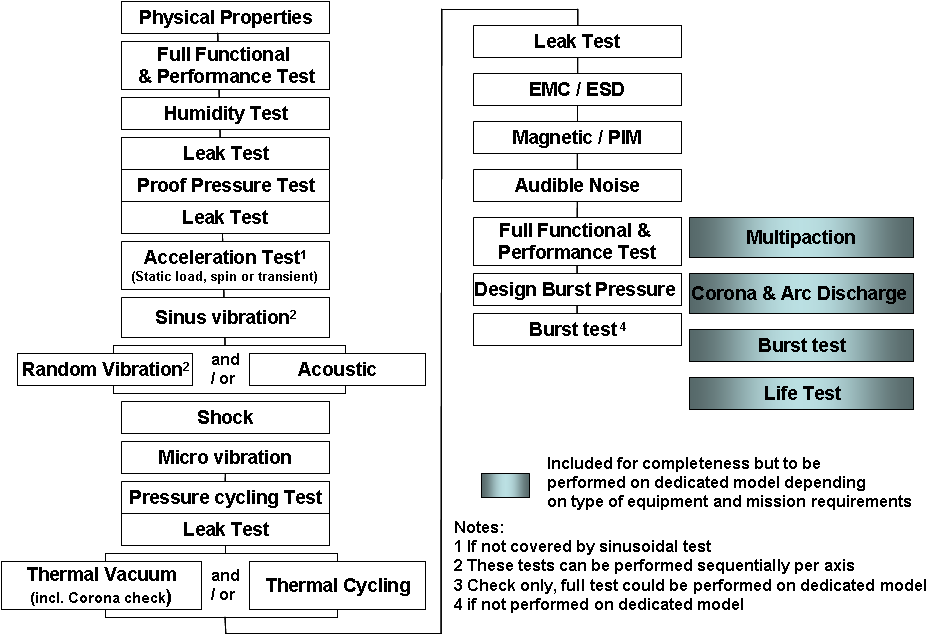

Figure 51: Space segment equipment test sequence

Figure 51: Space segment equipment test sequence

Qualification tests requirements

The space segment equipment qualification test baseline shall consist of the tests specified in Table 51 in line with requirement 5.1b, according to the type of the space segment equipment.

Table 51: Space segment equipment - Qualification test baseline

|

Test

|

Reference clause

|

Ref. to Level & Duration

|

Applicability versus types of space segment equipment

|

Application notes

| ||||||||||||||||

|

a

|

b

|

c

|

d

|

e

|

f

|

g

|

h

|

i

|

j

|

k

|

l

|

|

||||||||

|

General

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Functional and performance (FFT/RFT)

|

5.5.1.1

|

|

R

|

R

|

R

|

R

|

R

|

R

|

R

|

R

|

R

|

R

|

R

|

R

|

For k (solar array), the deployment test is mandatory before and after the environmental tests (manual deployment before the environmental tests).

| |||||

|

Humidity

|

5.5.1.2

|

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

-

|

X

|

For k (solar array) and l (solar panel), see ECSS-E-ST-20-08.

| |||||

|

Life

|

5.5.1.3

|

See Table 52 No 1

|

X

|

X

|

R

|

R

|

X

|

X

|

R

|

X

|

X

|

R

|

-

|

-

|

To be performed on dedicated model.

| |||||

|

Burn-in

|

5.5.1.4

|

|

X

|

-

|

-

|

X

|

-

|

-

|

X

|

-

|

-

|

-

|

-

|

-

|

The test is performed in parallel with other funct. & environm. tests.

| |||||

|

Mechanical

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Physical properties

|

5.5.2.1

|

|

R

|

R

|

R

|

R

|

R

|

R

|

R

|

R

|

R

|

R

|

R

|

R

|

Upon agreement with customer the CoG and MoI is not measured by test but calculated.

| |||||

|

Static load

|

5.5.2.2

|

See Table 52 No 2

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

-

|

One of the three types of test is performed if not covered by the sinusoidal vibration test.

| |||||

|

Spin

|

5.5.2.2

|

See Table 52 No 3

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

-

| ||||||

|

Transient

|

5.5.2.2

|

See Table 52 No 4

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

-

| ||||||

|

Random vibration

|

5.5.2.3

|

See Table 52 No 5

|

R

|

X

|

R

|

R

|

R

|

R

|

R

|

R

|

X

|

X

|

X

|

-

|

For k (solar array), the random vibration test should be added to acoustic test for fixed solar array mounted directly to the spacecraft side wall (without offset bracket).

| |||||

|

Acoustic

|

5.5.2.4

|

See Table 52 No 6

|

-

|

X

|

-

|

-

|

-

|

-

|

-

|

-

|

X

|

X

|

R

|

-

| ||||||

|

Sinusoidal vibration

|

5.5.2.5

|

See Table 52 No 7

|

R

|

R

|

R

|

R

|

R

|

R

|

R

|

R

|

R

|

R

|

R

|

-

|

|

|||||

|

Shock

|

5.5.2.6

|

See Table 52 No 8

|

R

|

X

|

R

|

R

|

R

|

X

|

R

|

X

|

R

|

R

|

-

|

-

|

If it is demonstrated that the susceptibility to shock of the space segment equipment is above the shock environment, the test needs not to be performed.

| |||||

|

Micro-vibration generated environment

|

5.5.2.7

|

|

X

|

X

|

-

|

X

|

X

|

-

|

X

|

-

|

-

|

X

|

-

|

-

|

Test to be performed only if need is identified by analysis.

| |||||

|

Micro-vibration susceptibility

|

5.5.2.8

|

See Table 52 No 9

|

X

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

X

|

X

|

-

|

-

|

Test to be performed only if need is identified by analysis.

| |||||

|

Structural integrity

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Leak

|

5.5.3.1

|

See Table 52 No 10

|

X

|

-

|

R

|

R

|

R

|

R

|

X

|

X

|

-

|

-

|

-

|

-

|

Leak and pressure tests may be combined.

| |||||

|

Proof pressure

|

5.5.3.2

|

See Table 52 No 11

|

X

|

-

|

-

|

R

|

R

|

R

|

R

|

-

|

-

|

-

|

-

|

-

| ||||||

|

Pressure cycling

|

5.5.3.3

|

See Table 52 No 12

|

X

|

-

|

-

|

R

|

R

|

R

|

R

|

-

|

-

|

-

|

-

|

-

| ||||||

|

Design burst pressure

|

5.5.3.4

|

See Table 52 No 13

|

X

|

-

|

-

|

R

|

R

|

R

|

R

|

-

|

-

|

-

|

-

|

-

|

|

|||||

|

Burst

|

5.5.3.5

|

See Table 52 No 14

|

X

|

-

|

-

|

R

|

R

|

R

|

R

|

-

|

-

|

-

|

-

|

-

|

To be performed on dedicated model or at the end of the QM programme.

| |||||

|

Thermal

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Thermal vacuum

|

5.5.4.1 & 5.5.4.2

|

See Table 52 No 15

|

R

|

X

|

R

|

R

|

R

|

X

|

R

|

R

|

R

|

R

|

-

|

R

|

|

|||||

|

Thermal ambient

|

5.5.4.1 & 5.5.4.3

|

See Table 52 No 16

|

R

|

X

|

R

|

R

|

R

|

X

|

R

|

R

|

R

|

R

|

-

|

-

|

For l (solar panels), the thermal tests at ambient pressure are applicable only to the DVT (Design Verification Test) coupon - see ECSS-E-ST-20-08).

| |||||

|

Electrical / RF

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

EMC

|

5.5.5.1

|

See Table 52 No 17

|

R

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

For equipment without electronic test are limited to Bonding test.

| |||||

|

Magnetic

|

5.5.5.2

|

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

Magnetic test to be performed if justified by mission needs, in accordance with the EMCCP.

| |||||

|

ESD

|

5.5.5.3

|

See Table 52 No 19

|

R

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

For k (solar array) and l (solar panels), the ESD test is covered by the ECSS-E-ST-20-08.

| |||||

|

PIM

|

5.5.5.4

|

See Table 52 No 19

|

X

|

X

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

|

|||||

|

Multipaction

|

5.5.5.5

|

|

X

|

X

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

To be performed on dedicated model.

| |||||

|

and arc discharge

|

5.5.5.6

|

See Table 52 No 20

|

R

|

R

|

R

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

To be performed on dedicated model.

| |||||

|

specific

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Audible noise

|

5.5.6.1

|

|

R

|

-

|

-

|

R

|

R

|

-

|

R

|

-

|

-

|

R

|

-

|

-

|

Required for space segment equipment for crewed space segment element.

| |||||

|

Types of space segment equipment

|

Key

| |||||||||||||||||||

|

a Electronic, electrical and RF equipment

|

d Valve

|

g Thruster

|

j Mechanism

|

R Required

| ||||||||||||||||

|

NOTE 1: Tests are categorized into “R” or “X” depending on the sensitivity of the space segment equipment type to the specific environment, the probability of encountering the environment, and project specificity.

| ||||||||||||||||||||

Table 52: Space segment equipment - Qualification test levels and duration

|

No

|

Test

|

Levels

|

Duration

|

Number of applications

|

NOTES

|

|

1

|

Life

|

Expected environment and maximum operational load

|

For duration and cycles:

|

1 test

|

|

|

2

|

Static load

|

KQ x Limit Load

|

As needed to record data (10 seconds minimum)

|

Worst combined load cases

|

Worst combined load cases are determined by analysis

|

|

3

|

Spin

|

x spin rate

|

As specified by the project

|

1 test

|

|

|

4

|

Transient

|

KQ x Limit Load

|

As needed to record data

|

As specified

|

|

|

5

|

Random vibration

|

Maximum expected spectrum +3 dB on PSD values

|

2 minutes

|

On each of 3 orthogonal axes

|

|

|

6

|

Acoustic

|

Maximum expected acoustic spectrum +3 dB

|

2 minutes

|

1 test

|

|

|

7

|

Sinusoidal vibration

|

KQ x Limit Load Spectrum

|

sweep at 2 Oct/min,

|

On each of 3 orthogonal axes

|

|

|

8

|

Shock

|

Maximum expected shock spectrum +3 dB qualification margin

|

Duration representative of the expected environment

|

The number of shock application covering the complete life cycle of the FM H/W in all 3 orthogonal axes.

|

NOTE 1: Qualification programme test of space segment elements can include a test where the shock generative device is activated. This test is performed with no margins to consolidate the shock specification of the space segment equipment.

|

|

9

|

Microvibration susceptibility

|

Maximum predicted environment

|

As needed for susceptibility determination

|

As specified by the project.

|

|

|

10

|

Leak

|

MDP

|

pressure maintained for 30 minutes as minimum

|

In conformance with Figure 51.

|

|

|

11

|

Proof pressure

|

jproof x MDP

|

5 minutes minimum hold time

|