Space engineering

Photovoltaic assemblies and components

Foreword

This Standard is one of the series of ECSS Standards intended to be applied together for the management, engineering and product assurance in space projects and applications. ECSS is a cooperative effort of the European Space Agency, national space agencies and European industry associations for the purpose of developing and maintaining common standards. Requirements in this Standard are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards.

This Standard has been prepared by the ECSS-E-ST-20-08C Rev.1 Working Group, reviewed by the ECSS Executive Secretariat and approved by the ECSS Technical Authority.

Disclaimer

ECSS does not provide any warranty whatsoever, whether expressed, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item are error-free. In no respect shall ECSS incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this Standard, whether or not based upon warranty, business agreement, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by ECSS.

Published by: ESA Requirements and Standards Division

ESTEC, ,

2200 AG Noordwijk

The

Copyright: 2012 © by the European Space Agency for the members of ECSS

Change log

|

ECSS-E-20-08A

|

First issue

|

|

ECSS-E-20-08B

|

Never issued

|

|

ECSS-E-ST-20-08C

|

Second issue

|

|

ECSS-E-ST-20-08C Rev.1

|

Second issue Revision 1

|

Introduction

The qualification, procurement, storage and delivery of space solar arrays are defined in the dedicated solar array specification, where requirements for the solar array electrical layout, structure and mechanism are specified.

This Standard outlines the requirements for the qualification, procurement, storage and delivery of the main assemblies and components of the space solar array electrical layout: photovoltaic assemblies, solar cell assemblies, bare solar cells, coverglass and protection diodes. This Standard does not outline the requirements for the qualification, procurement, storage and delivery of the solar array subsystem, comprising the solar panels, structural parts and mechanisms.

The general requirements are covered in the main part of this Standard (clauses 5 to 11). Annex A to Annex E specify the contents of the source control drawing of photovoltaic and solar cell assemblies, bare solar cells coverglasses and protection diodes and include the inspection data, physical and electrical characteristics, other ratings and acceptance and qualification specific requirements, which can be different for each space project.

This Standard is divided into five specific subjects, each one corresponding to each assembly or component:

Clause 5 defines requirements for photovoltaic assemblies,

Clause 6for solar cell assemblies,

Clause 7 for bare solar cells,

Clause 8for coverglasses,

Clause 9 for protection diodes.

Two additional clauses are dedicated to Sun simulators and calibration procedures (clause 10 and capacitance measurement methods (clause 11).

Scope

This Standard specifies the general requirements for the qualification, procurement, storage and delivery of photovoltaic assemblies, solar cell assemblies, bare solar cells, coverglasses and protection diodes suitable for space applications.

This standard does not cover the particular qualification requirements for a specific mission.

This Standard primarily applies to qualification approval for photovoltaic assemblies, solar cell assemblies, bare solar cells, coverglasses and protection diodes, and to the procurement of these items.

This standard is limited to crystaline Silicon and single and multi-junction GaAs solar cells with a thickness of more than 50 m and does not include thin film solar cell technologies and poly-crystaline solar cells.

This Standard does not cover the concentration technology, and especially the requirements related to the optical components of a concentrator (e.g. reflector and lens) and their verification (e.g. collimated light source).

This Standard does not apply to qualification of the solar array subsystem, solar panels, structure and solar array mechanisms.

This standard may be tailored for the specific characteristic and constrains of a space project in conformance with ECSS-S-ST-00.

Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this ECSS Standard. For dated references, subsequent amendments to, or revision of any of these publications do not apply, However, parties to agreements based on this ECSS Standard are encouraged to investigate the possibility of applying the more recent editions of the normative documents indicated below. For undated references, the latest edition of the publication referred to applies.

|

ECSS-S-ST-00-01

|

ECSS system – Glossary of terms

|

|

ECSS-Q-ST-60

|

Space product assurance — Electrical, electronic and electromechanical (EEE) components

|

|

ECSS-Q-ST-70-06

|

Space product assurance – Particle and UV radiation testing for space materials

|

|

ECSS-Q-ST-70-09

|

Space product assurance – Measurements of thermo-optical properties of thermal control materials

|

|

ISO 15387:2005

|

Space Systems – Single junction space solar cells – Measurement and calibration procedures

|

|

ISO 14644-1:1999

|

Cleanrooms and associated controlled environments – Part 1: Classification of air cleanliness

|

|

MIL-E-12397B

|

Eraser, rubber pumice for testing coated optical elements

|

|

IEC 60749-26:2006

|

Semiconductor devices – Mechanical and climatic test methods - Part 26: Electrostatic discharge (ESD) sensitivity testing – Human body model (HBM)

|

|

ASTM D1193-99

|

Standard specification for reagent water

|

|

ESCC 23800 Issue 1

|

Electrostatic Discharge Sensitivity Test Method

|

|

ESCC 24900 Issue 2

|

Minimum Requirements for Controlling Environmental Contamination of Components

|

|

DIN 53289

|

Testing of adhesives for metals; floating roller peel test

|

Terms, definitions and abbreviated terms

Terms from other standards

For the purpose of this Standard, the terms and definitions from ECSSSST0001 apply, in particular for the following terms:

qualification

verification

Terms specific to the present standard

General

blistering

forming of multiple small air bubbles inside the perimeter of a finish layer

bubbles

gaseous inclusion in the cell, coverglass or coverglass adhesive

chip

local absence of material along the edges and corners of a complete component and which extend through the thickness of the component

crack

fissure in the component with no separated portion from the remainder

Cracks can propagate from the edge of the material (edge cracks) or terminate at both ends within the material (surface cracks).

delamination

physical separation between two material layers, which are joined in design

discolouration

local variation of solar cell anti–reflection coating colour due to the influence of the structure orientation of the cell layer immediately below or the variation of the anti–reflection coating layer thickness

dig

cavities in the surface of a component caused by impact with a pointed object or by crushing a material into the surface

inclusion

volume contained within the component that is devoid of the substrate material

in–process testing

tests performed during the manufacturing of a component or assembly in order to identify, in advance, defects or low performances

nick

local absence of material on the surface of a complete component which does not extend through the thickness of the component

peeling

forming of a delamination of a finish layer at the edge of the finished area. A blister at the edge of the surface

procurement lot

set of shipment lots of solar cells assemblies, bare solar cells and coverglasses, manufactured with the same processes and materials, with identical manufacturing lines, that fill the same purchase order

scratch

linear marking of the component that represents a volume devoid of the substrate material emanating from a single face of the component and not penetrating through the whole thickness of the substrate at any point

shipment lot

solar cell assemblies, bare solar cells and coverglasses manufactured with the same processes and materials with identical manufacturing lines delivered to the customer as a part of a purchase order

spatter

small bits of solid coating material imbedded on or in the coating or substrate

voids

absence of deposited materials

Examples are absence of cell contact material or anti–reflection coating.

Photovoltaic assemblies

photovoltaic assembly

power generating network comprising the interconnected solar cell assemblies (strings and sections), the shunt and blocking diodes, the busbars and wiring collection panels, the string, section and panel wiring, the wing transfer harness, connectors, bleed resistors and thermistors

qualification coupon

non–flight representative test sample of flight panels, built with flight processes and containing representative materials and components to be used in the manufacture of flight panels, formerly also called DVT coupon

slicing

procedure to evenly distribute the total number of thermal cycles over temperature domains which are compatible with the temperature excursion on an orbit level rather than on the overall mission temperature envelope

Normally used for LEO missions.

Solar cell assemblies

cladding

application of a thin layer of material fully covering the surface, For instance silver cladding of an interconnector

deformed interconnector

interconnector whose initial conformed shape is modified

interconnected cell

solar cell with interconnector without coverglass

solar cell assembly

solar cell together with interconnector, coverglass and, if used, by–pass diode

tearing interconnector

interconnector physically separated from the cell due to a failure of the welding or soldering joint

Bare solar cells

bare solar cell

photovoltaic component capable to delivering electrical power when illuminated with light

component bare solar cell

specially manufactured solar cell, with only one active junction and the same spectral response as one sub cell of a multi–junction solar cell

contact vacuum evaporation batch

bare solar cells manufactured in the same contact vacuum evaporation run

drops

excess of metallization material on the solar cell contacts

remaining Factor

ratio of an electrical performance parameter at EOL to its value at BOL

E.g. maximum power of a solar cell.

solar cell anti–reflection coating

single or multi–layer coating which reduces the reflection coefficient of the incident solar radiation

uncoated area

area of the solar cell where the bare solar cell is exposed and is devoid of coatings

worm shaped bulge

protuberance of contact material shaped in linear irregular paths or single dots where the contact material is locally delaminated from the immediate lower layer

Coverglasses

coating

dielectric or conductive material applied to the glass substrate by vacuum deposition

Coatings applied to the external face of the coverglass is termed the “front surface coating”. Coatings applied to the internal face of the glass substrate to be bonded to the solar cell is termed the “rear surface coating”. Commonly used coatings include:

- single–layer anti–reflection coating,

- multi–layer anti–reflection coating,

- ultraviolet reflector,

- infrared reflector, and

- conductive coating.

conductive coating

transparent coating used to prevent the exposed surface from charging and consequently protecting the solar cell from the effect of electrostatic discharge

The coverglass usually comprises a suitable glass substrate and one or more of a combination of the coatings given in the note in clause 3.2.5.1.

coverglass

glass substrate and coatings applied to its surfaces

coverglass coating lot

collection of glass substrates subjected to the same coating run or runs (for coverglasses which have more than one coating)

infrared reflector

multi–layer dielectric coating which has a high reflectance coefficient in the infrared portion of the solar spectrum

The infrared reflector is used to reflect light that is not usefully converted to electrical energy by the solar cell thus reducing the operating temperature and increasing the conversion efficiency of the SCA.

mark

See stain

multi–layer anti–reflection coating

multiple layer coating which has the effect of increasing the transmission coefficient of the coverglass

single layer anti–reflection coating

simplest form of coating comprising a single layer of low index dielectric material which minimizes the reflection coefficient of the incident solar radiation thus increasing the transmission coefficient of the coverglass

The single layer of low index dielectrical material is usually done of MgF2.

stain

area which under inspection conditions can clearly be defined as not being optically homogeneous with the bulk material, and that cannot be categorized as an inclusion, scratch, crack, chip, dig, void or coating delamination

The term “mark” can be used as a synonymous.

ultraviolet reflector

multi–layer dielectric coating which has a high reflectance coefficient in the UV portion of the solar spectrum

The ultraviolet reflector is used to protect the underlying adhesive and to reflect light that is not usefully converted to electrical energy by the solar cell thus reducing the operating temperature of the solar cell and increasing the conversion efficiency of the SCA.

uncoated area

area of the coverglass where the bare coverglass substrate is exposed and is devoid of coatings

Verification processes

accelerated testing

test in which the life time requirement is verified in an accelerated way by intensifying one parameter of the environment or load.

The following are examples of accelerated tests:

- UV test done with increased sun intensity in the UV part of the spectrum,

- Electron and proton radiation tests with life time fluences in a limited period of time,

- humidity tests done at higher temperature and humidity,

- bake-out done at higher temperature,

- performance parameter degradation at higher temperature,

- thermal cycling with higher/lower cool-down and heat-up rates and without nominal operating dwell time in between.

acceptance test

test to determine that a system, subsystem, component or functional part is capable of meeting performance requirements prescribed in purchase specifications or other documents specifying what constitutes the adequate performance capability for the item and to demonstrate the item is free from manufacturing defects

In this document acceptance is associated with specified requirements which have a defined acceptance safety factor with respect to requirements corresponding with the actual loads and environments

delta qualification

qualification performed on an equipment which has undergone minor design modifications or has been qualified to operate in environments less severe than those specified

proto flight test

test requirements which have a defined qualification safety factor with respect to requirements corresponding with the actual loads and environments, but with limited test durations

qualification by similarity

process to demonstrate the ability to fulfil specified requirements by comparing a new design specification with a similar proven design specification

Abbreviated terms

For the purpose of this standard, the abbreviated terms of ECSS-S-ST-00-01 and the following apply:

|

Abbreviation

|

Meaning

|

|

ADP

|

acceptance data package

|

|

AOCS

|

attitude and orbit control system

|

|

AM0

|

air mass 0 (zero)

|

|

APTC

|

ambient pressure thermal cycling

|

|

AR

|

anti-reflection

|

|

ARC

|

anti-reflection coating

|

|

ATOX

|

atomic oxygen

|

|

BOL

|

beginning-of-life

|

|

BSC

|

bare solar cell

|

|

BSR

|

back surface reflector

|

|

CIC

|

connector integrated cell

|

|

CIDL

|

configuration item data list

|

|

CVCM

|

collected volatile condensable material

|

|

CVG

|

coverglass

|

|

DCR

|

documentation change request

|

|

DJF

|

design justification file

|

|

DRD

|

document requirements definition

|

|

DRB

|

delivery review board

|

|

DVG

|

direct voltage gradient

|

|

DVT

|

design verification test

|

|

EMC

|

electromagnetic compatibility

|

|

EOL

|

end-of-life

|

|

ESD

|

electrostatic discharge

|

|

FIT

|

failure in time

|

|

FMECA

|

failure modes, effects and criticality analysis

|

|

GaAs

|

gallium arsenide

|

|

GEO

|

geostationary orbit

|

|

IC

|

interconnected cell

|

|

Imp

|

maximum power current

|

|

Iop

|

current at operational voltage

|

|

IRR

|

infrared reflector

|

|

Isc

|

short-circuit current

|

|

IVG

|

inverted voltage gradient

|

|

LEO

|

low Earth orbit

|

|

LVDT

|

linear voltage displacement transducer

|

|

MLAR

|

multi-layer anti-reflection coating

|

|

NCR

|

nonconformance report

|

|

NRB

|

nonconformance review board

|

|

OSTC

|

on station thermal cycling

|

|

PAD

|

part approval document

|

|

PCDU

|

power control and distribution unit

|

|

PID

|

process identification document

|

|

Pmax

|

maximum power

|

|

PMCF

|

product manufacturing and control file

|

|

PMP

|

parts, materials and processes

|

|

PTH

|

power transfer harness

|

|

PVA

|

photovoltaic assemblies

|

|

r.m.s.

|

root mean square

|

|

RAMS

|

reliability, availability, maintainability and safety

|

|

RDC

|

relative damage coefficients

|

|

RML

|

recovered mass loss

|

|

S.C.

|

solar constant

|

|

S.C. (AM0)

|

solar constant at air mass 0

|

|

SCA

|

solar cell assembly

|

|

SCD

|

source control drawing

|

|

SLAR

|

single layer anti-reflection coating

|

|

SWS

|

secondary working standard

|

|

TAT

|

type approval test

|

|

D

|

to be defined

|

|

S

|

to be specified

|

|

TML

|

total mass loss

|

|

UVR

|

ultraviolet reflector

|

|

Vmp

|

maximum power voltage

|

|

Voc

|

open-circuit voltage

|

|

Vop

|

operational voltage

|

|

Vtest

|

test voltage

|

|

WRC

|

World Radiation Centre in Davos

|

General

Overview

Objective and organization

The objectives of this Standard are:

To define the rules for the flow of technical requirements from a project solar array specification down to component level in order to guarantee that lower level components and sub-assemblies are qualified according to specifications.

To define the set of requirements from component level up to photovoltaic assemblies (PVA) to enable a generic qualification for each level of assembly for about 90 % of the solar array applications within a certain range; for example, deployable solar arrays for GEO or LEO.

This clause describes the organization of the requirements and how they are applied.

The philosophy behind this Standard is two fold in that respect that:

Qualification of a specific level of assembly is based on the use of qualified components and sub-assemblies at lower levels. The specification hierarchy that photovoltaic assemblies and their components form part of is illustrated in Figure 41.

OR

Qualification of components for a specific application can be achieved at a sub-assembly level at which the qualification is unequivocally demonstrated. This means that certain types of qualification tests do not need to be duplicated at different level of assembly in case of a unique application of a dedicated design

This Standard defines the requirements for qualification at each level from components up to and including PVA on coupons. Coupons are built according to PVA design requirements with the objective of demonstrating that the design and manufacturing processes are ready for use on solar panels of a flight application.

For many parameters in this standard the value to be specified as requirement is dependent on the mission concerning duration and environmental conditions or the implemented solar array design. These parameter values are derived from the higher level subsystem specification and reflected in a dedicated document. In this standard the source control drawing has been selected generically on every level of assembly as an example of a document to reflect the specific requirements. So the source control drawing or equivalent set of documentation is the reference list for physical characteristics, performance requirements and environmental conditions.

Full qualification for an application is not only achieved after successful qualification of the PVA and its components on coupon level. Robustness against some environments can only be demonstrated in the final solar array configuration, that may comprise amongst others full size panel on-station thermal cycling and sine vibration, acoustic noise, and wing deployment testing at subsystem or spacecraft level.

Figure 41: Specification hierarchy

Figure 41: Specification hierarchy

Interfaces with other areas

In the specification hierarchy (Figure 41) only the components and assembly levels that are usually dedicated to solar arrays are shown. At every integration step, additional materials and components, not mentioned in the specification hierarchy, are used such as:

adhesives,

solder,

interconnectors and busbars,

diodes,

resistors,

thermistors,

connectors, and

wires.

Requirements for these materials and components can be found in their procurement specifications, and in EEE component specifications, which are reviewed as part of the qualification process. For EEE component specifications, see the ECSS-Q-ST-60 series of standards. For Materials Parts and processes specifications, see the ECSS-Q-ST-70.

The qualification of the use of these items is a pre-requisite for the qualification of the assembly they are part of (for example, coverglass adhesive at the SCA level and busbars at the qualification coupon level).

Non-PVA related solar array design, power subsystem interface and mission specific related topics such as grounding, electromagnetic compatibility, magnetic moment, spacecraft related geometrical loss factors and end-of-life performance prediction related topics, including loss factors, are not addressed in this Standard.

Specific design measures to support the solar array in order to satisfy the requirements of this Standard, such as grounding spots and blocking diodes, are however, taken into account.

Specific environmental conditions which can be a limitation in the qualification for general use, are not addressed in this Standard as these aspects are usually the subject of a project dedicated qualification (for example, the chemical contents in local ambient air).

Physical properties

The following physical properties of the components and materials shall be measured:

- coefficient of thermal expansion

- heat conductivity

- specific heat

- Young’s modulus and Poisson’s ratio

- Flex strength

The objective is to establish the boundaries for the qualification test program over the full range of application by means of analysis.

The data specified in requirement 4.2a shall be determined during the development phase of a new component and need not be repeated during the qualification program.

Test and storage

Test environment

The atmospheric conditions during all inspection, test operations and storage shall be as follows:

- Pressure: (1 013,25 33) hPa.

- Temperature: (23 5) C.

- Average relative humidity: 40 % - 60 %.

A pressure of (1 013,25 33) hPa is equivalent to (760 25) mmHg.

The room cleanliness level should be airborne particle count: Class 8 ISO 14644-1.

Every deviation from requirements 4.3.1a and 4.3.1b during tests shall be recorded in the data documentation package (DDP).

- 1 For DDP complete contents, refer to Annex G.

- 2 Semiconductor devices (i.e. planar diodes) can short-circuit if no special precautions are taken during long storage periods under certain atmospheric conditions. This is because chlorine content, in combination with illumination, can produce metal contact migrations on these semiconductor devices.

Test tolerances and accuracies

The accuracy of the instruments and test equipment used to control or measure test parameters shall be one order of magnitude higher than the tolerance on the variable to be measured.

Examples of where this cannot be achieved include measurements of electrical performance and temperatures.

All instrumentation used for qualification and acceptance tests shall:

- be calibrated, and

- be within the specified calibration period at the time of test.

Instrumentation whose calibration period runs out during the planned test time shall not be used.

The maximum test temperature tolerances for thermal testing shall be as given in Table 41.

The accuracy of mass measurements shall be better than 1 % or 0,01 g, whichever is higher.

The test condition tolerances shall be applied to the nominal test values specified.

The accuracy of the electrical performance test on PVA level shall be better than or equal to the calibration loss factor used in the power analysis.

TableTable 41: Test tolerances on temperature

|

Temperature range (C)

|

tolerance (C)

|

|

around - 175

|

-10 / +0

|

|

around - 100

|

-10 / +0

|

|

around + 90

|

-0 / +10

|

|

Around +130

|

-0 / +10

|

Margins

The margins to be applied to qualification test conditions shall be as defined in the solar array specification.

Critical materials

The critical interface information shall be part of the PMP list.

For PMP, see ECSS-Q-ST-70 Annex B.

Silver cladding shall be annealed and contain a minimum of 99,9 % pure silver.

Pure tin, cadmium and zinc shall not be present in finished space-qualified solar panels.

Pure tin refers to a tin alloy with less than three atomic percent of an alloying metal, e.g., lead. Pure cadmium and zinc is defined as these metals used or applied in a non-mixed metal or unalloyed state.

Solar panels containing Beryllium Oxide shall be clearly identified with the designation BeO.

Photovoltaic assemblies

Overview

Description

The photovoltaic assembly (PVA) comprises the electrical parts to satisfy the requirements of the solar array specification.

This Clause applies to solar arrays using a planar design without concentration and based on crystalline solar cells.

In case of concentration, this Clause applies to the PVA without the optics, provided that the electrical performance tests are adapted to the light incidence and intensity imposed by the optics.

Usually, a PVA consists of parallel connected strings. A string is the smallest operational component at the PVA level. A string consists of a series interconnected solar cells connected to the spacecraft bus. These strings are supported by a solar array panel substrate or frame.

The parts comprising a PVA usually include:

interconnected SCAs,

bleed resistors,

wiring,

panel connectors,

diodes (blocking and shunt),

thermal sensors,

telemetry indicator wiring, and

grounding.

Purpose and objective

In this Clause the design limits, including margins, and the responsibilities for PVA manufacturing are defined and include the:

design requirements (refer to clause 5.3);

mechanical and electrical interface;

manufacturing requirements for PVA (refer to clause 5.4);

qualification requirements for PVA (refer to clause 5.5.1);

acceptance requirements for PVA (refer to clause 5.5.2).

The values specified for the SCA level are provided by the solar cell assembly supplier and confirmed during the SCA qualification tests (refer to clause 6.4).

In order to design and verify a solar array, data for the following parameters and characteristics at the SCA level or lower are used:

characteristics of the SCA (Voc, Isc, Vmp and Imp);

spectral response;

reference calibration standard;

relative damage coefficient and electron-proton equivalence;

temperature coefficients as a function of radiation fluences;

reverse characteristics versus temperature;

UV and Sun spectrum characteristics (reflectivity);

capacitance versus temperature;

optical properties (hemispherical emissivity, and solar absorptance, and cover gain or loss);

behaviour with regard to specific mission environments:

ATOX sensitivity,

thruster erosion sensitivity,

micro-meteoroids and debris sensitivity;

loss factors for interconnecting the cells into a string.

Conditions and method of test

The conditions and methods of testing shall conform to the photovoltaic assembly source control drawing (SCD-PVA).

The PVA specification consists of two parts, the generic specification (this Standard) and the SCD. For the preparation of the SCD-PVA, refer to Annex A.

The SCD-PVA shall be prepared by the supplier, in conformance with Annex A, and provided to the customer for reviewing and agreement.

Any deviation from in-process, acceptance and qualification test shall be justified.

Deviations from this Standard applicable to the SCD-PVA shall:

- be agreed between the customer and the supplier;

- include alternative requirements equivalent to those of this Standard;

- not affect the reliability and performances of the photovoltaic assemblies;

- be only those specified in requirement 5.2c.

Photovoltaic assembly design

Overview

The objective of this standard at the PVA level is to specify the requirements for the detail design, performance, qualification, manufacture and acceptance testing of coupons equipped with the PVA. The inputs to these requirements are the solar array specification, which is prepared following the requirements of the mission specification, the ground test programme and the spacecraft design. In this clause the steps which influence specific design characteristics of the PVA have been listed. Requirements which merely determine the sizes of the PVA have not been taken into account, like intensity related loss factors and reliability requirements.

Parameters related to parts, materials and processes (PMP)

Outgassing

Flight hardware shall be constructed from space qualified materials having the following properties:

- A recovered mass loss (RML) of 1 % or less.

See ECSS-Q-ST-70-02.

- A collected volatile condensable material (CVCM) of 0,1 % or less when heated in a vacuum to 125 C and collected at 25 C. The PMP list shall include the RML and CVCM values for all materials used.

The mission specification can specify an absolute limit to the total mass loss and volatile condensable material of the solar array sub-system. The fulfilment of this system requirement can be verified either by analysis using the total amount of the applied materials, the individual material RML and CVCM data, outgassing field of view and temperature distribution, or by test of the representative subsystem and measurement of the outgassing product.

Toxicity

Any material used in the construction of the PVA that is dangerous to the health of the personnel shall be identified.

Preventive handling measures shall be taken in conformance with a standard approved by the customer.

Flammability

Any flammable materials used in the construction of the PVA shall be identified.

Corrosion

The supplier and customer shall agree on the measures to be taken to prevent corrosion during storage or in normal operational service.

Standard atmospheric conditions may be assumed for general applications in the spacecraft, over a period of time that is agreed between the supplier and customer.

To avoid electrolytic corrosion, a process, approved by the customer, shall be used.

Magnetism

Permanent magnetic materials shall be avoided when specified by the mission.

Non-magnetic materials should be used.

Erosion

PVA materials shall be capable of tolerating a defined erosion level resulting from spacecraft operation without degradation in the nominal performance of the PVA, in conformance with the PVA specification.

Example: thruster plumes.

Atomic oxygen (ATOX)

PVA materials shall be capable of tolerating a defined level of degradation resulting from an ATOX environment, without degradation in the nominal performance of the PVA, in conformance with the solar array specification.

The ATOX resistivity shall be determined by the individual resistivities of the used materials and components in their configuration.

Parameters related to design

Cell integration

The solar cells shall be structured such that the PVA is capable of withstanding all phases of ground handling, transportation, qualification testing and acceptance testing, launch and orbit operations as to conform to the mission requirements.

The capability for replacement of cracked, broken or damaged SCAs shall be included in the design.

Repair method shall be feasible in horizontal and vertical panel positions.

Stringing

If blocking diodes are applied in the design at the panel level, the positive end of the strings shall be connected to the panel connector by a blocking diode.

To enable performance measurement at the lowest level of assembly at the coupon level, strings shall be measured individually.

Potential parallel connections shall not prevent performance measurement specified in requirement 5.3.3.2b.

If the dimensions of the coupon enables the accommodation, the full flight string length shall be represented on the qualification coupon.

Coupon layout shall be as defined in a overall assembly drawing as part of the SCD-PVA.

Cell interspacing

The cell interspacing shall be compatible, as a minimum, with the following mission requirements:

- thermal expansion and contraction within the mission temperature extremes specified in the solar array specification;

- panel geometry;

- ESD requirements.

Sectioning

Sections shall not be included at the coupon level.

To test the technique of interconnecting strings, the negative ends of individual strings may be connected in a way that is representative for flight panels.

Reverse bias protection

The solar cells that are potentially subject to reverse bias shall be protected by shunt diodes unless the solar cells are insensitive to the effects of reverse bias.

Types of reverse bias include:

- AOCS failure shadowing,

- self shadowing, and

- power management (including maximum power point tracker when direct energy transfer function is acting at BOL).

Insulation

The following items shall be electrically insulated from each other:

- Any solar cell circuits to substrate (the grounding reference of the coupon).

- Solar cell circuits to solar cell circuits (if not connected at the negative ends).

- Thermal sensor to the solar cell circuits and to the substrate (the grounding reference of the coupon).

- Conductive coverglass grounding network, if used, to solar cell circuits.

Derating

For the derating requirements of components, see ECSS-Q-ST-30-11.

Redundancy

For redundancy requirements, see ECSS-Q-ST-30.

For failure modes requirements, see ECSS-Q-ST-30-02.

Fault tolerance

A FMECA shall be performed for the design of the solar array.

The design consequences shall be implemented on the qualification coupon, including:

- the photovoltaic assembly from solar cell strings to the connector, and

- redundant bleed resistors and, if any, redundant PVA assemblies or components.

- 1 Examples: Solar cell strings, blocking diodes, temperature sensors.

- 2 For FMECA, see ECSS-Q-ST-30-02.

No single fault shall result in the following: - The loss of integrity of the redundant parts indicated in requirement 5.3.3.9b.2.

- The propagation of the fault causing permanent damage or loss of use of the units connected to the PVA.

Examples: solar array regulator unit, solar array drive mechanism.

No failure shall be propagated from one solar array wiring group to another.

Fatigue resistance

The effects of fatigue shall be verified by analysis or test.

The design of the PVA shall include the result of the verification specified in requirement 5.3.3.10a.

Adherence to substrate

Measurement

The adherence of SCAs to the substrate shall be measured using representative process samples.

Property

The SCAs shall stay attached to the panel and conform to all requirements during the test campaign and all the phases of the mission.

The adherence shall be such that the SCAs integrated on the substrate can be repaired, removed and replaced.

Adhesive uniformity

The thickness boundaries, including manufacturing and repair tolerances, shall be defined by means of analysis or test.

The boundary requirements on minimum and maximum thickness, in conformance with requirement 5.3.3.12a, shall be guaranteed by a controlled application process demonstrated on separate samples.

The thermal conductance towards the panel substrate shall be such that the specified solar cell and protection diode temperature can be maintained.

Electrostatic discharge (ESD)

The solar array design shall be such that it can survive the charging environment and operating conditions defined by the mission.

Requirement 5.3.3.13a shall be either demonstrated by analysis or by testing.

During and after launch, the spacecraft is surrounded by a low density plasma of high energy electrons and protons. On insulated surfaces of the spacecraft, the electrons build up a charge which discharges when breakdown of the insulating materials is reached.

Electromagnetic compatibility (EMC)

The PVA shall be designed to meet the specific EMC requirements stated in the SCD-PVA.

Repairability

The capability of repairing, removing and replacing items down to component level shall be provided.

For example, for single SCAs, diodes, thermal sensors, wires and connectors.

PVA manufacturing

Process validation

The manufacturing and integration processes shall be validated for all the project specific design configurations and to meet the engineering design requirements.

Defect acceptability

The acceptability of defects at the PVA level shall be:

- agreed with the customer;

- defined in a production control document;

- validated by qualification testing.

In-process testing

Overview

The in-process tests are performed during the manufacturing of the PVA to detect deviations and defects as early as possible. This clause 5.4.3 lists the test to be performed during the manufacturing of the PVA.

Mass measurement

To determine the add-on mass of the SCA laydown process, the mass of the substrate shall be measured before and after the substrate is equipped with the SCA’s and be in conformance with SCD-PVA.

Wet insulation test

A wet insulation test shall be performed by the supplier to prove the integrity of the bare coupon insulation layer, as follows:

- Verify continuity between the conductive layer under the insulation to the test connection point.

- For the wet insulation test, use ethyl, isopropyl alcohol, or otherwise an equivalent fluid agreed with the customer, as contact fluid during the measurements.

- Apply a voltage which corresponds to the breakthrough value for short term exposure of the applied insulation material (Espec V/m) times the minimum guaranteed thickness.

For example, for Espec= 20 V/m and a (50 10) m insulation layer, a test voltage of 800 V applies.

The acceptance criteria shall be an insulation larger than 100 M.

In case of a failure, the coupon insulator layer shall be repaired.

Adherence to substrate

The adherence of the SCAs to the substrate, shall be performed in parallel to panel laydown.

The adherence to substrate shall be verified by means of one of the following two methods:

- Method 1

- Bond 3 SCAs following identical process to a representative PVA substrate of the following dimensions: 200 x 130 mm.

- After 1 week at room temperature, perform a pull test, with a pull force equal or larger than 1 N/cm2.

- Method 2

- In case no solar cell assemblies and substrate are available, bond together 2 Kapton foils of the same material as used in representative PVA and with dimensions of 250 mm x 150 mm.

- After 1 week at room temperature, perform a peel test of the foil according to DIN 53289.

- Use a peel force equal or larger than 1,8 N/cm.

- Ensure that the separation takes place within the adhesive for an area larger than 50 %.

Visual inspection

A visual inspection shall be made after stringing.

This is to determine, as early as possible, defects in the rear sides of solar cells and, when feasible, the front sides.

The visual inspection procedure and criteria shall be agreed with the customer and be described in the SCD-PVA.

Continuity check

The continuity of all strings shall be checked after stringing, in order to detect defects not detected during the visual inspection.

Continuity of harness, wires and diodes shall be checked, and measured after final assembly.

The maximum values of resistance shall be given in the SCD-PVA.

Identification and traceability

Components other than SCAs, bare cells and coverglasses shall be identified in conformance with the traceability requirements of Class 1 components, and PAD DRD of ECSS-Q-ST-60.

For requirements on the identification and traceability of parts and materials, see clauses 6.1.4, 7.1.3 and 8.3.3 for SCAs, bare cells and coverglass, respectively.

Recording

Before start manufacturing, all processes and process variables related to PVA manufacturing that have impact on the performance of the process, shall be identified by the supplier.

The processes variables specified in requirement 5.4.5a shall be recorded during manufacturing.

PVA tests

Qualification tests

Purpose

Qualification tests are performed to check and qualify the design requirements.

Process

Qualification tests shall be preceded by the acceptance tests as listed in clause 5.5.2, in order to be representative of the life of flight hardware.

All results of the qualification test shall be reported in a qualification test report.

Qualification margins shall not exceed component and material specifications unless agreed between supplier and customer.

The following environmental test shall be performed for qualification of PVAs as applied on solar panels:

- Fatigue thermal cycling test on the qualification coupon.

- Humidity test performed on dedicated test sample if not tested on SCA level.

- ESD test on a dedicated ESD coupon, if specified by the solar array requirement specification.

- Erosion of materials, due to thruster plume if specified by the solar array requirement specification.

The tests to be performed for each qualification are listed in Table 51 and described in clauses 5.5.2 and 5.5.3.

In cases where the same coupon is used for the fatigue thermal cycling test and the humidity test, in conformance with requirement 5.5.1.2d the humidity test sequence shall precede the fatigue thermal cycling test sequence.

Except in conformance with requirement 5.5.1.2e, each type of test shall be performed on a dedicated qualification coupon built specifically for the test.

The qualification coupon need not be the same size as the flight panels, but shall contain a representative number of components to enable reliable verification of flight panel processes and materials.

The processes used to build the qualification coupon shall be documented in a parts, materials and process (PMP) list to ensure that the flight panels are built with identical processes, materials and configurations.

Each qualification coupon shall be flight representative as far as allowed by the dimensions of the qualification coupon

Facilities shall be available to safely store the qualification hardware (included failed samples) for a minimum of 6 years (equivalent to five years in storage and one year in orbit).

TableTable 51: Qualification test plan for PVA

|

Check

|

Fatigue thermal cycling

|

Humidity test

|

ESD test

|

|

Full visual inspection (5.5.3.2)

|

1, 6, 9, 14

|

1, 5

|

1, 4

|

|

Electrical health check and performance (5.5.3.3 and 5.5.3.4)

|

2, 7, 10, 15

|

2, 6

|

2, 5

|

|

Capacitance (5.5.3.5)

|

3, (11), 16

|

|

|

|

X-ray photo (5.5.3.9)

|

4, (12), 17

|

|

|

|

Reflectance (5.5.3.8)

|

|

3, 7

|

|

|

Vacuum thermal cycling (5.5.3.11)

|

5, 13

|

|

|

|

Substrate integrity (5.5.3.10)

|

18

|

|

|

|

Fatigue thermal cycling (5.5.1.3)

|

8

|

|

|

|

Humidity (5.5.1.4)

|

|

4

|

|

|

ESD test (5.5.1.5)

|

|

|

3

|

|

NOTE: The numbers in each column indicate the sequence in which the checks are performed for each test.

| |||

Fatigue thermal cycling test

Purpose

The purpose of the thermal cycling test is to demonstrate the life fatigue compatibility of all components and processes in an assembly.

General

The PVA manufacturer shall demonstrate that lack of continuity is avoided at any time during cycles defined in requirement 5.5.1.3.4g, both on the solar cell and on the protection shunt diode circuits.

The test conditions, specifically the thermal gradients through the test sample thickness, shall be representative of the distribution predicted in space so that the components are not over-stressed or under-stressed beyond specified limits.

The temperature extremes of the thermal cycling shall be extended or a dedicated structural test shall be performed in cases where analysis demonstrates that the structural loading results in a greater stress than the thermal cycling.

For example, acoustic and noise can produce greater stress than thermal cycling in certain missions.

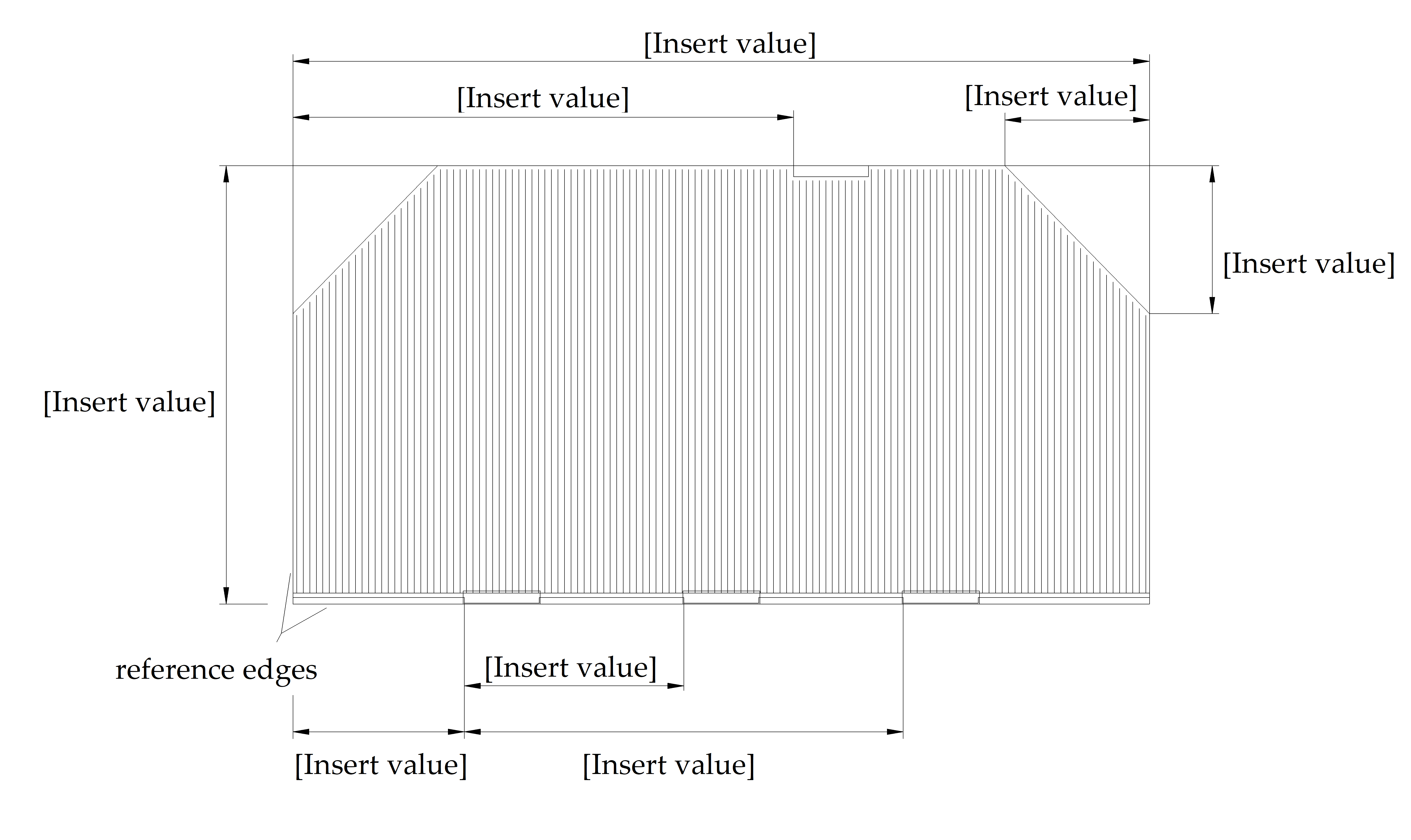

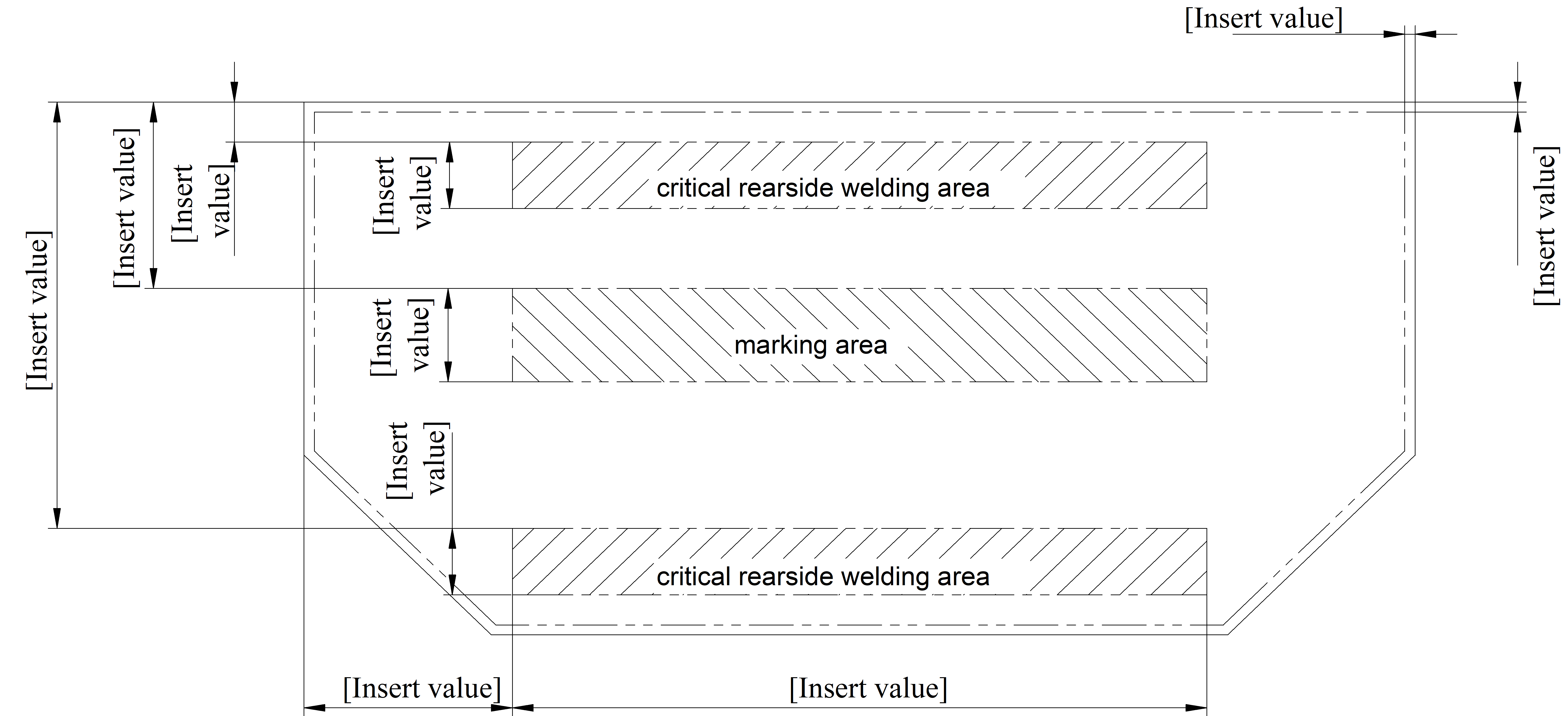

Qualification coupon

The qualification coupon shall be defined by means of a representative drawing, document or matrix in the SCD-PVA.

The representation of the critical areas of the solar array on the qualification coupon shall be agreed with the customer.

For example, the substrate represents a worst-case stress part of the flight panels.

The qualification coupon shall be manufactured using the same qualified materials and processes as the flight panel, and any deviation shall be identified by the PVA supplier.

The qualification coupon shall contain only one PVA technology.

The number of (non-cell) components shall correspond to the number in a flight configuration of the unit they belong to, but with a minimum of two.

For example, it can be one blocking diode per string, one shunt diodes per shunt interval, and two bleed resistors per panel, but in accordance with this requirement, in all these cases the minimum number is two.

If space is available, additional components may be included to be tested as separate items.

For every type of solar cell configuration (N-end tab, P-end tab or middle cell) one piece shall be repaired on the coupon after the acceptance test (only visual inspection and electrical health check), unless configurations are identical, in which case at least two cells shall be repaired.

The production of the qualification coupons shall be representative of the full processing of the flight hardware.

At least 3 thermocouples on the front side and 3 on the rearside of each qualification coupon shall be placed for temperature monitoring.

The qualification coupon subjected to the fatigue thermal cycling test need not follow the acceptance test sequence.

Dedicated electrical test points shall be included in the electrical design of the qualification coupon such that the capacitance of single strings can be measured.

Test

The number of cycles and temperature deltas may be determined using one of the following criteria:

- The number of cycles is four times the number of cycles that occur during the mission with 0 C temperature delta (at both upper and lower design temperature limit).

- The number of cycles is equal to 1,5 times the number of cycles occurring during the mission with a temperature delta of 10 C at extremes (both upper and lower qualification temperature limit).

If qualification margin temperature exceeds the brittle point of main elements of the PVA, the option to be used in conformance with requirement 5.5.1.3.4a shall be agreed with the customer.

For a GEO mission, the following cycling profiles shall be used: - Define GEO transfer orbit cycles in conformance with the mission profile.

- all on station representing fatigue cycles are identical”. For a LEO mission, the following cycling profiles shall be used:

- A temperature profile which envelopes the variation of temperature extremes during the mission.

- The total profile, divided into a number of equally shaped sub-profiles, where the number of sub-profiles are:

- equal to the number of years of the mission, and

- with extreme cycle temperatures derived from the slicing of the temperature profile of the whole mission.

The number of cycles and temperature limits of requirements 5.5.1.3.4a and 5.5.1.3.4b shall be stated in the SCD-PVA.

Monitoring of the insulation between the solar cell circuit and the substrate shall:

- be performed in conformance with clause 5.5.3.3.3, and

- take place during the cycles with the maximum temperature limits and for a minimum of two cycles at each test interval. Monitoring of the continuity of the solar cell circuits shall:

- be performed in conformance with clause 5.5.3.3.2,

- take place during cycles for the complete activity,

- be performed on a regular, at least daily basis for a number of cycles, such that:

- during 10 % of these cycles of the cell circuit, and

- during 90 % of these cycles on the protection diode network shall be monitored.

- be performed by measuring both cell circuit continuity, at the beginning and at the end of the cycles in conformance to the relevant percentage specified in requirement 5.5.1.3.4g.3. Insulation and continuity shall not be measured simultaneously.

Pass-fail criteria

On completion the test, the following conditions shall be met:

- there is electrical continuity (no open circuit), and

- the power output of the test coupon and the insulation is within the limits stated in the SCD-PVA.

Humidity

Purpose

The purpose of the humidity test is to demonstrate the endurance of assembled PVA components in a real-life environment against standard environmental conditions using accelerated tests.

General

If there are requirements on specific environmental conditions, they shall be stated in the SCD-PVA.

For example, chemical vapour requirements.

Test Sample

The test sample shall be manufactured using the same qualified materials and processes as the flight panels.

The production of the test sample shall be representative of the full processing of the flight hardware.

Test

The test sample shall be placed in a chamber at ambient pressure.

The chamber temperature shall then be increased to 60 C minimum.

Relative humidity shall be higher than 90 %.

The duration of the test shall be 30 days.

In the case of solar cells with aluminium content window layers, the HT test shall be extended to simulate on-ground expected duration and humidity and temperature conditions.

High-purity water in conformance with ASTM D1193-99, Type I, shall be used.

Water condensation on the surface of the test sample shall be prevented.

If there are requirements on specific environmental conditions, they shall be stated in the SCD-SCA.

For example, requirements on chemical vapour conditions.

Pass-fail criteria

On completion the test, the following conditions shall be met:

- there is electrical continuity (no open circuit), and

- the power output of the test coupon and the insulation is within the limits stated in the SCD-PVA for the specified temperatures.

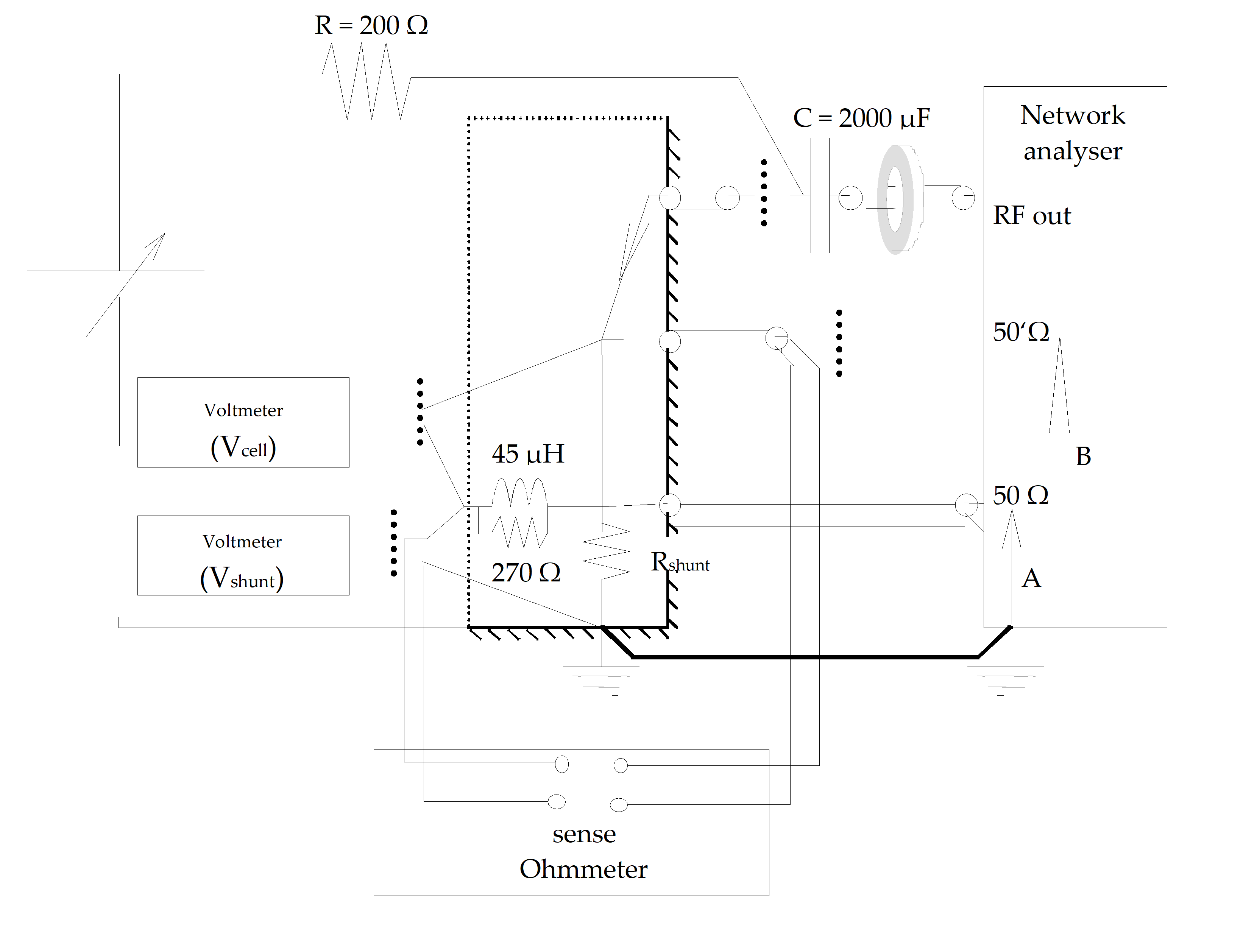

Electrostatic discharge (ESD) test

Purpose

The purpose of the ESD test is to demonstrate that the use of adequate design rules reduces the risk of ESD. This is done by demonstrating that ESD primary discharge does not lead to a self-sustained secondary arc, which can lead to loss of permanent power or insulation in the solar array.

The tests are performed on solar array coupons using instrumentation specially designed for that purpose.

Typical rules and a test procedure are described in ECSS-E-ST-20-06.

Pass-fail criteria

No sustained arc shall occur.

Testing shall demonstrate that the observed primary arcs do not produce any type of damage to the solar array or to the cells.

Erosion of materials

The test sequence, test definitions and requirements for the tests for erosion of material shall be agreed between the supplier and the customer and stated in the SCD-PVA.

EMC

The test sequence, test definitions and requirements related to the EMC of the PVA shall be agreed between the supplier and the customer and given in the SCD-PVA.

Acceptance tests for qualification coupons

Purpose

The acceptance tests are performed to check the workmanship of the supplier.

Applicability

Acceptance test are applicable to completed and qualified hardware, except if the acceptance tests are part of the qualification process.

Deliverables

The deliverable documentation shall be agreed with the customer.

The acceptance is dependent on this test and the documentation delivered.

Process

All acceptance tests shall be in conformance with clause 5.2.

All results of the acceptance test shall be reported in the data documentation package (DDP).

For the DDP, see clause 5.7 and Annex G.

The standard sequence of acceptance tests for PVA shall be as presented in Table 52.

The bake-out test shall be performed as part of the coupon acceptance test sequence only in the cases where the bake-out is included in the manufacturing process or in the acceptance test of the flight panels.

TableTable 52: Acceptance test plan

|

Sequence number

|

Test

|

|

Add-on mass (5.5.3.1)

|

0

|

|

Full visual inspection (5.5.3.2)

|

1, 6, 10

|

|

Electrical health check (5.5.3.3)

|

2, 7, 11

|

|

Capacitance (5.5.3.5)

|

3, 13

|

|

Electrical performance (5.5.3.4)

|

4, 8,12

|

|

Bake-out (5.5.3.6)

|

5

|

|

Thermal cycling (5.5.3.7)

|

9

|

|

NOTE: See 5.5.2.4d

| |

Definition of tests and checks

Add-on mass measurement

The mass of the panel shall be measured after the coupon is equipped with the PVA parts and the harness, and the add-on mass deduced.

The add-on mass of both the PVA and the harness shall be in conformance with the value given the SCD-PVA.

Full visual inspection

Purpose

The full VI is performed to detect imperfections in the complete hardware.

Process

A full visual inspection shall be performed against the inspection requirements stated in clauses 5.5.3.2.4 to 5.5.3.2.21, as follows:

- Visually examine each component for workmanship, identification and finish.

- Examine the deliverable items for conformance to general assembly drawings, with respect to critical dimensional parameters.

The inspection methods to be used include:

- electroluminescence

- infrared inspection;

- inspection with the naked eye;

- inspection using microscopes;

- any equivalent methods.

Training records of the personnel performing the visual inspection shall be made available to the customer under request.

General criteria

The PVA supplier shall define the inspection criteria for the PVA components, to be agreed by the customer, and included in the SCD-PVA.

Visual inspection of dimensions, stay-out zones, and stand-offs

The dimensions shall conform to the qualification coupon assembly drawing.

Cells and components shall not enter the stay-out zones indicated on the qualification coupon assembly drawing.

The stand-off distance of cells and components shall conform to the qualification coupon assembly drawing.

Visual inspection of the substrate

Substrates shall be inspected for any damage due to coupon assembly, handling and testing.

The insulator material shall show no evidence of delamination.

The insulator material is usually kapton.

The integrity of the substrate shall not deviate from the coupon assembly drawing.

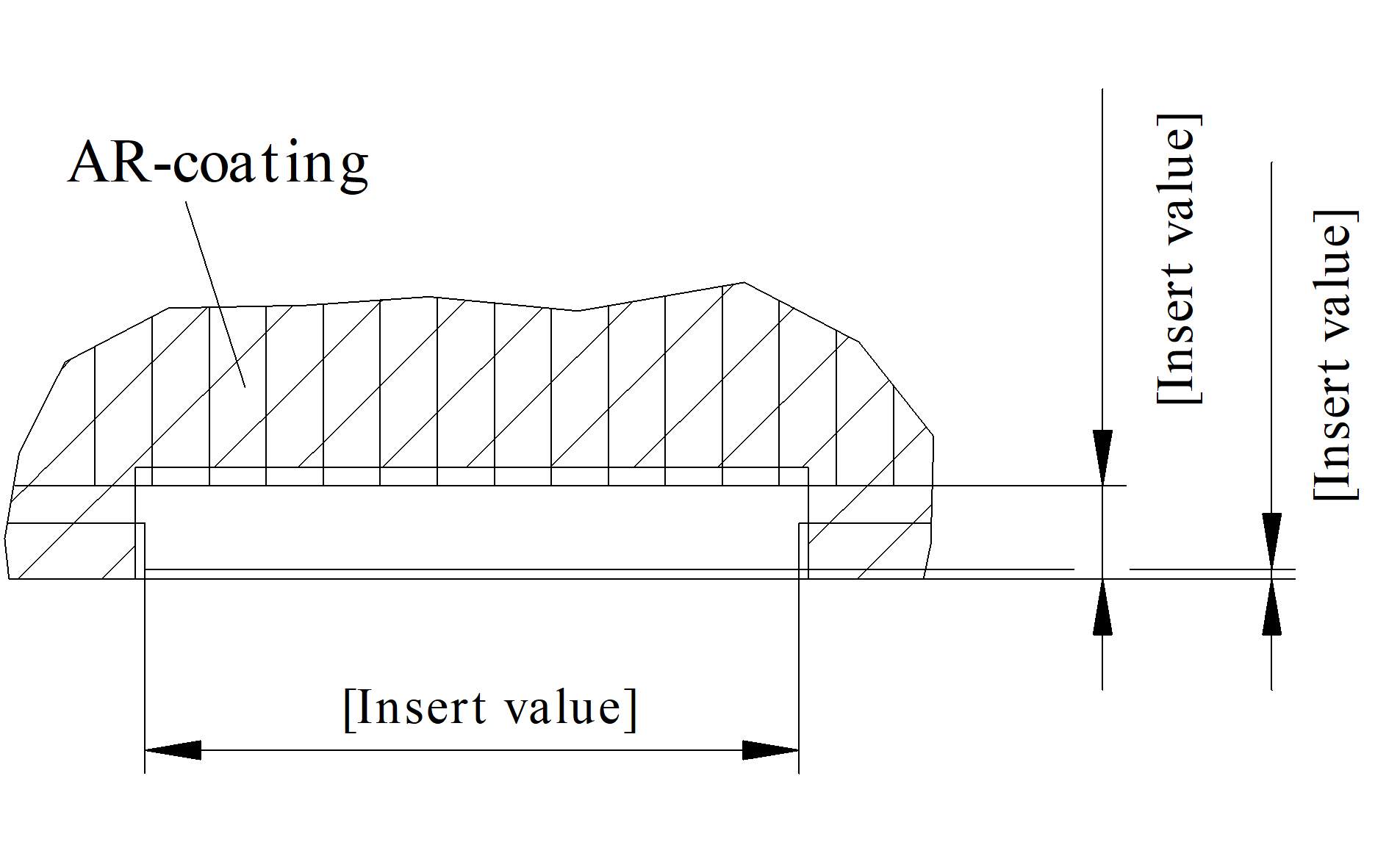

Visual inspection of the coverglass

All the coverglass shall be inspected for defects in conformance with requirements 5.5.3.2.6b to 5.5.3.2.6e.

No more than 5 % of the total number of coverglasses shall exhibit any of the following defects on the coupon, due to assembly, handling and acceptance:

- For 100 % covered cells, or cells where the unprotected solar cell surface is covered with the coverglass adhesive up to a maximum of 5 % of the cell area, chips and nicks in the coverglass with the characteristics specified in clause 6.4.3.1.4.

- Cracks on the coverglass, except if they meet the following conditions:

- no visible separation (in conformance with clause 6.4.3.1.4);

- no more than three per cover;

- meeting cracks if they are separated by more than 2 mm at the non-meeting end.

Any defect in conformance with requirement 5.5.3.2.6b, raised after acceptance shall be reported and traced throughout the qualification sequence.

Covers with dirty and contaminated surfaces shall be cleaned.

Coverglasses with any of the following defects shall be rejected at the end of acceptance:

- Coverglasses installed upside down as indicated by improper location of the coating orientation mark in conformance with clause 8.3.3.

- Coverglass which is not flush with or overhanging all four cell edges.

- Coverglasses with dirty and contaminated surface if they cannot be cleaned.

- Loose coverglasses.

- Corner chip exceeding the limits specified in requirement 5.5.3.2.6b.1.

- Edge chips exceeding the limits specified in clause 6.4.3.1.4.

- Coverglasses with intersecting cracks exceeding the limits specified clause 6.4.3.1.4.

Visual inspection of the coverglass adhesive

After coverglass or solar cell repair, there shall be no delamination or discoloration in the adhesive, except in the area opposite rear welds, where discoloration may be present.

After coverglass or solar cell repair, adhesive voids along the cover edge shall not exceed 0,6 mm in depth.

After coverglass or solar cell repair,, the maximum total projected area of additional bubbles shall not exceed 0,2 % of cell area, discounting:

- bubbles less than 0,02 mm2 in the projected area, and

- bubbles, discolorations and voids located at less than 2 mm from the interconnector edges.

Visual inspection of the solar cells

No more than 2 % of the total quantity of solar cells or one cell, whichever is larger, per coupon shall exhibit any of the following defects:

- More than the number of cracks per cell specified in the SCD-PVA.

- Cracks crossing more than the number of different gridlines specified in the SCD-PVA.

- Corner chips and edge chips greater than those specified in clause 6.4.3.1.4.

Any imperfections listed in requirements 5.5.3.2.8a.1 to 5.5.3.2.8a.3, raised after acceptance shall be reported and traced throughout the qualification sequence.

Solar cells with any of the following defects shall be rejected at the end of acceptance: - Cracks crossing more gridlines than defined in requirement 5.5.3.2.8a.2.

Multiple crossing of the same gridline can be present.

- More cracks than defined in requirement 5.5.3.2.8a.1 on a single cell.

- Cracks between the cell edges parallel to the gridlines and the outermost edges of the interconnectors.

- Corner chip exceeding the limits specified in clause 6.4.3.1.4.

- Edge chips exceeding the limits specified in clause 6.4.3.1.4.

Visual inspection of the solar cell bypass diodes

Cracks in the body of the diode, causing separation of the material, shall not be present.

Tarnishing of the diode body or attachment serpentines may be present.

Visual inspection of the interconnectors

No more than 2 % of the total number of interconnectors and no more than one interconnector per cell shall exhibit any of the following defects at the end of acceptance testing:

- Deformation.

- Solder or adhesive blocking, bridging, plugging or otherwise impeding the flexure of the stress relief loop.

- Foreign matter or contamination on the interconnector or within the interconnector weld or solder joint or within the stress relief loop.

Any imperfections listed in requirements 5.5.3.2.10a.1 to 5.5.3.2.10a.3, raised after acceptance shall be reported and traced throughout the qualification sequence.

None of the interconnectors shall exhibit lifting tears, breaks or cracks.

Interconnectors may be tarnished.

Visual inspection of the bus bars

None of the bus bars shall exhibit any of the following defects at the end of acceptance testing:

- Solder or adhesive blocking, bridging, plugging or otherwise impede the flexure of stress relief loops between solar cell strings.

- Foreign matter, or contamination on the interconnector, within the interconnector weld or solder joint, or within the stress relief loop.

- Tears, breaks or cracks.

Any defect listed in requirements 5.5.3.2.11a.1 to 5.5.3.2.11a.3, raised after acceptance shall be reported and traced throughout the qualification sequence.

Tarnishing may be present on the end terminations.

Visual inspection of the wiring

None of the wiring shall exhibit any of the following defects at the end of acceptance testing:

- Sharp bends, sharp twists, sharp buckles or creases in the wire.

- Delamination or looseness of the wire attachment.

- Chafing or abrasion of the wire insulation.

- Cracks, breaks or nicks in the wire insulation or conductor.

- Exposed shields on shielded wires. Any defects listed in requirements 5.5.3.2.12a.1 to 5.5.3.2.12a.5, raised after acceptance shall be reported and traced throughout the qualification sequence.

Visual inspection of the soldering

Soldering of wires at string terminations and terminals shall be in conformance with a standard agreed with the customer

For soldering, see for instance ECSS-Q-ST-70-08.

Visual inspection of the welding

Welding of wires at string terminations and terminals shall be in conformance with the SCD-PVA.

Visual inspection of the crimping

Crimping of wires shall be in conformance with a standard agreed with the customer.

For crimping, see for instance ECSS-Q-ST-70-26.

Visual inspection of the attachment materials

Attachments based on bonding techniques shall be fully cured and not exhibit any tackiness.

Visual inspection of the feed-throughs

Feed-throughs shall be firmly bonded.

Feed-throughs shall conform to the locations specified on the top assembly drawing.

Visual inspection of the marking

All identification markings specified by the customer shall be firmly adhered to the locations identified on the assembly drawing.

Identification markings shall be clearly legible.

Visual inspection of the hardware

Terminal board locations shall conform to the qualification coupon assembly drawing.

Stand-off of all components shall conform to the qualification coupon assembly drawing.

For mounted components (temperature sensor, resistors and diodes), the following shall be performed:

- Verify the status of the following items:

- fixation on the substrate;

- body aspect and absence of cracks;

- connections;

- shrinkage tube.

- Ensure that conformal coating of the components,:

- consist of a uniform layer of the specified adhesive, and

- encapsulate the components.

For the connectors, the status of the following items shall be verified:

- fixing on the substrate;

- absence of cracks;

- connections;

- shrinkage tube.

Visual inspection of the bonding integrity

100 % of the solar cells shall be inspected for bond integrity.

Any loose cells shall not be used unless an engineering disposition, specifying that it can be used, is issued.

Visual inspection of the cleanliness

When visually examined with the unaided eye, the coupon shall appear clean.

There shall be no loose material on the coupon.

Electrical health check

Purpose

All tests specified in this clause are part of the electrical health check. The purpose of the electrical health check together with the electrical performance measurement is to detect faults in the electrical functions of the electrically active parts of the PVA.

Electrical continuity check

All electrical circuits of the PVA shall be checked to ensure electrical continuity, and the test conditions shall be stated in the SCD-PVA.

Insulation resistance

An insulation test shall be performed at the voltage stated in the SCD-PVA to measure the insulation between the following:

- the structure ground or substrate (+) and the solar cell circuits (-) including soldering and wiring;

- adjacent solar cell strings if not parallel connected;

- the thermal sensor (+) and the substrate (-);

- the thermal sensor (+) and cell strings (-);

- the cover glass network (-) to cell strings (+) if the coverglass network is grounded;

- the cover glass network (+) to cell strings (-) if the coverglass network is grounded. The insulation shall be in conformance with that stated in the SCD-PVA.

Grounding resistance test

All resistance at grounding spots shall be measured.

The grounding resistance shall be the value stated in the SCD-PVA.

Bleed resistor test

The resistance of the bleed resistor shall be measured.

The resistance shall be the value stated in the SCD-PVA.

Blocking diode test

The reverse current of the blocking diode shall be measured of at a voltage equal to the predicted maximum Voc during the mission.

The reverse current measured shall be negligible with respect to the string current (usually less than 5 mA).

The forward voltage drop of the blocking diode shall be measured with the string at maximum Isc current.

Test conditions and requirements shall be stated in the SCD-PVA.

Shunt diode test

When all the cells are protected by shunt diodes, the forward voltage of shunt diodes shall be measured by reverse mode measurement of the interconnected string at the maximum operating current and the measured voltage shall be equal 1 % to the sum of the individual diode forward voltages at the maximum current.

When all the cells are protected by shunt diodes, the supplier shall provide the test method and precautions to be taken.

When all the cells are protected by shunt diodes, during the test, the temperature increase of the shunt diode shall be uniform and shall not exceed the value stated in the SCD-PVA.

If the measured voltage is outside the sum of the individual diode forward voltages at the maximum current 1 %, techniques such as thermographic photo recordings may be used to locate the failed shunt diodes.

Thermal sensor test

The thermal sensor resistance shall be measured at room temperature.

The thermal sensor resistance shall be the value stated in the SCD PVA.

Resistance measurement

The resistance of the harness shall be measured at the interface connector by measuring the redundant coupon wiring in series (i.e. positive end to positive end and negative end to negative end).

Test conditions and requirements shall be described in the SCD-PVA.

Electrical performance measurement

Purpose

The power output is measured in order to be able to detect any degradation before and after testing.

Process

The electrical power performance at the string level shall be measured at a reference temperature of 25 C at the interface connector.

The performance measurement shall be made under 1 S.C. (AM0).

The characteristics of the Sun simulator are given in clause 10.

The results shall be in conformance with those stated in the SCD-PVA.

The inaccuracies in current, voltage and power shall be specified in the SCD-PVA and include:

- spectral mismatch;

- uniformity of the test area;

- dynamic electrical effects of the test item

Example: capacitance.

- inaccuracies of the temperature sensors.

Calibration shall be done with an agreed primary standard reference and secondary working standard (SWS) in conformance with clause 10.

Pre-test and post-test measurements shall be made with the same test setup.

Capacitance test

Purpose

The purpose of the test is to measure the capacitance of the PVA by measuring the string capacitance in order to characterise the electrical dynamical behaviour of the PVA in interaction with the power regulator. Different types of power regulator require different measurement techniques. The methods described in clause 5.5.3.5.2 are applicable only to PVA interacting with a sequential switching shunt regulator.

Process

One of the following methods shall be followed for capacitance measurement:

- frequency domain single junction solar cell capacitance measurement as described in clause 11.1,

No method available for multi-junction measurement at the time being.

- Time domain capacitance measurement as described in clause 11.2.

The method for measuring the capacitance shall be stated in the SCDPVA.

The capacitance shall be measured at room temperature and averaged operational temperature.

The measurement at averaged operational temperature can be replaced by measurement of the SCA capacitance at operational temperature.

Bake-out

Measures to prevent outgassing, to be taken before exposure to vacuum conditions, shall be agreed with the customer.

If a vacuum bake-out at the panel level is specified in the solar array specification, a vacuum bake-out shall be performed on the PVA before thermal cycling at coupon level.

Temperature and test conditions shall be defined in SCD-PVA.

Thermal cycling acceptance test

Purpose

The thermal cycle acceptance tests assess the reliability of the PVA under stress and verify the workmanship of the supplier. In this way infant mortality stresses are identified and these parts can be replaced.

General

Thermal vacuum cycling should be used.

If gaseous cycling tests are used, the supplier shall demonstrate the equivalence of the test method.

The temperature extremes of the thermal cycling shall be extended or a dedicated structural test shall be performed in cases where analysis demonstrates that the structural loading results in a greater stress than the thermal cycling.

Process

The panels shall be exposed to the number of thermal cycles for acceptance as stated in the SCD-PVA.

The number of cycles specified in requirement 5.5.3.7.3a shall be between 4 and 10.

The temperature profile shall be the worst-case nominal temperature profile with a 5 C margin.

During thermal cycling, the electrical insulation shall be measured.

During thermal cycling, the continuity shall be measured at least during the last cycle.

Continuity and insulation shall not be measured simultaneously.

Acceptance criteria shall be:

- A maximum increment of IOP, and a minimum isolation, as stated in the SCD-PVA.

- The existence of electrical continuity (no open circuit).

- At the end of the test, less than a 2 % increase in cracked cells or one cracked cell, whichever is higher, not cumulative with the results of the bake-out test and which can have an impact on the electrical performance of the string.

Reflectance

The reflectance of the solar cell surface shall be measured before and after the humidity test to determine the possible degradation of the coverglass coatings.

The reflectance shall be measured over a range from 280 nm to 2 500 nm.

The reflectance shall not change during testing more than as stated in the SCD-PVA.

X-Ray

X-ray photographs shall be taken of all busbars, wire collection strips and diode boards on the qualification coupons.

The acceptance criteria shall be stated in the SCD-PVA.

Defects that cannot be detected by means of visual inspections (e.g. internal structural deformations or alterations in busbars and wire connections) can be traced by X-ray photographs.

Substrate integrity

Process

The structural integrity of the substrate shall be inspected after thermal cycling.

A non-destructive test method should be used for the inspection specified in requirement 5.5.3.10.1a.

If requirement 5.5.3.10.1b cannot be satisfied, a destructive test shall be applied.

The test method shall be described in the SCD-PVA.

Pass-fail criteria

The pass-fail criteria shall be those stated in the SCD-PVA.

Vacuum thermal cycling

Purpose

Vacuum thermal cycling is performed in order to verify the integrity of components, assemblies and interfaces in a vacuum environment.

Process

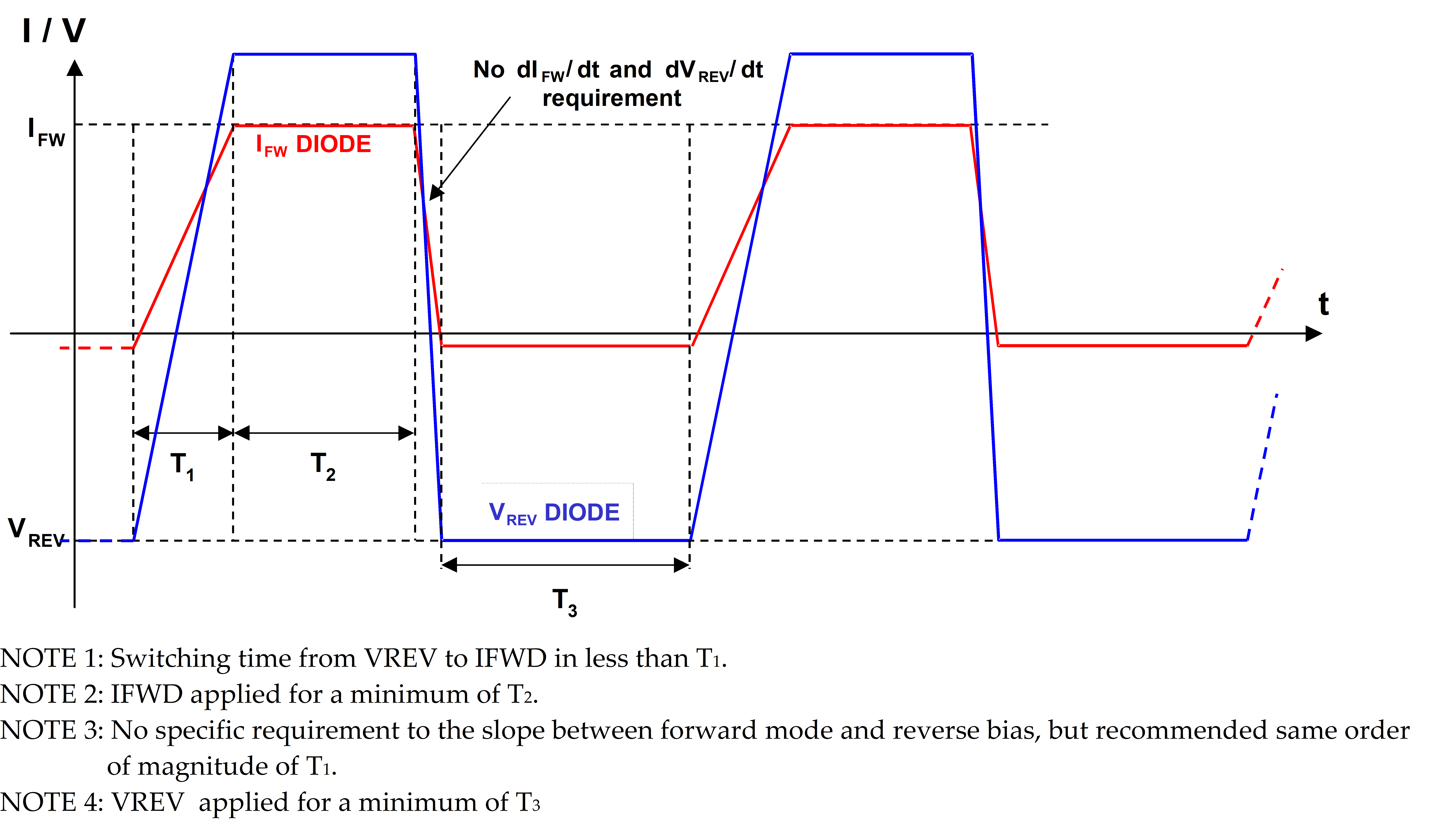

The components to be checked for electrical continuity shall be identified in the SCD-PVA.