Space product assurance

Qualification and procurement of printed circuit boards

Foreword

This Standard is one of the series of ECSS Standards intended to be applied together for the management, engineering and product assurance in space projects and applications. ECSS is a cooperative effort of the European Space Agency, national space agencies and European industry associations for the purpose of developing and maintaining common standards. Requirements in this Standard are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards.

This Standard has been prepared by the ECSS Executive Secretariat, endorsed by the Document and Discipline Focal Points, and approved by the ECSS Technical Authority.

Disclaimer

ECSS does not provide any warranty whatsoever, whether expressed, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item are error-free. In no respect shall ECSS incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this Standard, whether or not based upon warranty, business agreement, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by ECSS.

Published by: ESA Requirements and Standards Division

ESTEC, P.O. Box 299,

2200 AG Noordwijk

The Netherlands

Copyright: 2019 © by the European Space Agency for the members of ECSS

Change log

|

ECSS-Q-ST-70-60C

|

First issue

|

|

ECSS-Q-ST-70-60C Corrigendum 1

|

First issue, Corrigendum 1

|

|

History of superseded versions

| |

|

ECSS-Q-70-10A

|

First issue

|

|

ECSS-Q-70-10B

|

Never issued

|

|

ECSS-Q-ST-70-10C

|

Second issue

|

Introduction

PCBs are used for the mounting of electronic components to produce PCB assemblies that perform electrical functions. The PCBs are subjected to thermo-mechanical stress during assembly such as soldering of components, rework and repair under normal terrestrial conditions. In addition, the assembled PCBs are exposed to the launch and space environment. The reliability of the circuit depends on the robustness of the manufacturing processes, for which this standard specifies requirements. PCB technology needs detailed inspections to verify its reliability, which is specified for the qualification and procurement phases of the PCB technology.

Scope

This standard specifies the requirements for the PCB manufacturer, the procurement authority and the qualification authority for qualification and procurement of PCB technology.

ECSS-Q-ST-70-60 is applicable for all types of PCBs, including sequential, rigid and flexible PCBs, sculptured flex, HDI and RF PCBs.

This standard can be made applicable for other products combining mechanical and electrical functionality using additive or reductive manufacturing processes, as used in PCB manufacturing. Examples of such products are slip- rings, bus bars and flexible flat cables.

This standard may be tailored for the specific characteristics and constraints of a space project in conformance with ECSS-S-ST-00.

Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this ECSS Standard. For dated references, subsequent amendments to, or revision of any of these publications do not apply. However, parties to agreements based on this ECSS Standard are encouraged to investigate the possibility of applying the more recent editions of the normative documents indicated below. For undated references, the latest edition of the publication referred to applies.

|

ECSS-S-ST-00-01

|

ECSS system — Glossary of terms

| |

|

ECSS-Q-ST-10-09

|

Space product assurance — Nonconformance control system

| |

|

ECSS-Q-ST-20

|

Space product assurance — Quality assurance

| |

|

ECSS-Q-ST-70

|

Space product assurance — Material, mechanical parts and processes

| |

|

ECSS-Q-ST-70-02

|

Space product assurance — Thermal vacuum outgassing test for the screening of space materials

| |

|

ECSS-Q-ST-70-08

|

Space product assurance — Manual soldering of highreliability electrical connections

| |

|

ECSS-Q-ST-70-12

|

Space product assurance — Design rules for printed circuit boards

| |

|

ECSS-Q-ST-70-21

|

Space product assurance — Flammability testing for the screening of space materials

| |

|

ECSS-Q-ST-70-22

|

Space product assurance — Control of limited shelflife materials

| |

|

ECSS-Q-ST-70-29

|

Space product assurance — Determination of offgassing products from materials and assembled articles to be used in a manned space vehicle crew compartment

| |

|

ECSS-Q-ST-70-38

|

Space product assurance —High reliability soldering for surface mount and mixed technology printed circuit boards

| |

|

EN 9100:2016

|

Quality management systems – Requirements for aviation, space and defense organisations

| |

|

IEC 60326-2-am 1 (1992-06)

|

Printed boards. Part 2: Test methods

| |

|

IEC 60194 (1999-04)

|

Printed board design, manufacture and assembly — Terms and definitions

| |

|

IPC-A-600J (2016)

|

Acceptability of Printed Boards

|

|

|

IPC-T-50M (2015)

|

Terms and definitions for interconnecting and packaging electronic circuits

| |

|

IPC-TM-650

|

Test methods manual

| |

|

IPC-1710A (2004)

|

OEM Standard for Printed Board Manufacturers' Qualification Profile

| |

|

IPC-4101E (2017)

|

Specification for base materials for rigid and multilayer printed boards

| |

|

IPC-4103A-WAM1 (2014)

|

Specification for Base Materials for High Speed/

| |

|

IPC-4203A (2013)

|

Adhesive Coated Dielectric Films for Use as Cover Sheets for Flexible Printed Circuitry and Flexible Adhesive Bonding Films

| |

|

IPC-4204A-WAM1 (2014)

|

Flexible Metal-Clad Dielectrics for Use in Fabrication of Flexible Printed Circuitry

| |

|

IPC-6012D (2015)

|

Qualification and performance specification for rigid printed boards

| |

|

IPC-6012DS (2015)

|

Space and military avionics applications addendum to IPC-6012D

| |

|

IPC-6013D (2017)

|

Qualification and Performance Specification for Flexible Printed Boards

| |

|

IPC-6018C (2016)

|

Qualification and Performance Specification for High Frequency (Microwave) Printed Boards

| |

|

IPC-6018CS (2016)

|

Space and Military Avionics Applications Addendum to IPC-6018C

| |

|

ISO 9001:2015

|

Quality management systems - Requirements

| |

|

ISO-14644-1 (2015)

|

Cleanrooms and associated controlled environments - Part 1: Classification of air cleanliness by particle concentration

|

Terms, definitions and abbreviated terms

Terms from other standards

For the purpose of this Standard, the terms and definitions from ECSS-S-ST-00-01 apply, and in particular the following terms:

customer

supplier

See clause 4.2 for a description of roles of customer and supplier.

For the purpose of this Standard, the terms and definitions from ECSS-Q-ST-70-12 apply, and in particular the following terms:

annular ring

area array device (AAD)

aspect ratio

basic copper

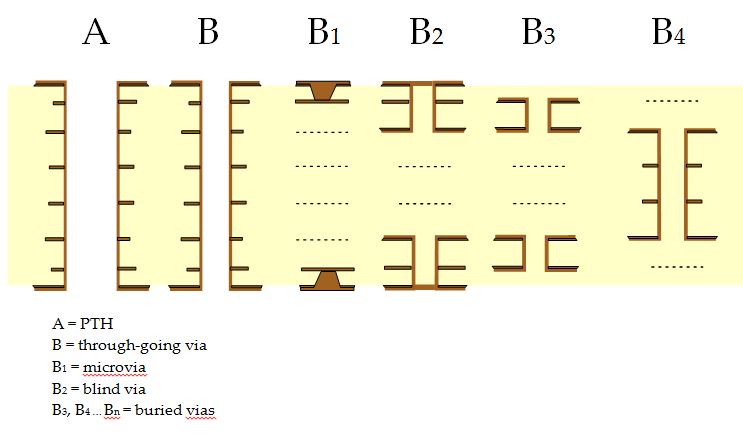

blind via

bond-ply

build-up

buried via

conductor

FR4

hole wall pull away

heat sink

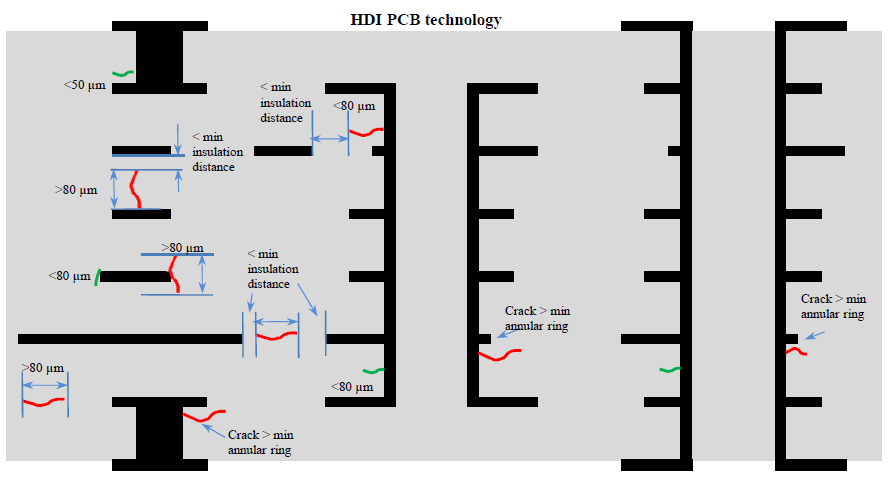

high density interconnect (HDI)

interlayer

intralayer

laminate

microvia

no-flow prepreg

non-functional pad

non-pated hole

normal pitch

panel

plated through-hole (PTH)

prepreg

printed circuit board (PCB)

resin starvation

serialization

spacing

stack

track

via

X,Y direction

Z direction

Terms specific to the present standard

automated optical inspection (AOI)

inspection method using an automated equipment to verify the pattern on an etched layer

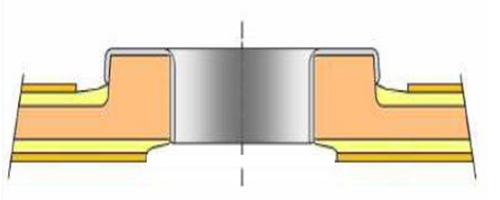

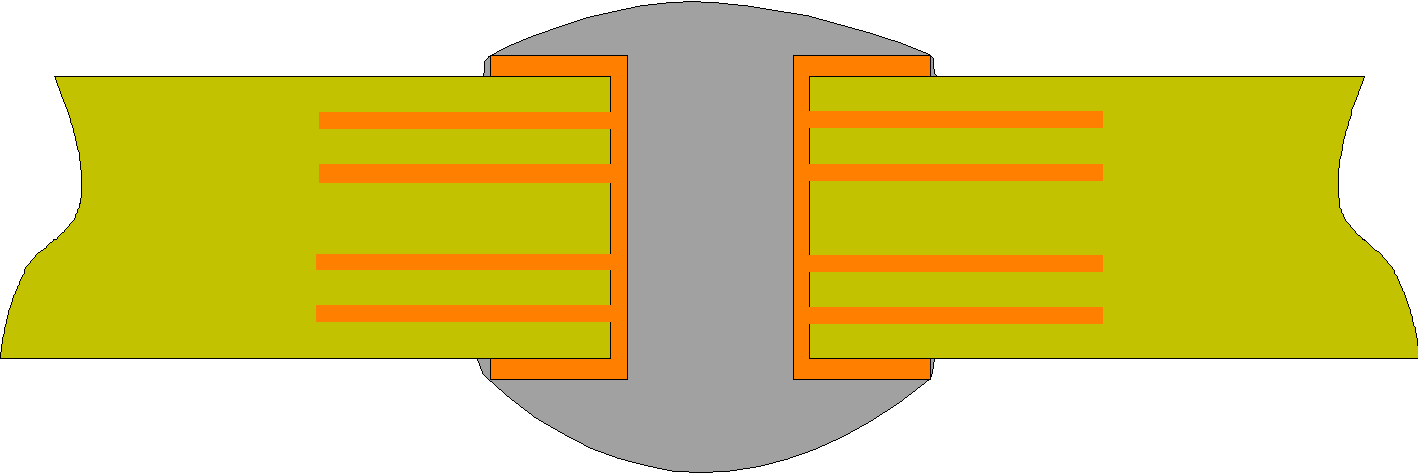

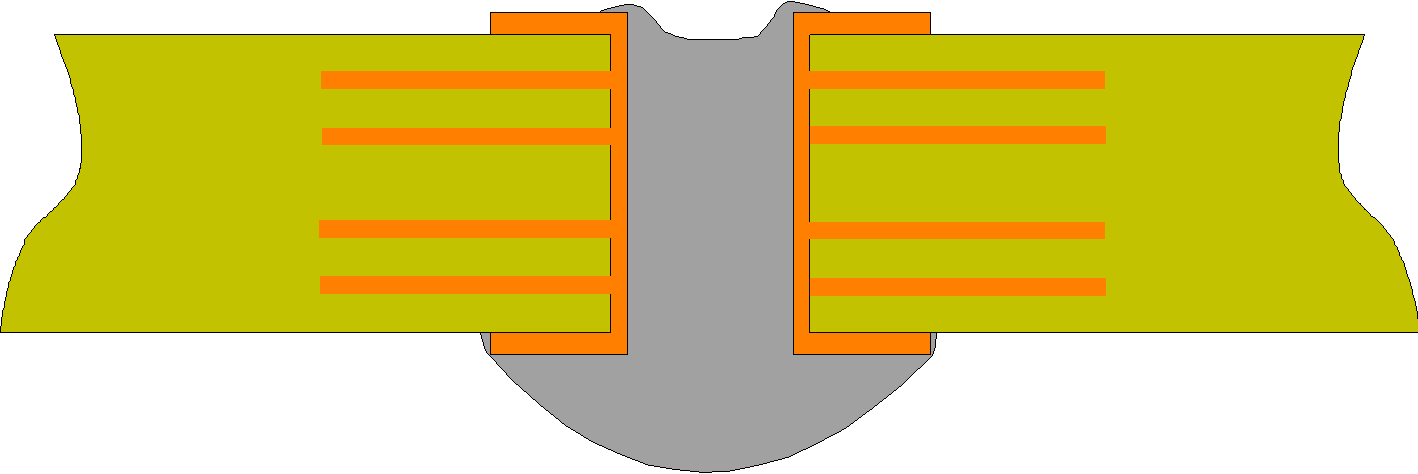

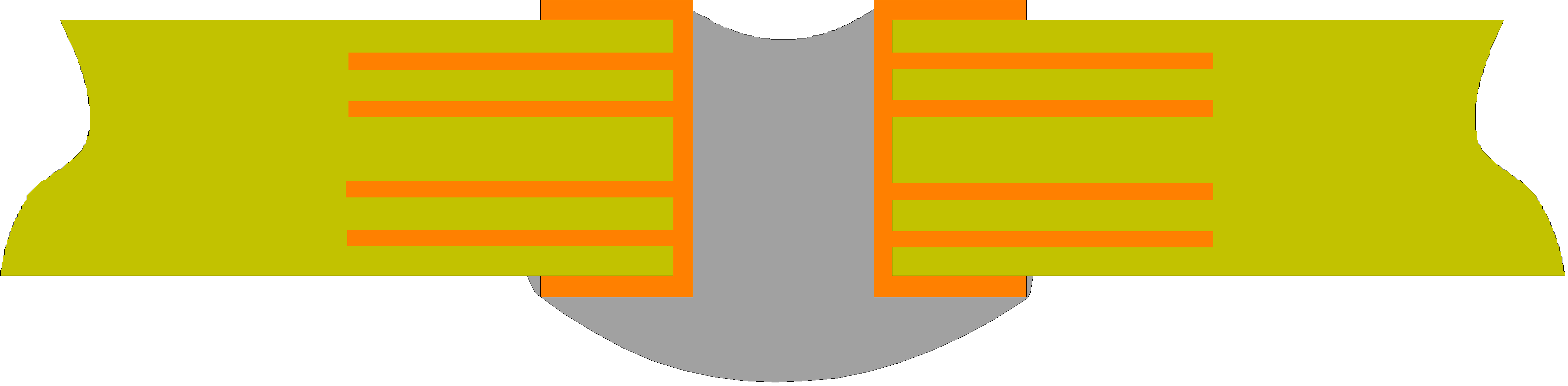

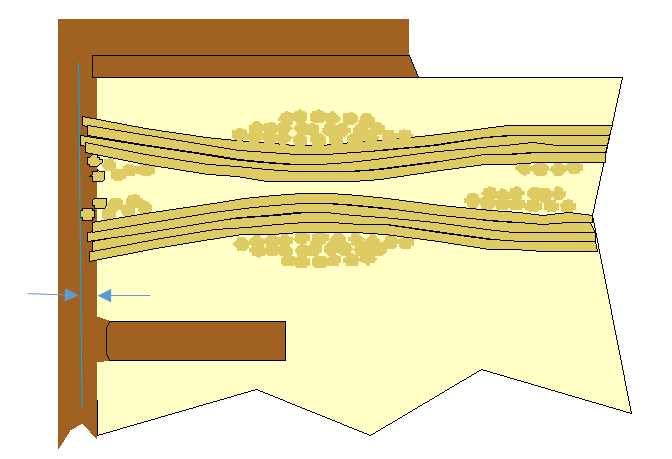

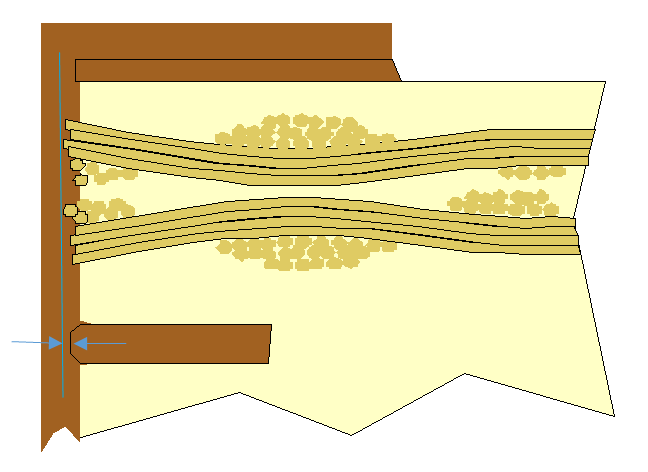

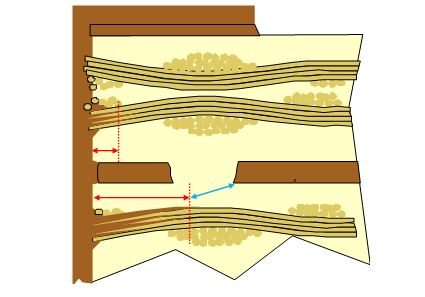

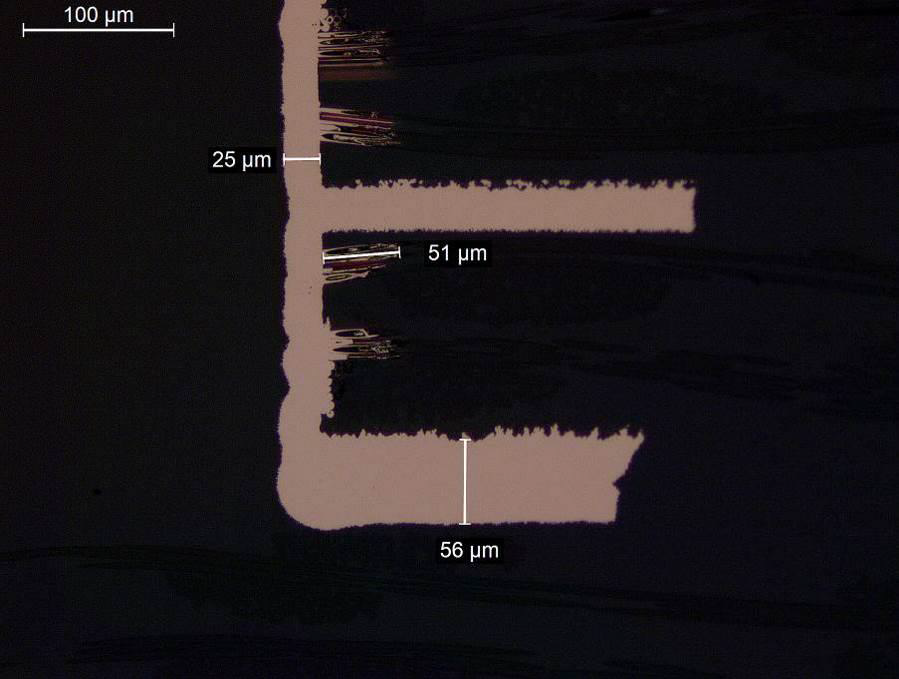

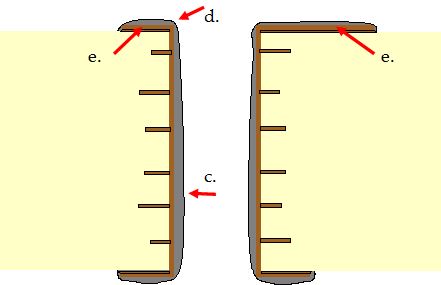

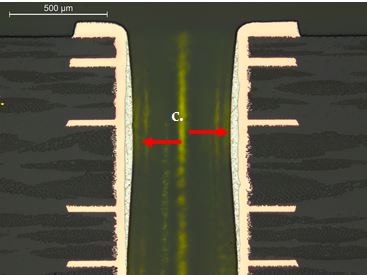

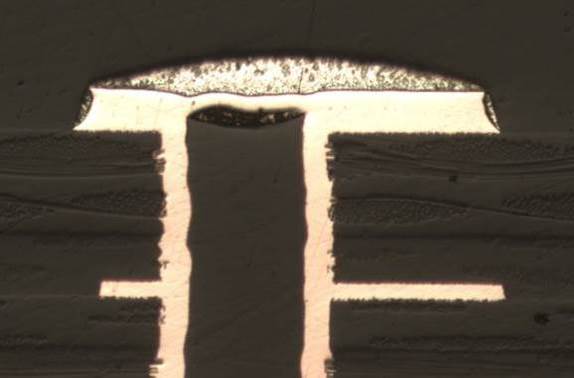

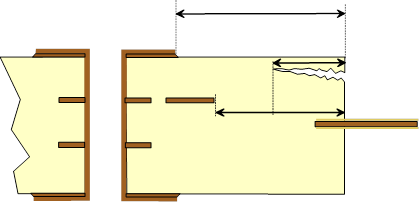

back-drilled via

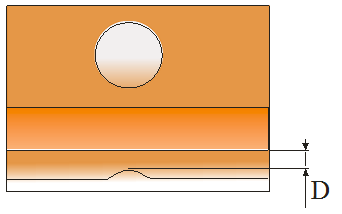

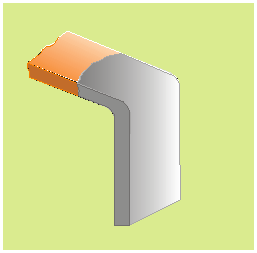

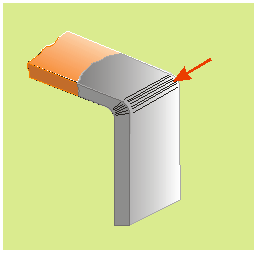

type of via with part of its metallisation removed on one side by depth controlled mechanical drilling with a larger diameter drill

batch

group of PCBs and coupons that are covered by the same CoC and the same traveller

- 1 A batch is processed approximately at the same time. See 6.8a.

- 2 The terms “lot” and “work order” are synonymous.

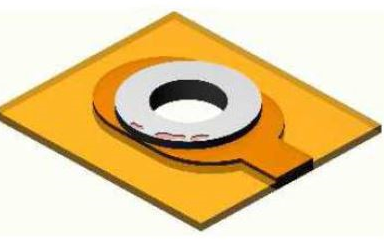

blind-via-in-pad

type of via directly underneath a SMT pad

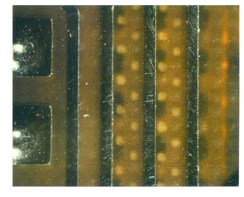

blister

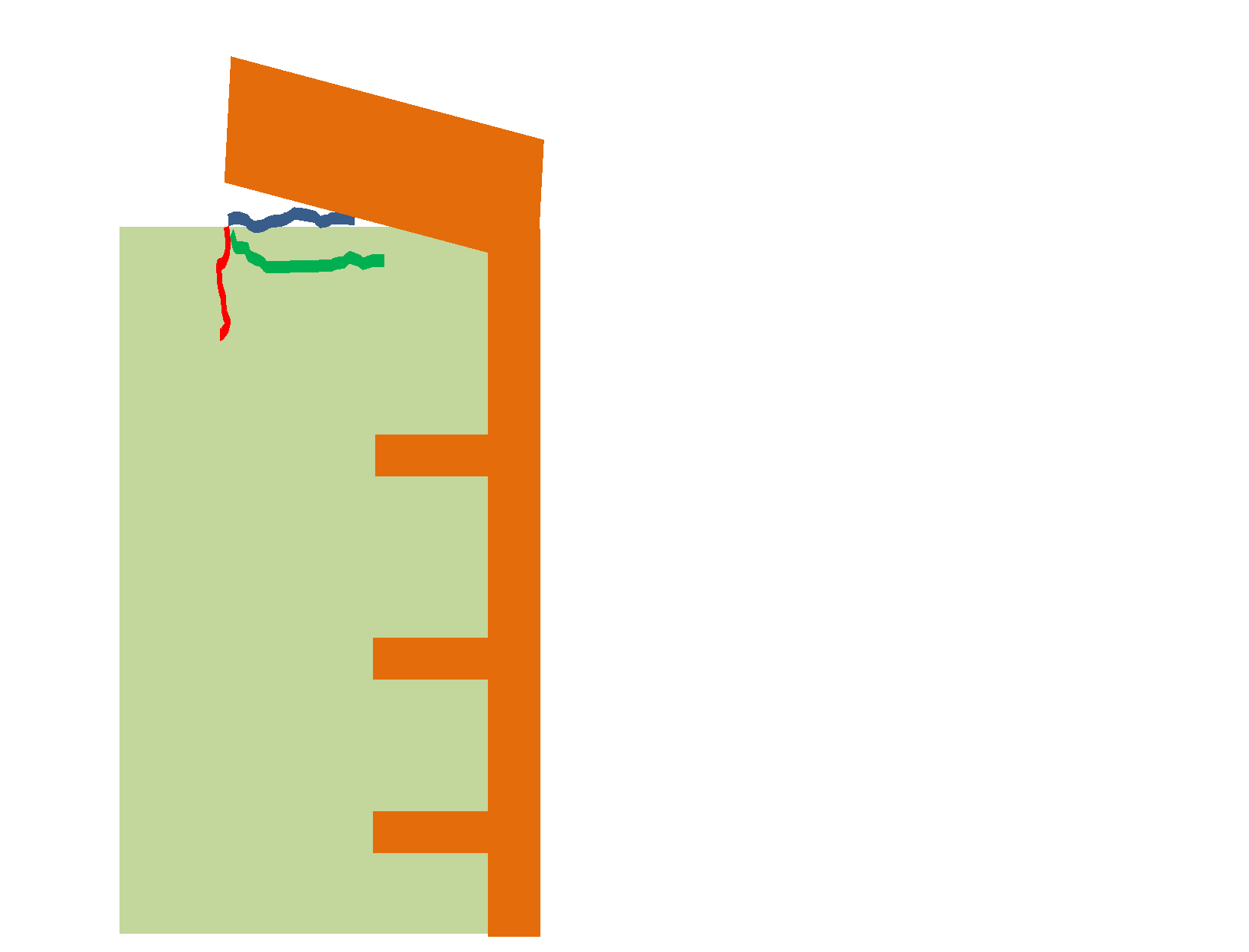

delamination in the form of a localized swelling and separation between any of the layers of a laminated base material, or between base material and conductive foil or protective coating

[IPC-T-50M]

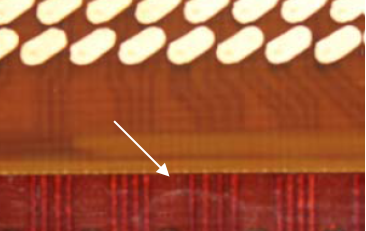

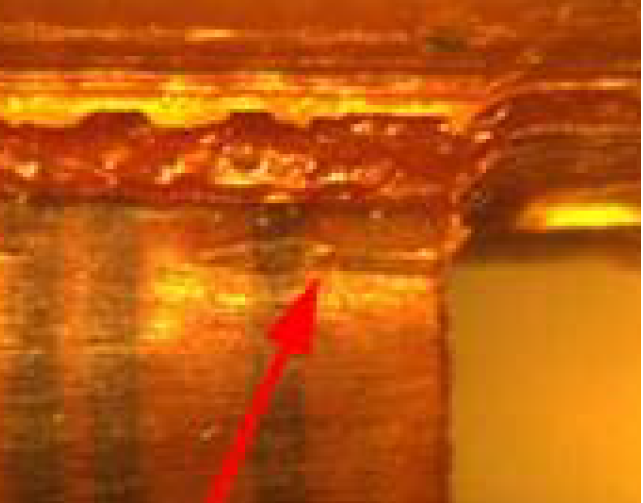

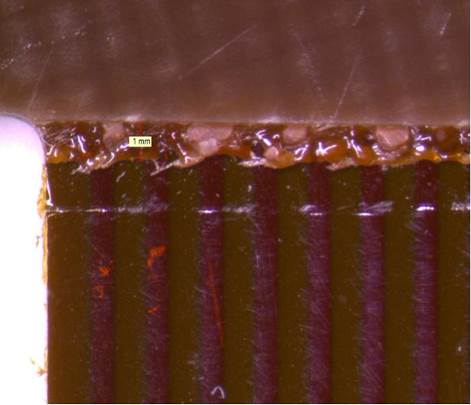

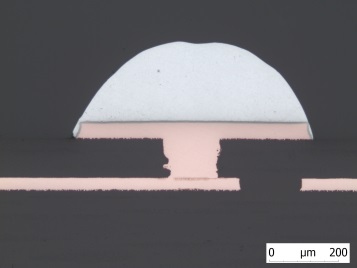

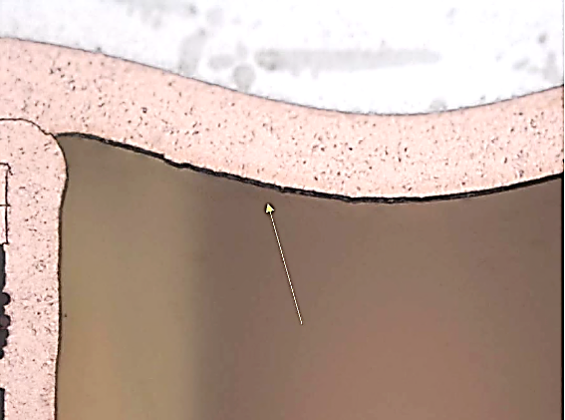

cap lift

separation between resin in blind via and copper cap plating on surface

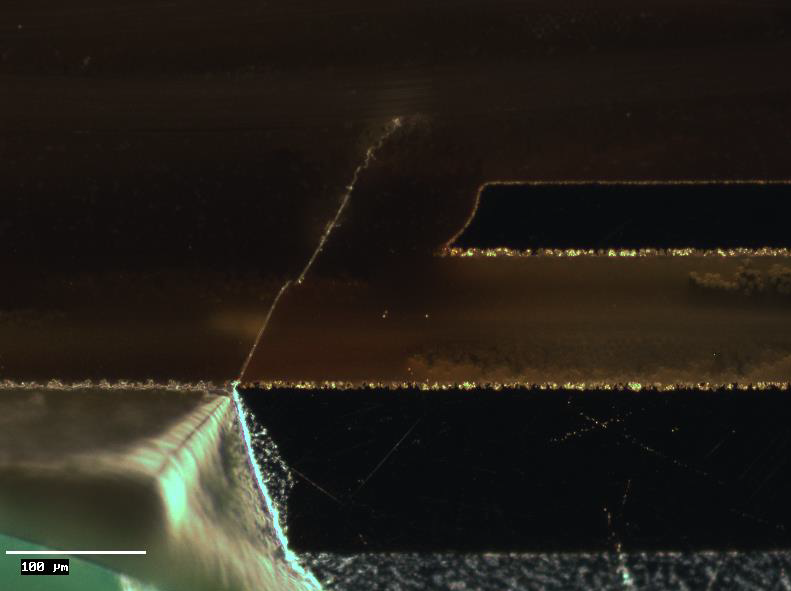

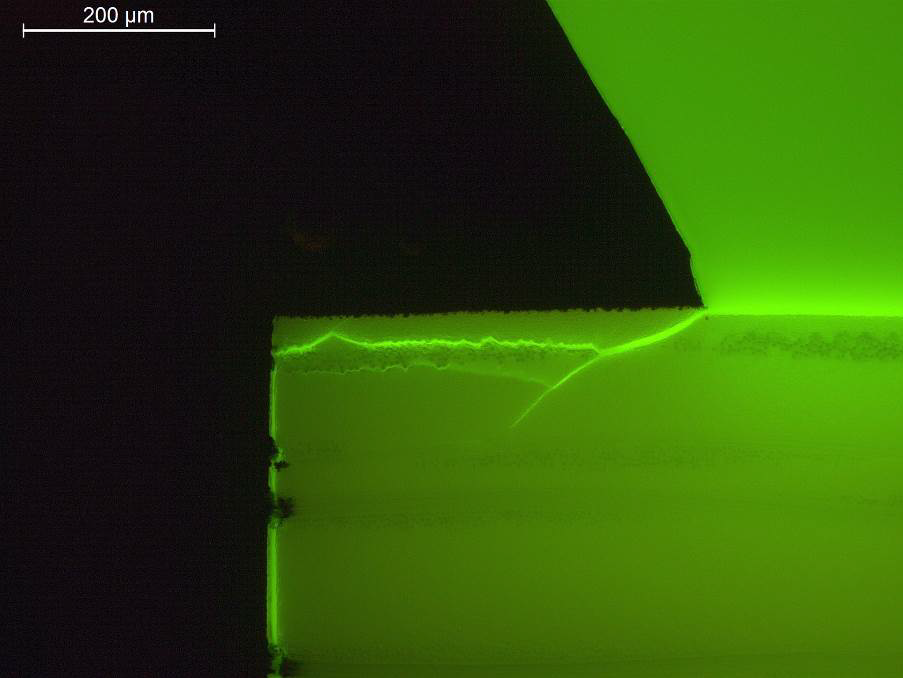

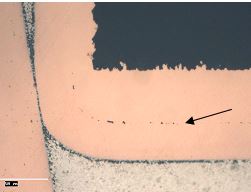

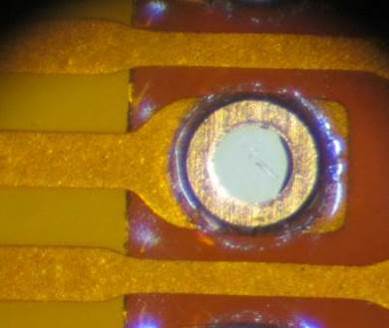

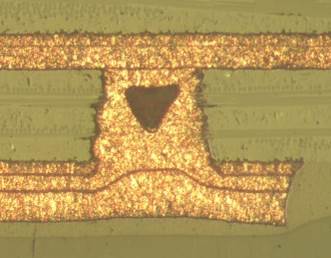

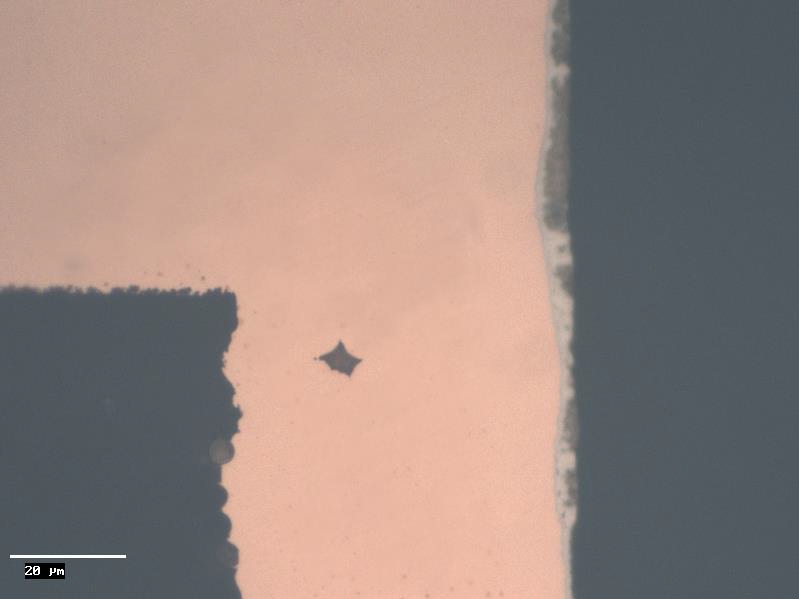

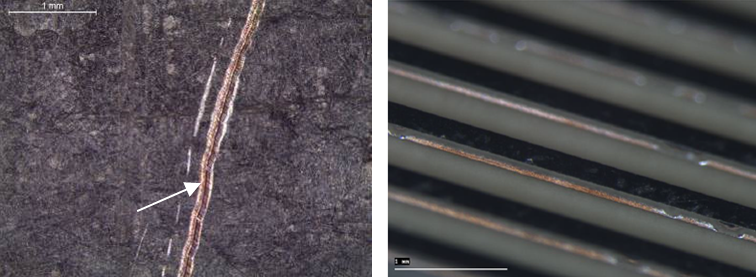

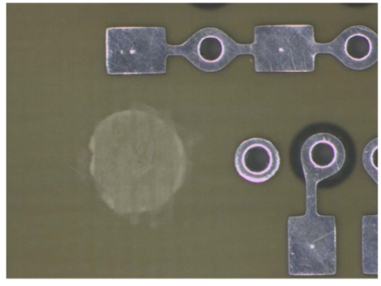

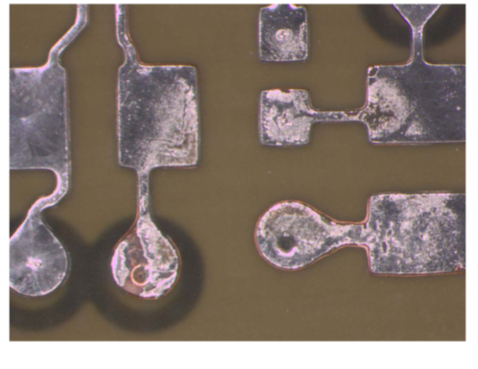

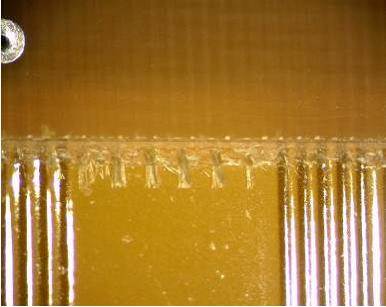

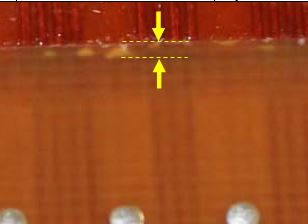

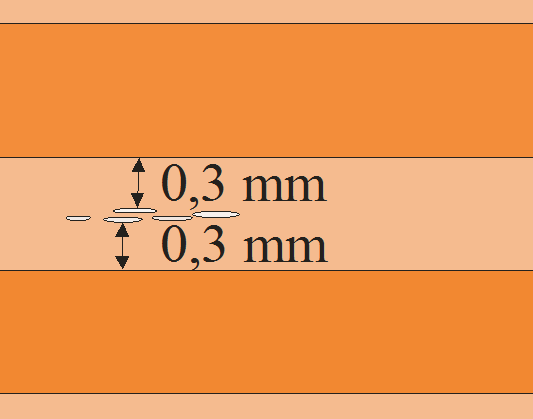

Cap lift can be shown as bulging and as thin line separation, as shown in Table 1018.

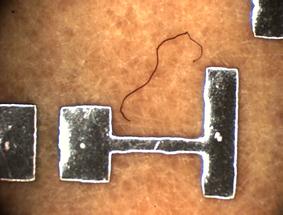

contamination

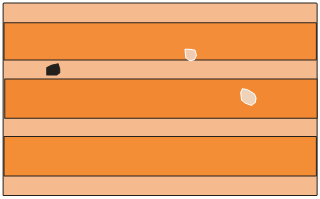

<CONTEXT: Qualification and procurement of PCBs>

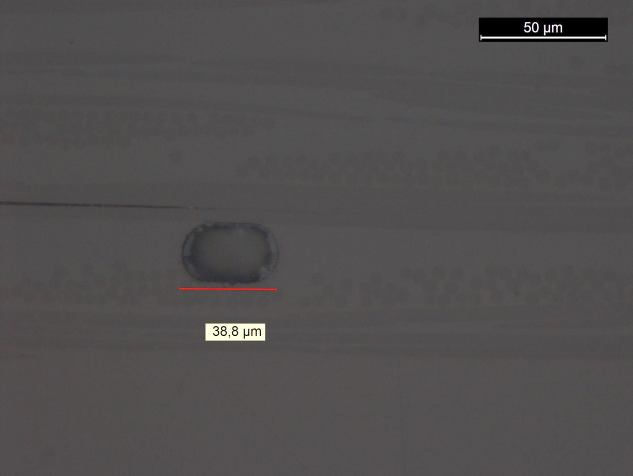

foreign material embedded in dielectric material

-

1 Synonyms are: FOD, inclusion (see definition 3.2.20), foreign material, debris, pollution.

-

2 Contamination can be organic, metallic, particulate or fibres.

coupon

small piece of test circuitry that is used for quality conformance evaluation by specific tests and inspection -

1 The coupon is manufactured as part of a panel and at the final manufacturing stage it is separated from it. The coupon is thus associated with the PCBs within the panel, with which it was simultaneously manufactured.

-

2 The term ‘coupon’ refers to a generic pattern, whereas the term ‘IST coupon’ refers to the specific IST pattern.

[adapted from IPC-T-50M]

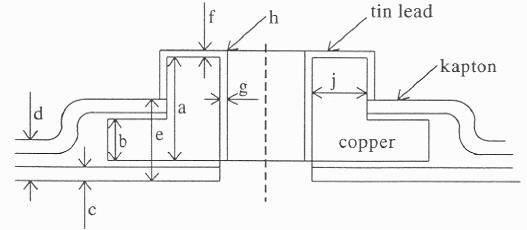

coverlay

thin dielectric material used to encapsulate circuitry, most commonly for flexible circuit applications

The terms ‘cover layer’ and ‘cover material’ are synonymous.

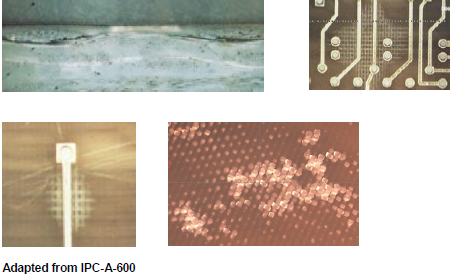

crazing

condition that occurs in reinforced laminate base material whereby glass fibre bundles are separated from the resin not limited to the weave intersections

- 1 This condition manifests itself in the form of connected white spots or crosses that are below the surface of the base material. It is usually related to thermally or mechanically induced stress. Crazing is a more severe defect than measling. Delamination is a further worsening of crazing.

- 2 See also “measling”.

delamination

separation between plies within a base material, between base material and a conductive foil, or any other planar separation with a PCB

See also ‘blister’, which is a local delamination.

[IPC-T-50M]

destructive physical analysis (DPA)

analysis method using sampling, potting, grinding, polishing and inspection which, thus, destroys the test vehicle

The term ‘microsectioning’ is approximately synonymous.

dewetting

condition that results when molten solder coats a surface and then recedes to leave irregularlyshaped mounds of solder that are separated by areas that are covered with a thin film of solder and with the base metal not exposed

[IPC-T-50M]

dross

oxide and other contaminants that form on the surface of molten solder

[IPC-T-50M]

etchback

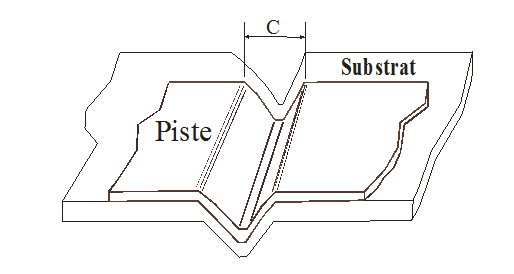

distance from resin of hole wall to innerlayer foil

fine pitch

spacing of tracks or pads that is more dense than for normal pitch

Pitch is specified in clause 7.4 of ECSS-Q-ST-70-12.

flexible

PCB technology that uses only flexible layers in its build up

The term ’flex’ is synonymous.

glass compression

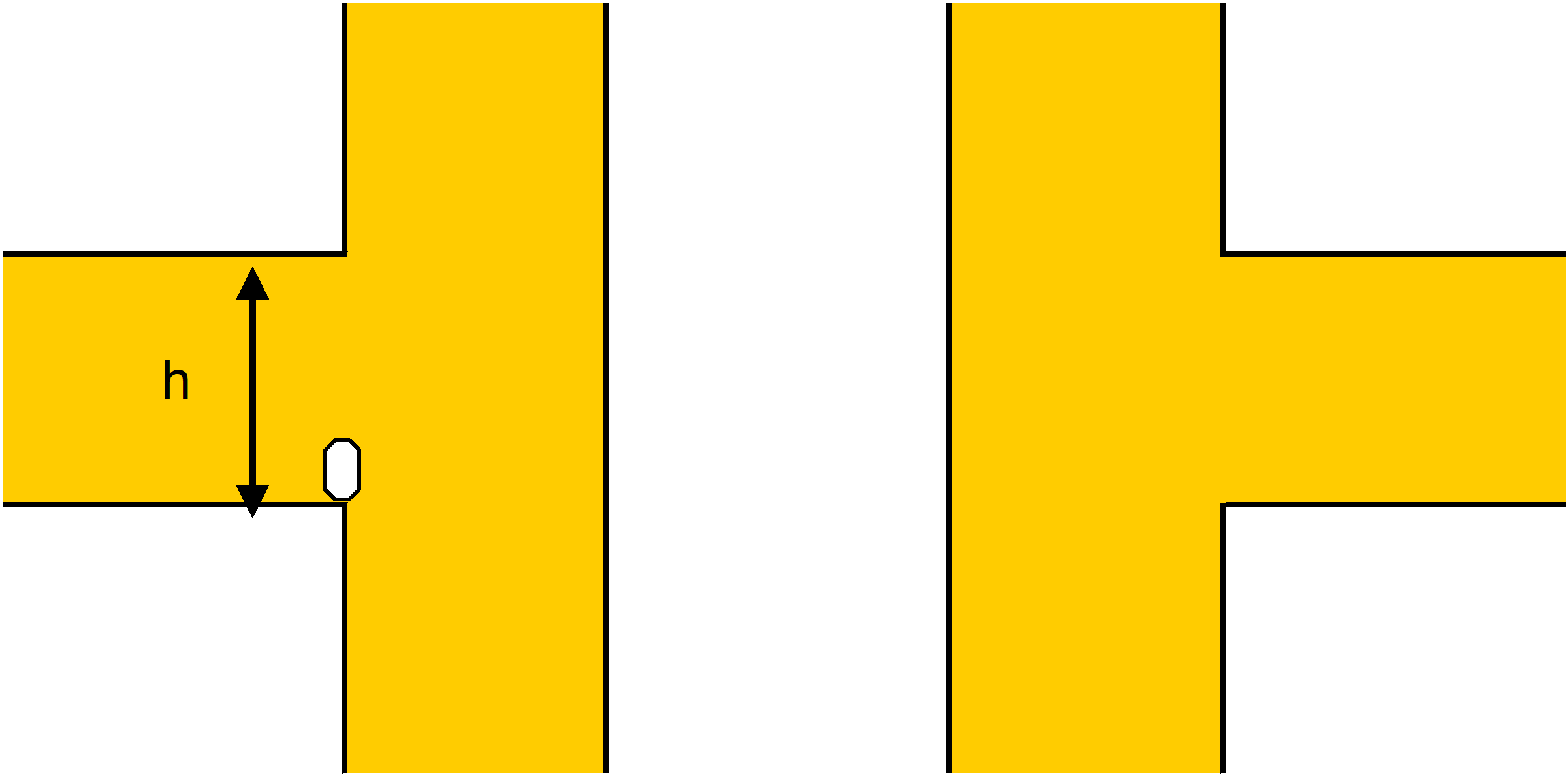

deformed glass fibre bundles of prepreg causing absence of resin between glass and copper due to profiled copper pattern

See also ‘resin starvation’.

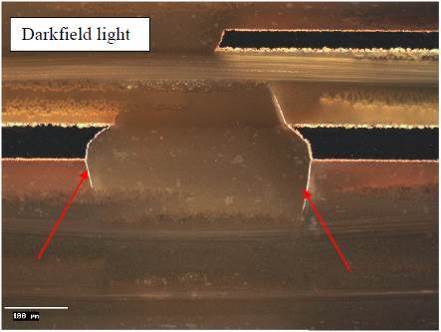

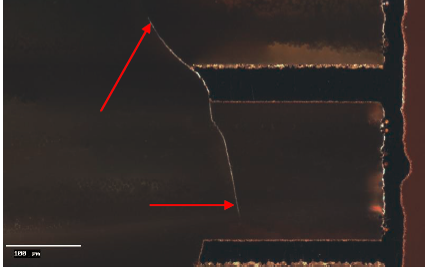

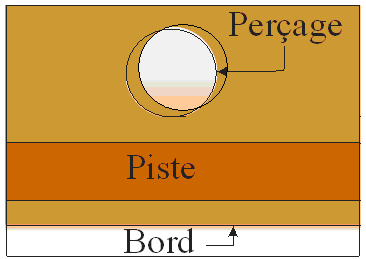

haloing

mechanicallyinduced fracturing or delamination, on or below the surface of a base material, that is usually exhibited by a light area around holes or other machined features

[IPC-T-50M]

inclusion

foreign particle, metallic or nonmetallic, that can be entrapped in an insulating material, conductive layer, plating, base material or solder connection

[IPC-T-50M]

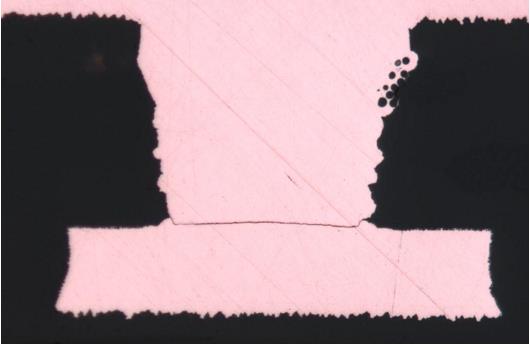

interconnect defect (ICD)

separation at the interface between internal layer and through-hole plating

- 1 The term ‘innerlayer separation’ is synonymous.

- 2 See ‘smear’ for additional explanation.

[IPC-6012D]

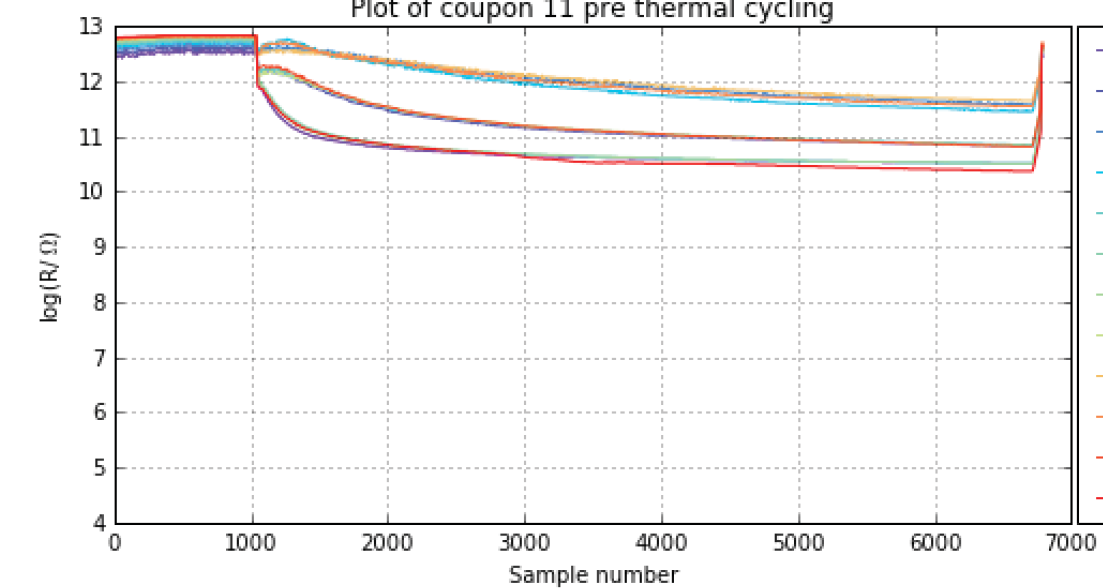

interconnect stress test (IST)

test method using a specific IST coupon and a specific IST equipment

IST coupon

specific coupon for IST

The term ‘coupon’ refers to a generic pattern, whereas the term ‘IST coupon’ refers to the specific IST pattern.

key personnel

personnel with specialist knowledge responsible for defined production or product assurance areas

lay-out

design of the conductive pattern on a layer

measling

condition that occurs in laminated base material whereby glass fibre bundles are separated from the resin limited to the weave intersection

- 1 This condition manifests itself in the form of discrete white spots or “crosses” that are below the surface of the base material. It is usually related to thermallyinduced stress or humidity.

- 2 See also “crazing”, which is a further worsening of measling.

[IPC-T-50M]

metal core

layer or local insert of thick metal embedded inside the PCB usually used as a heat sink, grounding layer or restriction of thermal expansion

milling

mechanical method that removes a portion of the material outlining a PCB using a cutting bit

See also ‘routing’.

multilayer

PCB technology that uses lamination of several copper layers and plated holes for interconnection

PCBs that are not multilayer, are double-sided or single-sided PCBs. See also “sequential”.

plated hole

hole that is used as an interlayer connection

Types of plated holes are PTH and vias.

PCB manufacturer

entity that manufactures the PCB

The PCB manufacturer is supplier to the procurement authority.

PCB technology

category of manufacturing processes, materials and design for PCBs

Examples of PCB technology are:

- Polyimide sequential rigid

- Polyimide sequential rigid/flex

- Epoxy sequential rigid

- Epoxy non-sequential rigid/flex

- HDI with microvias

- RF

- Flexible and sculptured flex

plugged via

via type that is cap plated and filled with resin in a specific via filling process

Blind vias can be resin-filled using resin from the prepreg during sequential lamination. Plugged vias use a resin that does not originate from the prepreg and the filling process does not occur during lamination.

procurement authority

entity that procures the PCB

- 1 The procurement authority is customer of the PCB manufacturer.

- 2 The procurement authority can be supplier to the prime contractor.

qualification authority

entity that qualifies the PCB technology and PCB manufacturer

radio frequency (RF)

electronic functionality that requires specific design precautions on dielectric materials and copper pattern to maintain time dependant signal integrity

- 1 The term ‘high speed’ is synonymous.

- 2 The term ‘RF PCB’ identifies the PCB technology.

rigid

PCB technology that uses only rigid layers in its build-up

rigid/flex

PCB technology that uses a combination of rigid and flexible layers in its build-up

routing

the lay-out and connection of conductors between plated-holes and pads

The term ‘routing’ is also used for ‘milling’. This second meaning is not used in ECSS-Q-ST-70-60 to avoid confusion.

scratch

narrow furrow or grove in a surface

It is usually shallow and caused by the marking or rasping of the surface with a pointed or sharp object.

[IEC 60194 (1999-04)]

sculptured flex

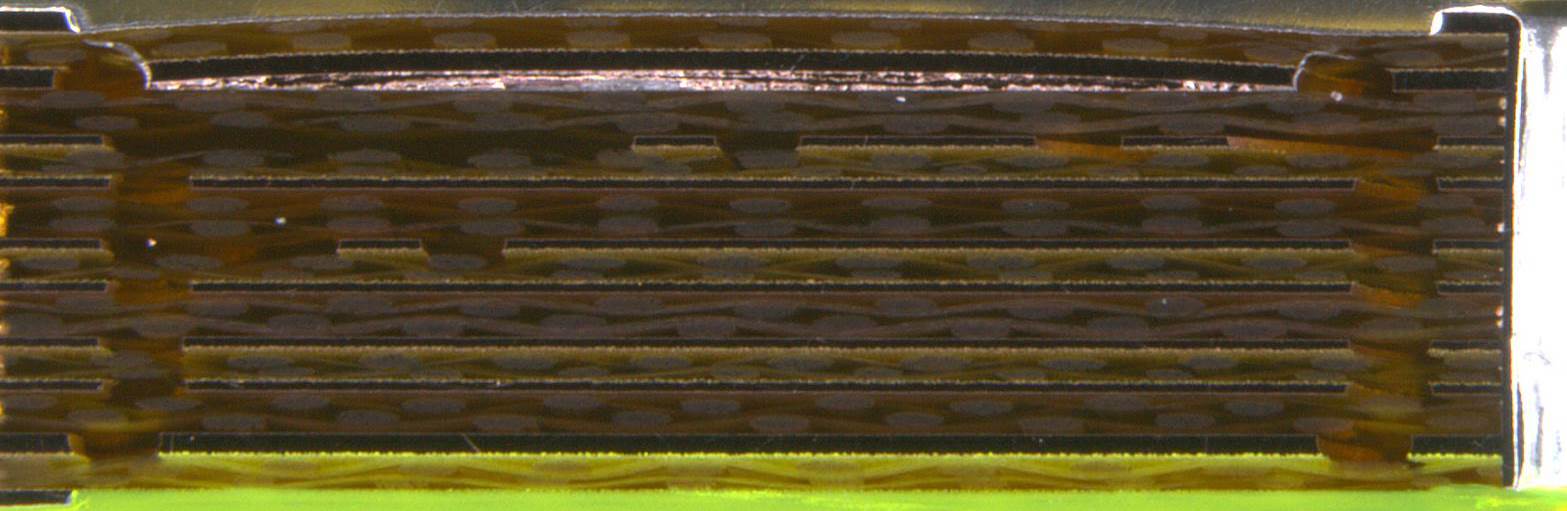

flexible PCB technology that uses profiled copper tracks

Aviflex is a commercial identification of sculptured flex.

sequential

PCB technology that uses more than one lamination or drilling step

The term ‘sequential’ also implies that the PCB is of type ‘multilayer’. The opposite is ‘non-sequential’.

sequential via

via type that interconnects layers within the same plating sequence

Examples of sequential vias are blind vias and buried vias.

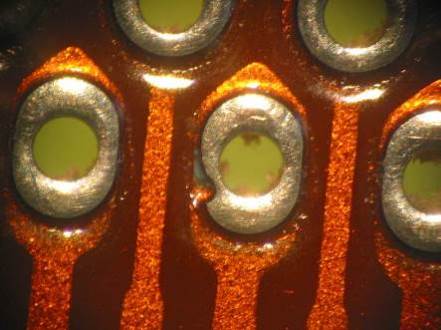

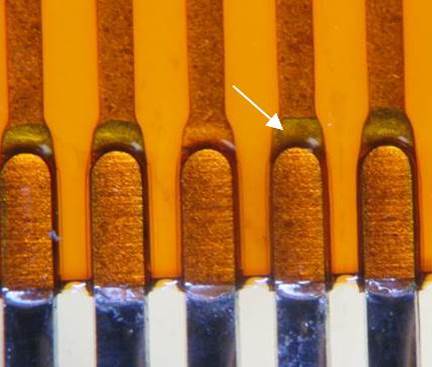

skip plating

local missing deposition of plating

Skip plating can occur on electroless copper plating on glass in the hole wall. Skip plating can also occur on surface finish.

smear

base material resin that covers the interface between the exposed edge of an innerlayer pad and through-hole plating

- 1 The resin transfer is usually caused by the drilling operation and removed during the desmear process. The term ‘resin smear’ or ‘smearing’ are synonymous.

- 2 The aspect of smear can be mistaken for interconnect defect, or vice versa. Smear is the presence of resin, whereas interconnect defect is an adhesive separation of copper plating.

[adapted from IPC-T-50M]

test pattern

part of the PCB or coupon that refers to the copper pattern for a specific test

[adapted from IPC-T-50M]

through-going via

type of via that is drilled through the entire thickness of the PCB

traveller

documentation kept with the batch during the manufacturing processes in which the order of specific processes are recorded

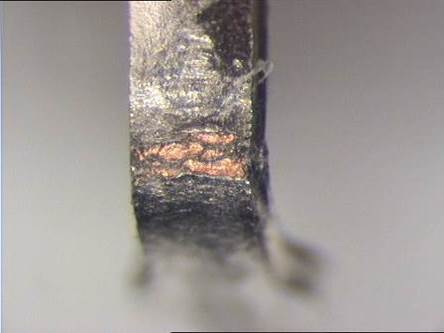

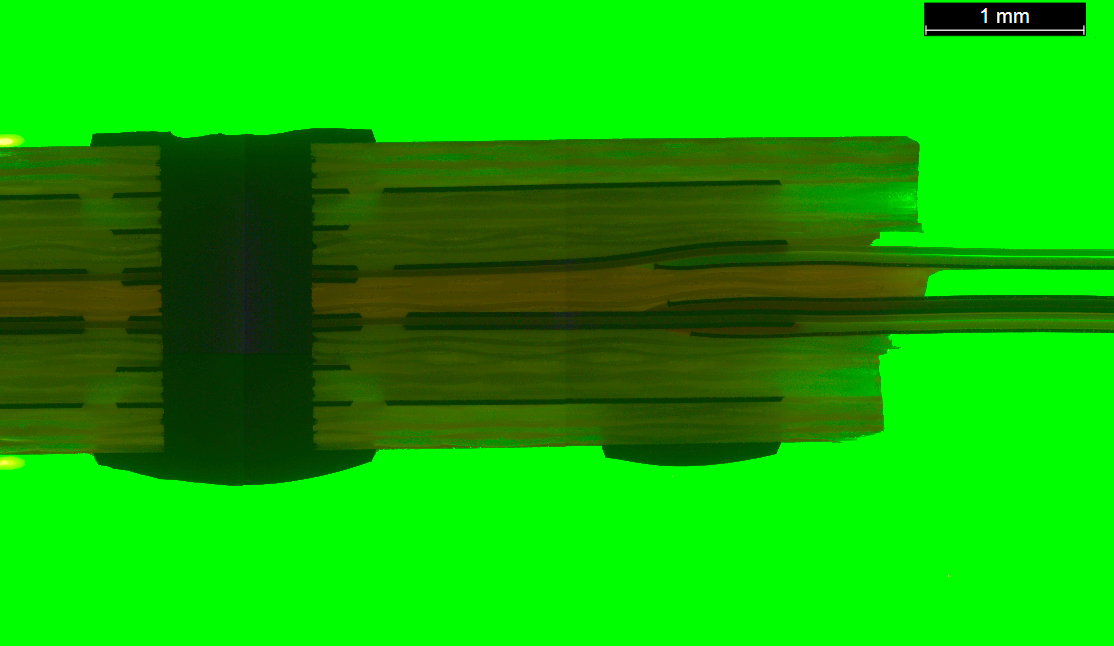

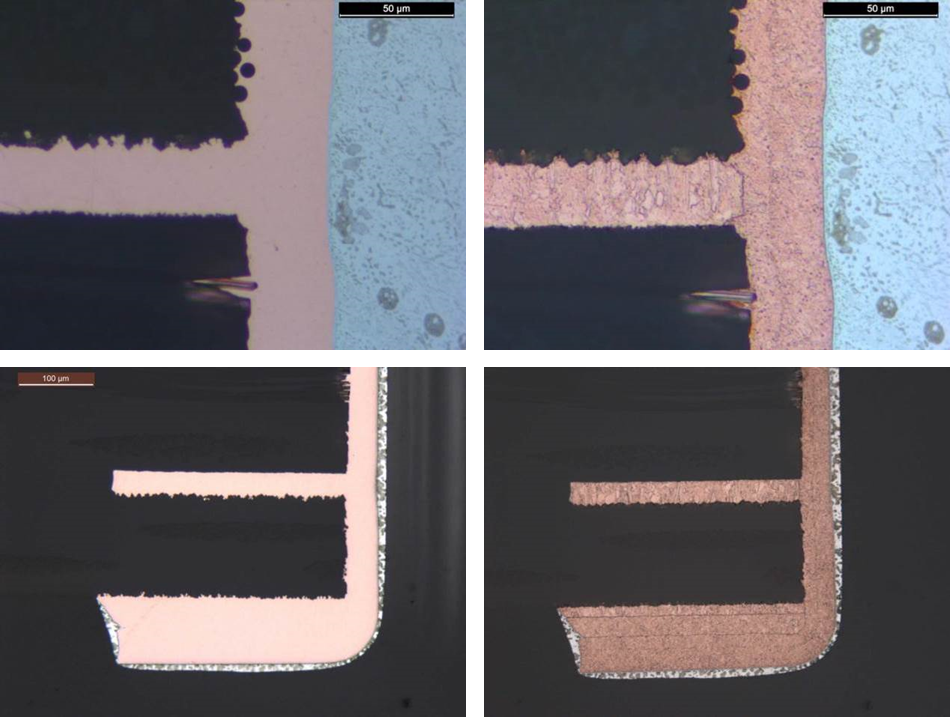

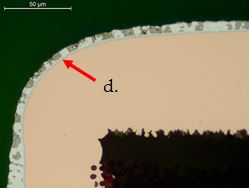

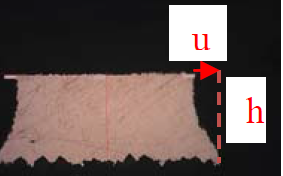

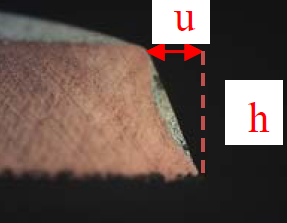

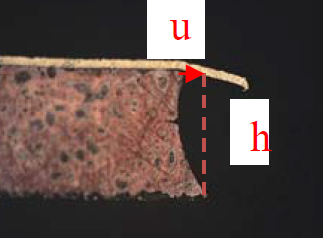

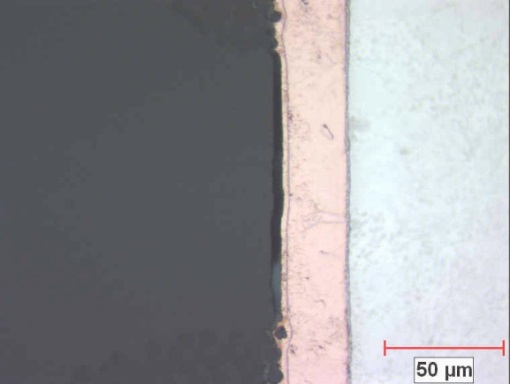

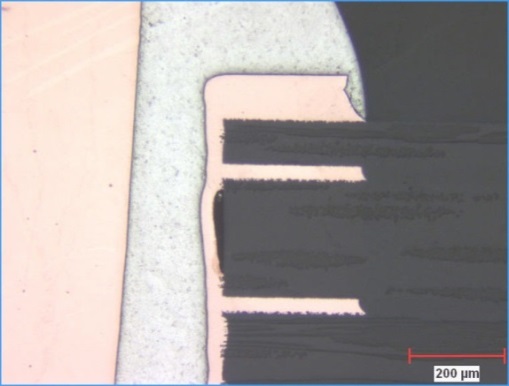

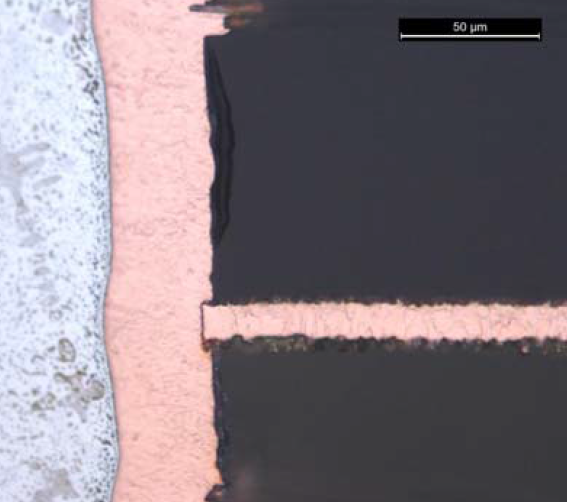

treatment side of foil

the side of copper foil that is submitted to a surface treatment process by the materials supplier or by the PCB manufacturer

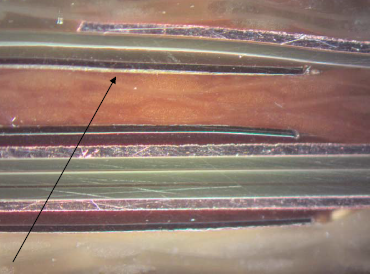

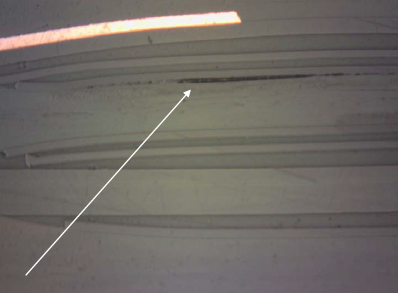

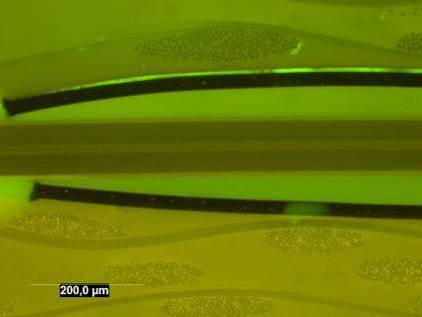

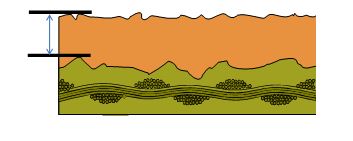

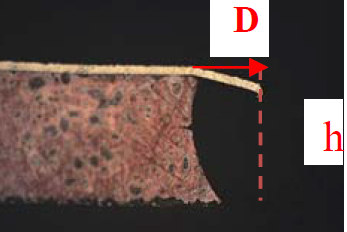

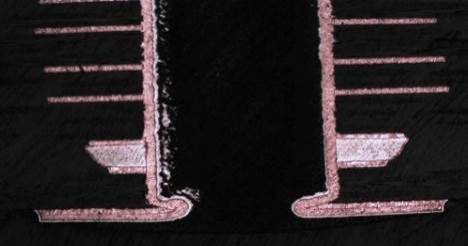

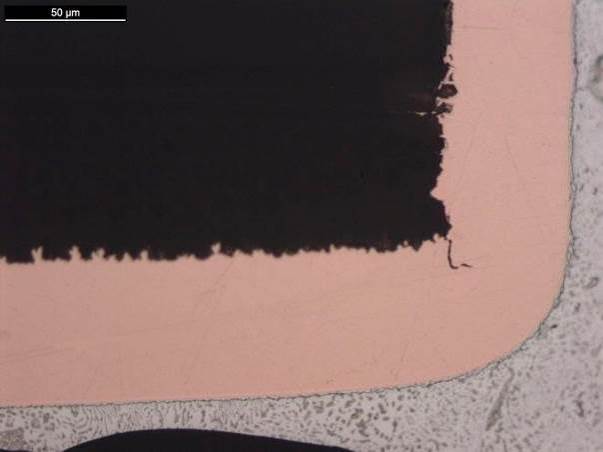

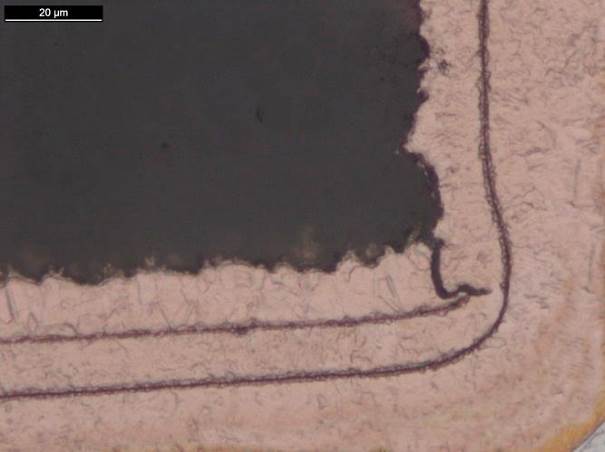

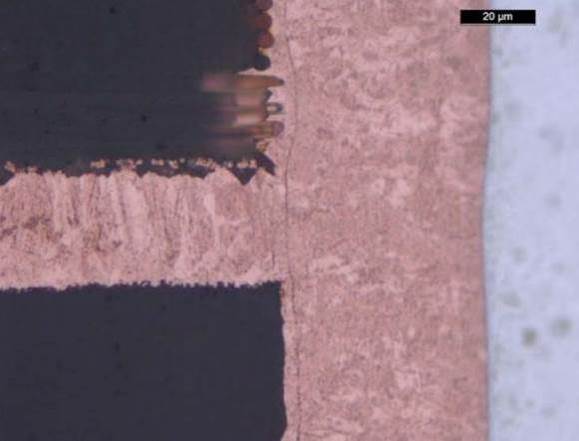

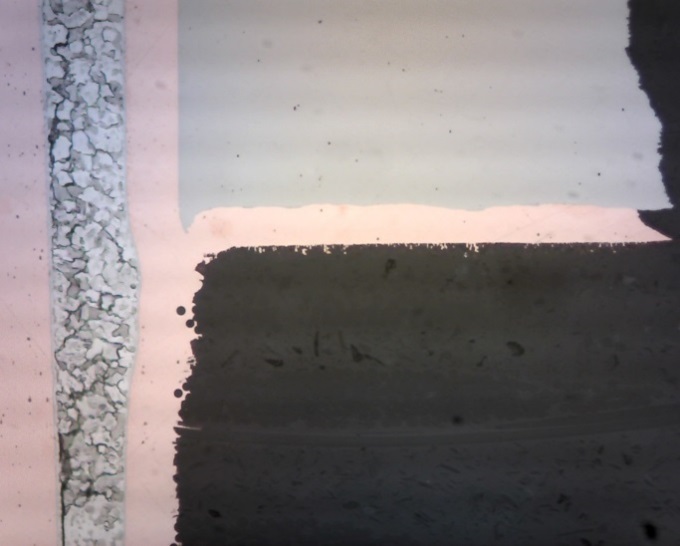

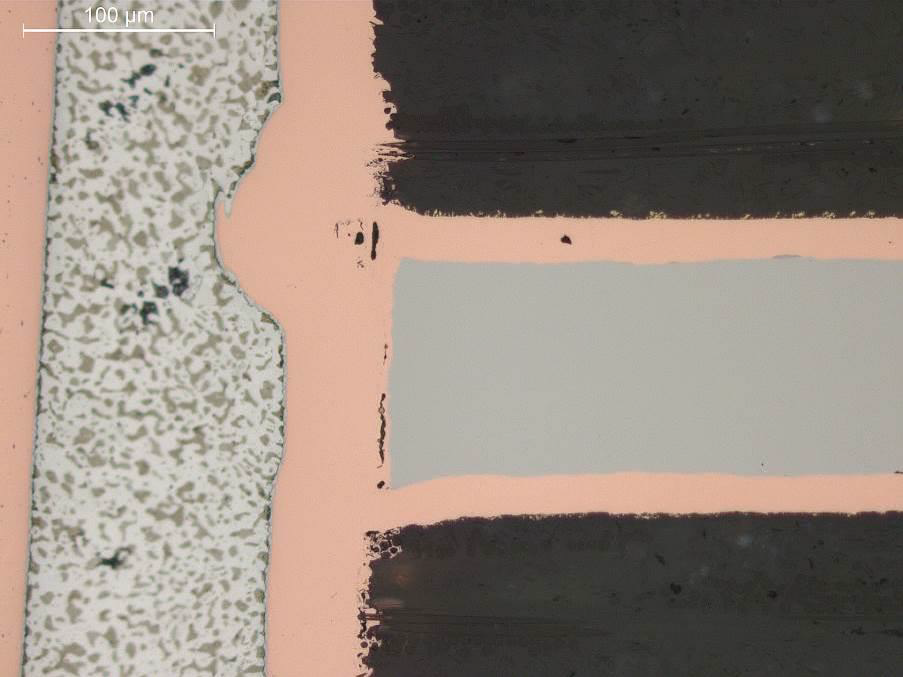

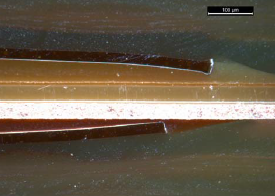

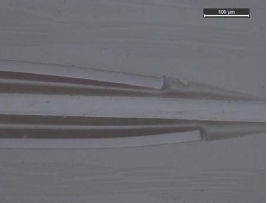

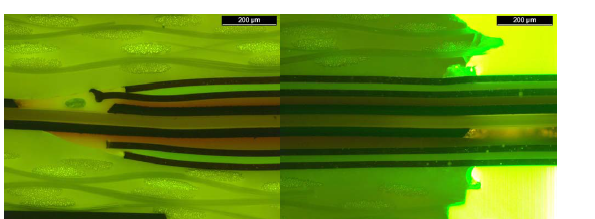

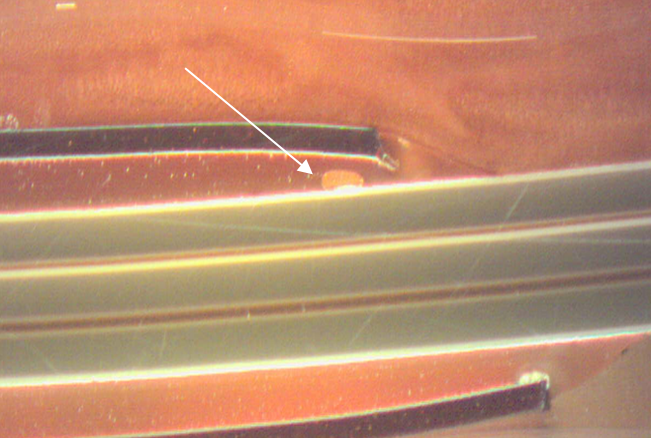

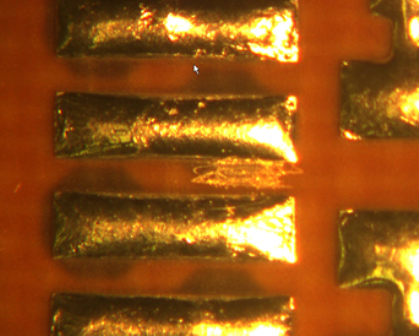

The material supplier treatment side of copper foil on laminate is typically rougher. See Figure 31.

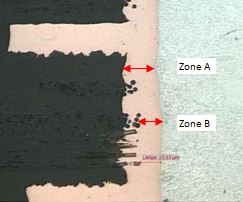

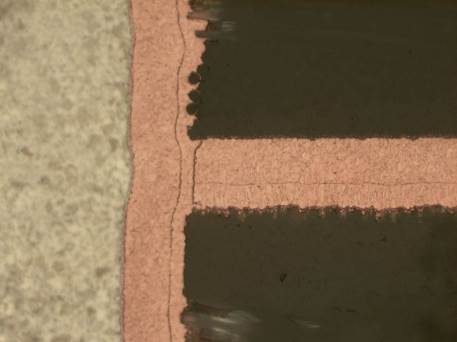

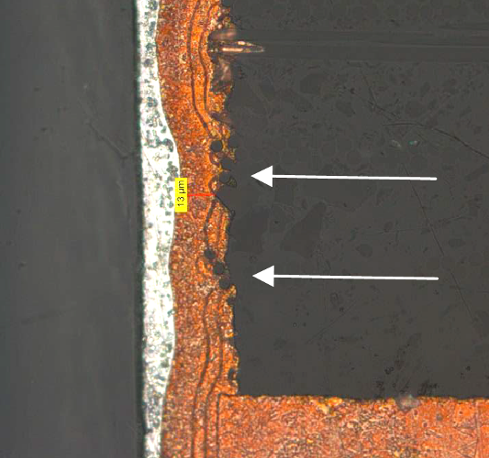

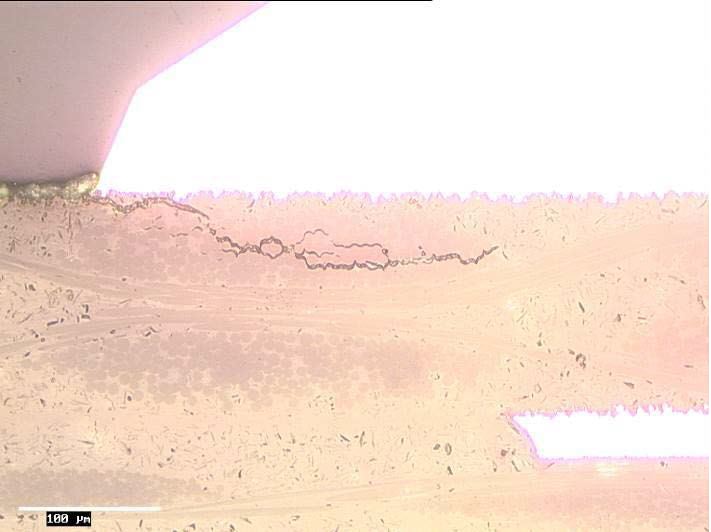

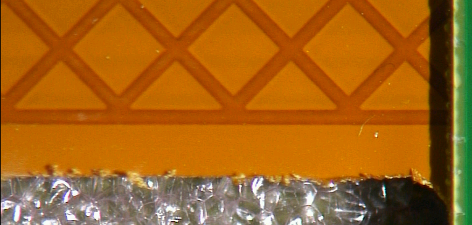

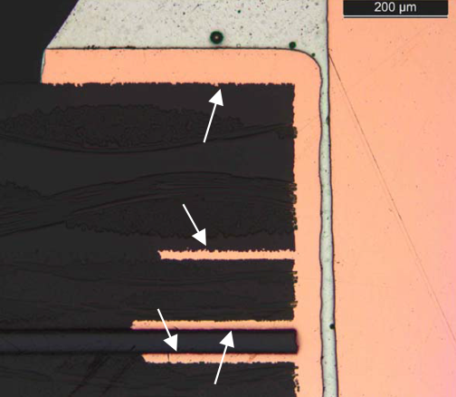

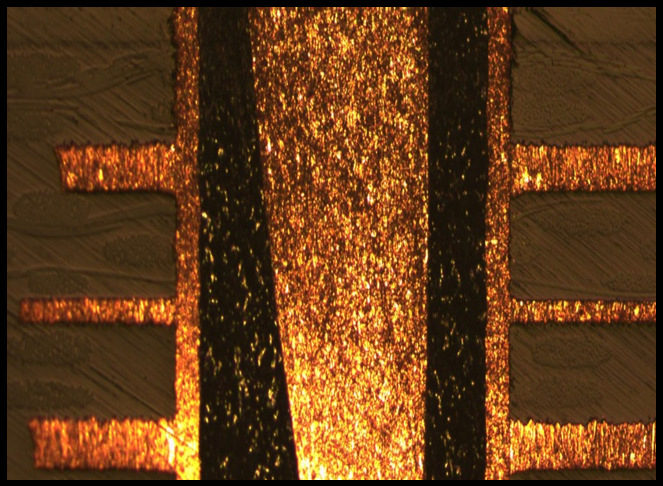

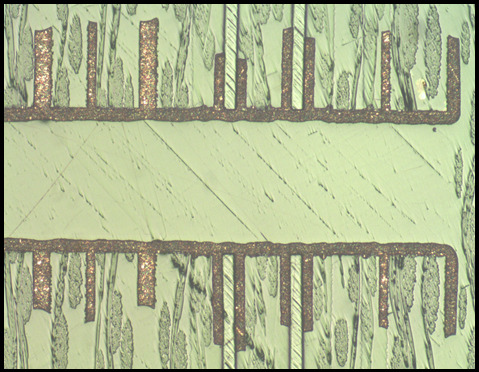

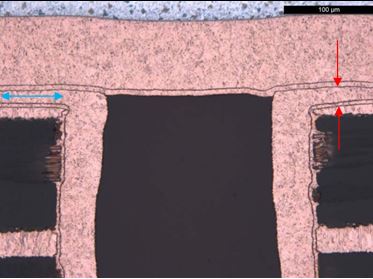

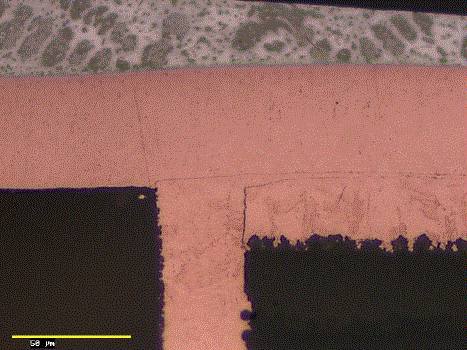

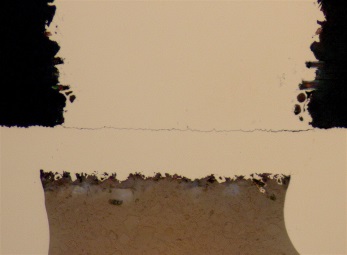

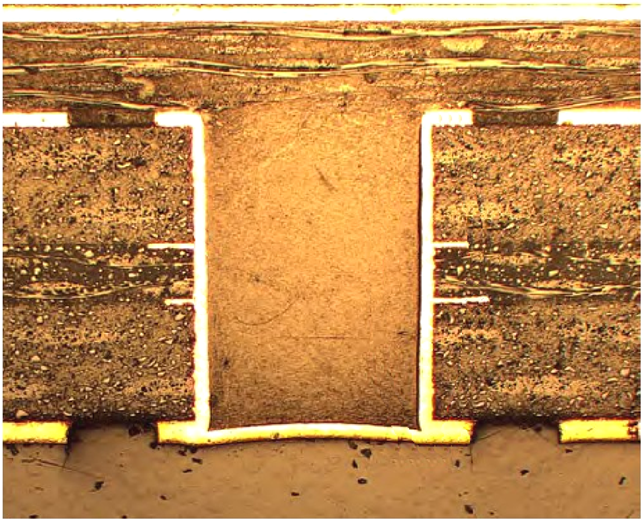

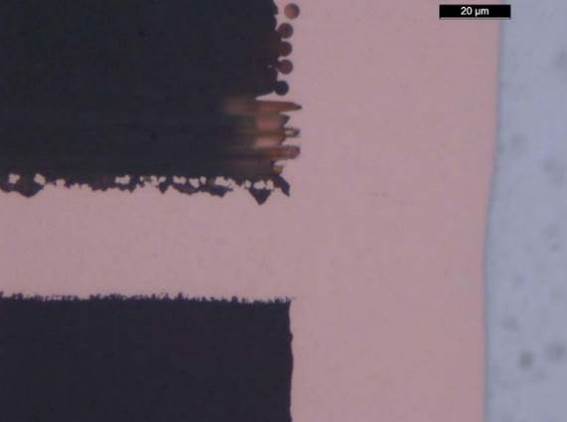

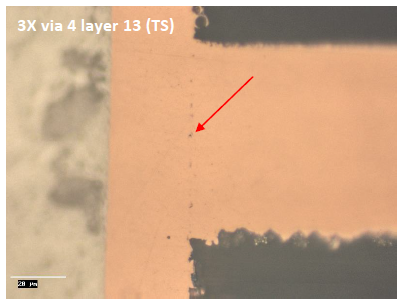

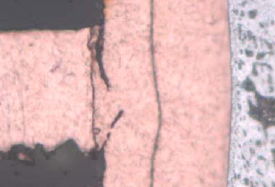

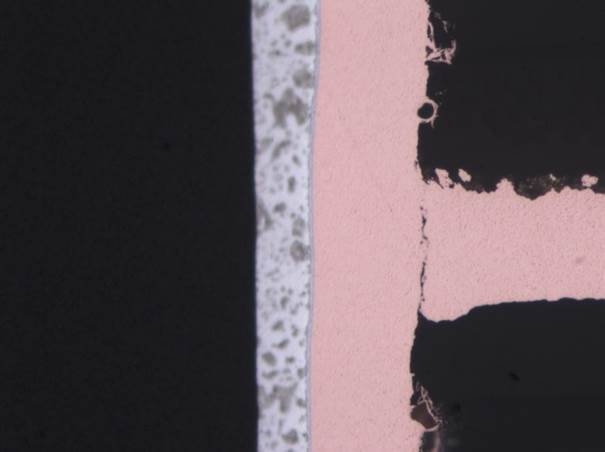

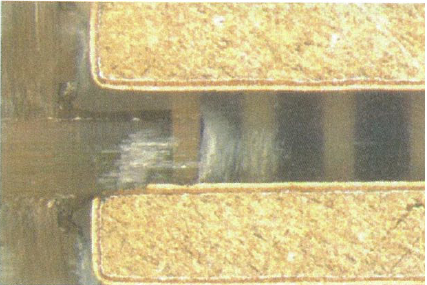

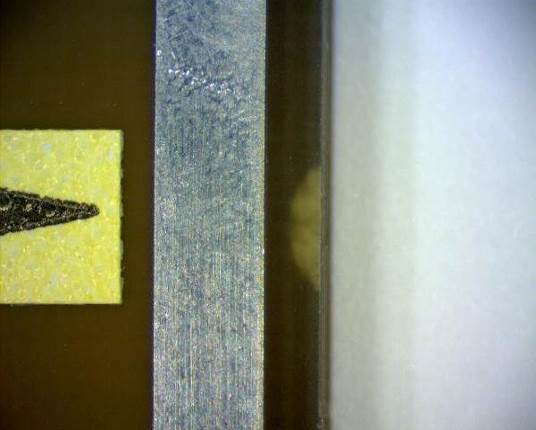

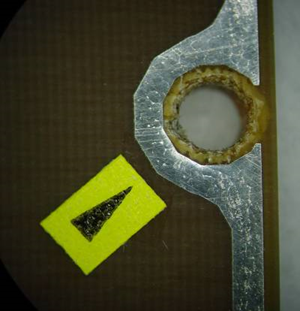

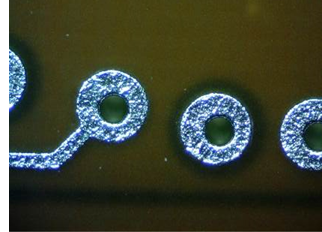

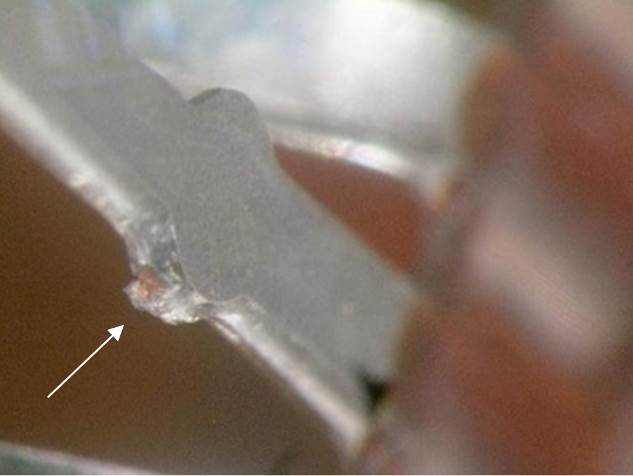

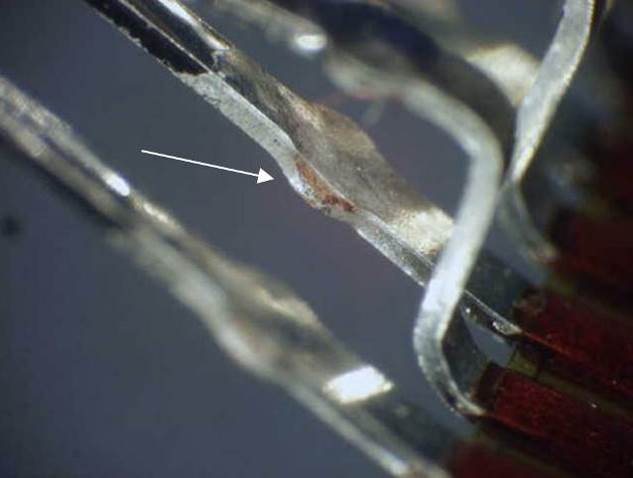

Figure 31: Example of material supplier treatment side of foil (white arrows) and PCB manufacturer treatment side of foil (opposite side)

Figure 31: Example of material supplier treatment side of foil (white arrows) and PCB manufacturer treatment side of foil (opposite side)

waiver request

written agreement between PCB manufacturer and procurement authority to deliver PCBs with a nonconformance to a requirement from a specification

- 1 The following terms are synonymous: “request for concession”, “demande de derogation”, “request for waiver”, “request for deviation”.

- 2 In space projects the terms RFW and RFD have specific meaning as specified in ECSS-Q-ST-70. This specific meaning does not strictly apply in the context of PCB procurement.

weave exposure

a base material surface condition in which unbroken fibres of woven glass are not completely covered by resin

See also ‘weave texture’.

[IPC-T-50M]

weave texture

a surface condition of base material in which a weave pattern of cloth is apparent although the unbroken fibres of woven cloth are completely covered by resin.

See also ‘weave exposure’.

[IPC-T-50M]

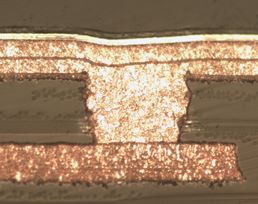

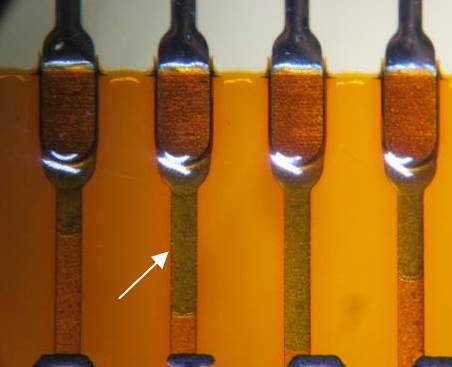

wicking

infiltration of copper plating into the dielectric of the hole wall

The terms “copper infiltration” and “copper ingress” are synonymous.

work instruction

quality document that describes the technical details about processes, material usage, inspection and acceptance criteria

- 1 The terms ‘manufacturing procedure’ or ‘control procedure’ or ‘process instruction’ are synonymous.

- 2 Work instructions can include process flow charts, production documents (e.g. manufacturing plans, travelers, routers, work orders, process cards) and inspection documents.

Abbreviated terms

For the purpose of this Standard, the abbreviated terms from ECSS-S-ST-00-01 and the following apply:

|

Abbreviation

|

Meaning

|

|

AAD

|

area array device

|

|

AC

|

alternating current

|

|

AOI

|

automated optical inspection

|

|

AR

|

as received

|

|

CDR

|

critical design review

|

|

CIC

|

copper-invar-copper

|

|

CoC

|

certificate of conformance

|

|

CTE

|

coefficient of thermal expansion

|

|

Cu

|

copper (element)

|

|

CVCM

|

collected volatile condensable material

|

|

DC

|

direct current

|

|

DML

|

declared materials list

|

|

DPA

|

destructive physical analysis

|

|

DR

|

design review

|

|

DRB

|

delivery review board

|

|

DRD

|

document requirements definition

|

|

DSC

|

differential scanning calorimetry

|

|

DWV

|

dielectric withstanding voltage

|

|

EBB

|

elegant breadboard

|

|

ECM

|

electrochemical migration

|

|

EM

|

engineering model

|

|

EOL

|

end of life

|

|

EQM

|

engineering qualification model

|

|

FAI

|

first article inspection

|

|

FCSI

|

final customer source inspection

|

|

FM

|

flight model

|

|

FOD

|

foreign object debris

|

|

FR4

|

type of epoxy resin for PCBs

|

|

FS

|

flight spare

|

|

HDI

|

high density interconnect

|

|

ICD

|

interconnect defect

|

|

IMC

|

intermetallic compound

|

|

IPA

|

isopropanol

|

|

IPC

|

association connecting electronic industries

|

|

IST

|

interconnect stress test

|

|

KPI

|

key performance indicator

|

|

max

|

maximum

|

|

min

|

minimum

|

|

MIP

|

mandatory inspection point

|

|

MPCB

|

material and processes control board

|

|

MRR

|

manufacturing readiness review

|

|

MTO

|

metal turnover

|

|

n. a.

|

not applicable

|

|

NCR

|

nonconformance report

|

|

NRB

|

nonconformance review board

|

|

OTD

|

on time delivery

|

|

PCB

|

printed circuit board

|

|

PCN

|

process change notice

|

|

PDR

|

preliminary design review

|

|

PFM

|

proto flight model

|

|

PID

|

process identification document

|

|

PTH

|

platedthrough hole

|

|

PTFE

|

polytetrafluoroethylene

|

|

QA

|

quality assurance

|

|

QM

|

qualification model

|

|

QML

|

qualified manufacturers list

|

|

QPL

|

qualified product list

|

|

r.m.s.

|

rootmeansquare

|

|

R&D

|

research and development

|

|

Ref

|

reference (for tables in clause 10)

|

|

RF

|

radio frequency

|

|

RFA

|

request for approval

|

|

RML

|

residual mass loss

|

|

RW

|

rework simulation

|

|

SB

|

solder bath float

|

|

SMT

|

surface mount technology

|

|

SPC

|

statistical process control

|

|

sq

|

square (in unit Ω/sq)

|

|

TBD

|

to be defined

|

|

TDR

|

time domain reflectometry

|

|

T288

|

time to delamination at 288˚C

|

|

Td

|

temperature of decomposition

|

|

Tg

|

temperature of glass transition

|

|

TGA

|

thermogravimetric analysis

|

|

TMA

|

thermomechanical analysis

|

|

wk

|

week

|

Nomenclature

The following nomenclature applies throughout this document:

The word “shall” is used in this Standard to express requirements. All the requirements are expressed with the word “shall”.

The word “should” is used in this Standard to express recommendations. All the recommendations are expressed with the word “should”.

It is expected that, during tailoring, recommendations in this document are either converted into requirements or tailored out.

The words “may” and “need not” are used in this Standard to express positive and negative permissions, respectively. All the positive permissions are expressed with the word “may”. All the negative permissions are expressed with the words “need not”.

The word “can” is used in this Standard to express capabilities or possibilities, and therefore, if not accompanied by one of the previous words, it implies descriptive text.

In ECSS “may” and “can” have completely different meanings: “may” is normative (permission), and “can” is descriptive.

The present and past tenses are used in this Standard to express statements of fact, and therefore they imply descriptive text.

Principles

General

This standard specifies requirements for the manufacture, qualification, procurement, test and inspection of PCBs.

Roles

In the context of ECSS-Q-ST-70-60 the roles “PCB manufacturer”, “procurement authority” and “qualification authority” were explicitly introduced and defined in clause 3.2 to allow proper allocation of requirements.

References to acceptance criteria

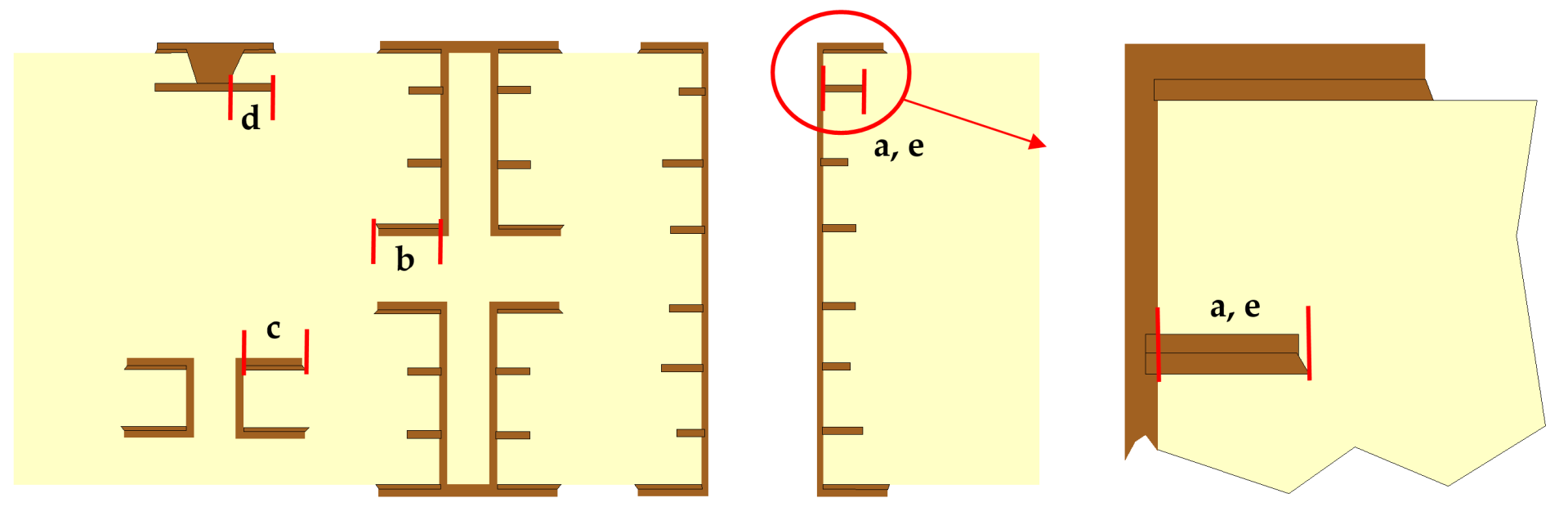

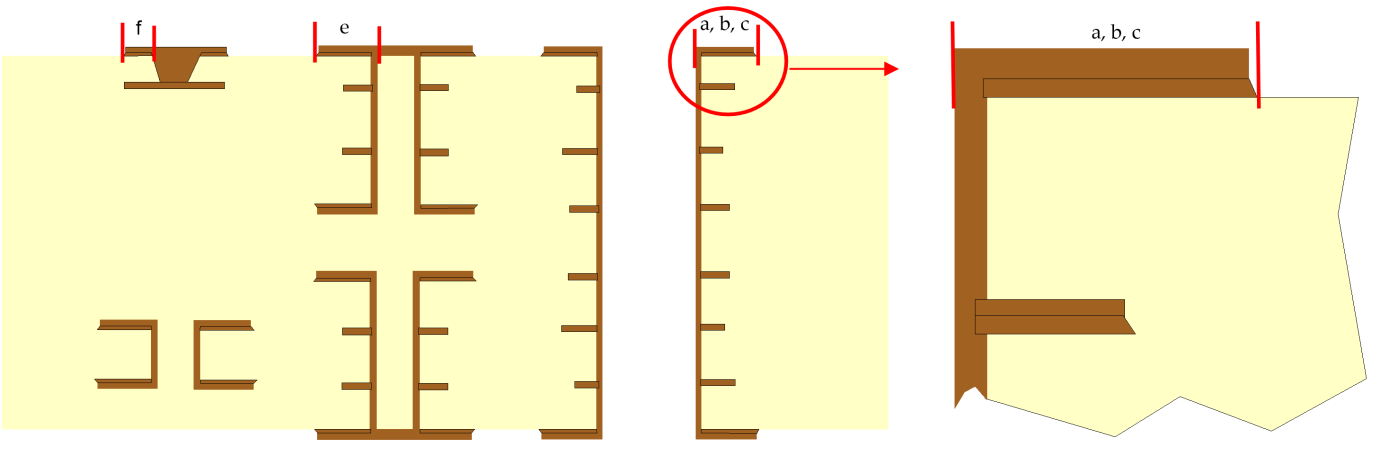

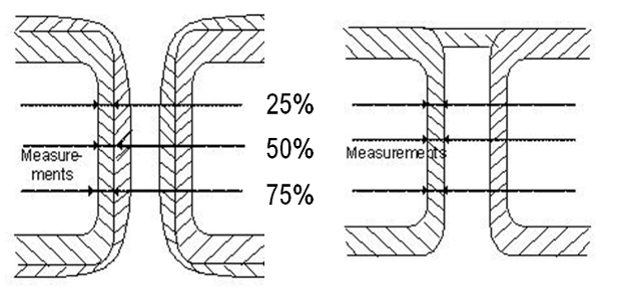

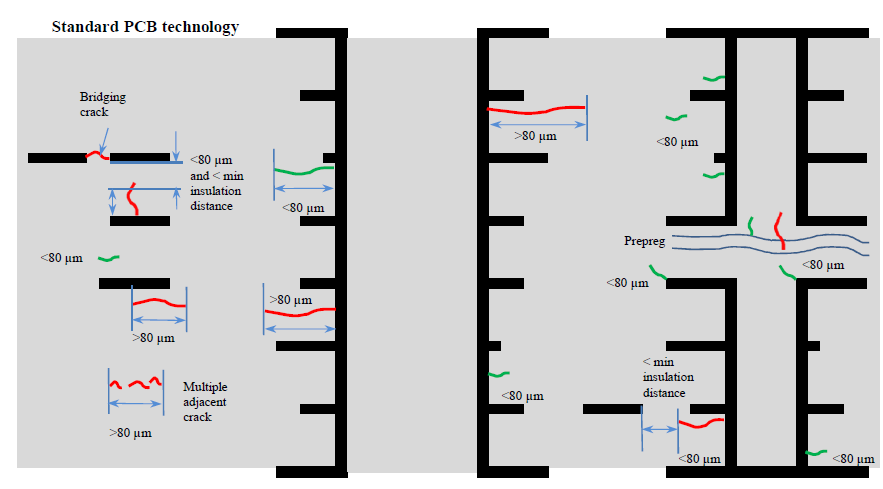

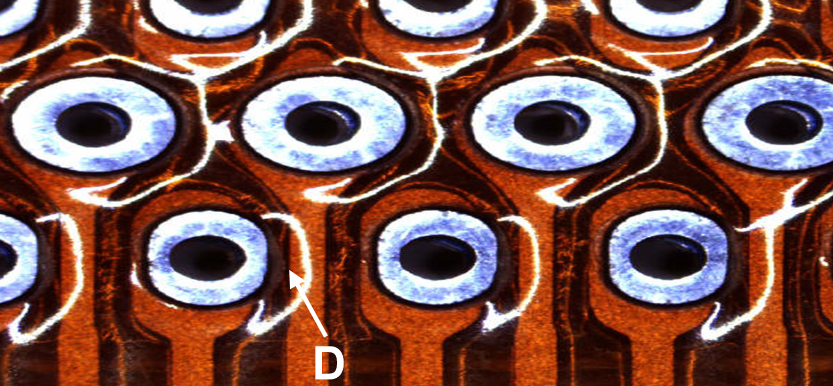

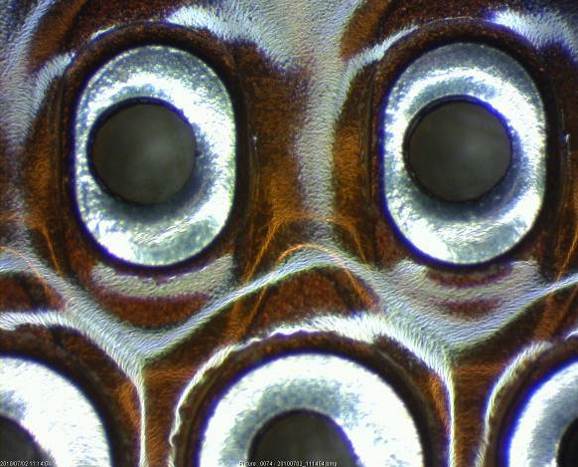

Clause 10 includes tables to specify acceptance criteria for certain technological features. The technological features can be further subdivided in each table. This is indicated with a reference letter in the first column and abbreviated as “Ref x”. This allows cross-referencing to specific line items in the table, rather than to an entire table. An example of this is “internal annular ring on an inner layer at the end of a blind via” which is cross-referenced as Ref. b in Table 101.

QA for qualification

Qualified PCBs

Qualified PCBs for space applications shall meet all the following conditions:

- the PCB is procured in conformance with clauses 6 and 8,

- the PCB is procured from a PCB manufacturer that is qualified in conformance with clauses 5 and 7 and as specified in the PID,

- the PCB design is in conformance with the requirements of ECSS-Q-ST-70-12.

Some specific PCB technologies can be used that are not covered by a valid PID or by a company qualification. Procurement can be done under RFA, including tests for (delta) qualification and tests for procurement but it can exclude the qualification of the company. Examples of specific PCB technology are complex HDI, complex RF and flex technology that are under development. This is described in clauses 5.2 and 7.7.

The qualification of PCBs in conformance with this standard shall cover for a maximum operational temperature of 85 °C.

- 1 This is also described in clause 1 "Scope" of ECSS-Q-ST-70-08 and clause 1 "Scope" of ECSS-Q-ST-70-38.

- 2 This is in conformance with current rating requirements from clause 13.6.2 of ECSS-Q-ST-70-12.

- 3 PCBs are not qualified for a specific voltage as this is depending on PCB design in conformance with ECSS-Q-ST-70-12.

Ceramic PCB technology

PCBs manufactured using ceramic filled laminate shall be in conformance with ECSS-Q-ST-70-60.

This is opposed to ceramic substrates using thick film or thin film processes that are in conformance with ESCC-2566000.

Flexible PCB

General

Flexible PCBs can be used as harness or cable for interconnection of PCB assemblies, components or detectors, in which case they are short, typically less than 0,5 m. Flexible PCBs can also be used to interconnect larger elements such as equipment, solar cells or solar panels. And they can be used as radiating RF element for antennae. In such applications the flexible PCBs can be long, typically more than 1 m. Moreover, they can be used in dynamic applications such as solar array drive mechanisms, thruster orientation mechanisms or antenna pointing mechanisms.

Products can include various terminology, such as “flat cable”, “flexprint”, “ribbon flex” and similar. These products are referred to in this standard as “flexible PCB”. A specific type of flexible PCB also referred to in this standard is the “sculptured flex PCB”, which is typically used for interconnection of components to PCBs or in between PCBs.

Encapsulation of separate copper strings or wires to form a flexible cable is not a conventional PCB manufacturing process, and can therefore be considered a cable. Etching of copper clad flexible laminate and lamination of coverlay, among others, are conventional PCB manufacturing processes and are covered by ECSS-Q-ST-70-60.

Heaters are in conformance with ESCC-4009. Cables are in conformance with ESCC-3901.

Qualification of flexible PCB

For flexible PCBs, a company specific qualification with auditing and review of QA should be performed.

This is good practice to verify batch-to-batch reproducibility.

In case the flexible PCB is not qualified in conformance with ECSS-Q-ST-70-60, the project qualification of flexible PCB shall be reviewed under RFA in conformance with clause 7.7.2.

Flexible PCB for harness shall be qualified and procured as per ECSS-Q-ST-70-60 and designed as per ECSS-Q-ST-70-12, except for the cases from requirements 5.3.2d and 5.3.2e.

In case the self-heating of maximum 10 °C in conformance with requirement 13.6.2a from ECSS-Q-ST-70-12 or in case the operational temperature of maximum 95 °C in conformance with requirement 13.6.2c from ECSS-Q-ST-70-12 is exceeded, it shall be specifically covered by the project qualification of flexible PCB for harness.

Current rating of ECSS-Q-ST-70-12 can be too conservative for harness applications for power lines.

In case double insulation in Z-direction is not in conformance with Table 13-6 from ECSS-Q-ST-70-12, it shall be specifically covered by the project qualification of flexible PCB for harness.

The test plan can be based on the test selection for a change in dielectric material from clause 7.2d.

Electrical testing of the integrated subsystem of connector and flexible PCB shall be specifically covered by the project qualification of flexible PCB for harness.

An example of a relevant electrical test is DWV in conformance with clause 9.6.4, using 1000 VDC for 30 s. Another example of a relevant electrical test is the whole length voltage test and whole length insulation resistance test in conformance with clauses 9.7b and 9.8b from ESCC-3901. Tests for qualification and for procurement in conformance with ECSS-Q-ST-70-60 includes high resistance electrical test with a 1 GΩ insulation resistance threshold in conformance with clause 9.3.7.2 and continuity test in conformance with 9.3.8.

Dynamic application shall be specifically covered by the project qualification of flexible PCB for harness, including at least the following:

- evaluation of the mechanical integrity of the insulation due to routing limitations, and

- mechanical testing from ESCC-3901 tailored to meet the application, and

- electrical evaluation before and after mechanical test and qualitative evaluation by microsectioning after mechanical test.

- 1 Mechanical integrity of the insulation can be impacted by abrasion, point loads and the dynamic movement.

- 2 In addition, dynamic application can be covered at unit level as specified in clause 4.8.3 of ECSS-E-ST-33-01. Unit level qualification testing is performed at a later stage in the project than qualification of subassemblies including the flexible PCB.

RF application shall be specifically covered by the project qualification of flexible PCB.

Assembly to flexible PCB using PTH or SMT shall be verified in conformance with ECSS-Q-ST-70-08 and ECSS-Q-ST-70-38.

Qualification process

The process for PCB qualification shall contain the following stages:

- request for qualification and associated documentation in conformance with clause 5.5,

- evaluation of a technology sample in conformance with clause 5.8,

- audit of the manufacturing facility in conformance with clause 5.9,

- qualification programme in conformance with clause 5.10. The approval from the qualification authority of the completed qualification shall be in conformance with clause 5.12.

Request for qualification

The PCB manufacturer shall send a formal request for qualification to the qualification authority.

The PCB manufacturer shall provide the company profile including the following information:

- description of the manufacturer capabilities,

- business plan with basic financial figures for sales and R&D.

The business plan demonstrates a healthy economical business and a strong commitment to quality assurance for space products.

The PCB manufacturer shall demonstrate the heritage on the PCB technologies for which qualification is requested, by providing the types of technology and quantity of PCBs produced for non-space customers, industrial space customers and space agencies.

This is in particular important for the approved surface finishes, such as hot oil reflowed tin-lead.

The PCB manufacturer shall provide a letter of support from the main industrial space customers.

The PCB manufacturer shall provide a preliminary strategic planning, indicating the following:

- the space projects for which qualified PCBs are foreseen to be provided,

- identification of the current customers that can benefit from possible qualification,

- identification of new customers or orders that can be gained in case qualification is achieved,

- identification of technologies that are foreseen to be qualified initially and in the medium and longer term,

- the internal resource estimate for achieving qualification,

- a target schedule for all activities related to achieving qualification.

The PCB manufacturer shall provide the completed survey for assessment of the PCB manufacturer’s capabilities in conformance with IPC-1710.

The PCB manufacturer shall demonstrate that it meets the requirements for quality assurance in conformance with clause 5.6.

Quality standards

The quality assurance requirements specified in ECSS-Q-ST-20 shall apply.

The PCB manufacturer shall manage nonconformances in accordance with ECSS-Q-ST-10-09.

The PCB manufacturer shall hold certification for its quality management system in conformance with ISO 9001:2015 and EN 9100:2016 or demonstrate that he has a quality management system in line with the above standards.

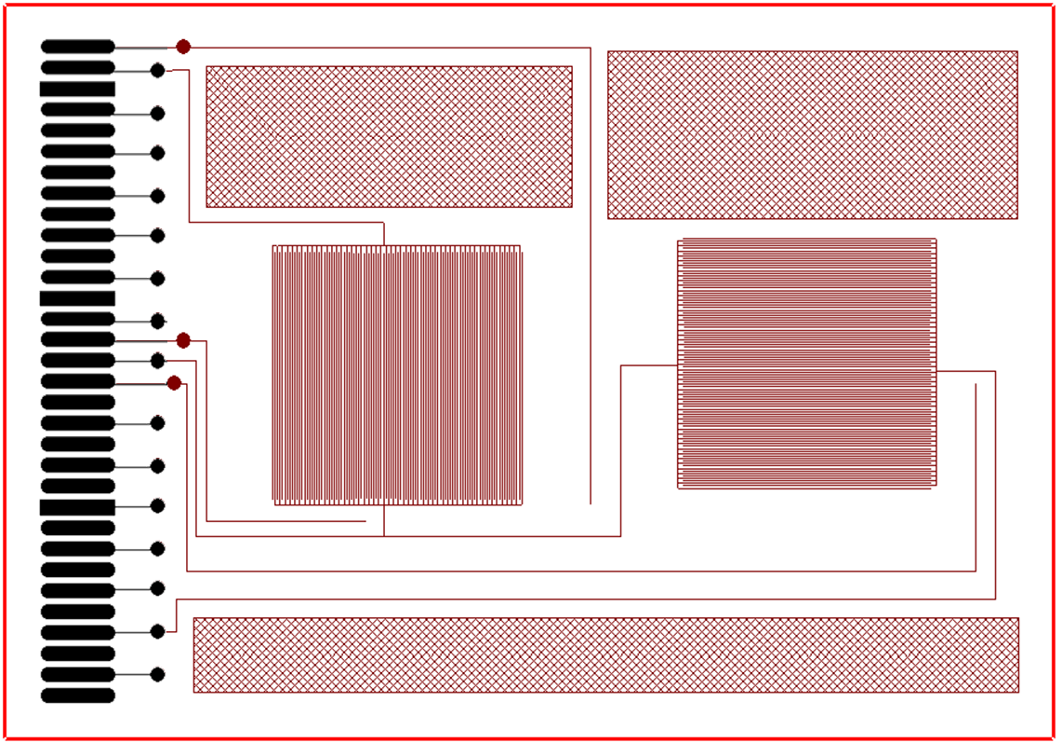

Description of qualification vehicle

The PCB manufacturer shall provide the PCB definition dossier, in conformance with the DRD in Annex A of ECSS-Q-ST-70-12, to the qualification authority for approval of the qualification vehicle.

The qualification vehicle shall be representative of the highest technological complexity for which qualification is requested.

The design of the qualification test vehicle shall accommodate the tests specified in clause 7.

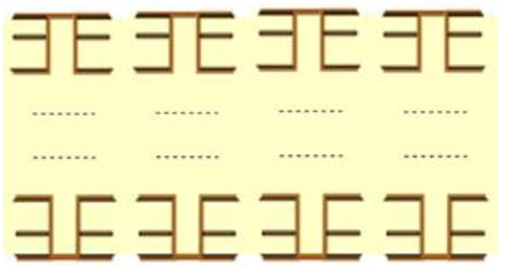

Examples of test patterns are shown in IPC-2221B.

The design of the qualification vehicle shall be in conformance with requirements from ECSS-Q-ST-70-12.

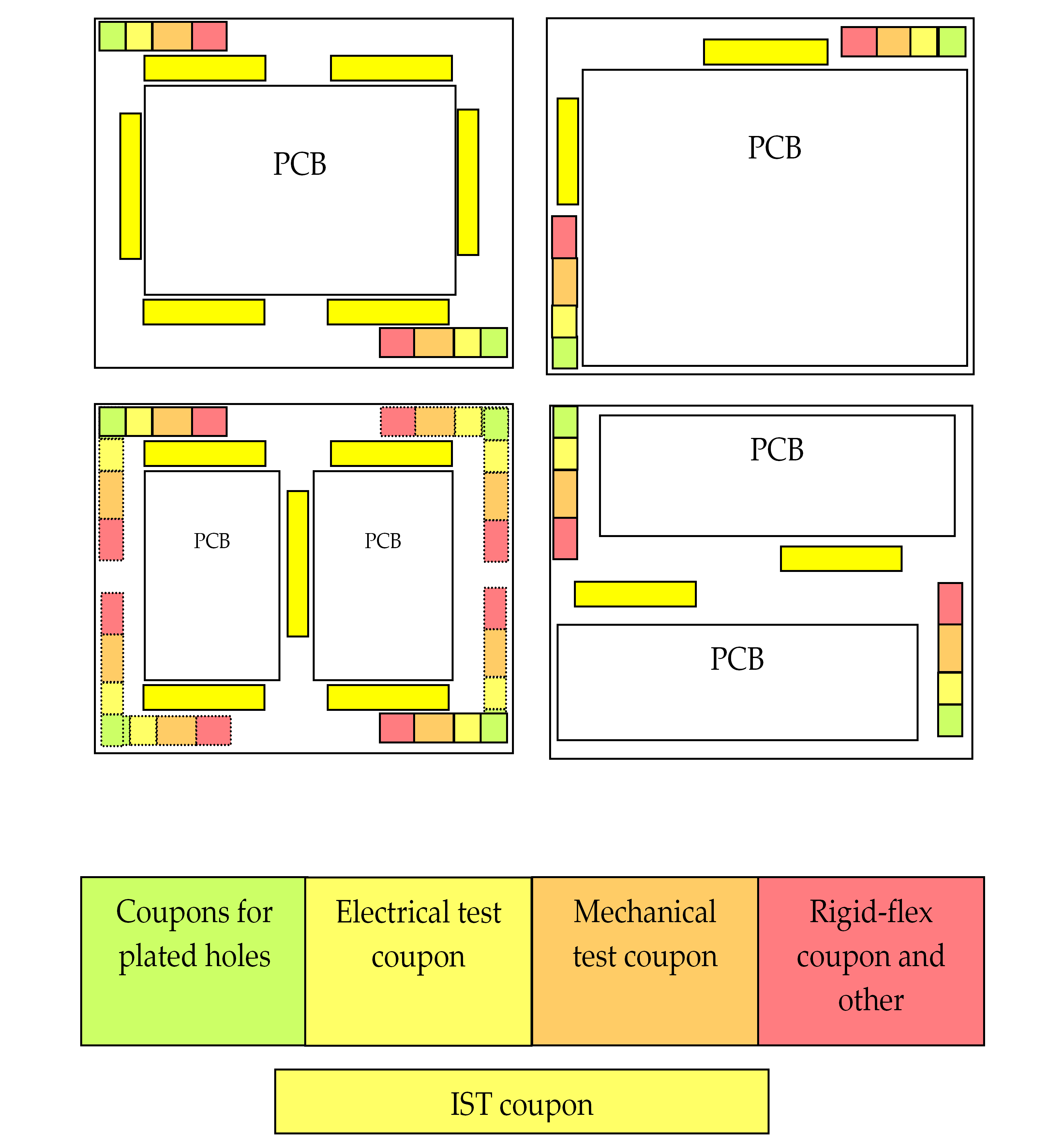

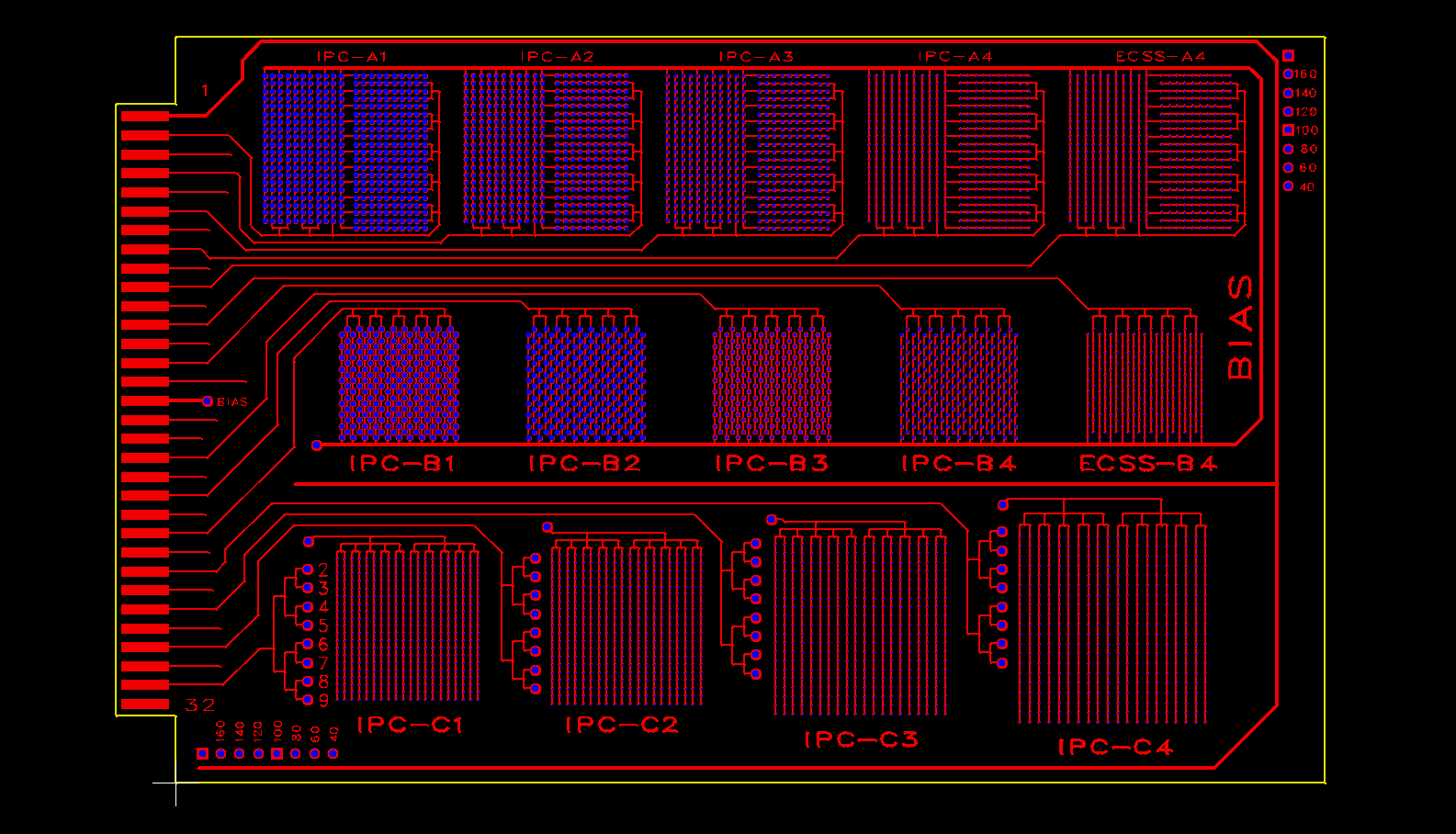

The coupons that are included in the qualification vehicle shall be in conformance with the clauses 8.2.2 and 8.2.3.

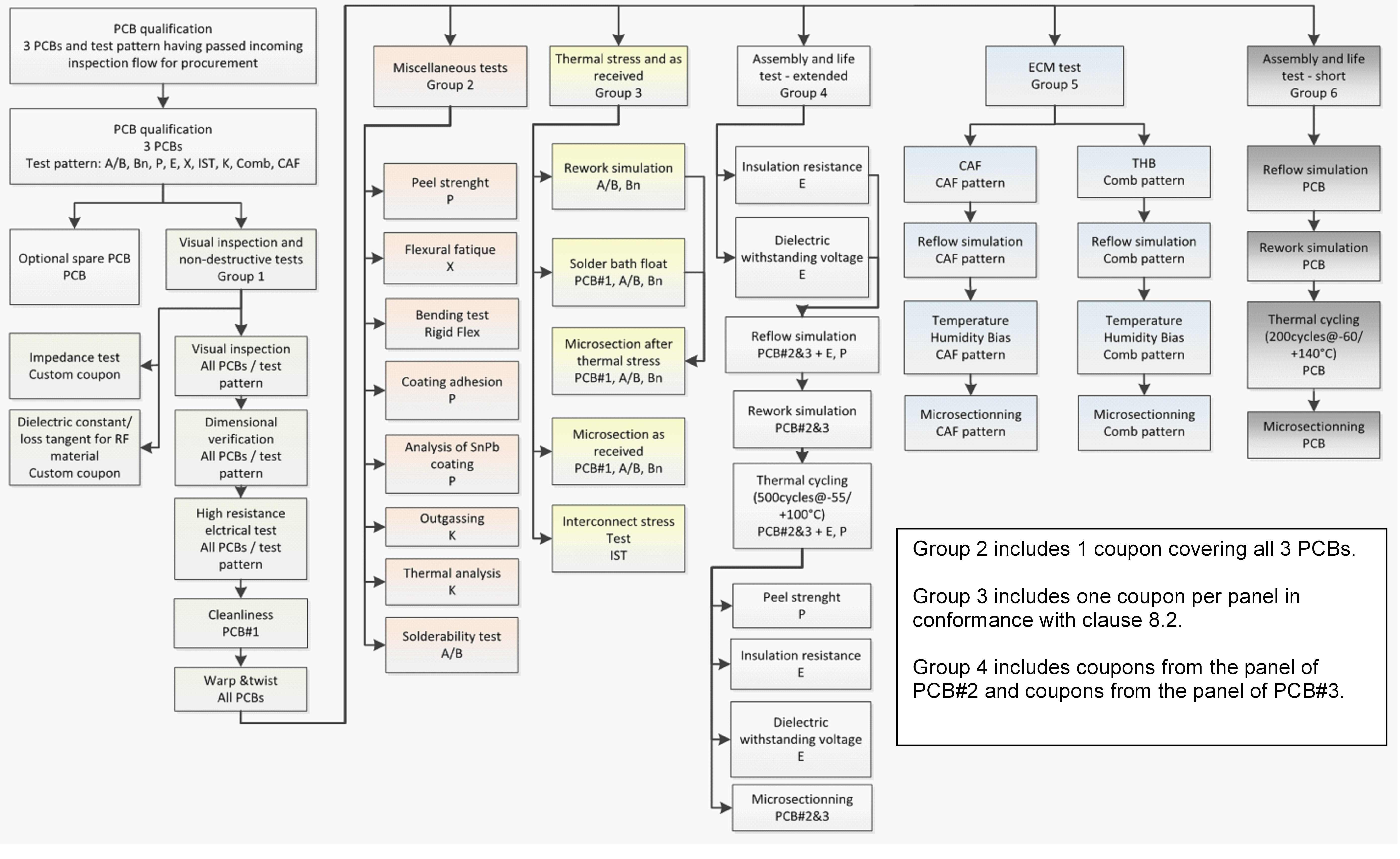

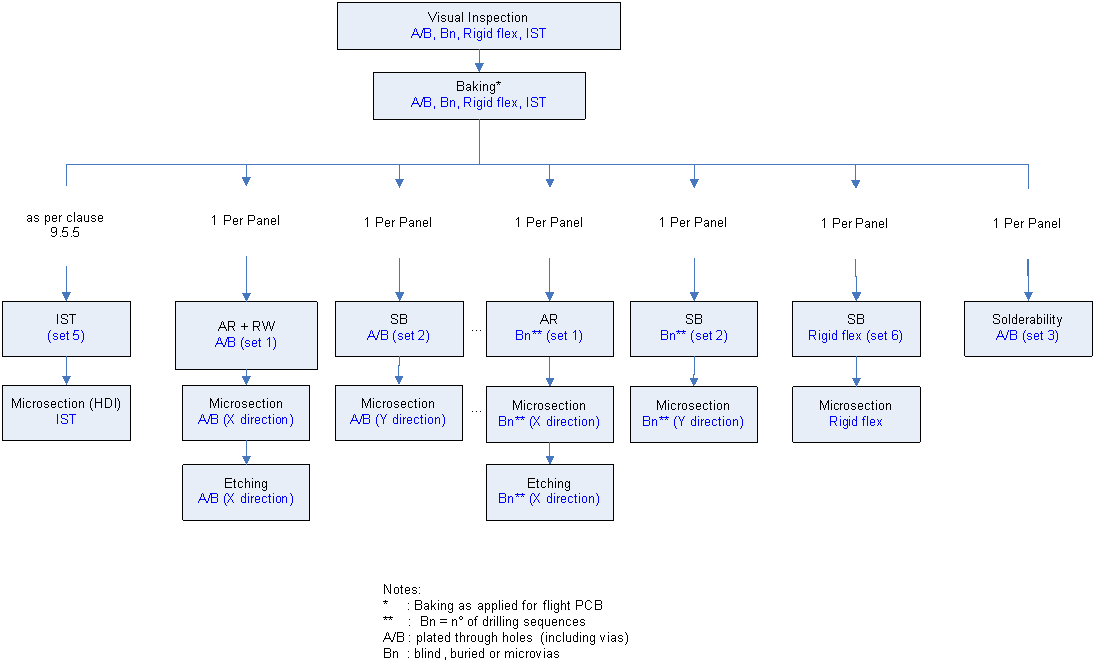

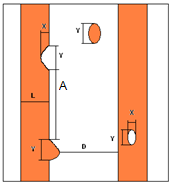

Initial qualification of a PCB manufacturer or PCB technology in conformance with requirement 7.2b shall be performed on at least 3 PCBs and the coupons in conformance with Figure 71.

Initial qualification of a PCB manufacturer or PCB technology in conformance with requirement 7.2b should include a spare PCBs and spare coupons in conformance with Figure 71.

Delta qualification and qualification renewal in conformance with requirement 7.2 shall be performed on at least 1 PCB and associated coupons.

Evaluation

The requirements of clause 5.7 shall apply to the evaluation samples.

The submission of evaluation samples shall include PCB, coupons, microsections and documentation in conformance with requirement 5.15a.

A first set of evaluation samples should be evaluated by a third-party.

It is beneficial to request a third-party evaluation by a company with knowledge on evaluation in conformance with ECSS-Q-ST-70-60.

The test flow for evaluation shall be in conformance with requirements from clause 7.5.

- 1 This test flow includes DPA of PCB and coupons and IST.

- 2 Any duplication of IST tests on panels for evaluation, qualification and procurement allows assessment of batch-to-batch reproducibility.

- 3 The evaluation phase is only performed in case of qualification of new PCB manufacturers. It is intended as a relatively fast assessment of the quality to gain confidence in the product before initiating the full qualification programme. Therefore the evaluation typically does not include mission representative thermal cycling, which is included in qualification.

The qualification authority shall perform the evaluation and issue the test report.

The qualification authority shall provide to the PCB manufacturer the authorization to proceed with the qualification in case all the following conditions are met: - Evaluation is acceptable.

- Assessment of the request for qualification, in conformance with the clause 5.5, is acceptable.

It is the intention to perform a PCB evaluation only once. In case the first attempt fails, a second final opportunity for passing the evaluation successfully can be offered. The qualification process can be discontinued in case the evaluation fails or in case the schedule as agreed in the strategic planning is exceeded.

Audit

The qualification authority shall audit the manufacturing line.

The audit shall occur when PCB production is in progress.

Before the audit, the PCB manufacturer shall make the following documents available to the qualification authority for review and approval:

- PID in conformance with the DRD in Annex D;

- Qualification test plan in conformance with clause 7.1 including test description, test vehicle and schedule.

The qualification authority shall submit to the PCB manufacturer an audit checklist that verifies the requirements from ECSS-Q-ST-70-60 and its normative references one month prior to the date of the audit.

The PCB manufacturer shall provide the response to the audit checklist to the qualification authority at least one week prior to the date of the audit.

The response from the PCB manufacturer in the audit checklist shall include the following: - compliance level as follows:

- “compliant” or

- “non-compliant” or

- "partial compliant” or

- “not applicable”,

- a comment explaining any non-compliance, partial compliance or non-applicability,

- references to work instructions that specify the verified requirement. During the audit, the PCB manufacturer shall make the following documents available to the qualification authority:

- Documented information in conformance with EN 9100:2016 clause 4.2.2.

- Business process procedures, in conformance with EN 9100.

- Work instructions, in conformance with EN 9100.

- 1 Quality manual is one possible type of Documented information from 5.9g.1.

- 2 See definition of work instructions in clause 3.2.54.

In case of an audit for qualification renewal, the PCB manufacturer shall provide the following: - A summary of the QA reports in conformance with clause 5.14.

- Lists of PCBs per PID supplied in conformance with ECSS-Q-ST-70-60 since the previous audit. The qualification authority shall issue the audit report and any findings, in conformance with clause 5.9j.

The minutes of meeting can be the audit report.

Findings from the audit shall be categorised by the qualification authority as follows:

- “Major nonconformance” is a nonconformance against ECSS-Q-ST-70-60 that is evaluated by the qualification authority as mandatory to disposition by a corrective action for successful audit closure.

- “Minor nonconformance” is a nonconformance against ECSS-Q-ST-70-60 that is a longer term action for continuous improvement and therefore not preventing successful audit closure according to the qualification authority.

- “Observation” is a recommendation or observation that does not prevent successful audit closure and that is not a nonconformance against ECSS-Q-ST-70-60.

The audit report and any findings shall be approved and signed by the PCB manufacturer and qualification authority.

Corrective actions from findings shall be added to the updated audit report or minutes of meeting of a delta audit.

The final conclusion of the audit process shall be provided in the final audit report or minutes of meeting.

Qualification test programme

The requirements of clause 5.7 shall apply to the qualification vehicle.

The PCB manufacturer shall perform the qualification tests as specified in the qualification test plan in conformance with requirement 7.2b and approved by the qualification authority in conformance with requirements 5.9c and 5.9k.

The PCB manufacturer can use labs from a third-party or from the customer to perform tests.

The PCB manufacturer shall issue the qualification test report in conformance with the DRD in Annex C.

The PCB manufacturer shall provide the qualification test report to the qualification authority for review and approval.

The qualification authority may request to the PCB manufacturer an additional test vehicle or microsections for evaluation.

PID

The PCB manufacturer shall issue the PID in conformance with the DRD of Annex D.

The specific parts of the PID shall be issued, in conformance with D.2.1.2, for the following PCB technologies in separate documents:

- Polyimide rigid

- Polyimide rigid/flex

- Epoxy rigid

- Epoxy rigid/flex

- HDI

- RF

- Flexible

- Sculptured flex

- Low thermal expansion materials

Qualification approval

Upon successful qualification, the qualification authority shall issue a qualification letter in conformance with the DRD in Annex A.

The qualification authority shall publish the qualification status.

The reason for a change or updated qualification status shall be published as a comment to the qualification status.

The term “qualified” can be used to indicate a valid qualification status. The term “not qualified” can be used to indicate an invalid qualification status, for instance as a result of nonconformances during qualification renewal or as a result of an expired qualification period. The status is not definite and can be updated when new results are available. A comment is included to clarify the reason for the qualification status. A definite disqualification or discontinuation of PCB technology or PCB manufacturer can be indicated by deletion from the published list or by the terms “disqualified” or “discontinued”.

The qualification authority shall grant qualification approval to the PCB manufacturer based on the acceptance of the evaluation in conformance with clause 5.8, the audit in conformance with clause 5.9 and the qualification programme in conformance with clause 5.10.

The qualification approval shall be valid for a period of maximum two years.

In case nonconformances have been encountered, the qualification authority may grant a period of validity for the qualification that is shorter than two years.

One year is a commonly used qualification period to ensure a more frequent verification of the process control for a critical technology.

Process change

Process changes shall include process parameters, chemistry, material, equipment, process flow and inspections.

Process changes shall be categorised by the PCB manufacturer as “major” or “minor” in the PCN.

Requests for major process changes shall be submitted to the qualification authority for approval.

Review of process changes by the qualification authority in a timely manner is important for the continuation of manufacturing.

The implementation of a major change shall be submitted to the qualification authority for approval.

Minor process changes may be implemented by the PCB manufacturer without prior approval of the qualification authority.

The PCN for a minor change includes the acceptable evaluation of the affected acceptance criteria in conformance with E.2.1b6.

For major and minor process changes, the PCB manufacturer shall issue a process change notice in conformance with the DRD in Annex E to the qualification authority.

All process change notices should be submitted to the procurement authority for information.

Major process change notices should be submitted to the procurement authority for approval.

QA report

The PCB manufacturer shall issue a QA report to the qualification authority in conformance with the DRD in Annex F.

The QA report shall be issued quarterly.

Qualification renewal

The PCB manufacturer shall submit to the qualification authority the following items for qualification renewal at least two months prior to expiration of the qualification:

- A PCB from a normal production batch, not older than one year, that is representative of the highest technological complexity that is qualified,

- CoC in conformance with requirement 6.4b.1,

- Coupons and microsections in conformance with clause 8.2,

- The description, drawing and review items from the PCB definition dossier in conformance with clauses A.2.1<2> , A.2.1<4> A.2.1<6> of ECSS-Q-ST-70-12,

- The justification from the PCB manufacturer for the highest technological complexity being submitted,

- The PCB manufacturer’s test report on a second identical PCB.

- 1 The coupons from 5.15a.3 include an IST coupon if this is specified for the technology in accordance with requirement 8.2.3a. The coupons from 5.15a.3 also include several coupons that are untested by the PCB manufacturer, in conformance with Table 82. It is important that these coupons are included, as it is good practice to perform, for instance, peel strength testing for qualification renewal.

- 2 The highest technological complexity is difficult to obtain on a single PCB for all design features. Therefore the PCB manufacturer justifies the selection of technology submitted for qualification renewal.

- 3 It is good practice to manufacture two PCBs in a panel, one of which is evaluated by the PCB manufacturer, and the other one submitted for qualification renewal together with the required coupons.

In case requirement 5.15a is not achieved because the sample is sent late, the qualification status shall be “not qualified” after the expiration date until completion of qualification renewal, including a comment to the qualification status in conformance with the requirement 5.12c.

It is good practice that the PCB manufacturer sends the sample earlier than 2 months before expiration. If the PCB manufacturer sends multiple samples at the same time, it is good practice to allow for more than 2 months for evaluation.

The qualification authority shall issue a qualification renewal test report.

An audit of the PCB manufacturer shall be performed by the qualification authority at least every second year.

Upon successful qualification renewal, the qualification authority shall approve the qualification in conformance with the clause 5.12 and issue a new qualification letter in conformance with requirement 5.12a.

The qualification authority may decide to initiate a new qualification in the following cases:

- the manufacturing was interrupted or qualification was expired for more than 2 years,

- major changes in production line and its location.

Nonconformances during qualification renewal

In case nonconformances are observed during qualification renewal, the PCB manufacturer shall perform the following:

- Investigate root cause, implement corrective actions on associated processes and materials, demonstrate repeatability.

- Investigate why nonconformance was not detected by outgoing inspection and perform training.

- Verify how the nonconformance affects the running orders and inform customers.

- Evaluate a new PCB and provide test report in conformance with 5.15a.6.

- Have a new PCB sample evaluated by a third-party lab and provide test report.

- Upon approval from the qualification authority, submit a new sample for qualification renewal.

Third-party evaluation from requirement 5.16a.5 is also specified in requirement 5.8c.

In case nonconformances are observed during qualification renewal, the qualification authority should indicate the qualification status as “not qualified” until acceptable completion of the qualification renewal, including a comment to the qualification status in conformance with the requirement 5.12c, except in case of 5.16c.

In case the PCB manufacturer demonstrates that nonconformances observed during qualification renewal are of a one-time occurrence, the qualification authority should indicate for a maximum period of 6 months the qualification status as “qualified” with a comment to identify the failed and ongoing qualification renewal.

- 1 A one-time occurrence of a nonconformance does not invalidate the qualification of other orders in case the efficiency of outgoing inspection is verified. A one-off nonconformance is relatively straightforward to correct for and the qualification renewal of a second sample is, therefore, done within the maximum period of 6 months.

- 2 Since the PCB manufacturer re-submits the sample for qualification renewal 2 months prior to the expiration of the qualification status in conformance with requirement 5.15a, this provides him with 4 months to complete remanufacture of the sample, third-party evaluation and all other actions specified in 5.16a.

The qualification authority may withdraw the qualification in case: - Repeated nonconformances are observed during evaluation of a PCB during qualification renewal,

- Repeated nonconformances are observed during audits,

- Repeated nonconformances are observed with respect to the quality requirements from ECSS-Q-ST-70-60.

QA for manufacture and procurement

Overview

This clause describes requirements on quality assurance during the procurement and the manufacturing stages of the PCB.

Procurement process

Overview

This clause describes various steps in the procurement process of PCBs. This is followed by the manufacturing and inspection. Table 61 provides an estimation of typical lead time for the various phases for a typical batch size.

Table 61: Example of lead time in weeks (wk) for various phases of PCB procurement, manufacture, test and inspection.

|

Phase

|

Rigid non sequential

|

Rigid sequential

|

Flex rigid

|

HDI

|

|

Tooling including design review and MRR

|

2-3 wk

|

2-3 wk

|

2-3 wk

|

2-3 wk

|

|

IST coupon design data

|

2 wk

|

2 wk

|

2 wk

|

2 wk

|

|

MRR approval

|

0,5-1 wk

|

0,5-1 wk

|

0,5-1 wk

|

0,5-1 wk

|

|

Manufacturing & inspection

|

4 wk

|

5-6 wk

|

5-6 wk

|

6-7 wk

|

|

IST

|

2,5-4 wk

|

2,5-4 wk

|

2,5-4 wk

|

2,5-4 wk

|

|

Total

|

11-14 wk

|

12-16 wk

|

12-16 wk

|

13-17 wk

|

Procurement specification

ECSS-Q-ST-70-60 shall be used as the PCB procurement specification.

It is not good practice that the procurement authority issues his own procurement specification in which he refers to ECSS-Q-ST-70-60 as an applicable or a reference document. A reason for this is because traceability of compliance to ECSS-Q-ST-70-60 can be lost. Another reason for this is because the PCB manufacturer issues its CoC against the procurement standard and he categorises his KPIs according to the used procurement standard. In case the procurement authority desires specific additional requirements that are not covered by ECSS-Q-ST-70-60, it is good practice to include these in the PCB definition dossier or in the purchase order.

Quotation

The procurement authority shall start the procurement process by requesting the quotation and lead time from the PCB manufacturer for tooling, production and test of a specified quantity based on the provided PCB definition dossier.

The provided PCB definition dossier can be in a draft form, as specified in requirement 5.2e of ECSS-Q-ST-70-12.

The procurement authority shall maintain the PCB definition dossier under configuration control.

The procurement authority should specify in the PCB definition dossier the reporting of work in progress, content and frequency.

The procurement authority shall record double insulation in the PCB definition dossier.

Double insulation is specified for critical nets in conformance with requirement 13.9.2a from ECSS-Q-ST-70-12.

The presence of blind-via-in-pad for soldering should be recorded in the PCB definition dossier.

This can be done by a tick box.

In case the procurement authority does not define the tolerances in the PCB definition dossier, the following tolerances shall be used:

- external dimension: 0,2 mm,

- thickness over dielectric: 10 %,

- diameter of all hole types: 0,1 mm,

- external dimension for flex PCB: 0,4 mm;

- thickness for flex PCB: 20 %;

- clearance in coverlay for flex PCB: 0,50 mm;

Tolerance of 0,1mm on hole diameter is equal to maximum of 0,2mm.

Purchase order

The procurement authority shall issue the purchase order including the reference to the quotation, the ordered quantity of PCBs, the contact persons and the completed MRR checklist in conformance with Annex G of ECSS-Q-ST-70-12.

The PCB manufacturer shall acknowledge the purchase order, confirm the delivery date and start the tooling activities.

Design review (DR)

The PCB manufacturer shall initiate the DR, as specified in requirement 5.2a to 5.2g from ECSS-Q-ST-70-12 and provide compliance of the provided PCB definition dossier to the PID.

- 1 This is also done at MRR which is at a later stage in the procurement. It is important that this information is available at the quotation phase.

- 2 Design review includes design rule check (DRC).

- 3 Design review is included within the tooling process.

MRR

The PCB manufacturer shall complete the MRR checklist.

See example of MRR checklist in Annex G of ECSS-Q-ST-70-12.

The PCB manufacturer shall perform the MRR in conformance with the requirements 5.2h to 5.2k from ECSS-Q-ST-70-12.

The PCB manufacturer and procurement authority shall review during the MRR as a minimum the following aspects:

- Design review of PCB definition dossier including review items

- Traceability of any design modifications

- Build-up

- Panelisation, placement of coupons and PCBs in the panel

- Risk assessment

- Compliance to ECSS-Q-ST-70-12

- Compliance to ECSS-Q-ST-70-60

- Compliance to PID recorded in PCB approval sheet part 2 from Annex G.2.1b.

For the risk assessment, it is good practice to use a risk rating from 1 to 5. At a risk rating until 3 it is typical that the PCB manufacturer endorse the responsibility of the risk. At a risk rating of 4 or 5 it is typical that the procurement authority endorses the responsibility of the risk. At a risk rating from 3 to 5 it is good practice to involve the project for acceptance of the risk, because there can be a potential schedule impact.

In case more than three prepreg sheets are used between layers, it shall be a review item in the MRR.

More than three prepreg sheets can be used in case a large volume to be filled with resin while maintaining a specific dielectric thickness, such as for thick copper layers or blind vias.

Final and in-process inspection

The PCB manufacturer shall demonstrate that the available manpower and equipment are able to perform the final and in-process inspection.

The verification of this requirement is performed during the audit.

The PCB manufacturer shall include coupons on the panel for in-house quality control.

The panel also includes coupons for batch release and spare coupons. These are described in clause 8.

Visual standards that specify the quality characteristics shall be available to each inspector.

Visual standards for final inspection can consist of photos or drawings of microsections, which are given in clause 10.

Work instructions shall specify the processes for which an in-process inspection is performed.

Work instructions shall specify the methodology for final inspection in conformance with clause 8.

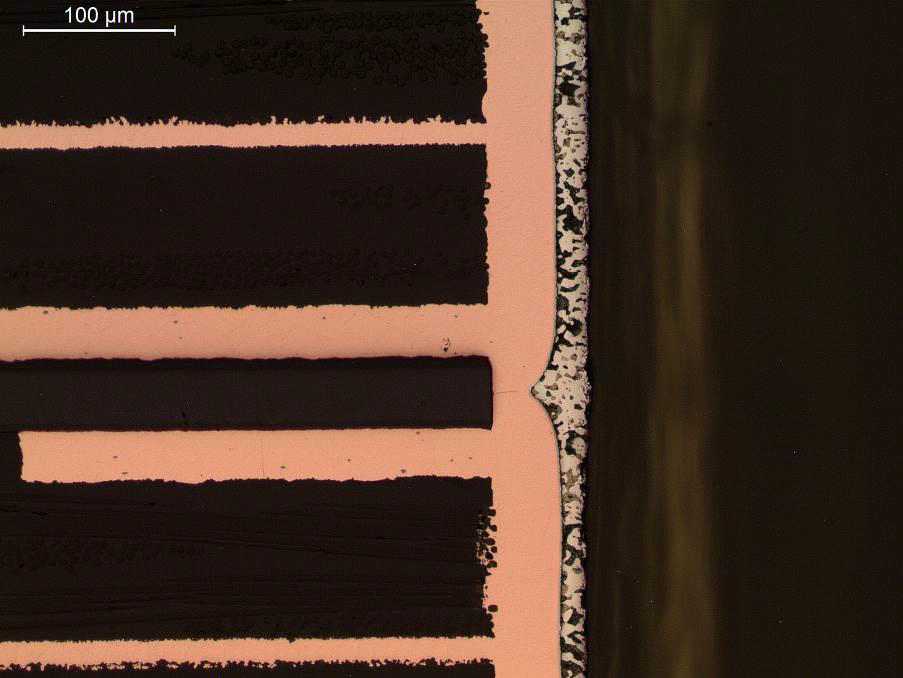

In-process inspection shall be specified in the PID , at least for the following processes:

- Microvia laser drilling, to verify the diameter to the capture pad in conformance with requirement 11.4.2g of ECSS-Q-ST-70-12;

- Microvia cleaning, to verify its efficiency;

- Etching, to verify the tolerances on track width and spacing;

- The AOI process, to verify its efficiency by calibration;

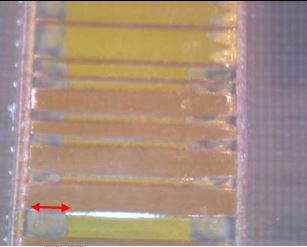

- Coverlay bonding, to verify the aspect of flex laminate and coverlay in conformance with Table 1051 and the absence of overlap of coverlay and pads in conformance with Table 1016 Ref. c;

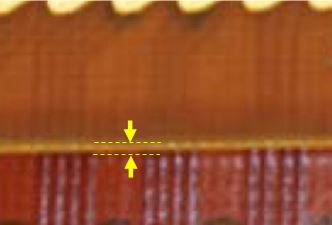

- Thickness measurements after lamination.

- 1 For microvia laser drilling and microvia cleaning in process 6.3f.1 and 6.3f.2, a homogeneous dielectric thickness in microvia layers is necessary to avoid nonconformances such as interconnect defect. The local thickness of dielectric can be affected by the designed footprint and the tolerances of prepreg thickness.

- 2 This requirement specifies which processes are verified by in-process inspection. The work instructions referenced in the PID specify the verification method, in conformance with D.2.1.1a.8.

Comparison of lay-out to the drawing from the PCB definition dossier shall be performed to verify presence of plated and non-plated holes and milling.

The PCB manufacturer shall specify in its PID an approach for TMA measurements to determine Tg and CTE in Z-direction, including frequency of test and material and technology of test vehicle.

This test is specific for a build-up and for the used process equipment.

The PCB manufacturer shall specify in its PID the range of etchback.

In-process control by IST testing shall be in conformance with clause 9.5.5.2.1.

Quality records for manufacture and procurement

The PCB manufacturer shall retain the quality records for at least ten years and in accordance with business agreement requirements.

The quality records shall be composed of the following:

- Documentation of the final inspection of manufactured PCBs, including CoC and lab reports in conformance with Annex B;

- Nonconformance reports and corrective actions in conformance with ECSS-Q-ST-10-09;

- Qualification test reports, in conformance with requirement 5.10c;

- Traveller;

- Batch summary statistics;

- Process records.

Process records typically include SPC of chemical processes, maintenance and calibration records.

Non-nominal performance of equipment, materials or processes shall be documented including the following topics:

- Root cause investigation;

- Corrective action;

- Effect on previous, ongoing and future manufacturing batches;

- Assessment by QA personnel.

These topics are the same as for an NCR in conformance with ECSS-Q-ST-10-09.

The PCB manufacturer shall maintain a database for calibration of electrical and mechanical manufacturing and test equipment.

The PCB manufacturer should provide to the procurement authority the list of nonconformances specific to them, as reported quarterly in the QA report in conformance with F.2.1a.3.

Control of materials and chemistry

The base materials shall be in conformance with clause 5 from ECSS-Q-ST-70.

The base materials shall be in conformance with IPC-4101E for rigid laminates, IPC-4103A for RF laminates, IPC-4204A for flexible laminates and IPC-4203A for coverlay.

In case of double insulation in conformance with requirement 6.2.3d, the base materials for rigid laminates and prepreg shall be in conformance with IPC-4101E Appendix A.

Double insulation is specified in clause 13.9 of ECSS-Q-ST-70-12. Annex I describes the more stringent cleanliness requirements for prepreg and laminate from IPC-4101E Appendix A.

Base materials in conformance with IPC-4101E Appendix A shall be manufactured by a laminate supplier that is listed in the IPC QPL or that passed a specific audit from the PCB manufacturer.

For requirement 6.5b, newer revisions of the referenced IPC standards may be used in case raw materials can only be procured in conformance to those newer revisions.

For requirement 6.5c and 6.5d, newer revisions of the referenced IPC-4101E standard may be used in case

- raw materials can only be procured in conformance to those newer revisions, and

- it is in conformance with Appendix A from IPC-4101E.

The text from Appendix A of IPC-4101E is included in Annex I.

Prepreg, laminate, flex laminate, coverlay, bond-ply, copper foil, heat sinks and metal core shall be selected, inspected and tested in conformance with the work instruction as specified in the PID.

Tests can include chemical and physical testing.

The PCB manufacturer shall separate, and prevent the use of raw materials and semifinished products that are awaiting completion of test results.

The PCB manufacturer shall segregate, mark and record noncompliant materials and PCBs.

The PCB manufacturer shall control the storage conditions and duration of materials and chemistry with limited shelflife and verify the validity of the relevant material for use.

The verification and relife procedure of limited shelf-life materials shall be in accordance with ECSS-Q-ST-70-22, except for prepreg in conformance with requirement 6.5l.

The verification and re-life procedure of prepreg shall be performed by the raw material supplier and documented in a new CoC for the prepreg.

- 1 The new prepreg CoC include a new shelf-life. Shelf-life and storage conditions are important for the flow factor of prepreg, particularly for no-flow prepreg.

- 2 It is good practice to allow for the lead time for relife tests when anticipating supply of material for PCB manufacture.

Control of plating chemistry

Pure tin finish with > 97 % purity shall not be used, in conformance with the requirement 5.2.2a of ECSS-Q-ST-70.

Electrolytic copper plating shall have a purity of ≥ 99,5 % copper.

Electrolytic soft gold plating shall have a purity of ≥ 99,8 % gold, except for the case of electrolytic hard gold plating.

Electrolytic hard gold plating may contain 0,3 % cobalt.

For solderless connection hard gold shall be used.

For wire bonding or adhesive bonding soft gold shall be used.

For wire bonding bright aspect is preferred but matt aspect can be used.

Electrolytic pure nickel plating shall have a purity of ≥ 99,95 % nickel, except in the case of electrolytic nickel alloy plating.

Electrolytic gold plating shall have ≤ 0,2 % silver.

ENIG, ENEPIG and ENIPIG finish plating thickness shall be verified once per panel in conformance with Table 1013.

ENIG, ENEPIG and ENIPIG finish plating thickness shall be in conformance with IPC-4552A, IPC-4556, chemistry supplier specifications and plating company work instructions.

ENIG, ENEPIG and ENIPIG thickness measurements using XRF shall be calibrated in conformance with IPC-4552A and IPC-4556.

ENIG, ENEPIG and ENIPIG adhesion shall be verified once per panel by peel test on a coupon specified by the PCB manufacturer.

The responsible operator for ENIG, ENEPIG and ENIPIG process shall be informed about the type of dielectric materials of the PCB.

Conformance with IPC-4552A and IPC-4556 for ENIG, ENEPIG and ENIPIG processes shall be evaluated by audit, including MTO, physical and chemical bath parameters, bath contamination, SPC and verification procedures.

Cleanliness of PCB processes

Overview

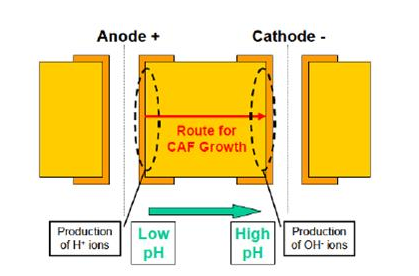

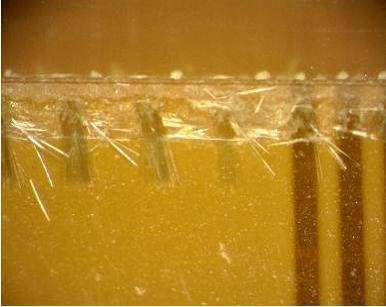

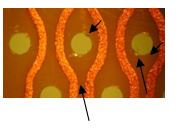

PCBs can fail due to latent short circuits, which can be caused by random contamination inside the dielectric PCB material. Contamination can comprise of fibres in laminate or on prepreg layers and can originate from the PCB manufacturing processes or from the base material supply chain.

Cleanliness of base materials is addressed to the base material supply chain as described in requirements 6.5c and 6.5d.

High resistance electrical test is specified on final PCBs with the aim to identify leakage current that can be caused by contamination, as specified in 9.3.7.

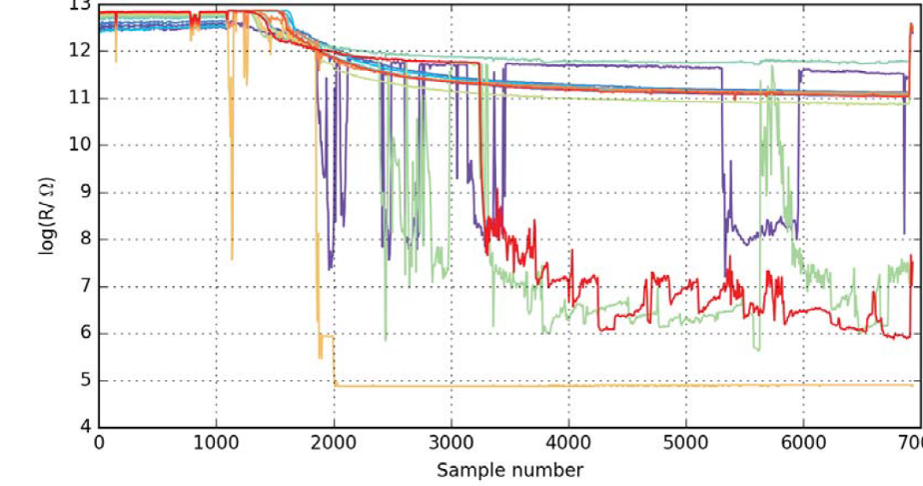

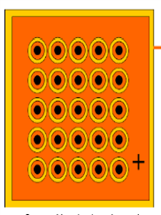

THB test on coupons is specified in 9.7.2 with the aim to determine the effects of contamination on ECM.

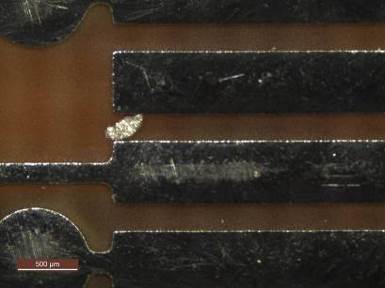

Clause 6.7.2 specifies requirements for the PCB manufacturing processes. The processes after innerlayer etching until lay-up are considered critical with respect to cleanliness. The PCB manufacturing processes are mostly taking place in rooms with controlled environment. This environment can, however, include the risk of collecting dust particles on materials processed or stored in these rooms. The lay-up process is the final process during which innerlayers can be inspected. This process is also the most critical one for introducing unwanted contamination. The requirements specified in this clause address this risk. This can be referred to by the term “FOD prevention”.

Another risk can be created by contaminants, such as agglomerations of solvent residue, that can be embedded and remain invisible on raw materials. High temperature during lamination can cause these contaminants to carbonise. This risk is not specifically addressed or mitigated by this clause.

Cleanliness control

The PCB manufacturer shall treat all processes from innerlayer etching until lay-up as critical processes with respect to cleanliness.

The PCB manufacturer shall have a cleanliness control procedure that includes at least the following:

- cleanliness of prepreg sheets until the lay-up process and any cleaning methods in conformance with requirement 6.7.2f;

- cleanliness of etched innerlayers until the lay-up process and any cleaning methods in conformance with requirement 6.7.2f;

- verification of the efficiency of cleaning on innerlayers and prepreg and its acceptance criteria;

- restrictions of the use of materials that charge statically and attract fibres;

- clean room practices in lay-up area in conformance with requirements 6.7.2c, 6.7.2d, 6.7.2e, 6.7.2g and 6.7.2h;

- reference to work instructions for the general cleaning of the room;

- reference to work instructions to segregate epoxy resin dust from polyimide in conformance with requirement 6.7.2i.

- 1 Materials used with innerlayers that show static charging are, for instance, separator sheets or transport trays.

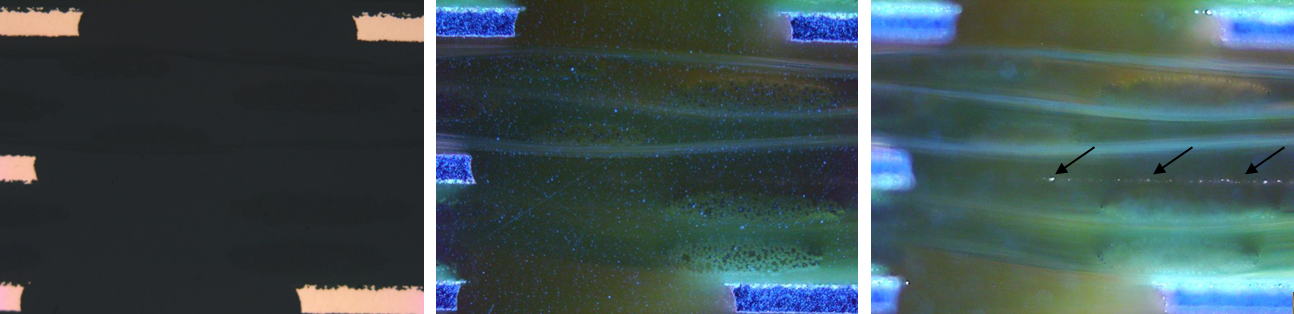

- 2 Verification of cleanliness of innerlayers or prepreg can be done by inspection under UV light and bright light. Dust particles are UV fluorescent. Epoxy resin dust is UV fluorescent. Polyimide resin dust is typically not UV fluorescent.

The room for the lay-up process shall include the following: - overpressure;

- filtered air supply;

- protective clothing that do not release fibres for operators;

- prevention of sticky surfaces or cavities in furniture where fibres collect.

Protective clothing can include shoes, hat, coat, and gloves.

The room for the lay-up process should include the following:

- monitoring of airborne contamination;

- general clean room class 8 or better, in accordance with ISO-14644-1:2015.

A formal cleanroom class as per ISO specification is difficult to obtain because of handling prepreg inside the room that creates dust. The objective is to reduce the risk of foreign contaminants in the room.

Local measures for cleanliness at the lay-up area should include the following:

- laminar flow bench;

- de-ionisation equipment;

- local monitoring of particulate contamination;

- local cleanliness class 6 or better, in accordance with ISO-14644-1:2015.

Prior to lay-up, cleaning of prepreg sheets and etched inner layers should be performed by using vacuum hovering or by use of tacky rollers or wipes.

Motor parts for any vacuum hovering should be located outside of the room for lay-up.

A vacuum hose can be brought into the room through the wall.

The use of particle counters at the lay-up area should allow for the presence of prepreg dust.

Measurements can be taken on Monday morning prior to the first operation in the room. As soon as prepreg sheets are handled, measurements are compromised by the prepreg dust that is not a breach of cleanliness as long as it is similar material used for the lay-up.

Segregation of polyimide and epoxy materials in the lay-up area shall prevent inclusion of epoxy prepreg dust in the lay-up of polyimide.

This is done because epoxy can decompose and carbonise during the processing of polyimide. This can also be important for other materials combinations.

The PCB manufacturer shall provide instructions to operators on the measures specified in its cleanliness control procure.

Examples of instructors to operators can include labels on the work floor, photographic instructions on best practices, identification of critical areas, and training.

Traceability

The PCB manufacturer’s records shall identify for all batches of PCBs the traceability of all raw materials and semifinished products listed in the traveller and the individual process steps mentioned herein.

- 1 In most cases a batch of PCBs is manufactured using raw materials from the same production batch. But it is also common practice to mix raw material from various production batches within the same PCB batch. This requirement provides this traceability.

- 2 Traceability to raw materials does not need to be included in the CoC, since the procurement authority is not able to evaluate this information. Instead, the QA documentation of the PCB manufacturer is subject to audit or to specific enquiry from its customers.

All panels within a batch shall be laminated on the same day and plated on the same day, except the case in requirement 6.8c.

In case panels within a batch are not laminated on the same day or not plated on the same day, it shall be reported on the CoC.

In case panels within a batch are not laminated on the same day or not plated on the same day, the reason for it should be reported on the CoC.

Each PCB and coupon shall have a unique marking for traceability to batch and panel number.

The marking on PCB and coupon shall be resistant to tests and processes.

Marking on coverlay for flexible PCB and sculptured flex PCB shall not lift after tape test in conformance with clause 9.4.5.

The marking shall be in conformance with the PCB definition dossier.

The outgassing of marking shall be in conformance with ECSS‐Q‐ST‐70‐02.

Conductive marking shall be treated as a conductive element on the PCB.

The traceability from the PCB manufacturer shall enable localisation of PCBs and coupons on the panel.

The PCB manufacturer shall issue a CoC in conformance with the DRD from Annex B for delivered PCBs within the batch.

In case some PCBs within the batch are delivered later, the PCB manufacturer shall at least issue a new declaration of conformance from the CoC in conformance with B.2.1.2.

Spare PCBs can be stored by the PCB manufacturer and delivered to the customer at a later time if re-ordered. In case the lab reports from the original delivered CoC covers the spare ones, a new lab report does not need to be issued. The new declaration of conformance is sufficient to ensure traceability.

Operator and inspector training

All operators and inspectors shall be trained for their task and for the understanding of the applicable quality assurance requirements.

Repair of bare PCBs

Overview

Repair are operations done on a PCB at the end of the manufacture. They are usually the consequence of the visual inspection.

General

Repair operations shall be documented and justified in a work instruction by the PCB manufacturer and referenced in the PCB manufacturer’s PID.

Prior approval from the procurement authority shall be obtained for repair operations.

Approval can be recorded for instance in MRR, statement of compliance to this standard or the PCB definition dossier.

The capability of operators performing repair operations shall be validated by the PCB manufacturer.

This is the case for all operations, but is specifically mentioned here because of the criticality of the repair operation.

The repaired area shall be re-submitted to visual inspection in conformance with clause 9.3.1 and 9.3.2 by the PCB manufacturer by a different operator than the one who performed the repair.

The CoC shall provide traceability of all repair operations.

This traceability includes the location on the PCB.

The repaired area shall be submitted to visual inspection in conformance with clause 9.3.1 and 9.3.2 by the procurement authority during incoming inspection.

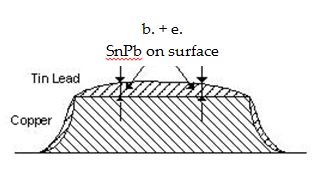

In case SnPb is missing on the surface, it may be added with a solder iron and flux on bare surface copper in case all the following conditions are met:

- the documented repair operation includes limits for temperature, duration and flux in conformance with ECSS-Q-ST-70-08;

- the PCB manufacturer has inspected plated holes to verify the absence of missing SnPb inside them;

- the PCB manufacturer has verified that the copper is non-etched in the area of missing SnPb.

Non-etched copper has a flat surface, whereas etched copper has a concave surface. In case copper is affected by etching, the missing SnPb is a process indicator of a problem that can affect plated holes, which cannot be repaired.

In case dual surface finish of SnPb and electrolytic gold is used, oxidation of SnPb may be removed with a solder iron and flux.

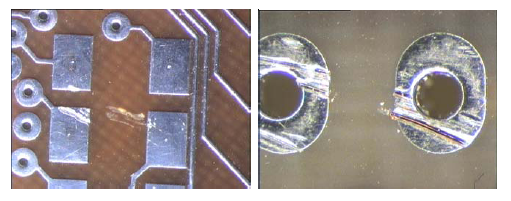

Excess surface copper may be removed in case it is submitted to visual inspection for the absence of weave exposure in conformance with Table 1043, Table 1044 and other nonconformances.

Copper removal can be done with a scalpel or laser.

The total number of repairs in conformance with the requirements 6.10.2g, 6.10.2h and 6.10.2i shall not exceed 6 per 50 cm2 and 6 per PCB.

This is based on ECSS-Q-ST-70-28 considering a maximum per PCB and per surface area, whichever is more restrictive.

Haloing exceeding the requirements of Table 1050 and Table 1045 may be repaired using adhesive in case all the following conditions are met:

- the haloing is not in contact with conductors on surface layer and the underlying layer;

- the length of PCB edge for a single repair does not exceed 1 cm;

- the total number of repairs on the PCB edges do not exceed 4.

Depaneling can cause haloing if an inadequate cutting method is used.

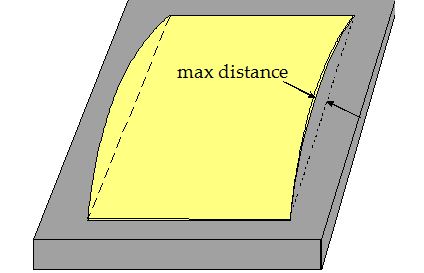

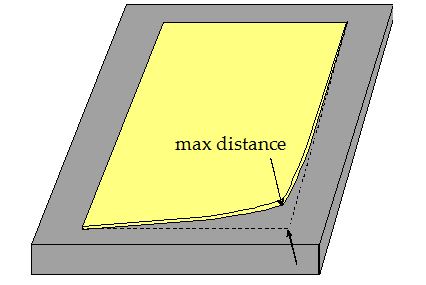

In case a PCB exceeds warp or twist requirements from clauses 9.3.3.2 or 9.3.3.3, it may be flattened using pressure and elevated temperature in case the initial warp and twist does not exceed 1,6 %.

Approval for this process is specified in requirement 6.10.2b because the PCB can increase its non-flatness after storage, bake-out or assembly processes. These processes are not under control of the PCB manufacturer. The main cause for non-flatness is asymmetric build-up or shape, which is driven by the design from the procurement authority.

Nodules that reduce the diameter of PTH to below the requirement may be removed in case all the following conditions are met:

- The nodules are caused by fibres connecting to only 1 side of the hole wall;

- The nodules are removed by applying slight mechanical force by probing with a gauge;

- The integrity of the hole wall after repair is not compromised;