Space product assurance

High-reliability soldering for surface-mount and mixed technology

Foreword

This Standard is one of the series of ECSS Standards intended to be applied together for the management, engineering and product assurance in space projects and applications. ECSS is a cooperative effort of the European Space Agency, national space agencies and European industry associations for the purpose of developing and maintaining common standards. Requirements in this Standard are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards.

This Standard has been prepared by the ECSS Executive Secretariat, reviewed by the Document and Discipline Focal point, and approved by the ECSS Technical Authority.

Disclaimer

ECSS does not provide any warranty whatsoever, whether expressed, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item are error-free. In no respect shall ECSS incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this Standard, whether or not based upon warranty, business agreement, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by ECSS.

Published by: ESA Requirements and Standards Division

ESTEC, P.O. Box 299,

2200 AG Noordwijk

The Netherlands

Copyright: 2017© by the European Space Agency for the members of ECSS

Change log

|

ECSS-Q-70-38A

|

First issue

|

|

ECSS-Q-70-38A Rev.1

|

Second issue

|

|

ECSS-Q-70-38B

|

Never issued

|

|

ECSS-Q-ST-70-38C

|

Third issue

|

|

ECSS-Q-ST-70-38C Rev.1

|

Third issue, Revision 1

|

Introduction

This Standard prescribes requirements for electrical connections of leadless and leaded surface mounted devices (SMD) on spacecraft and associated equipment, utilising a range of substrate assemblies and employing solder as the interconnection media. The principal types of SMDs can be gathered in the following families:

|

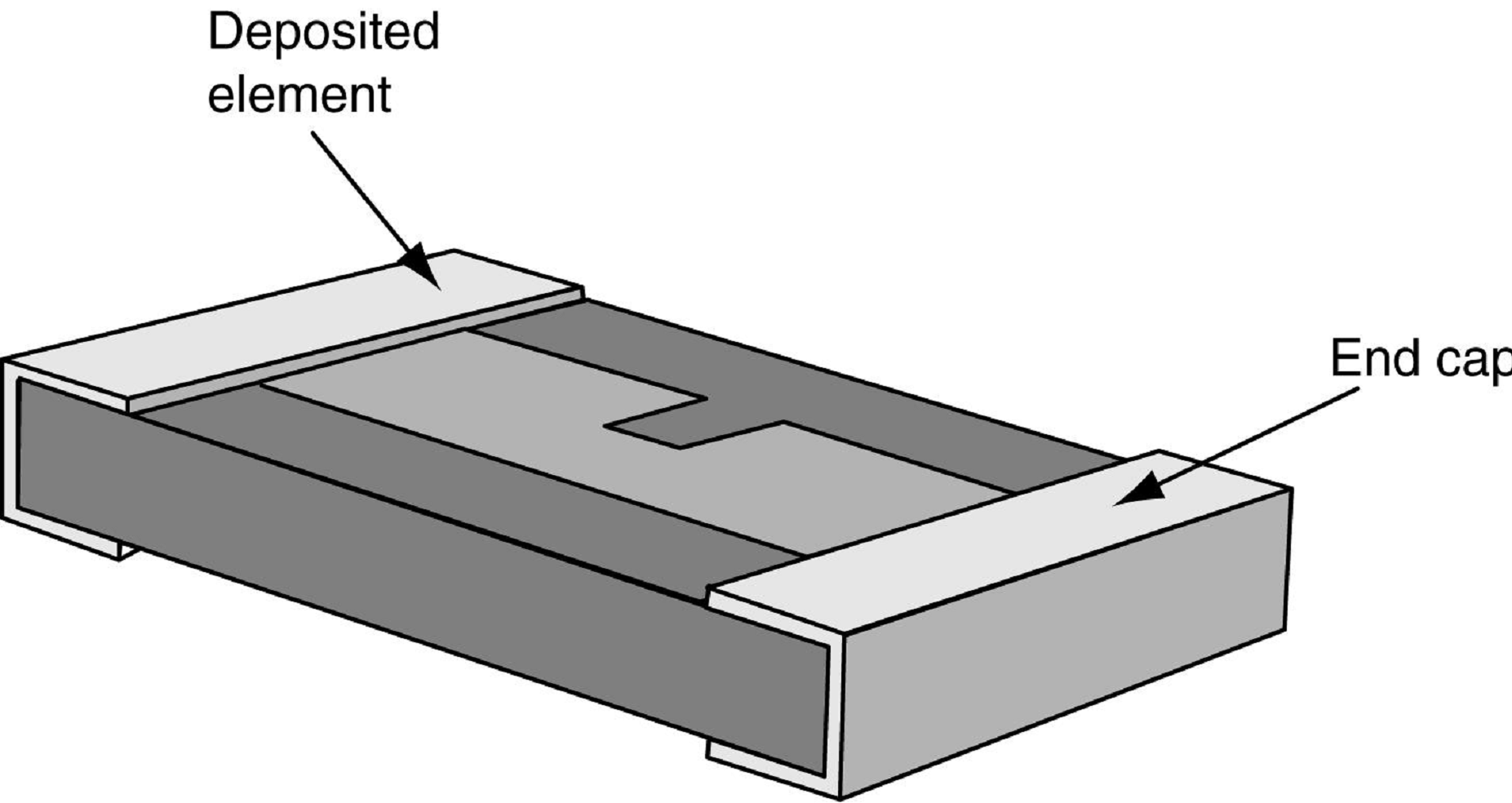

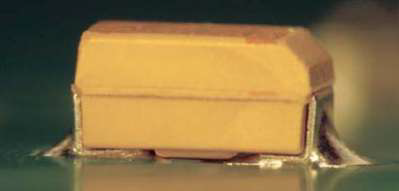

Rectangular and square end-capped or end-metallized device with rectangular body, leadless chip (see 11.5.2)

|

|

|

Cylindrical and square end-capped devices with cylindrical body, leadless chip (see 11.5.4)

|

|

|

Bottom terminated chip device (see 11.5.3)

|

|

|

Castellated chip carrier device (see 11.5.5)

|

|

|

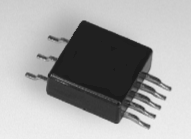

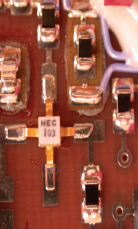

Flat pack and gull-wing leaded device with round, rectangular , ribbon leads (see 11.5.6)

|

|

|

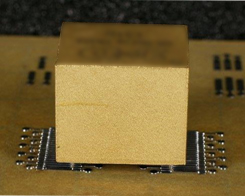

Moulded magnetics (see 11.5.13)

|

|

|

“J” leaded device (see 11.5.7)

|

|

|

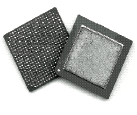

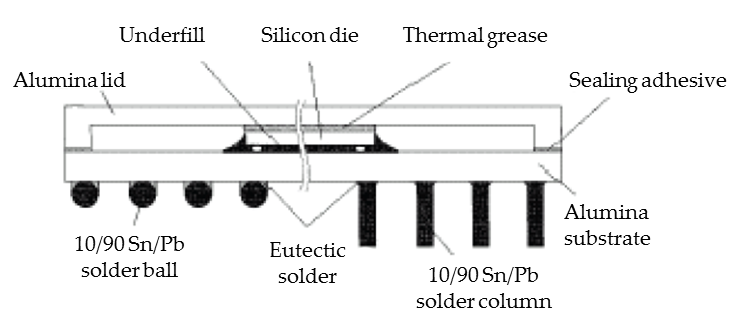

Area array devices (AAD) (see 11.5.8)

|

|

|

Devices with ribbon terminals without stress relief (flat lug leads) (see 11.5.9)

|

|

|

Device with Inward formed L-shaped leads (see 11.5.10)

|

|

|

Stacked modules devices with leads protruding vertically from bottom (see 11.5.11)

|

|

|

Leaded device with plane termination (see 11.5.12)

|

|

Scope

This Standard defines the technical requirements and quality assurance provisions for the manufacture and verification of high-reliability electronic circuits based on surface mounted device (SMD) and mixed technology.

The Standard defines acceptance and rejection criteria for high-reliability manufacture of surface-mount and mixed-technology circuit assemblies intended to withstand normal terrestrial conditions and the vibrational gloads and environment imposed by space flight.

The proper tools, correct materials, design and workmanship are covered by this document. Workmanship standards are included to permit discrimination between proper and improper work.

The assembly of leaded devices to through-hole terminations and general soldering principles are covered in ECSS-Q-ST-70-08.

Requirements related to printed circuit boards are contained in ECSS-Q-ST-7010, ECSS-Q-ST-70-11 and ECSS-Q-ST-70-12 .

The mounting and supporting of devices, terminals and conductors prescribed herein applies to assemblies at PCB level designed to continuously operate over the mission within the temperature limits of -55 C to +85 C.

For temperatures outside this normal range, special design, verification and qualification testing is performed to ensure the necessary environmental survival capability.

Special thermal heat sinks are applied to devices having high thermal dissipation (e.g. junction temperatures of 110 C, power transistors) in order to ensure that solder joints do not exceed 85 C.

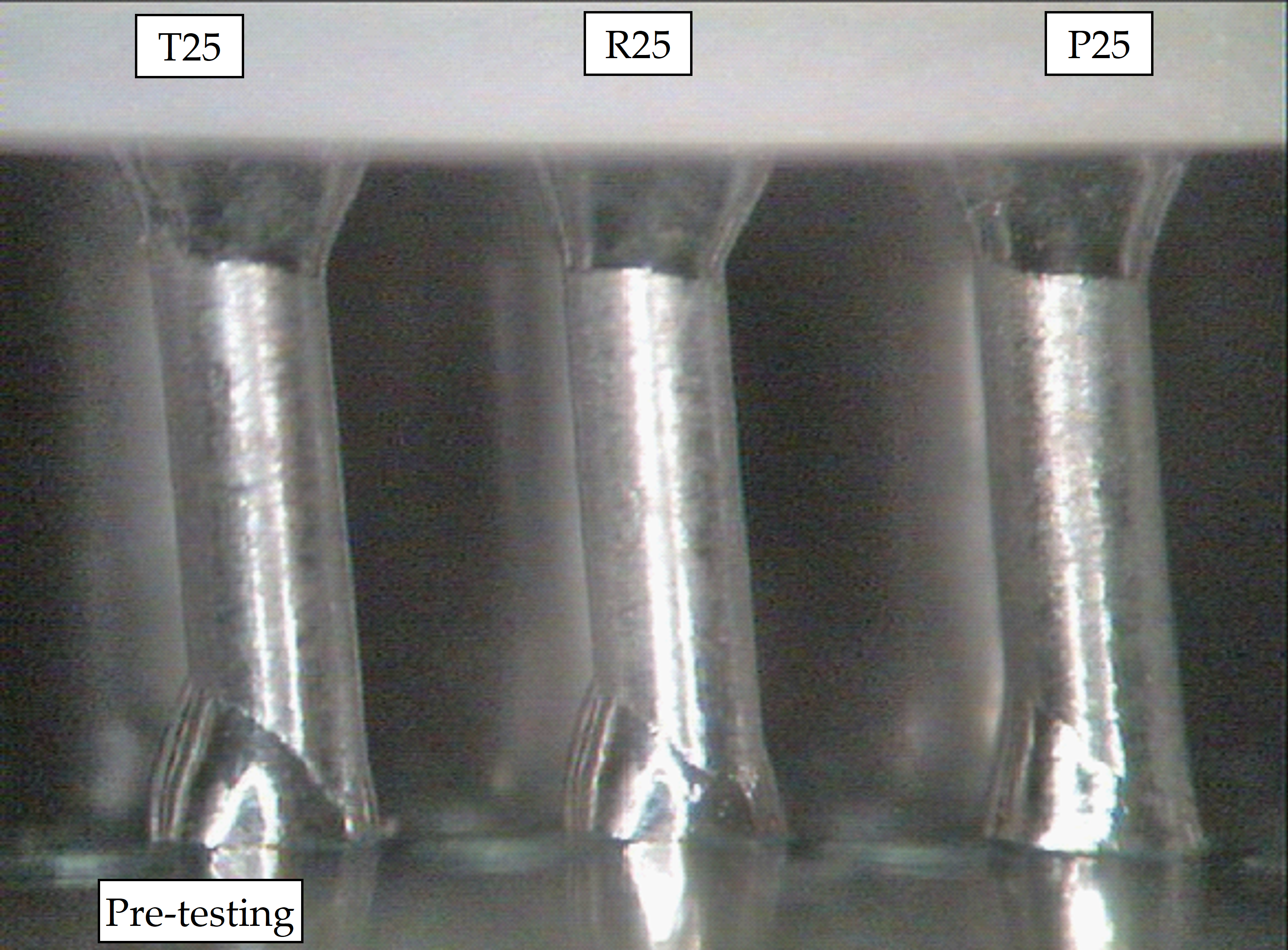

Verification of SMD assembly processes is made on test vehicles (surface mount verification samples). Temperature cycling ensures the operational lifetime for spacecraft. However, mechanical testing only indicates SMD reliability as it is unlikely that the test vehicle represents every flight configuration.

This Standard does not cover the qualification and acceptance of the EQM and FM equipment with surface-mount and mixed-technology.

The qualification and acceptance tests of equipment manufactured in accordance with this Standard are covered by ECSS-E-ST-10-03.

This standard may be tailored for the specific characteristics and constraints of a space project, in accordance with ECSS-S-ST-00.

Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this ECSS Standard. For dated references, subsequent amendments to, or revisions of any of these publications do not apply. However, parties to agreements based on this ECSS Standard are encouraged to investigate the possibility of applying the most recent editions of the normative documents indicated below. For undated references the latest edition of the publication referred to applies.

|

ECSS-S-ST-00-01

|

ECSS system — Glossary of terms

|

|

ECSSMST40

|

Space project management — Configuration and information management

|

|

ECSSQST10-09

|

Space product assurance — Nonconformance control system

|

|

ECSSQST20

|

Space product assurance — Quality assurance

|

|

ECSSQST60

|

Space product assurance — Electrical, electronic and electromechanical (EEE) components

|

|

ECSSQST60-05

|

Space product assurance — Generic requirements for hybrids

|

|

ECSS-Q-ST-60-13

|

Space product assurance - Commercial electrical, electronic and electromechanical (EEE) components

|

|

ECSSQST70

|

Space product assurance — Materials, mechanical parts and processes

|

|

ECSSQST70-01

|

Space product assurance — Cleanliness and contamination control

|

|

ECSSQST70-02

|

Space product assurance — Thermal vacuum outgassing test for the screening of space materials

|

|

ECSSQST70-08

|

Space product assurance — Manual soldering of high–reliability electrical connections

|

|

ECSSQST70-10

|

Space product assurance — Qualification of printed circuit boards

|

|

ECSSQST70-11

|

Space product assurance — Procurement of printed circuit boards

|

|

ECSS-Q-ST-70-12

|

Space product assurance — Design rules for printed circuit boards

|

|

ECSS-Q-ST-70-28

|

Space product assurance — Repair and modification of printed circuit board assemblies for space use.

|

|

ECSSQST70-71

|

Space product assurance —Materials processes and their data selection

|

|

MIL-STD-883 Method 2009

|

Test Method Standard, Microcircuits

|

|

IPC-TM-650: 2.6.3.3 Issue 2004

|

Test methods manual. Surface Insulation Resistance, Fluxes

|

Terms, definitions and abbreviated terms

Terms from other standards

For the purpose of this Standard, the terms and definitions from ECSSSST0001 apply.

For the purpose of this Standard, the terms and definitions from ECSS-Q-ST-60 apply, in particular for the following term(s):

commercial component

For the purpose of this Standard, the terms and definitions from ECSS-Q-ST-70-28 apply, in particular for the following term(s):

repair

rework

Terms specific to the present standard

approval authority

entity that reviews and accepts the verification programme, evaluating the test results and grants the final approval

bonding

application process of adhesive under a SMD package for mechanical or thermal purpose where adhesive joint is not visible

co-planarity

maximum distance between lowest and highest termination when device rests on flat surface

collective assembled devices

set of components that are soldered to PCB in one operation

critical zone

area in the solder joint in which the existence and magnitude of cracks is subject to acceptance or rejection

device

package, component or part

dynamic wave soldering machine

system that achieves wave soldering and which consists of stations for fluxing, preheating, and soldering by means of a conveyer

electrical clearance

spacing between non-common electrical conductors on external layers of a printed circuit board assembly

The distance between conductors depends on the design voltage and DC or AC peaks. Any violation of minimum electrical clearance as a result of a nonconformance is a defect condition.

reprocessing

preparatory operation done on a device prior to assembly

Retinning, degolding, lead forming are examples of reprocessing.

scavenging (leaching)

basis metal or metallization partly or wholly dissolved in melted solder during a soldering operation

selective plating

tin-lead plated solder footprints connected to gold plated copper tracks

It is usually related to RF circuits.

sensitive devices

device prone to have cracks in solder joint exceeding 75 % of acceptance criteria or showing nonconformance outside the component manufacturer limit

- 1 ESA list of sensitive devices is published on ESCIES for information, see www.escies.org.

- 2 Each company maintains its own list of sensitive devices in the PID.

solder balling (solder balls)

numerous spheres of solder having not melted in with the joint form and being scattered around the joint area normally attached by flux residues

Can be caused by incorrect preheating or poor quality solder.

stacking

application process of adhesive at extremities of a SMD package for mechanical purpose where adhesive joint is partially visible

solder stand-off

thickness of solder between the underside of the device termination and the surface of the PCB footprint

test vehicle

substrate assembled with Surface Mounted Devices subjected to a verification programme

tombstoning

chip devices lifting off one of their two terminal footprints causing the chip to stand up like a tombstone

Normally caused by:

- bad design where one footprint reaches solder reflow temperature before the other;

- different quantities of solder paste on each footprint;

- different solderability of one footprint or one termination with respect to the other.

underfill

encapsulant material deposited between a device and substrate

Abbreviated terms

For the purpose of this Standard, the abbreviated terms from ECSSSST0001 and the following apply:

|

Abbreviation

|

Meaning

|

|

AAD

|

area array device

|

|

BGA

|

ball grid array

|

|

CBGA

|

ceramic ball grid array

|

|

CCGA

|

ceramic column grid array

|

|

CGA

|

column grid array

|

|

CLCC

|

ceramic leaded chip carrier

|

|

CTE

|

coefficient of thermal expansion

|

|

DPAK

|

diode package

|

|

DRD

|

document requirement definition

|

|

FM

|

flight model or flight hardware

|

|

FP

|

flat pack package

|

|

JEDEC

|

Joint Electron Device Engineering Council

|

|

LCCC

|

leadless ceramic chip carrier

|

|

MELF

|

metal electrode face bonded

|

|

MIP

|

mandatory inspection point

|

|

PCB

|

printed circuit board

|

|

PLCC

|

plastic leaded chip carrier

|

|

PID

|

process identification document

|

|

QFN

|

quad flat pack no leads

|

|

QFP

|

quad flat pack

|

|

r.m.s.

|

root-mean-square

|

|

SIR

|

surface insulation resistance

|

|

SMD

|

surface mounted device

|

|

SMT

|

surface-mount technology

|

|

SO

|

small outline

|

|

SOD

|

small outline device

|

|

SOT

|

small outline transistor

|

|

SOP

|

small outline package

|

|

TO

|

transistor outline

|

|

TSOP

|

thin small outline package

|

Nomenclature

Formal verbs

The following nomenclature apply throughout this document:The word “shall” is used in this document to express requirements. All the requirements are expressed with the word “shall”.

The word “should” is used in this document to express recommendations. All the recommendations are expressed with the word “should”.

It is expected that, during tailoring, all the recommendations in this standard are either converted into requirements or tailored out.

The words “may” and “need not” are used in this document to express positive and negative permissions respectively. All the positive permissions are expressed with the word “may”. All the negative permissions are expressed with the words “need not”.

The word “can” is used in this document to express capabilities or possibilities, and therefore, if not accompanied by one of the previous words, it implies descriptive text.

In ECSS “may” and “can” have a complete different meaning: “may” is normative (permission) and “can” is descriptive.

The present and past tense are used in this document to express statement of fact, and therefore they imply descriptive text.

Principles of reliable soldered connections

The following are the general principles to ensure reliable soldered connections:

Reliable soldered connections are the result of proper design, control of tools, materials, processes and work environments, and workmanship performed in accordance to verified and approved procedures, inspection control and precautions.

The basic design concepts to ensure reliable connections and to avoid solder joint failure are as follows:

Stress relief is an inherent part of the design, which reduces detrimental thermal and mechanical stresses on the solder connections.

Where adequate stress relief is not possible materials are so selected that the mismatch of thermal expansion coefficients is a minimum at the constraint points in the device mounting configuration.

The assembled substrates are designed to allow easy inspection.

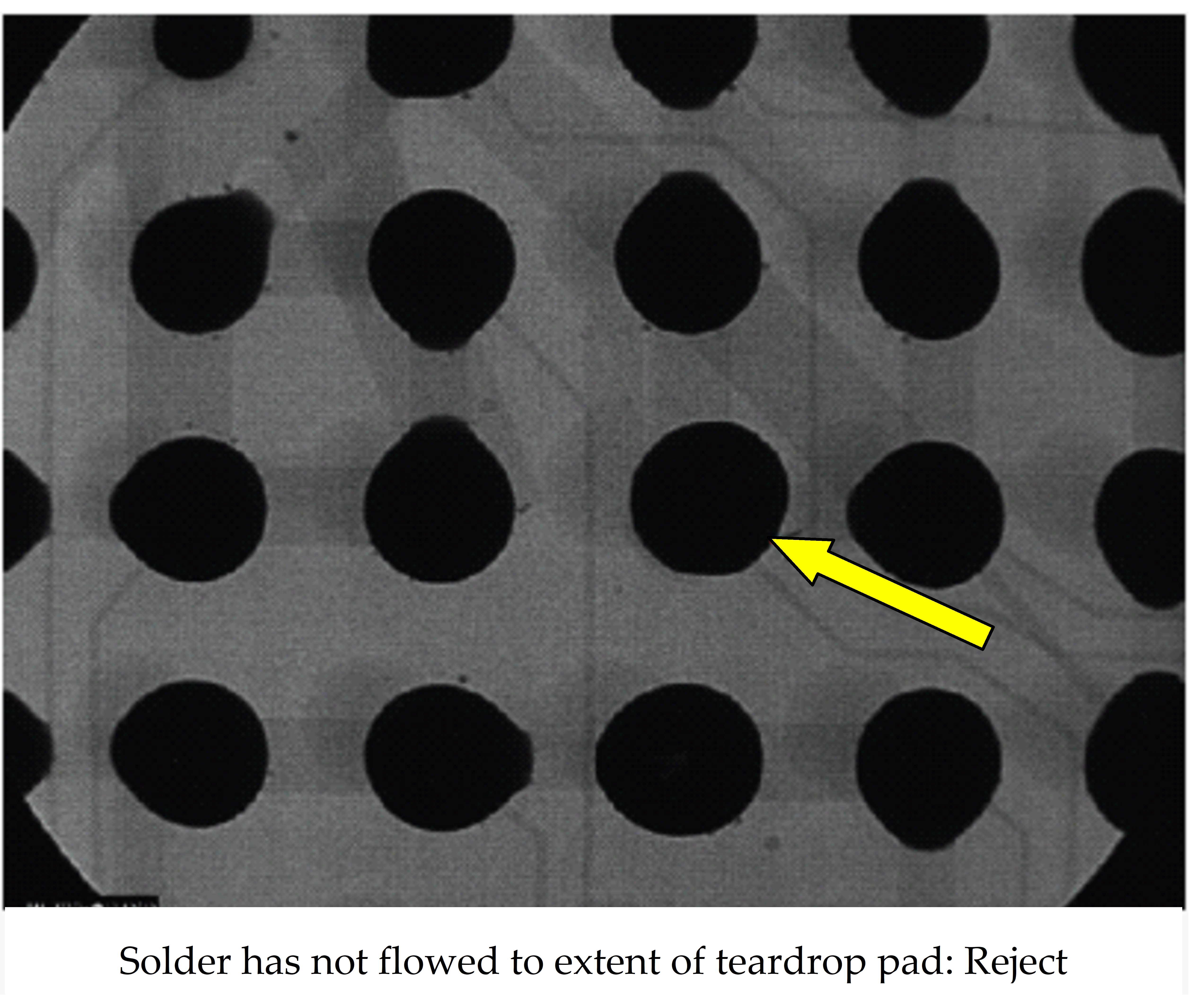

Since only the outer row of solder joints to area array packages can be visually inspected, inner rows are inspected using X-ray techniques. To facilitate X-ray inspection of the solder joints to BGAs, the solder footprints can have a teardrop design.

Circuit designs for area array devices, (e.g. BGA, CGA) have clearance around the perimeter of these packages to ensure that reflow nozzles can perform rework or repair operations (see ECSSQST70-28). The clearance depends on the equipment used for reworking and the height of adjacent components.

Unpopulated areas on the underside of the substrate assist indirect heating for removal of these packages.

Soldering to gold using tin-lead alloy can cause failure.

Process identification document (PID)

General

Purpose

The purpose of the PID is to ensure that a precise reference is established for the assembly processes approved in accordance with this Standard.

The PID provides a standard reference against which any anomalies occurring after the approval can be examined and resolved.

Document preparation

The supplier shall prepare the PID in conformance with DRD from Annex F.

The supplier shall provide a draft PID prior to any start of verification to the Approval Authority.

The first issue of the PID shall fully comply to this standard.

For supplier, already approved on the basis of reliable tests results which supported the approval of any deviation finally recorded in the PID, then the PID may supersede the corresponding requirements from this standard.

<<deleted>>

<<deleted>>

<<deleted>>

Approval

The PID shall be submitted to the Approval Authority for approval.

The approval can be achieved by PID signature or minutes of meeting being signed by the Approval Authority.

<<deleted>>

SMT contact person

The supplier shall appoint a contact person for SMT topics.

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

Process identification document updating

The PID shall be managed in accordance with ECSS-M-ST-40.

A PID shall represent the current verified manufacturing processes and production controls.

Any proposed change to the PID shall be agreed by the Approval Authority.

<<deleted>>

The supplier shall initiate a review of the PID, the SMT summary table and the relevant applicable documents at least every two years for agreement by the Approval Authority.

Preparatory conditions

Calibration

The supplier shall maintain records of tool calibration and verification.

Requirements from clause 5.1 from ECSSQST7008 shall apply for “Calibration”.

Facility cleanliness

Requirements from clause 5.2 from ECSSQST7008 shall apply for “Facility cleanliness”.

Environmental conditions

Requirements from clause 5.3 from ECSSQST7008 shall apply for “Environmental conditions”.

Precautions against static charges

Requirements from clause 5.5 from ECSSQST7008 shall apply for “Precautions against static charges”.

Lighting requirements

Requirements from clause 5.4 from ECSSQST7008 shall apply for “Lighting requirements”.

Equipment and tools

Brushes

Requirements from clause 5.6.2 from ECSSQST7008 shall apply for "Brushes".

Cutters and Pliers

Requirements from clause 5.6.3 from ECSSQST7008, shall apply for "Cutters and Pliers".

Bending tools

Requirements from clause 5.6.4 from ECSSQST7008 shall apply for "Bending tools".

Clinching tools

Requirements from clause 5.6.5 from ECSSQST7008 shall apply "Clinching tools".

Insulation strippers

Requirements from clause 5.6.6 from ECSSQST7008 shall apply for "Insulation strippers".

Soldering tools

Requirements from clause 5.6.8 from ECSSQST7008 shall apply for "Soldering tools".

Soldering irons and resistance soldering equipment

Requirements from clause 5.6.7 from ECSSQST7008 shall apply for “Soldering irons and resistance soldering equipment”.

For surface mounted devices, the soldering tip shall not exceed 340 C.

Based on the device manufacturer’s recommendations, solder iron can be substituted by applying, for instance, hot air in order to avoid thermal shock.

<<deleted>>

<<deleted>>

Solder baths for degolding and pretinning

Requirements from clause 7.2.3.2.2 from ECSSQST7008 shall apply for "Solder baths" for degolding and pretinning.

Soldering machines and equipment

General

Machines and equipment used to solder surface mount devices shall either be a type incorporating dynamic single or dual solder wave, or be of the solder reflow type.

The soldering machine shall be grounded in order to avoid electrostatic discharge.

The supplier shall ensure that the soldering conditions do not exceed the values given by the individual device data sheets

Examples of soldering conditions include. maximum temperature to avoid internal melting, removal of marking ink, degradation of encapsulating plastic.

Temperature and time profiles for assembly shall be identified by the supplier and approved by the Approval Authority.

The supplier shall identify changes and implement a verification programme in compliance with the requirements from clause 14.13.

The supplier shall demonstrate the reproducibility of their reflow processes.

Dynamic wave-solder machines

Dynamic soldering machines shall be of automatic type and of a design offering the following:

- Controllable preheating to drive off volatile solvents and to avoid thermal shock damage to the PCB and device packages.

- The capacity to maintain the solder temperature at the printed circuit board assembly to within 5 C of the established bath temperature throughout the duration of any continuous soldering run when measured 3,0 mm below the surface of the wave.

- A wave system that limits shadowing and allows solder fillet formation.

- Carriers made from a material that cannot contaminate, degrade or damage the printed circuit board or substrate nor transmit vibrations or shock stress from the conveyors to a degree permitting physical, functional or electrostatic damage to devices, board or substrate during transport through preheating, soldering and cooling stages.

- An extraction system, either integral or separate, conforming to the requirements of clauses 6.2a and 6.3a.

Condensation (vapour phase) reflow machines

Condensation reflow machines shall conform to the following requirements:

- Not transmit a movement or vibration into the assemblies being soldered that result in misalignment of devices or disturbed solder joints.

- Be capable of preheating an assembly with solder paste to the temperature recommended by the solder paste manufacturer prior to soldering.

- Use a reflow fluid whose boiling point is a minimum of 12 C above the melting point of the solder being used.

- Maintain the preselected temperature to within 5 C in the reflow zone during soldering.

- Include an extraction system that conforms to requirements 6.2a and 6.3a.

Hot gas reflow machines

Hot gas reflow machines shall conform to the following requirements:

- Does not transmit movement or vibration to the assemblies being soldered which result in misalignment of devices or disturbed solder joints.

- Preheats an assembly with solder paste to the temperature recommended by the solder paste manufacturer prior to soldering.

- <<deleted>>

- Prevents the reflow of adjacent devices.

- Maintains the preselected reflow temperature within 5 C as measured at the substrate surface.

<<deleted>>

<<deleted>>

Convection and radiation reflow systems

Convection and radiation reflow machines shall be of design such that the system meets the following requirements:

- Provides a controlled temperature profile and does not transmit movement or vibration into the assembly being soldered.

- Preheats an assembly with solder paste to the temperature recommended by the solder paste manufacturer prior to soldering.

- Heats the area of the assembly to be soldered using focused or unfocussed energy, to a preselected temperature that is a minimum of 12 C above the melting point of the solder being used as measured at laminate or substrate surface.

- Maintains the preselected temperature to within ±5 C in the reflow zone during soldering.

Other equipment for reflow soldering

Other solder reflow systems may be approved for use by the Approval Authority, if compliance with clauses 6.7.1 to 6.7.6 is demonstrated.

Ancillary equipment

General

Equipment shall not generate, induce or transmit electrostatic charges to devices being placed.

The supplier shall demonstrate the reproducibility of their SMT processes.

Solder deposition equipment

Equipment used to deposit solder pastes shall be of a screening, stencilling, dispensing, roller coating, dotting or jet printing type.

Equipment shall apply pastes of a viscosity and quantity such that the positioned device is retained on the board before and during soldering operations, ensuring self-centring and solder fillet formation.

Equipment used to apply solder preforms shall ensure alignment of the preform with the land or device lead and termination.

Automatic device placement equipment

Automatic or computer controlled equipment used for device placement shall be of the coordinate-driven pick-and-place type or of the robotic type.

The placement equipment used shall be of a type that:

- prevents device or board damages

- indexes devices with respect to the circuit

- aligns the device leads or castellations with the board terminal areas.

<<deleted>>

<<deleted>>

Cleanliness testing equipment

Requirements from clause 11.3.1 from ECSSQST7008 shall apply for “Cleanliness testing”.

Magnification aids

Clause 13.1 shall apply.

X-ray inspection equipment

The maximum dose during X-Rays inspection shall be less than 5 % of the eligible dose of the most sensitive component according to its specification.

X-ray equipment shall be calibrated in order to evaluate the total dose received by the devices during the inspection.

In order to minimize the dose given to the device, it is good practice to:

- Record the total dose received.

- Use off-line image analysis as much as possible.

- Use filters, optimizing the direction of the X-ray beam and masking sensitive areas.

The resolution of the X-ray equipment shall be able to detect solder balls having a diameter of 0,03 mm.

The sensitivity shall be demonstrated by means of actual 0,03 mm diameter solder balls, stuck to adhesive tape, attached to the multilayer board assembly being inspected.

<<deleted>>

Metallographic equipment

The metallographic equipment shall enable cross-sectioning and polishing of the moulded solder interconnections.

Material selection

General

Material selection shall be performed in accordance with ECSSQST7071 and ECSS-Q-ST-70.

Solder

Form

Solder paste, ribbon, wire and preforms shall be used provided that the alloy and flux meet the requirements in clause 7.2.2.

Alloy for use in solder baths shall be supplied as ingots (without flux) and be compliant with requirements from clause 7.2.2.

Composition

The solder alloy shall have a composition specified in Table 71.

- 1 Use EN 61190-1-3 for solder and EN 61190-1-1 for flux, EN 61190-1-2 for solder paste.

- 2 The solder alloy used depends upon the application. See Annex E.2 for Guide for choice of solder type.

Solder paste

<<deleted>>

The metal purity shall be as specified in Table 71.

Table 71: Chemical composition of spacecraft solders

|

ESA designation |

Sn |

Pb |

In |

Sb |

Ag |

Bi |

Cu |

Fe |

Zn |

Al |

As |

Cd |

Other |

|

min % - max % |

max % |

min % – max % |

max % |

min % – max % |

max % |

max % |

max % |

max % |

max % |

max % |

max % |

max % |

|

|

63 tin solder |

62,5-63,5 |

remainder |

- |

0,05 |

- |

0,10 |

0,05 |

0,02 |

0,001 |

0,001 |

0,03 |

0,002 |

0,08 |

|

62 tin silver loaded |

61,5-62,5 |

remainder |

- |

0,05 |

1,8-2,2 |

0,10 |

0,05 |

0,02 |

0,001 |

0,001 |

0,03 |

0,002 |

0,08 |

|

60 tin solder |

59,5-61,5 |

remainder |

- |

0,05 |

- |

0,10 |

0,05 |

0,02 |

0,001 |

0,001 |

0,03 |

0,002 |

0,08 |

|

96 tin solder |

remain |

0,10 |

- |

0,05 |

3,5-4,0 |

0,10 |

0,05 |

0,02 |

0,001 |

0,001 |

0,03 |

0,002 |

0,08 |

|

75 indium lead |

max 0,25 |

remainder |

74,0-76,0 |

0,05 |

- |

0,10 |

0,05 |

0,02 |

0,001 |

0,001 |

0,03 |

0,002 |

0,08 |

|

70 indium lead |

0,00-0,10 |

remainder |

69,3-70,7 |

0,05 |

- |

0,10 |

0,05 |

0,02 |

0,001 |

0,001 |

0,03 |

0,002 |

0,08 |

|

50 indium lead |

0,00-0,10 |

remainder |

49,5-50,5 |

0,05 |

- |

0,10 |

0,05 |

0,02 |

0,001 |

0,001 |

0,03 |

0,002 |

0,08 |

|

10 tin lead |

9,0-10,5 |

remainder |

- |

0,05 |

- |

0,10 |

0,05 |

0,02 |

0,001 |

0,001 |

0,03 |

0,002 |

0,08 |

Maintenance of paste purity

When purchased premixed or mixed in house, the purity of solder paste shall be maintained.

Manufacturers’ instructions shall be applied for the handling and storage of containers of solder paste purchased premixed.

Refrigerated solder paste shall reach room temperature before opening the container.

Neither paste purchased premixed nor paste mixed in-house shall be used if the use-by date or shelf life recommended by the manufacturer of the paste or paste constituents has expired.

When the solder paste’s shelf life has expired it shall not be used unless:

- relifing is performed

- tests that include visual inspection and viscosity measurements (according to the manufacturer’s recommendations) are passed successfully.

When relifing is performed, and the material passes the specified tests, the new shelf life shall be half the initial shelf life.

Tools used for removing solder paste from the container shall not contaminate the paste dispensed or that remaining within.

Flux

Rosin based flux

Requirements from clause 6.3.1 from ECSSQST7008 shall apply for "Rosin based flux".

Corrosive acid flux

Requirements from clause 6.3.2 from ECSSQST7008 shall apply for "INH1 Corrosive acid flux".

Flux controls for wave-soldering equipment

A controlled method shall be established and implemented for wave-soldering machines such that the flux is not contaminated with remaining residues from previous non-space works.

Solvents

Requirements from clause 6.4 from ECSSQST7008 shall apply for "Solvents".

Flexible insulation materials

Requirements from clause 6.5 from ECSSQST7008 shall apply for "Flexible insulation materials".

Terminals

Requirements from clause 6.6 from ECSSQST7008 shall apply for "Terminals".

Wires

Requirements from clause 6.7 from ECSSQST7008 shall apply for "Wires".

Printed circuit substrates

Printed Circuit Boards shall be designed in conformance with the requirements of clause 14 of ECSSQST70-12.

Printed Circuit Boards shall be made of materials and manufactured in conformance with the requirements of clause 9 of ECSSQST70-10.

Printed Circuit Boards shall be procured in conformance with the requirements of clauses 5 and 6 of ECSSQST70-11.

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

Table 72: <<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

Devices

General

Devices and their finishes shall be selected from those approved in conformance with requirements from clauses 4, 5 and 6 of ECSSQST60, for “manufacturer and component evaluation” and “Procurement control”.

<<deleted>>

Solder may be applied to the terminations by hot dipping or by electroplating from a solution.

Devices with terminations finished by electroplating can impact the device wetting.

<<deleted>>

The incoming inspection of each device batch shall include the verification by test of the termination composition, to avoid assembly of pure tin finish, in accordance with requirement 4.3.7b from ECSS-Q-ST-60.

Pure tin finish with more than 97 % purity shall not be used.

This is due to the possibility of whisker growth and transformation to grey tin powder at low temperatures.

<<deleted>>

<<deleted>>

Devices shall be capable of withstanding cleaning processes currently used in space projects.

Parts with silver palladium finish shall not be used.

Reprocessing shall not damage the device.

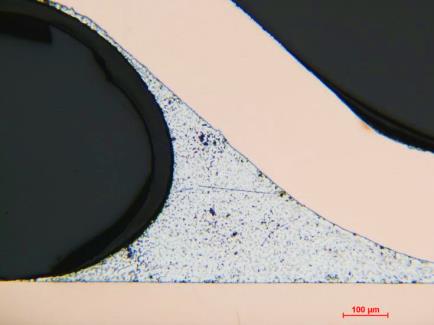

Reprocessing of ceramic chip capacitors is advised to be avoided due to potential crack formation.

If devices initially designed for insertion-mount application are used for surface mounting, they shall be of a type that can be surface-mount adapted.

The adaptation specified in the requirement 7.9.1l shall not functionally or physically degrade the device or the substrate to which the adapted device is to be attached.

Connectors shall be of a configuration incorporating either male or female quick-disconnect contacts and stress relief provision for the soldered connection of each individual contact when such connections are completed.

Type II chip ceramic capacitors shall not be reworked.

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

Moisture sensitive devices

Moisture sensitive devices shall be stored and handled in conformance with the device manufacturer’s recommendations. .

Many types of plastic encapsulated devices, particularly some plastic BGAs, are moisture sensitive.

When moisture sensitive devices are used, bakeout shall be performed in accordance with clause 8.5b.

<<deleted>>

<<deleted, modified and moved to 7.9.1l>>

<<deleted, modified and moved to 7.9.1m>>

<<deleted>>

<<deleted>>

<<deleted and moved to 7.9.1n>>

Adhesives, encapsulants and conformal coatings

Adhesives shall be dispensable, non-stringing, and have a reproducible dot profile after application.

Adhesives, encapsulants and conformal coating shall be non-corrosive to devices and substrates.

The uncured strength shall be capable of holding devices during handling prior to curing.

Adhesives, encapsulants and conformal coatings shall conform to the outgassing requirements of ECSSQST70-02.

Adhesives, encapsulants and conformal coatings shall have no adverse effects upon materials used on the substrate, or devices attached thereon.

The effects of some conformal coatings on the reliability of mounted SMDs are described in ESA SP-1173.

Adhesives, encapsulants and conformal coatings shall be selected based on their thermal conductivity and dielectric properties.

Some thermally conductive adhesives used to dissipate Joule heating are listed in ESA STM-265 “Evaluation of Thermally Conductive Adhesives as Stacking Compounds during the Assembly of Spacecraft Electronics”.

The capability of the adhesives to meet their requirements shall be demonstrated by means of a verification programme in conformance with clause 14.

<<deleted>>

Stress relief of device leads shall not be negated by the encapsulants or conformal coatings.

- 1 This is particularly important at low service temperatures.

- 2 The coefficient of expansion, glass transition temperature and modulus of adhesives used under devices for thermal reasons, for achieving stand-off heights or mechanical support during vibration, can be considered to ensure that the additional stress put on the solder joints does not degrade the solder joint reliability.

Adhesive shall not be in contact with terminal of component.

Bonding shall not be performed on fused tin lead unless the tin lead surface is limited to < 25 % by area of the bonding surface and demonstrated by verification as specified in clause 14.

Spread of bonding material onto surrounding areas shall not be accepted unless it does not reduce the volume of the initial bonding joint.

Bonding material shall not be in contact to surrounding devices.

Bonding with epoxy adhesive directly to glass bodied devices shall not be used.

It is good practice to use a sleeve between glass and the epoxy adhesive.

Preparation for soldering

Preparation of devices and terminals

Preparation of wires and terminals

Requirements from clause 7.2 from ECSSQST7008, clause “Preparation of conductors, terminals and solder cups” shall apply.

Preparation of surfaces to be soldered

Requirements from clause 7.2.2 from ECSSQST7008, clause “Surfaces to be soldered” shall apply.

Degolding and pretinning of conductors

Requirements from clauses 7.2.3 and 7.2.4 from ECSSQST7008 shall apply for "Degolding and pretinning of conductors".

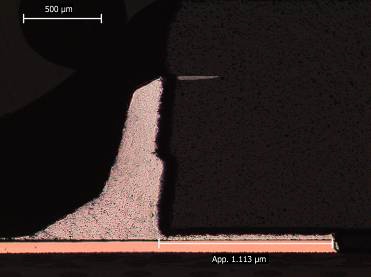

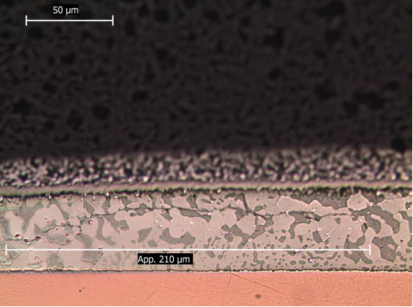

Alloying of pure tin finish

<<deleted>>

Pure tin device terminations shall be pretinned with full tin lead solder coverage.

Pure tin device terminations shall be in compliance with requirements from clauses 7.2.4 and 7.2.6 of ECSS-Q-ST-70-08 and requirement 8.1a from ECSS-Q-ST-60-13.

- 1 Pure tin terminations can be dipped into liquid solder as described in ECSSQST7008, clause 7.2.6 in order to replace the tin with tin-lead alloy.

- 2 Reprocessing of ceramic chip capacitors is not recommended due to potential crack formation.

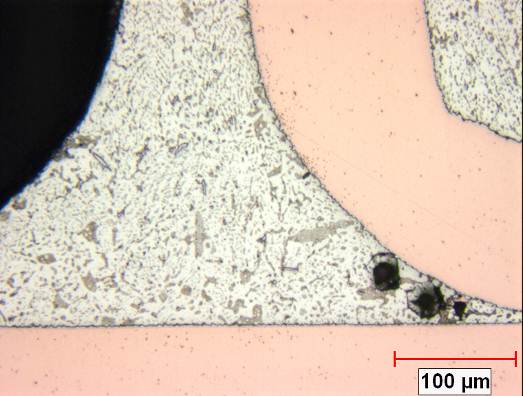

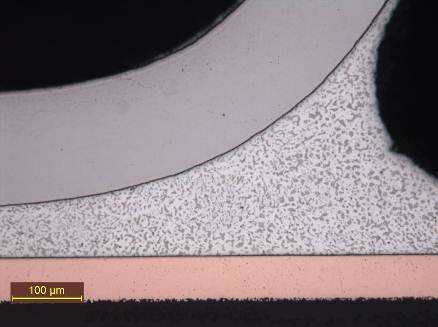

The reprocessing process shall be verified by micro sectioning and SEM/EDX with respect to alloying and full coverage.

Preparation of solder bit

Requirements from clause 7.3 from ECSSQST7008 shall apply for "Preparation of solder bit".

Handling

Requirements from clause 7.5 from ECSSQST7008 shall apply for "Handling".

Storage

Requirements from clause 7.6 from ECSSQST7008 shall apply for "Storage".

Baking of PCBs and moisture sensitive devices

<<deleted>>

Baking of moisture sensitive devices shall be implemented before any reprocessing or assembly process in conformance with JEDEC classification.

This is to counteract the “popcorn” effect in soldering using oven or vapour phase reflow techniques.

Baking times and temperatures, for moisture sensitive devices, shall be in compliance with manufacturer recommendations and baking times as specified in J-STD-033 and documented.

- 1 Typical baking conditions are from 6 h to 24 h at 125 C depending on the JEDEC classification, except for devices delivered in reels for which a lower temperature and longer time are used.

- 2 It is good practice to store devices under nitrogen, dry air (20 % RH maximum) or partial vacuum.

Baking of unpopulated PCBs should be made as a minimum of 8 hours at 120 °C.

Baking of populated PCBs shall be performed when the PCB has been kept under clean room conditions for more than 72 hours.

Storage of PCBs in dry cabinet interrupts the accumulated baking time.

Baking of populated PCB shall be made at a temperature which does not degrade the devices or assembly.

To limit the bake out operation, which can induce later failure, the PCB can be stored in dry environment after the baking.

Mounting of devices prior to soldering

General requirements

Requirements from clause 8.1 from ECSSQST7008, “Mounting of components – General” shall apply.

Lead bending and cutting requirements

Requirements from clause 8.2 from ECSSQST7008, clause “Lead bending requirements” shall apply.

Mounting of terminals to PCBs

Requirements from clause 8.3 from ECSSQST7008 shall apply for "Mounting of terminals to PCBs".

Lead attachment to through holes

Requirements from clause 8.4 from ECSSQST7008 shall apply for "Lead attachment to through holes".

Mounting of devices to terminals

Requirements from clause 8.5 from ECSSQST7008 shall apply for "Mounting of components to terminals".

Mounting of through hole connectors to PCBs

Requirements from clause 8.6 from ECSSQST7008 shall apply for "Mounting of through hole connectors to PCBs".

Surface mount requirements

General

Devices to be mounted shall be designed for, and be capable of withstanding the soldering temperatures of the particular process being used for fabrication of the assembly.

Surface mounted devices can be mounted on either one side or both sides of a printed circuit assembly.

<<deleted>>

Devices incapable of withstanding machine soldering temperatures shall be hand soldered in a subsequent operation.

Supplier shall ensure that degolding, pretinning, reprocessing and soldering conditions do not exceed the device suppliers mandated processing conditions.

- 1 In case of non-compliant mounting procedure with a component manufacturer, a company can apply different soldering temperature compliant with clause 6 after successful verification tests as described in clause 14 and dedicated tests at component levels showing there is no degradation of these components.

- 2 To mount component by hand soldering at very low temperature can degrade reliability of component and PCB by increasing the duration of soldering necessary to obtain an acceptable solder joint.

Supplier shall ensure that degolding and pretinning has been performed such that the solder fillet is not in contact with the gold or AuSn intermetallic.

Supplier shall ensure repeatability of the mounting when artificial standoff is adopted.

Stress relief

When PCBs with high CTE compensation are employed, the supplier shall accommodate CTE mismatch by the mounting technology.

- 1 Pure eutectic tin-lead solder or indium-lead solder provide better stress relief (due to their ductility) than those with additional elements, e.g. antimony, gold.

- 2 Leadless devices with e.g. end-cap terminations, metallization, can have some stress relief (such as additional foil or wire leads, possibly attached by welding or high melting point solder).

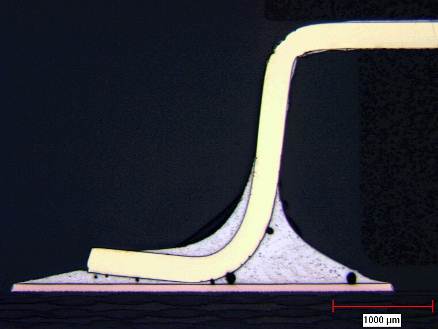

- 3 A solder stand-off (see Figure 11-1, dimension “X”) can assist stress relief; in this situation, the CTE mismatch strain is taken up by the ductile solder.

- 4 <<deleted>>

Registration of devices and footprints

Devices shall be mounted on their associated terminal footprints .

The spacing between conductive elements shall not be reduced below the minimum electrical spacing specified in clause 7.3 of ECSS-Q-ST-70-12.

Some surface mounted devices that are not bonded to the PCB can self-align during the soldering process. It is the registration after soldering that is important.

Lead forming

The leads of leaded surface mount devices shall be formed to their final configuration prior to mounting.

Forming shall not degrade the solderability or cause loss of plating adhesion to the leads.

Forming shall not cause mechanical damage to the leads or attachment seals.

Leads of dual-in-line and gull-wing packages, flat-packs and other multileaded devices shall be dressed, mechanically re-aligned to ensure co-planarity providing that the lead to package connection is not subjected to plastic deformation.

Formed leads shall not be re-bent.

Lead forming shall be symmetrical.

Mounting devices in solder paste

Both leaded and leadless surface mounted devices shall be mounted in solder paste prior to reflow soldering.

It is good practice to optimize the pick and place mounting force on the device lead, ball or column.

The solder paste deposited on each solder land shall be visually inspected for registration and coverage by the operator prior to mounting the devices.

<<deleted>>

Leadless devices

Devices shall not be stacked.

<<deleted>>

The active element shall be mounted with that surface facing away from the printed circuit board or substrate, except the case specified in the requirement 9.7.6g.

See Figure 91 for details.

Devices that are bonded to the PCB prior to wave- or reflow-soldering shall be placed so that the requirements after soldering given in clause 11 are met.

The adhesive shall not extend onto the solder footprints.

Artificial solder stand-off shall be reproducible.

Artificial solder stand-off can be achieved by removable spacers or other techniques in conformance with assembly process procedures.

The active element may be facing the substrate in case required by electrical performance.

For example: RF applications.

Figure 91: Exposed element

Figure 91: Exposed element

Leaded devices

Surface mounting of leaded (round or rectangular cross section) devices shall be parallel to the board surface.

<<deleted>>

<<deleted>>

Stacking and bonding of heavy devices

Adhesive shall be selected in conformance with clause 7.10.

Some surfaces can be prepared to enhance the adhesion (e.g. by mechanical abrasion).

<<deleted>>

Adhesive shall be mixed and cured in accordance with the manufacturer’s procedures.

The process of applying the adhesive shall be documented by a written procedure or by configured drawings which define the location of the adhesive, the shape and the spread area (between device bottom surface and substrate upper surface).

The adhesive shall not be in contact with the terminal or negate the stress relief of the device, nor come into contact with surrounding devices.

<<deleted and created as recommendation 9.7.9g>>

All devices weighing more than 5 g should be stacked.

- 1 This is to minimize shock and vibration loading on the leads.

- 2 The adhesive compound can be applied either before or after soldering in conformance with the supplier’s process identification document.

Stacking and bonding shall be performed on clean surfaces.

Attachment of conductors to terminals, solder cups and cables

Requirements from clause 9 from ECSSQST7008 shall apply for “Attachment of conductors to terminals, solder cups and cables”.

Soldering to printed circuit boards

General

Requirements from clause 10.1 from ECSSQST7008, clause “Soldering to terminals and printed circuit boards – General” shall apply.

<<deleted>>

<<deleted>>

Solder applications to PCBs

Requirements from clause 10.3 from ECSSQST7008 shall apply for "Solder applications to PCBs".

Wicking

Requirements from clauses 10.3.1, 10.3.2, 10.3.4 and 10.4 from ECSSQST7008 shall apply for "Wicking".

Soldering of SMDs

General requirements

Devices shall not be mounted on flexible substrates as defined “flexible printed boards” in ECSSQST70-10.

Soldering to gold with tin-lead alloys shall not be performed.

- 1 See also requirement 11.5.1h.

- 2 See also clause 8.1.3 "Degolding and pretinning of conductors".

Devices shall not be stacked nor bridge the space between other devices or terminals.

Positioning of devices shall not reduce the specified minimum electrical clearance to adjacent tracks or other metallized elements in conformance with requirements from clause 13 and clause 14 of ECSS-Q-ST-70-12.

Non-axial-leaded devices shall be mounted with all leads seated on a terminal area to ensure mechanical strength.

Solder shall cover and wet the solderable surfaces as specified in clause 13.2.

The footprint shall be designed as the entire terminal of the device lies on its associated footprint on the finished board.

Soldering to gold finish with tin-lead shall not be performed unless the gold finish is thinner than 0,1 μm and all the following conditions are met: - PCB is qualified in compliance with the requirements of clause 6 of ECSS-Q-ST-70-10,

- Assembly verification programme is reviewed and accepted by the Approval Authority, and

- Assembly verification is compliant to requirements of clause 14.

The device footprint on FM shall be same as used in verification programme.

Devices verified by similarity shall use same design principle for the footprint.

The device positioning shall be such that visual inspection can be undertaken.

If visual inspection of a fully populated assembly is not possible, the assembly and inspection shall be made in steps enabling visual inspection.

Artificial stand-off value shall be documented in procedure.

The footprint design shall be done in such way as to avoid, during soldering, contact between the device and the soldering tip.

Any deviation to requirements from clauses 11.5.2 to 11.5.11 shall be demonstrated by verification in compliance with requirements from clause 14.

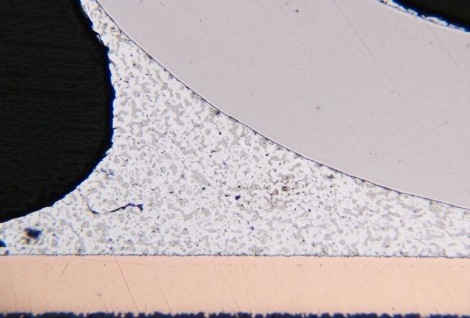

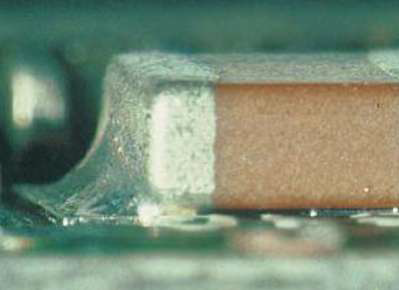

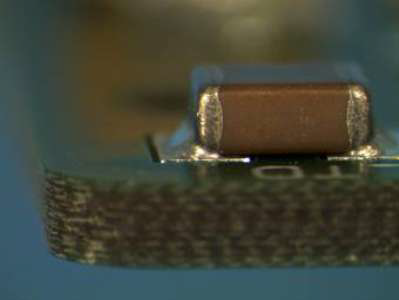

End-capped and end-metallized devices

There shall be no discernible discontinuities in the solder coverage of the terminal areas of devices.

Solder shall not encase any portion of the body of the device following reflow.

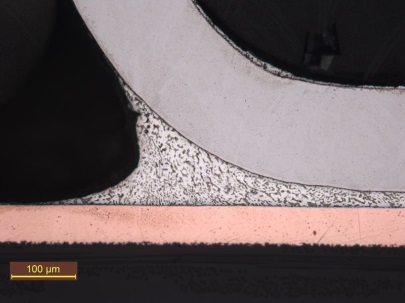

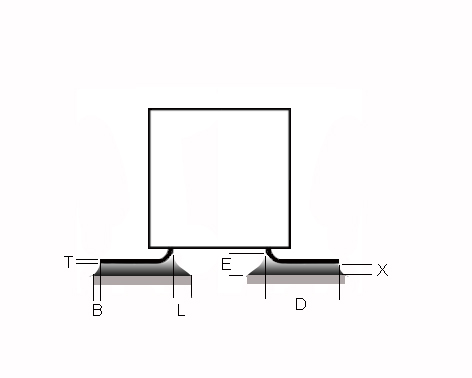

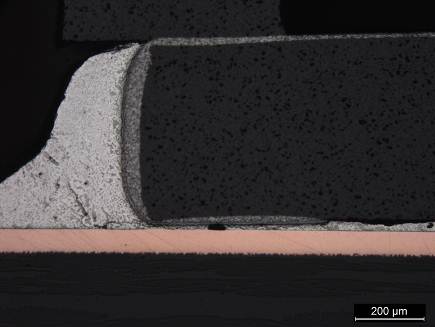

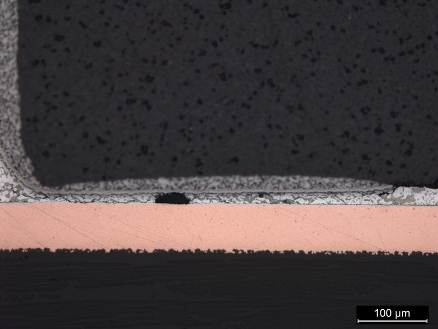

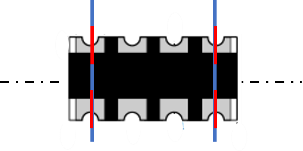

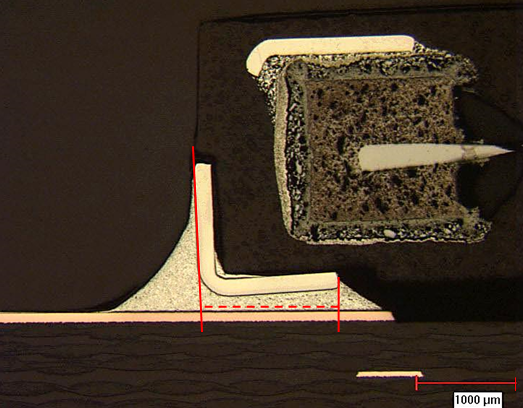

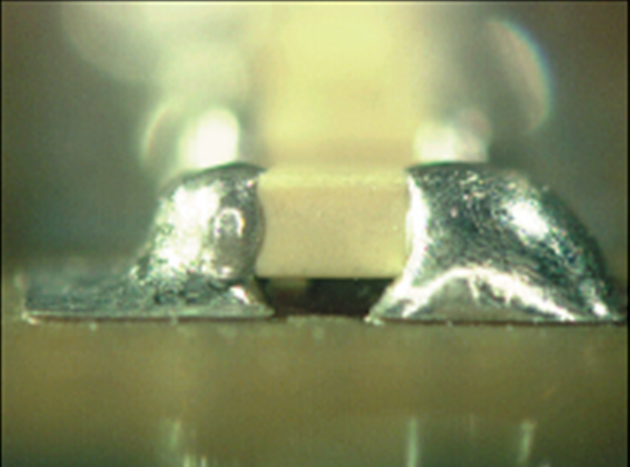

The solder joints to these devices shall meet the dimensional and solder fillet requirements of Table 111 and Figure 111.

End-capped and end-metallized devices having terminations of a square or rectangular configuration (such as chip resistors, chip capacitors and similar leadless discrete devices) can have three or five face terminations, as shown in “a” and “b” in Figure 111.

Table 111: Dimensional and solder fillet for rectangular and square end capped devices

|

Parameter

|

Dimension

|

Dimension limits

|

|

Maximum side overhang

|

A

|

0,1 × W

|

|

End overhang

|

B

|

Not permitted

|

|

Minimum lap contact

|

L

|

75% single terminal length only

|

|

Minimum fillet height

|

E

|

X + 0,3 × H or X + 0,5 mm whichever is less

|

|

Solder Stand-off (elevation)

|

X

|

Present

|

|

Maximum tilt limit

|

C

|

10

|

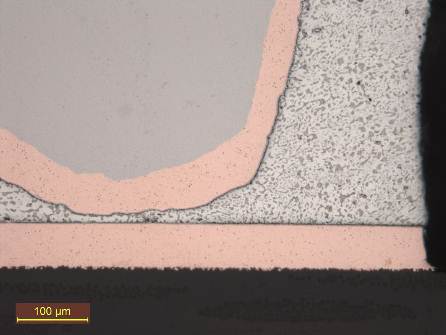

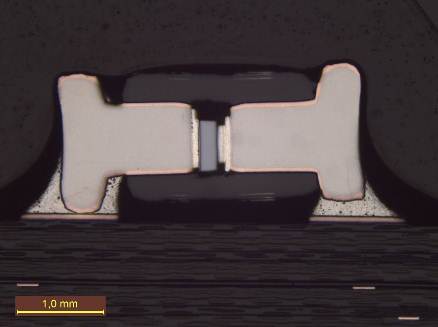

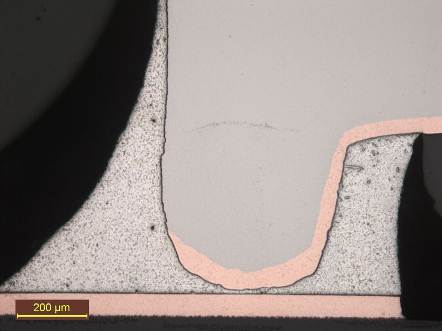

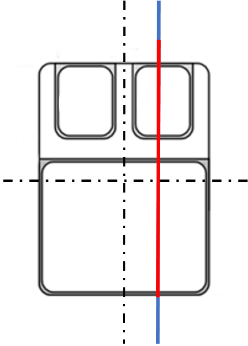

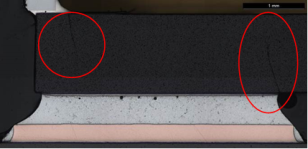

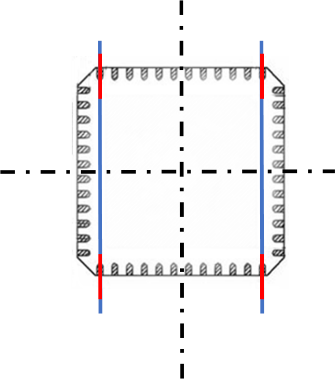

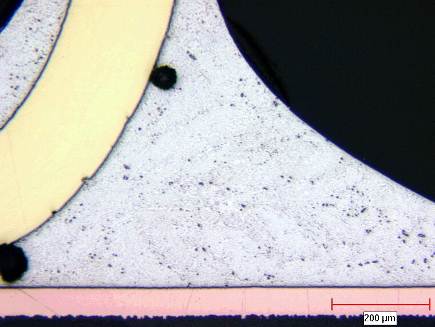

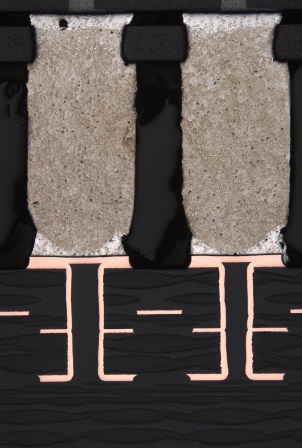

Figure 111: Mounting of rectangular and square end-capped and end-metallized devices

Figure 111: Mounting of rectangular and square end-capped and end-metallized devices

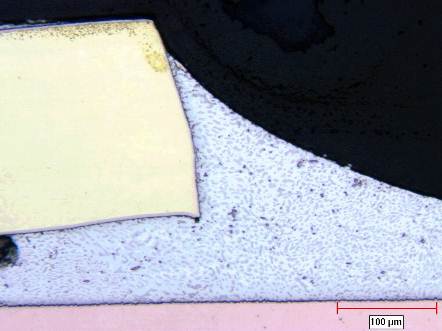

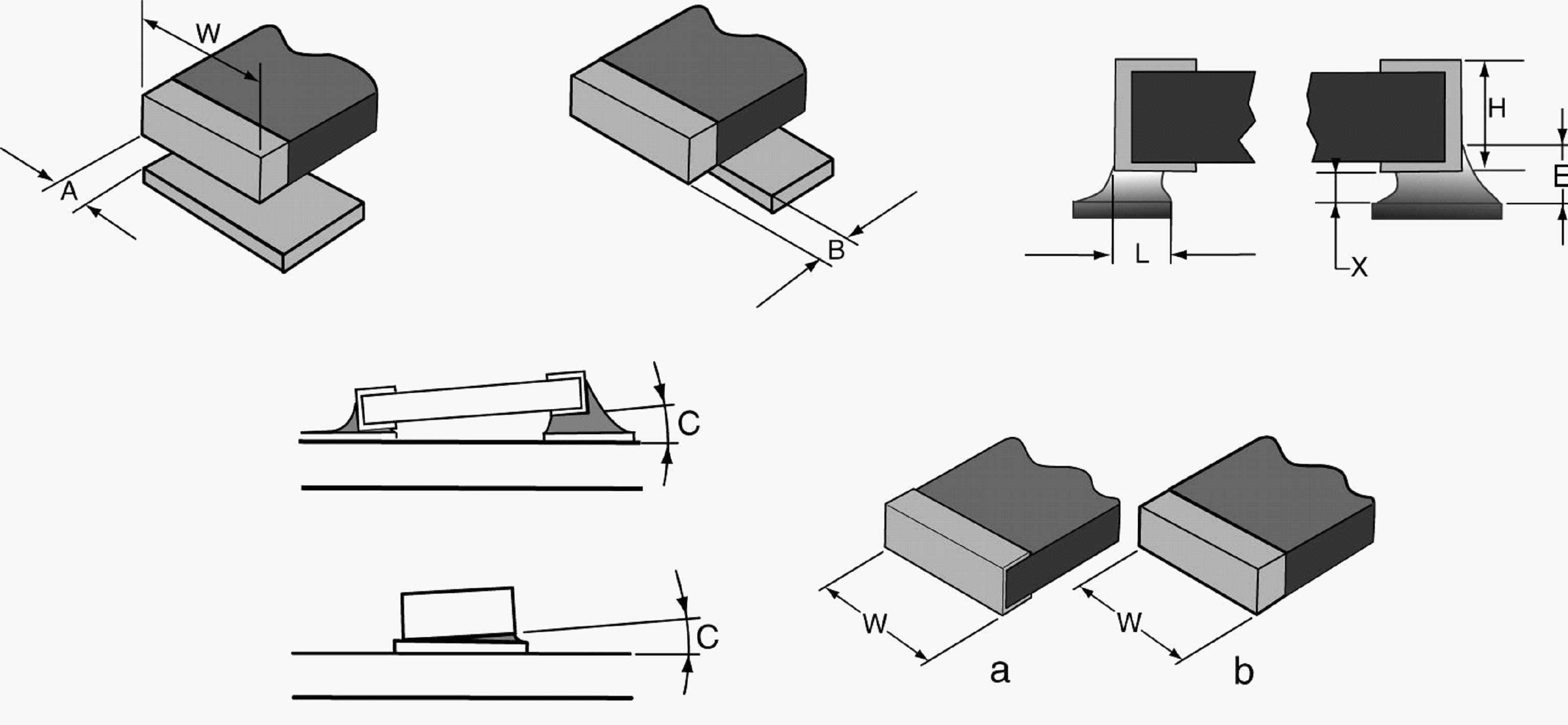

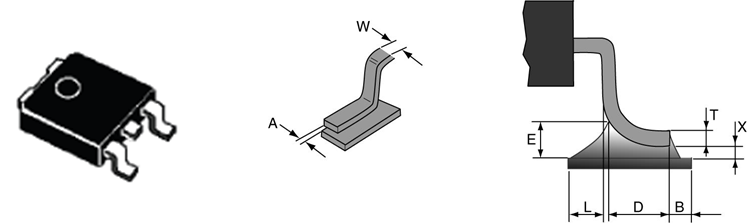

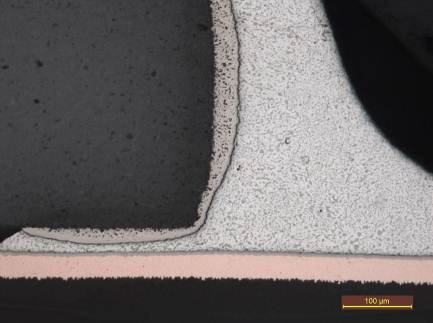

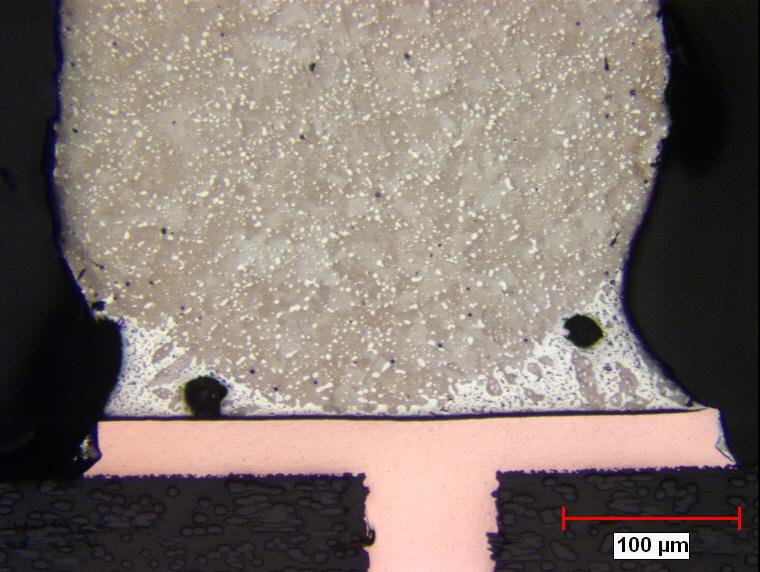

Bottom terminated chip devices

Devices having metallized terminations on the bottom side only shall meet the dimensional and solder fillet requirements of Table 112 and Figure 112.

Solder fillet shall show acceptable wetting on all visible sides.

Table 112: Dimensional and solder fillet for bottom terminated chip devices

|

Parameter

|

Dimension

|

Dimension limits

|

|

Maximum side overhang

|

A

|

0,1 W

|

|

End overhang

|

B

|

Not permitted

|

|

Minimum lap contact

|

L

|

Entire terminal of device

|

|

Solder Stand-off (elevation)

|

X

|

Present

|

|

Maximum tilt limit

|

|

10

|

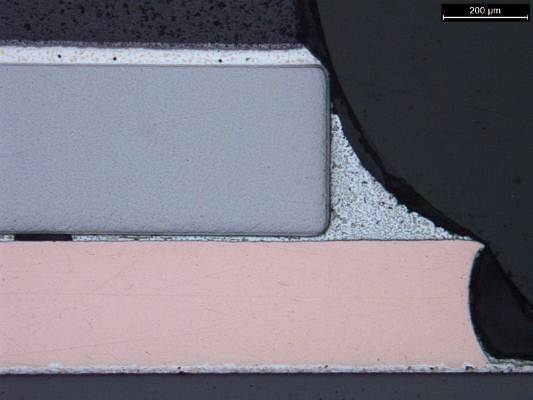

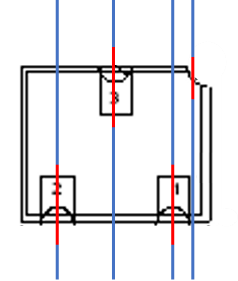

Figure 112: Mounting of bottom terminated chip devices

Figure 112: Mounting of bottom terminated chip devices

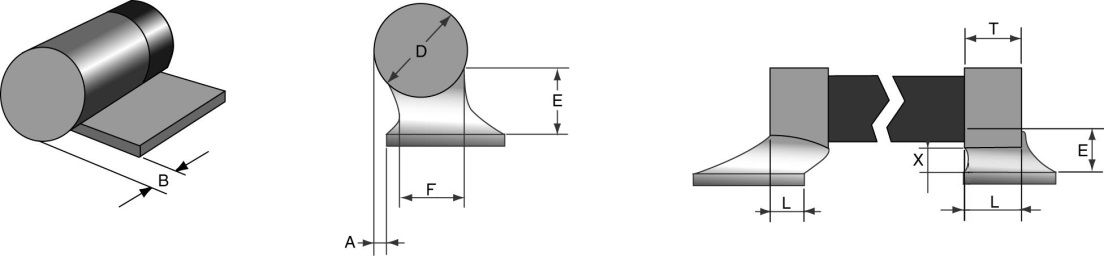

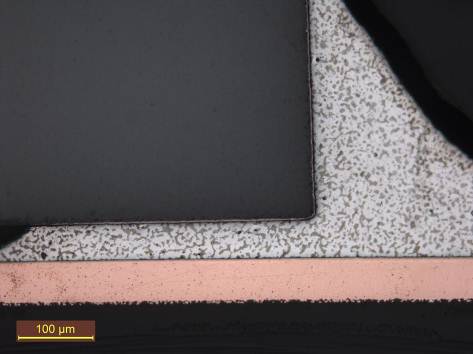

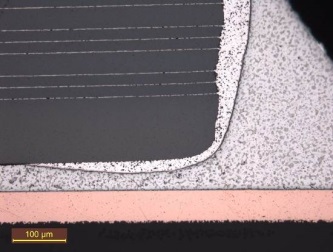

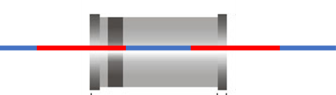

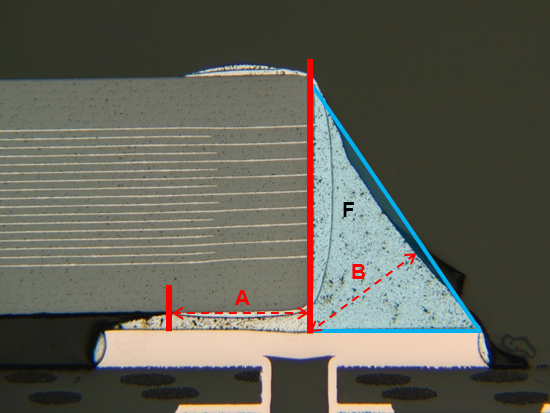

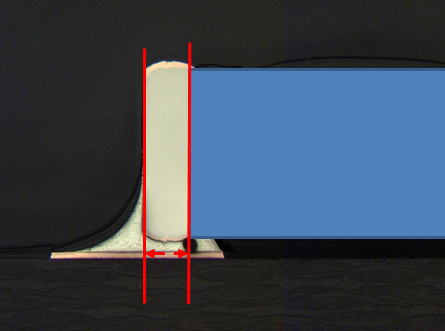

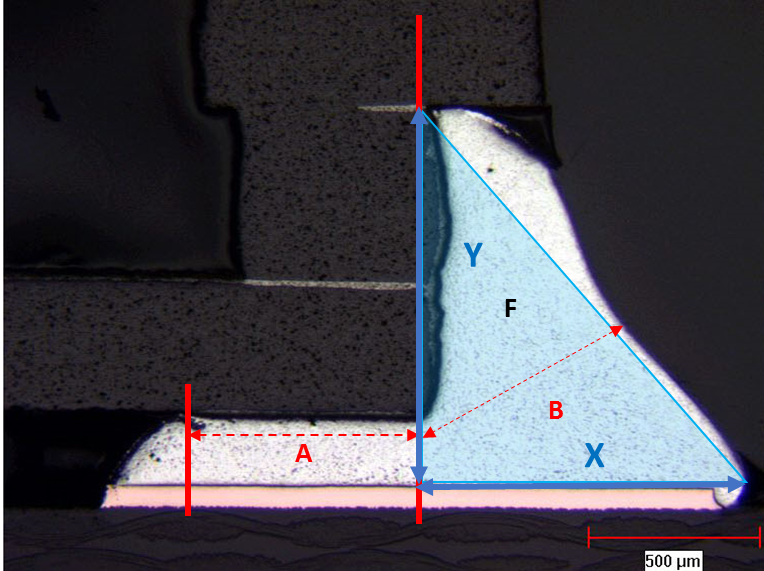

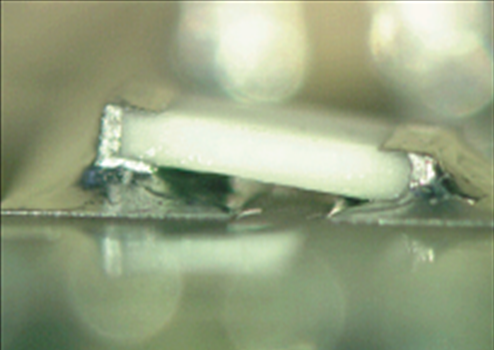

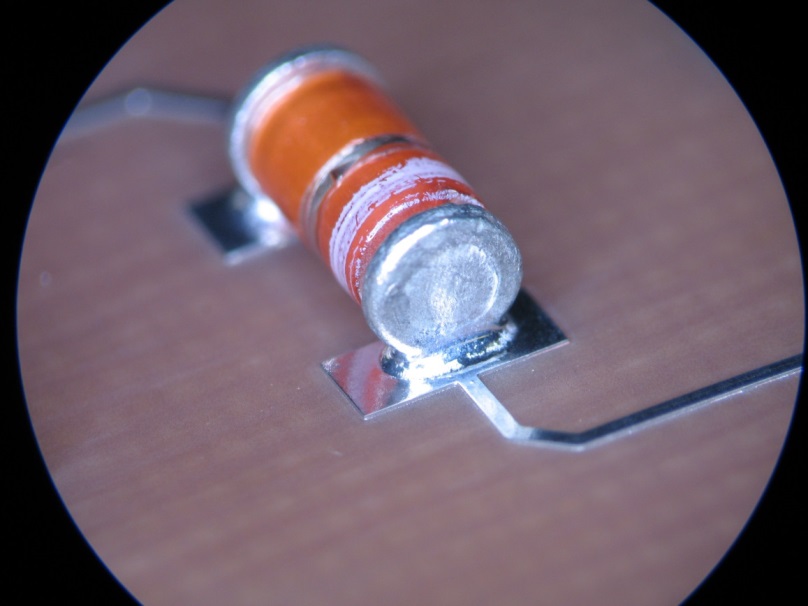

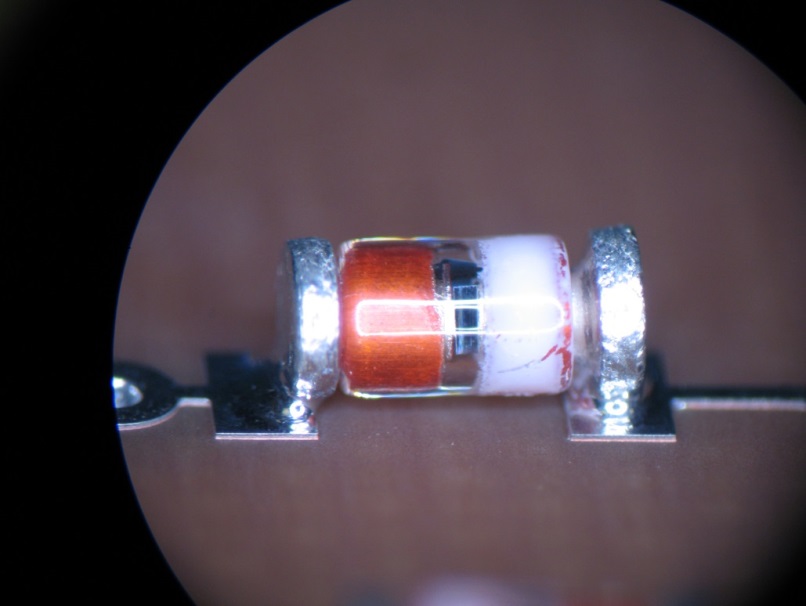

Cylindrical and square end-capped devices

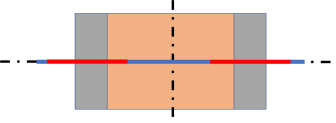

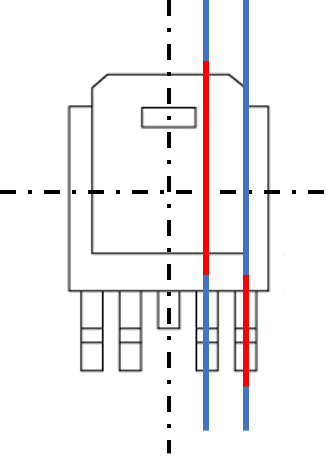

Solder joints to devices having cylindrical terminations shall meet the dimensional and solder fillet requirements of Table 113 and Figure 113.

Table 113: Dimensional and solder fillet for cylindrical end-capped devices

|

Parameter

|

Dimension

|

Dimension limits

|

|

Maximum side overhang

|

A

|

0,25 D

|

|

End overhang

|

B

|

Not permitted

|

|

Minimum fillet width

|

F

|

0,5 D

|

|

Minimum fillet height

|

E

|

X + 0,3 D or

|

|

Minimum side fillet length

|

L

|

0,5 T

|

|

Stand-off (elevation)

|

X

|

Present up to 0,75 mm

|

Figure 113: Mounting of cylindrical end-capped devices

Figure 113: Mounting of cylindrical end-capped devices

Solder joints to devices having square terminations shall meet the dimensional and solder fillet requirements of Table 114 and Figure 114.

Table 114: Dimensional and solder fillet for square end-capped devices

|

Parameter

|

Dimension

|

Dimension limits

|

|

Maximum side overhang

|

A

|

0,25 W (square width)

|

|

End overhang

|

B

|

Not permitted

|

|

Minimum fillet width

|

F

|

0,5 W

|

|

Minimum fillet height

|

E

|

X + 0,3 W or

|

|

Minimum side fillet length

|

L

|

0,5 T

|

|

Stand-off (elevation)

|

X

|

Present up to 0,75 mm

|

Figure 114: Mounting of square end-capped devices

Figure 114: Mounting of square end-capped devices

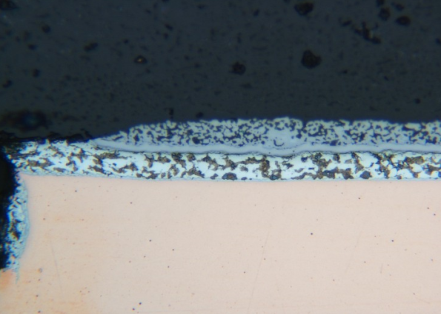

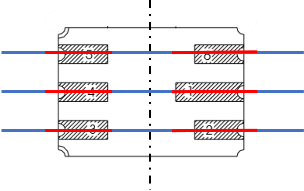

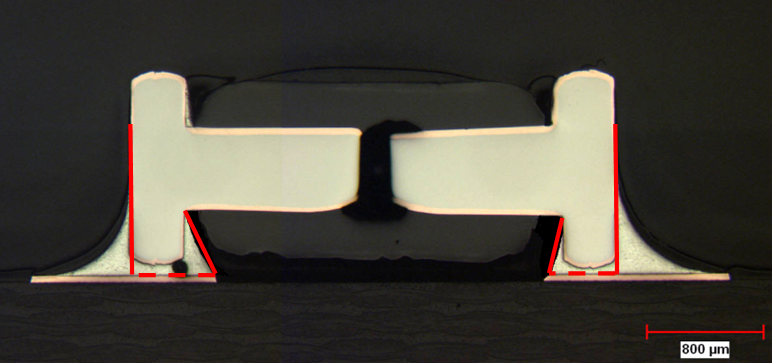

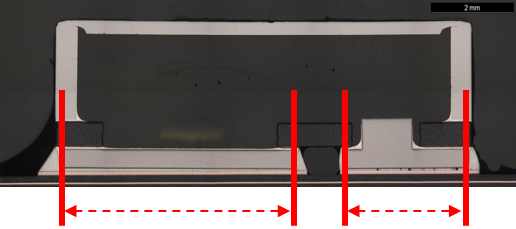

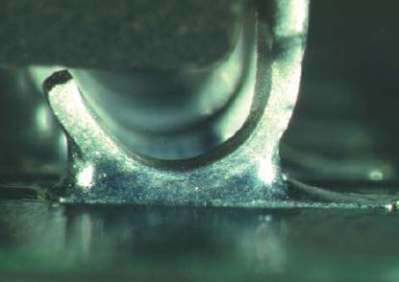

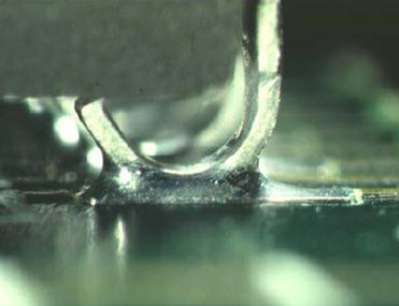

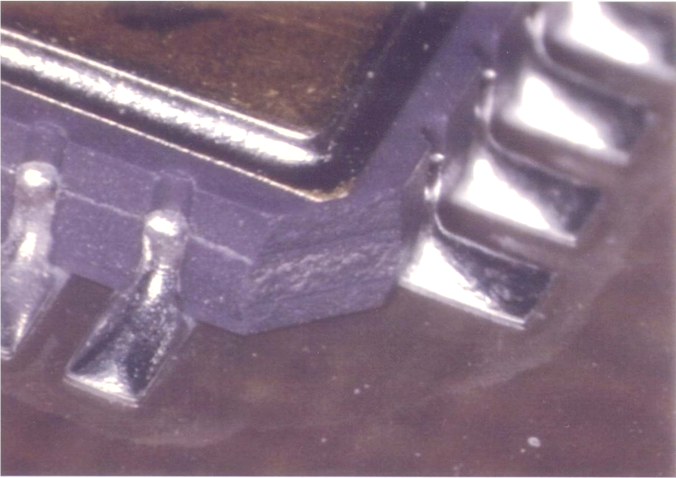

Castellated chip carrier devices

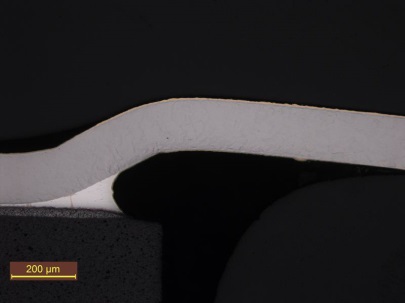

Joints to castellated device terminations shall meet the dimensional and solder fillet requirements of Table 115 and Figure 115.

- 1 The stand-off enables adequate cleaning beneath the assembled LCCC and also to enhance solder fatigue life (see also clause 9.7.6f)

- 2 <<deleted>>

Table 115: Dimensional and solder fillet for castellated chip carrier devices

|

Parameter

|

Dimension

|

Dimension limits

|

|

Maximum side overhang

|

A

|

Zero

|

|

Maximum fillet length

|

F

|

P (length of the pad)

|

|

Minimum fillet height

|

E

|

0,50 H (H= Castellation metallisation height)

|

|

Solder Stand-off (elevation)

|

X

|

Present

|

|

Underneath lap connection

|

|

Entire terminal of device

|

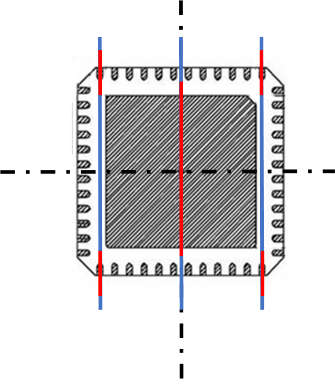

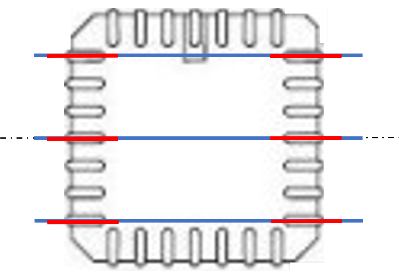

Figure 115: Mounting of castellated chip carrier devices

Figure 115: Mounting of castellated chip carrier devices

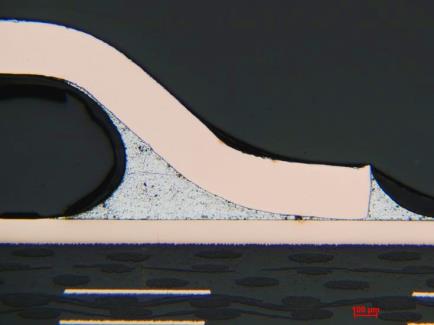

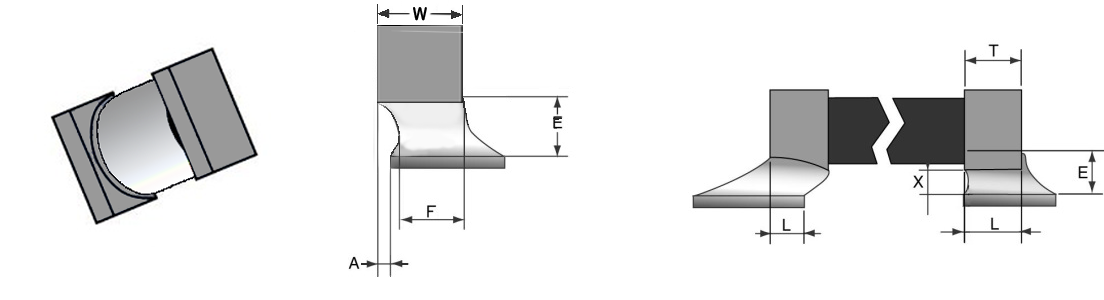

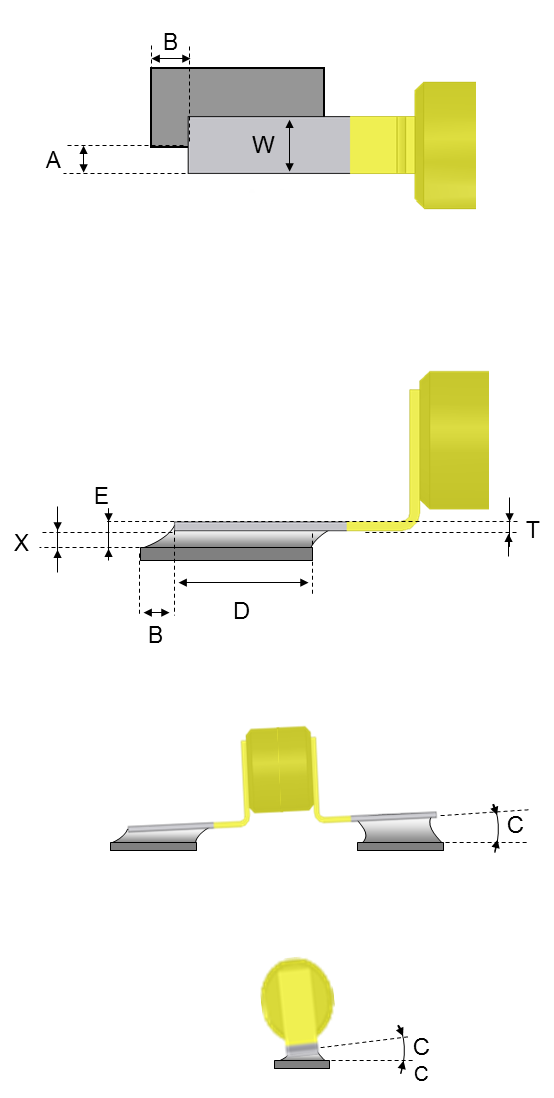

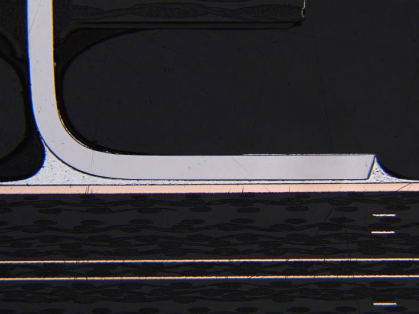

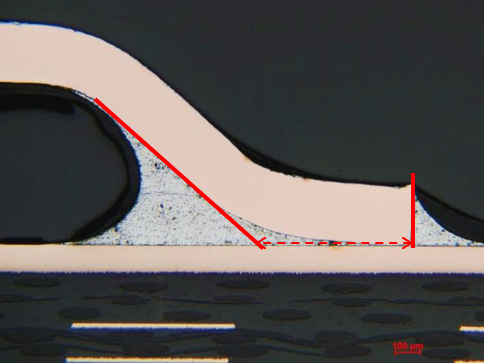

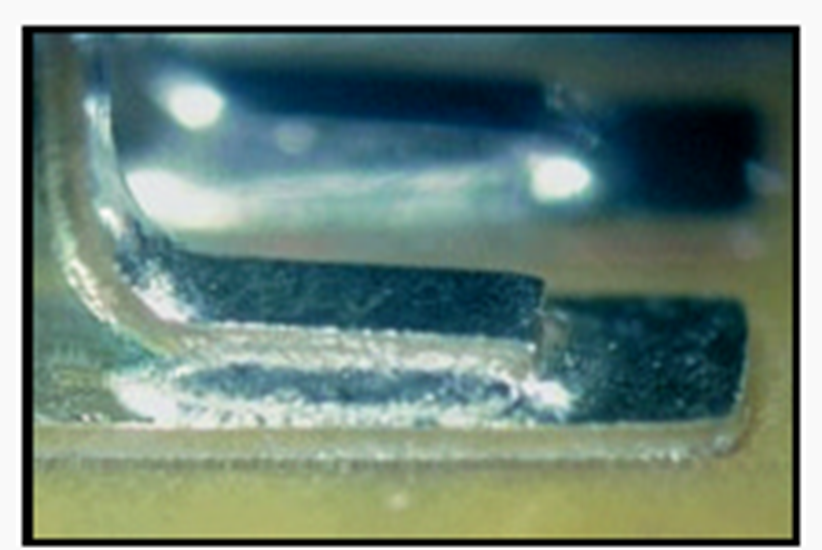

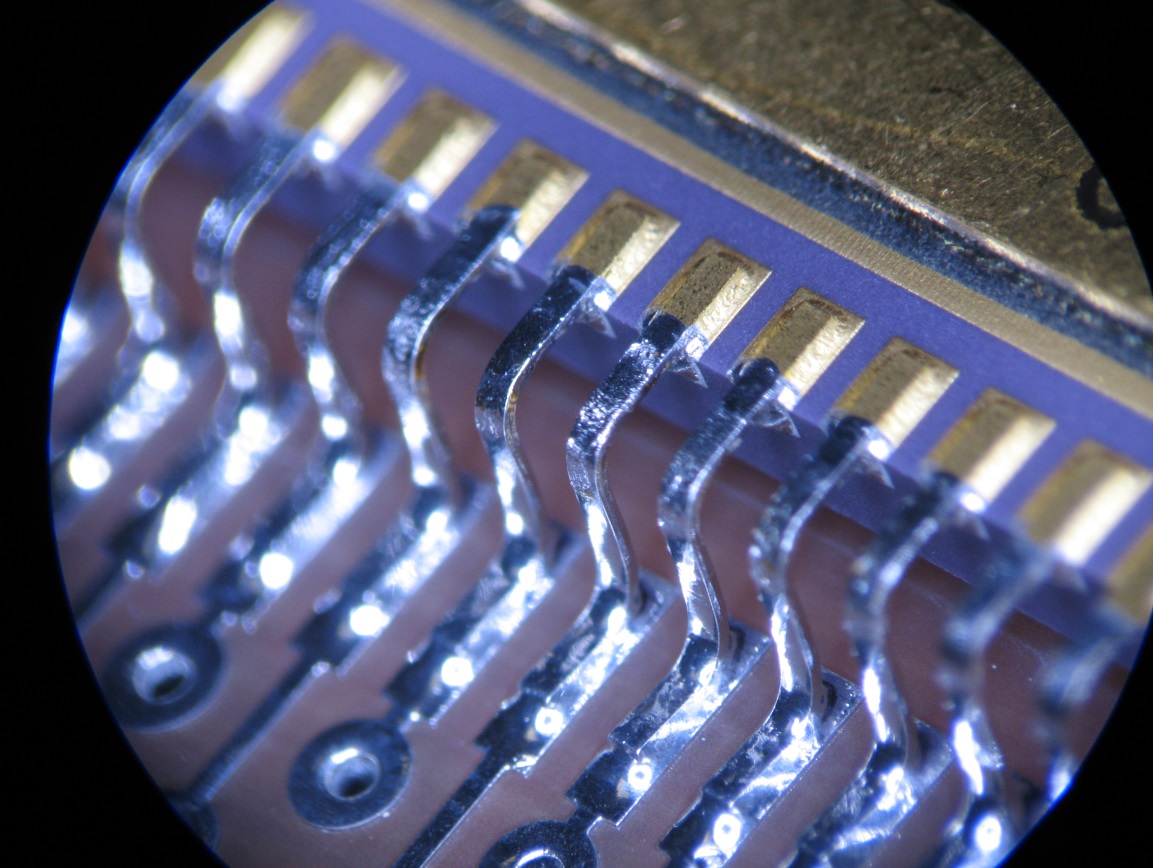

Flat pack and Gull-wing leaded devices with round, rectangular, ribbon leads

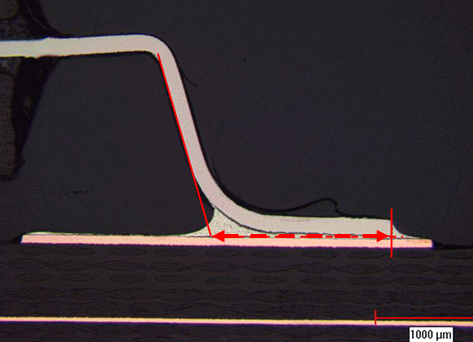

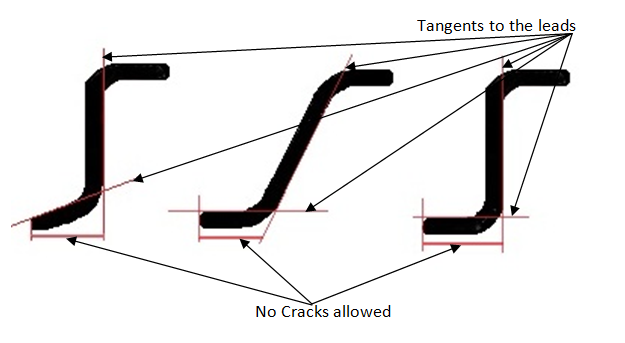

Solder joints formed to flat pack and gull-wing leaded devices with round, rectangular, ribbon leads shall meet the dimensional and solder fillet requirements of Table 116 and Figure 116.

Solder fillet shall be visible on the side of the terminal lap connection.

Table 116: Dimensional and solder fillet for gull-wing leaded devices with round, rectangular, ribbon leads

|

Parameter

|

Dimension

|

Dimension limits

|

|

Maximum side overhang

|

A

|

0,1 W

|

|

Minimum distance to footprint edge at toe

|

B

|

0,20 mm

|

|

Minimum distance to footprint edge at heel

|

L

|

0,5 W

|

|

Minimum side joint length

|

D

|

full lap connection soldered

|

|

Minimum heel fillet height

|

E

|

X + T

|

|

Solder Stand-off

|

X

|

Present

|

Figure 116: Mounting of gull-wing leaded devices with round, rectangular, ribbon leads

Figure 116: Mounting of gull-wing leaded devices with round, rectangular, ribbon leads

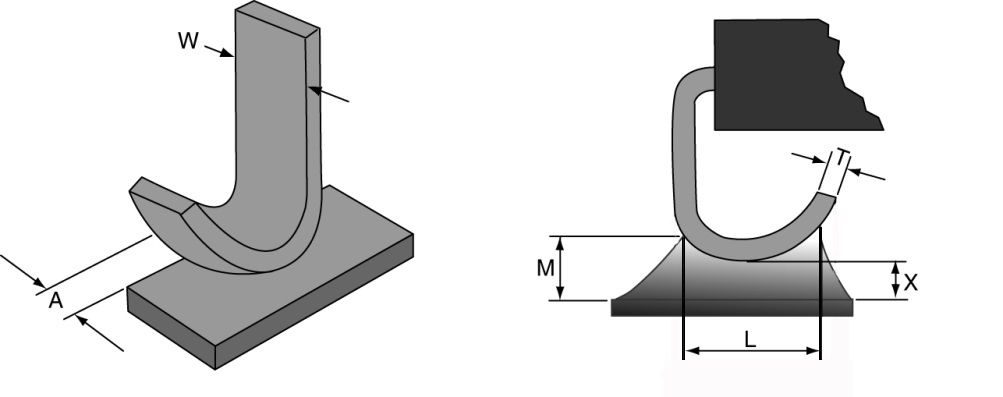

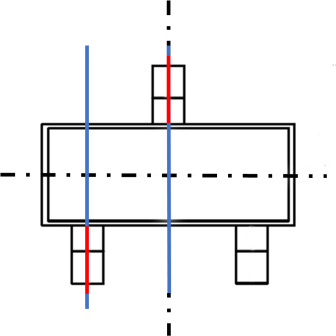

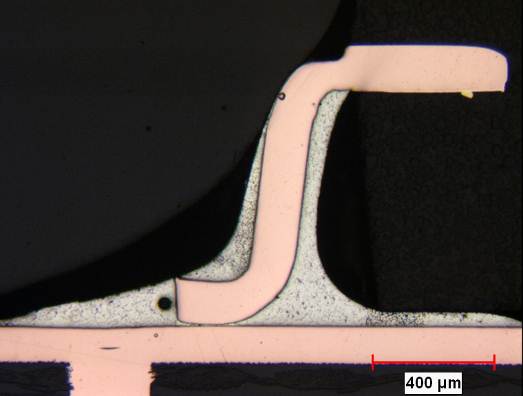

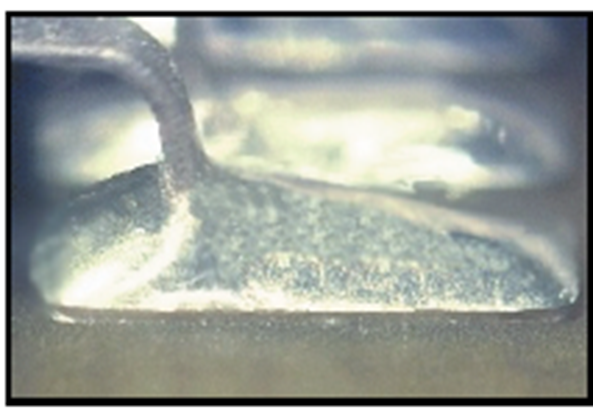

Devices with “J” leads

Solder joints formed to “J” and “V” shaped leads shall meet the dimensional and solder fillet requirements of Table 117 and Figure 117.

Table 117: Dimensional and solder fillet for devices with “J” leads

|

Parameter

|

Dimension

|

Dimension limits

|

|

Maximum side overhang

|

A

|

0,1 W

|

|

Minimum side joint length

|

L

|

1,5 W

|

|

Minimum heel fillet height

|

M

|

X + T

|

|

Maximum stand-off

|

X

|

Present

|

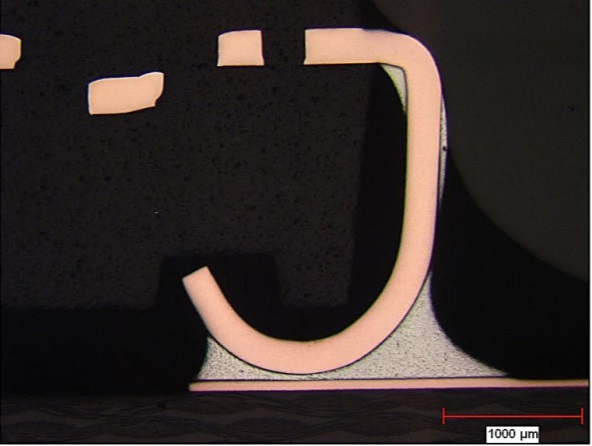

Figure 117: Mounting of devices with “J” leads

Figure 117: Mounting of devices with “J” leads

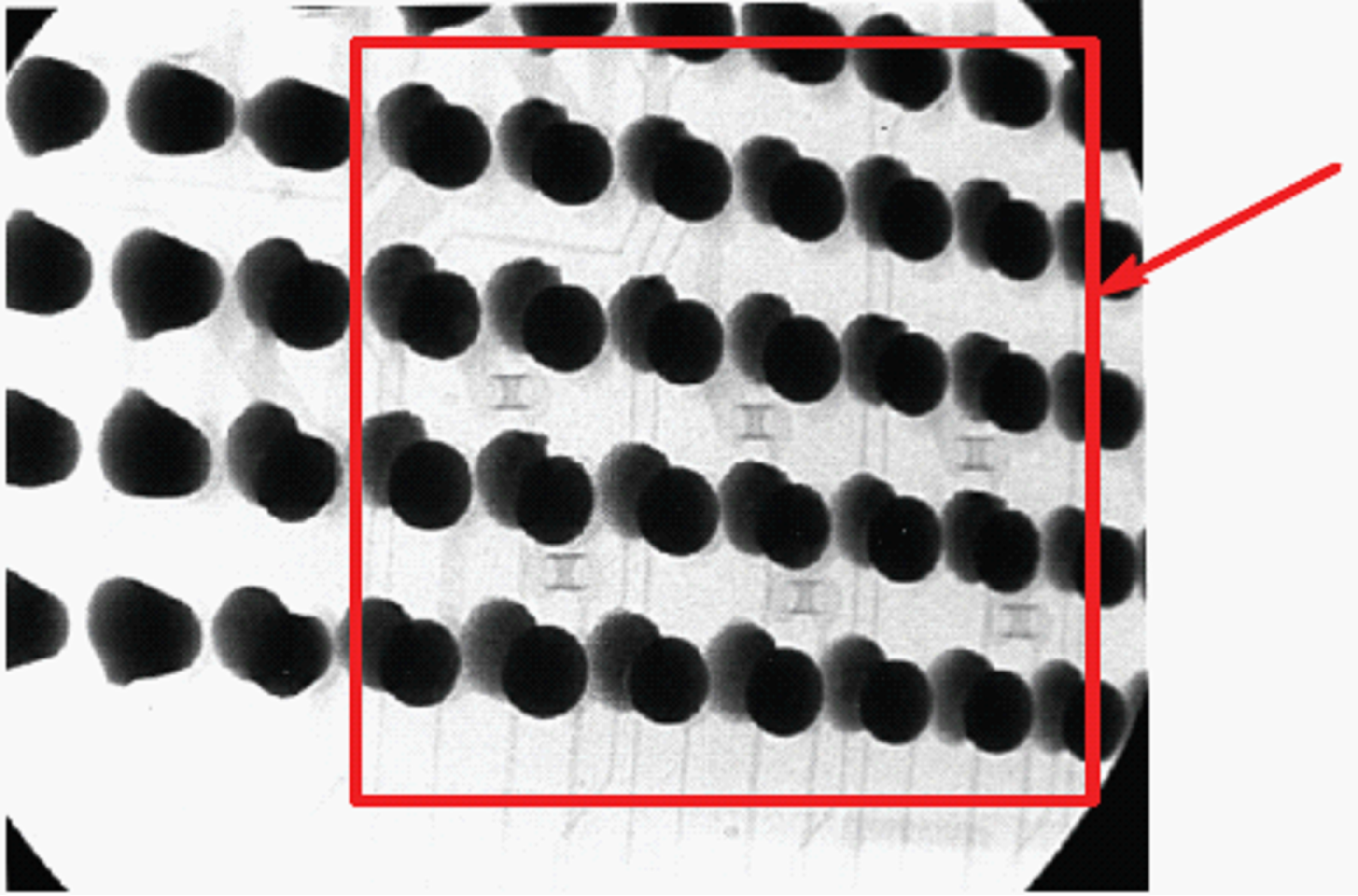

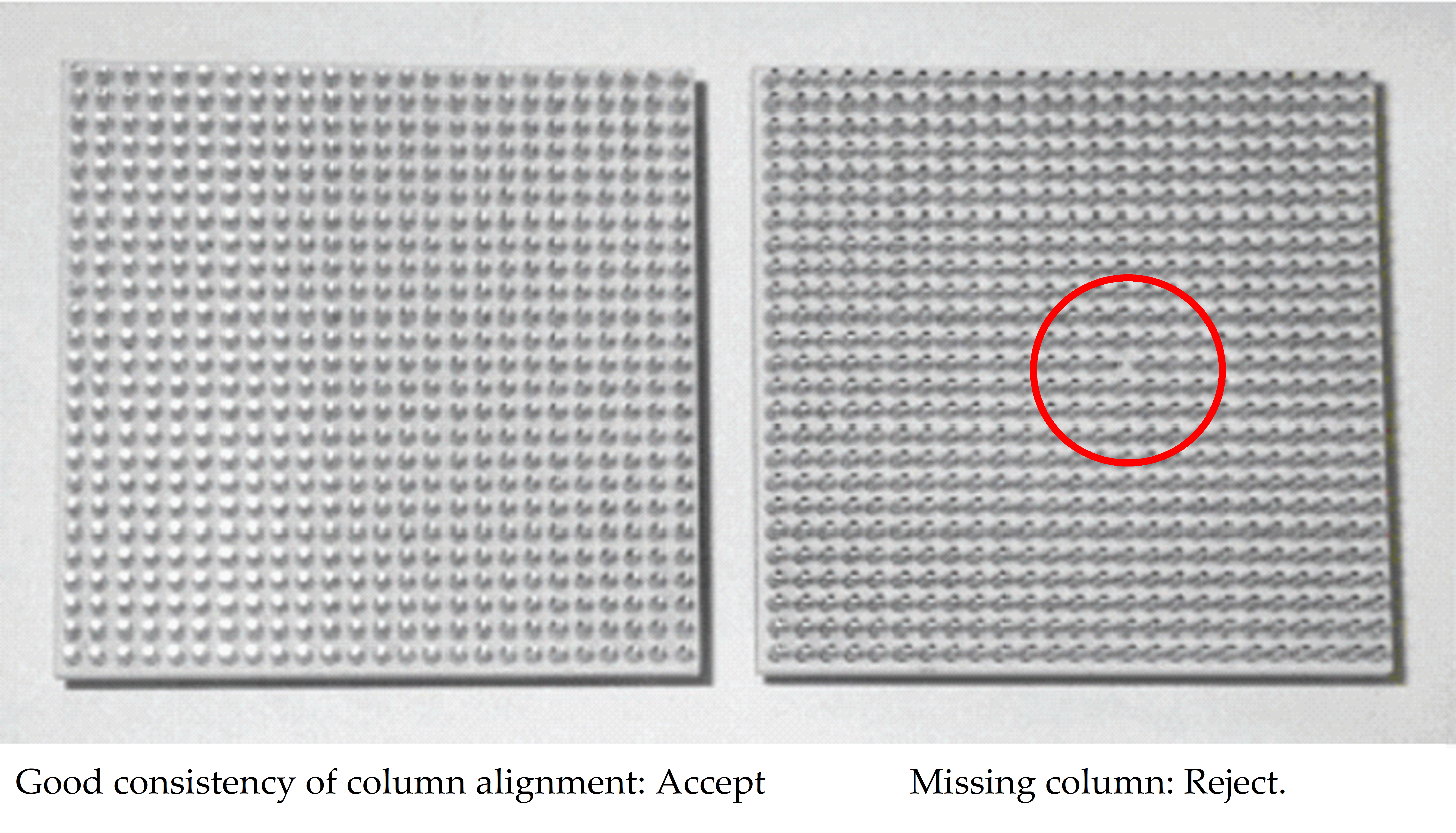

Area array devices

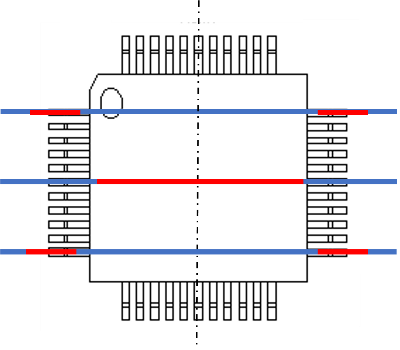

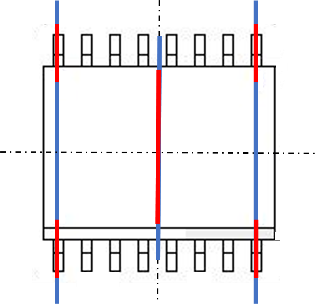

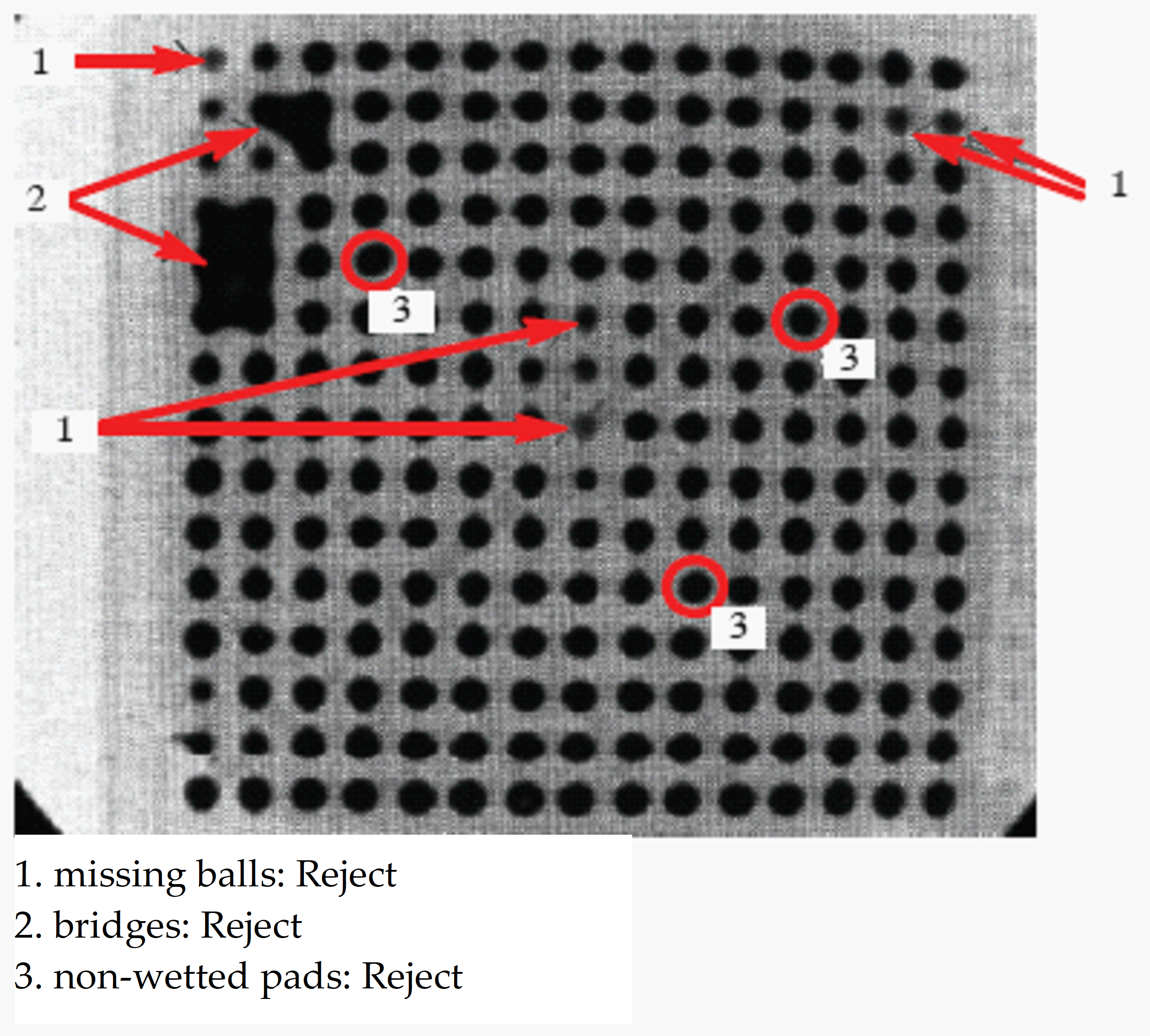

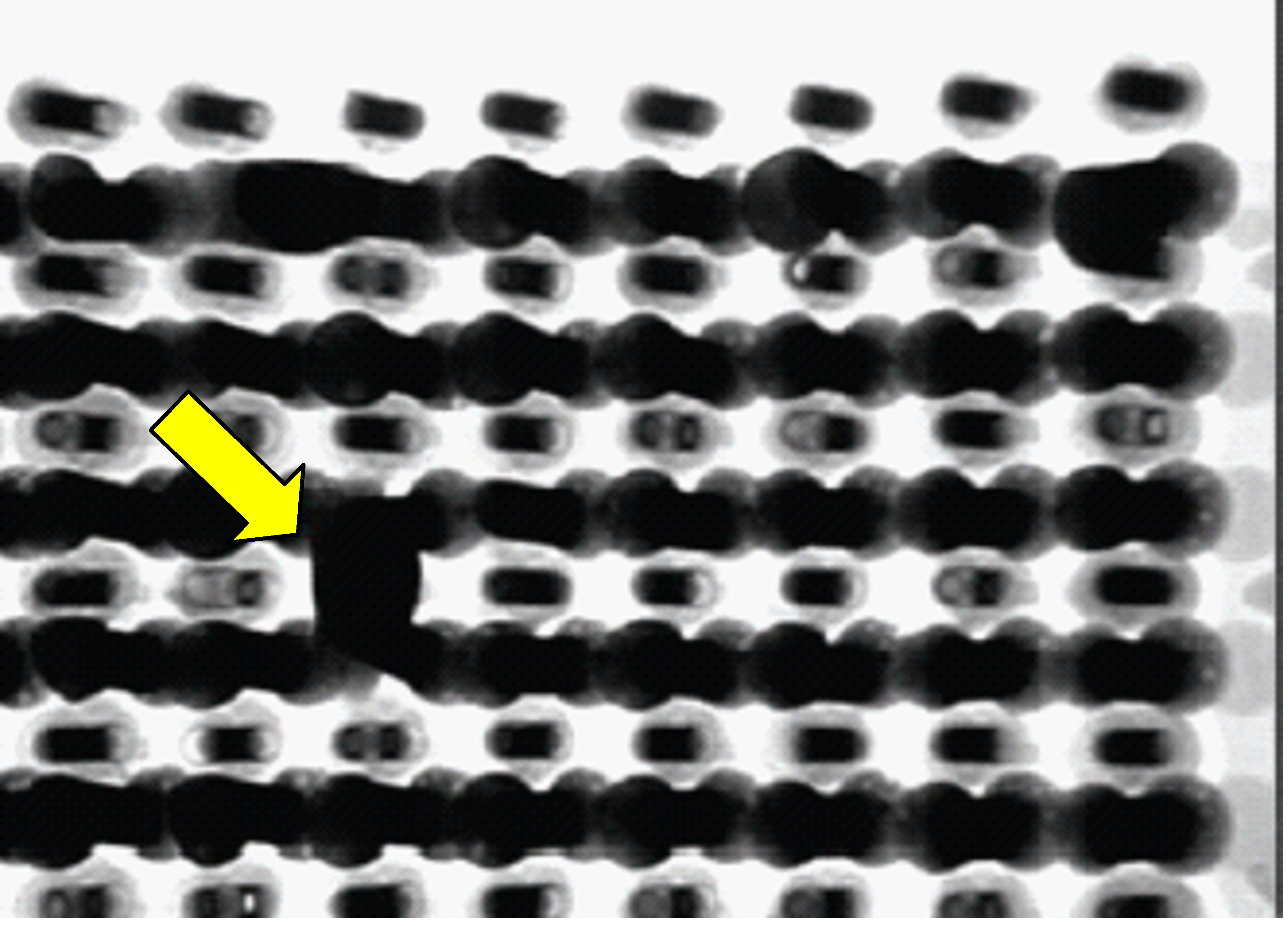

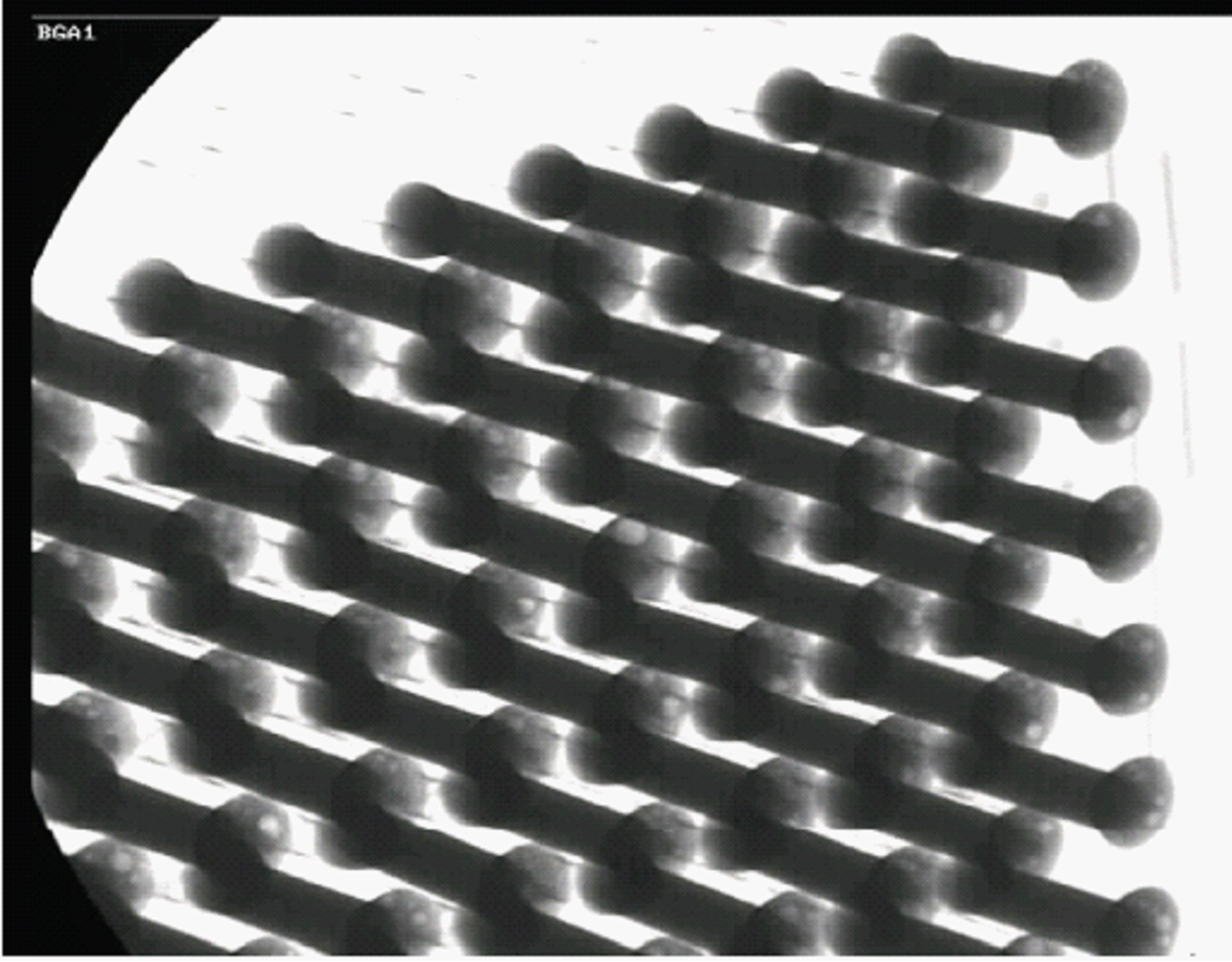

The outer row of solder joints to area array devices shall be visually inspected by looking from the side in accordance with the requirements in 11.5.1 and Table 118 and with the rejection criteria specified in clauses 13.3 and 13.4.

Solder joints shall be inspected using X-ray techniques in accordance with clause 6.8.7 and Table 118.

- 1 <<deleted>>

- 2 As it is impossible to visually inspect solder joints to area array devices, reliability of these devices cannot be assured by inspection and rework. Even using X-ray techniques, some types of defect are difficult to detect. Therefore, reliability of these solder joints can only be assured by robust process control.

- 3 Examples of typical area array devices are shown in Figure 118, Figure 119 and Figure 1110.

X-ray techniques shall be used to verify the acceptable wetting, the absence of bridge, solder balls and minimum electrical clearance.

Table 118: Dimensional and solder fillet for area array devices

|

Parameter

|

Dimension limits

|

|

Misalignment

|

No footprint overhang

|

|

BGA ball

|

Collapse of BGA ball does not violate minimum electrical clearance or become less than 0,10 mm.

|

|

Maximum device height

|

Overall height of device does not exceed maximum specified.

|

|

Soldered connection

|

a. BGA balls contact and wet to the land forming a continuous connection

|

|

Solder balls

|

No solder balls.

|

|

Maximum CGA column tilt

|

10 degrees

|

|

D = Ball or column diameter

| |

Figure 118: <<deleted>>

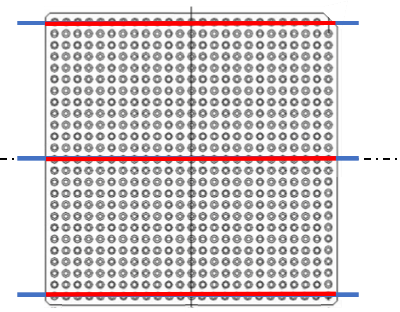

Figure 119: Typical ceramic area array showing ball grid array configuration on left and column grid array on right (CBGA & CCGA)

Figure 119: Typical ceramic area array showing ball grid array configuration on left and column grid array on right (CBGA & CCGA)

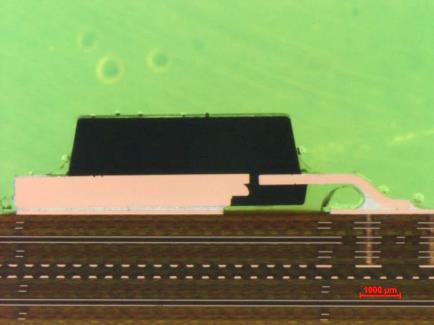

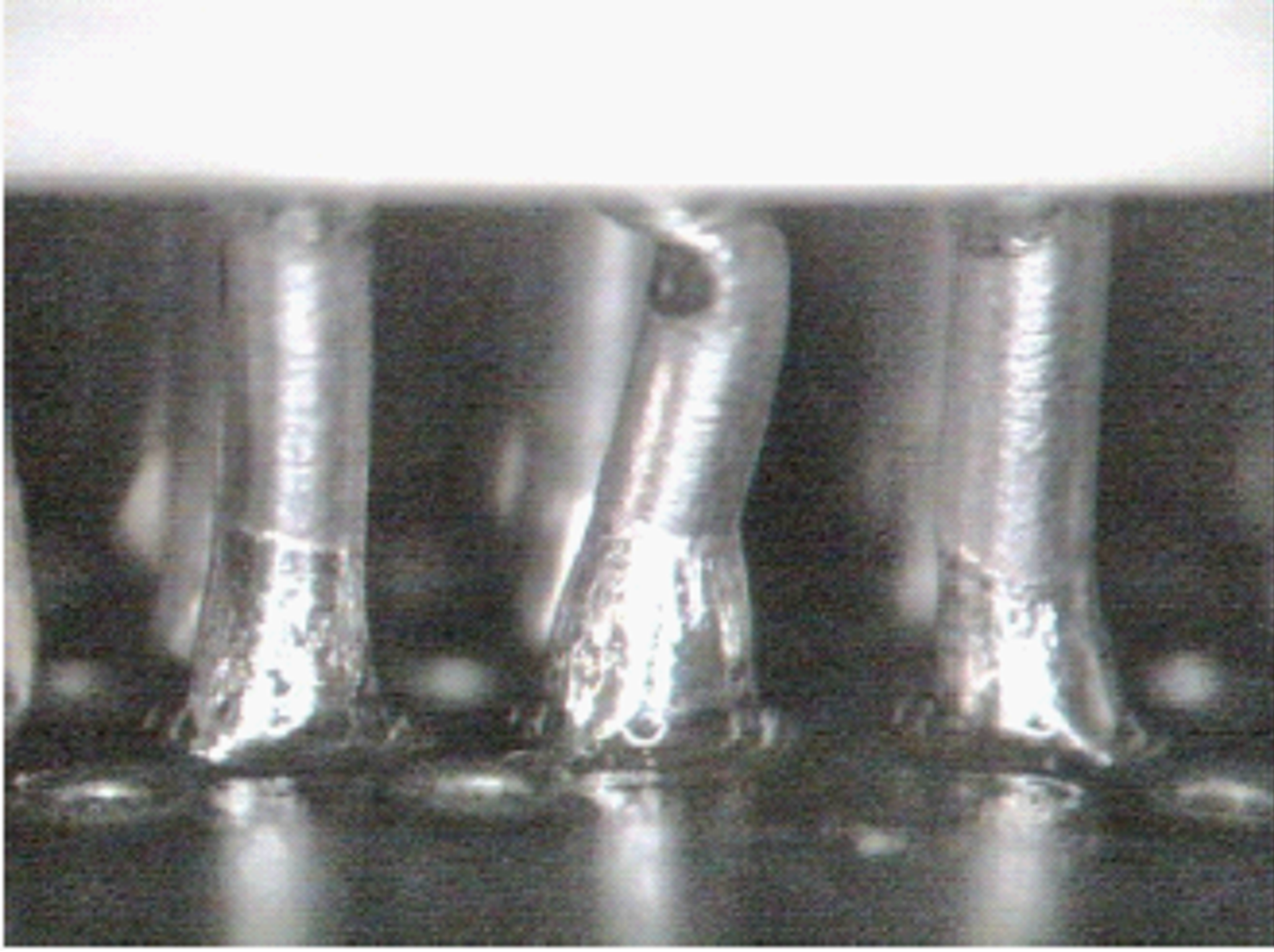

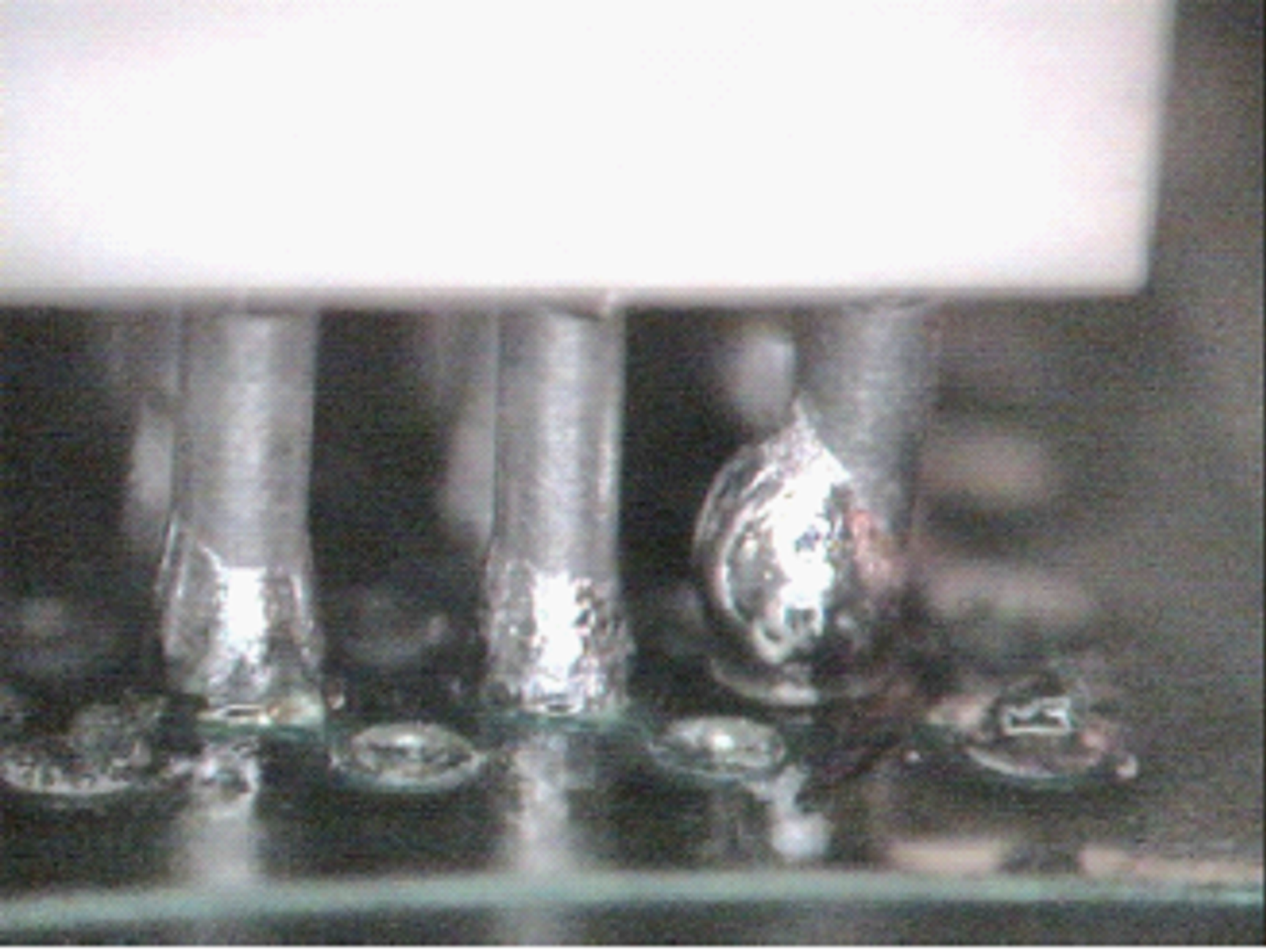

Figure 1110: Typical assembled CCGA device

Figure 1110: Typical assembled CCGA device

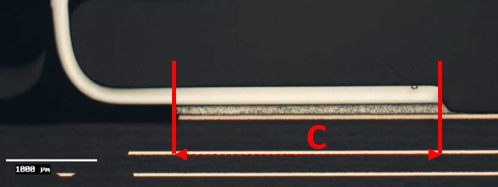

Devices with ribbon terminals without stress relief

Solder joints formed shall meet the dimensional and solder fillet requirements of Table 119 and Figure 1111.

The degolding and pretinning zone shall be outside the PCB footprint.

This is to ensure that the degolding and pretinning has been performed such that the solder fillet is not in contact with the gold or AuSn intermetallic.

Table 119: Dimensional and solder fillet for devices without stress relief

|

Parameter

|

Dimension

|

Dimensions Limits

|

|

Maximum side overhang

|

A

|

≤ 0,1 x W

|

|

Minimum distance to footprint edge at toe

|

B

|

≥ 0,20 mm

|

|

Stand-off

|

X

|

Present

|

|

Minimum side joint fillet

|

D

|

3xW with full lap soldered connection

|

|

Maximum tilt

|

C

|

10°

|

Figure 1111: Mounting of devices without stress relief

Figure 1111: Mounting of devices without stress relief

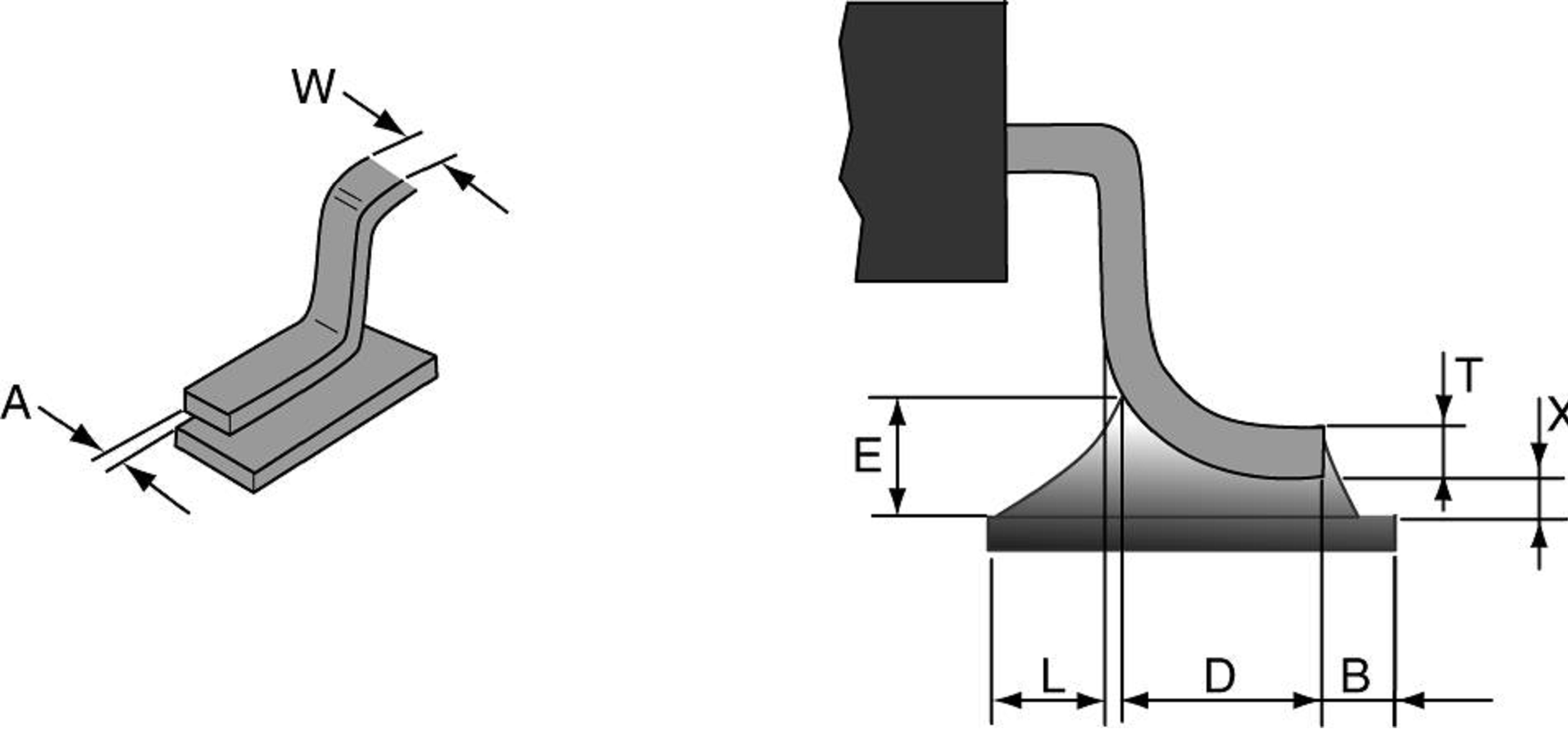

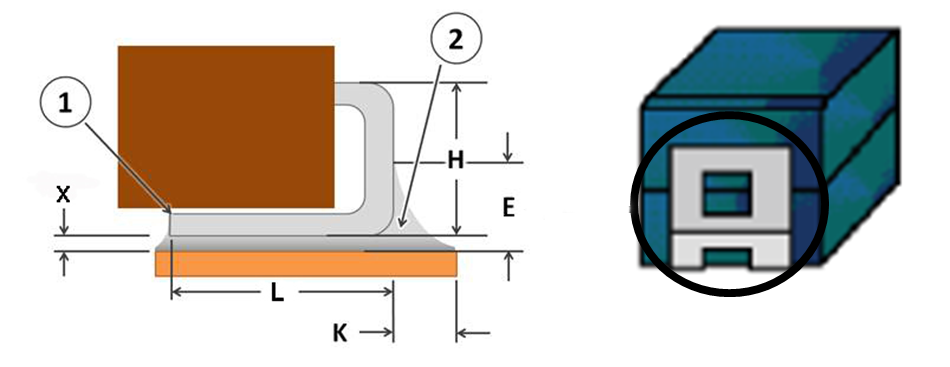

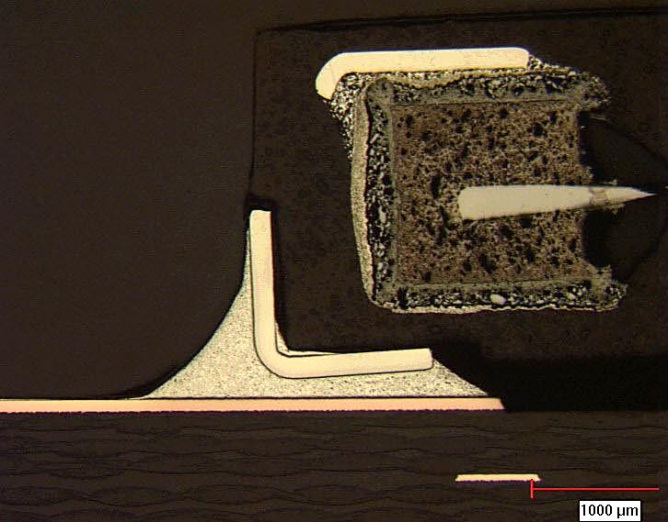

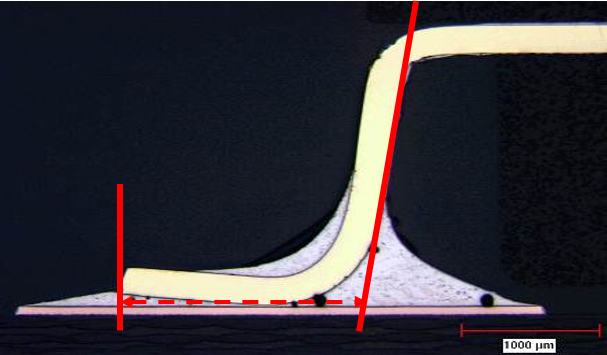

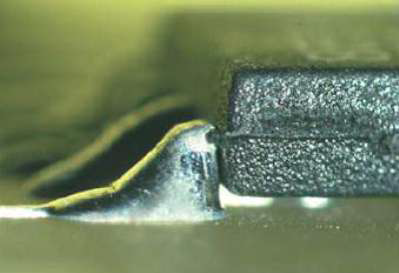

L-Shape inwards devices

Devices having L-shape inwards terminals shall meet the dimensional and solder fillet requirements of Table 1110 and Figure 1112.

Solder fillet shall be visible on the side of the terminal on the connection.

The device shall be centred on its footprints such as the minimum lap contact length is fulfilled.

Table 1110: Dimensional and solder fillet for “L-shape inwards” devices

|

Parameter

|

Dimension

|

Dimension limits

|

|

Minimum fillet height, heel

|

E

|

(0,25 x H)+X or X +1mm whichever is less

|

|

Minimum distance to footprint edge

|

K

|

0,2 mm

|

|

Minimum Lap contact length

|

L

|

75% terminal of device, limited to one side

|

|

Stand-off (elevation)

|

X

|

Present

|

|

Side of terminal wetting

|

|

Evidence of solder wetting

|

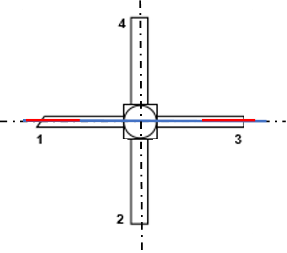

Figure 1112: Mounting of devices with “L-shape inwards” leads (1 = Toe, 2 = Heel)

Figure 1112: Mounting of devices with “L-shape inwards” leads (1 = Toe, 2 = Heel)

Stacked modules devices with leads protruding vertically from bottom

Stacked modules devices shall meet the dimensional and solder fillet requirements of Table 1111 and Figure 1113.

Solder fillet shall be visible in the heel fillet.

Table 1111: Dimensional and solder fillet for stacked modules devices with leads protruding vertically from bottom

|

Parameter

|

Dimension

|

Dimension limits

|

|

Maximum side overhang

|

A

|

0,1 W

|

|

Minimum distance to footprint edge at toe

|

B

|

0,20 mm

|

|

Minimum distance to footprint edge at heel

|

L

|

0,5 W

|

|

Minimum side joint length

|

D

|

full lap connection soldered

|

|

Minimum heel fillet height

|

E

|

Wetting solder visible in the heel fillet, X+ 0,5T

|

|

Solder Stand-off

|

X

|

Present

|

|

Lead thickness

|

T

|

|

Figure 1113: Mounting of stacked modules devices with leads protruding vertically from bottom

Figure 1113: Mounting of stacked modules devices with leads protruding vertically from bottom

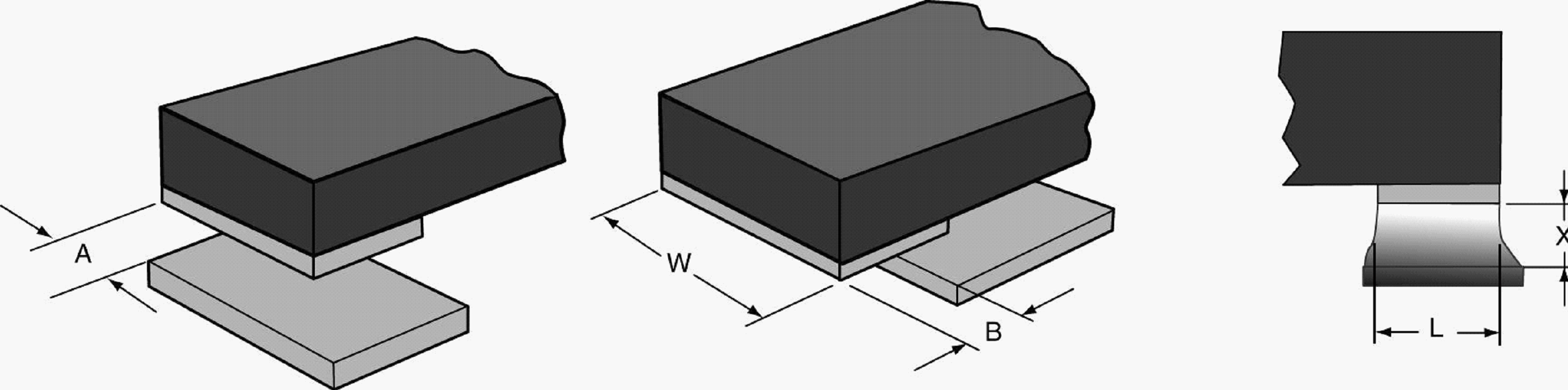

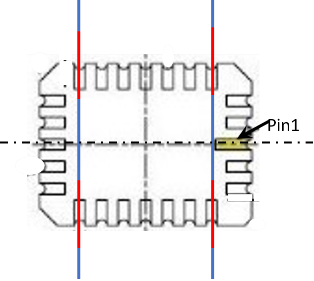

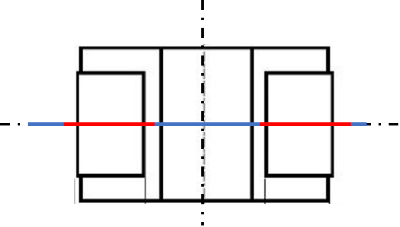

Leaded device with plane termination

Leaded devices with plane termination shall meet the dimensional and solder fillet requirements of Table 1112 and Figure 1114.

Solder fillet shall be visible in the heel fillet.

Termination plane shall be inspected with X-ray equipment according to clause 6.8.7.

Plane termination shall meet X-ray criterion according to requirements 13.4a.2 to 13.4a.5.

Table 1112: Dimensional and solder fillet for leaded devices with plane termination

|

Parameter

|

Dimension

|

Dimension limits

|

|

Maximum side overhang

|

A

|

0,1 W

|

|

Minimum distance to footprint edge at toe

|

B

|

0,20 mm

|

|

Minimum distance to footprint edge at heel

|

L

|

0,5 W

|

|

Minimum side joint length

|

D

|

full lap connection soldered

|

|

Minimum heel fillet height

|

E

|

X + T

|

|

Solder Stand-off

|

X

|

Present

|

Figure 1114: Mounting of leaded devices with leads with plane termination

Figure 1114: Mounting of leaded devices with leads with plane termination

Moulded magnetics

Moulded magnetics devices shall meet the dimensional and solder fillet requirements of Table 1111 and Figure 116.

Solder fillet shall be visible in the heel fillet.

<<deleted>>

<<deleted>>

<<deleted>>

Figure 1115: <<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

Cleaning of PCB assemblies

General

Requirements from clause 11.1 from ECSSQST7008, clause “Cleaning of PCB assemblies – General” shall apply.

Ultrasonic cleaning

Requirements from clause 11.2 from ECSSQST7008 shall apply for "Ultrasonic cleaning".

Monitoring for cleanliness

Requirements from clause 11.3 from ECSSQST7008 shall apply for "Monitoring for cleanliness".

Final inspection

General

Each soldered connection shall be visually inspected in accordance with the criteria specified in the requirements 13.1d, 13.1e, and 13.1f

<<deleted>>

<<deleted>>

Devices and conductors shall not be physically moved to aid inspection.

The substrate, solder joint, devices and device position, shall be inspected in accordance with the requirements in clause 11.5.

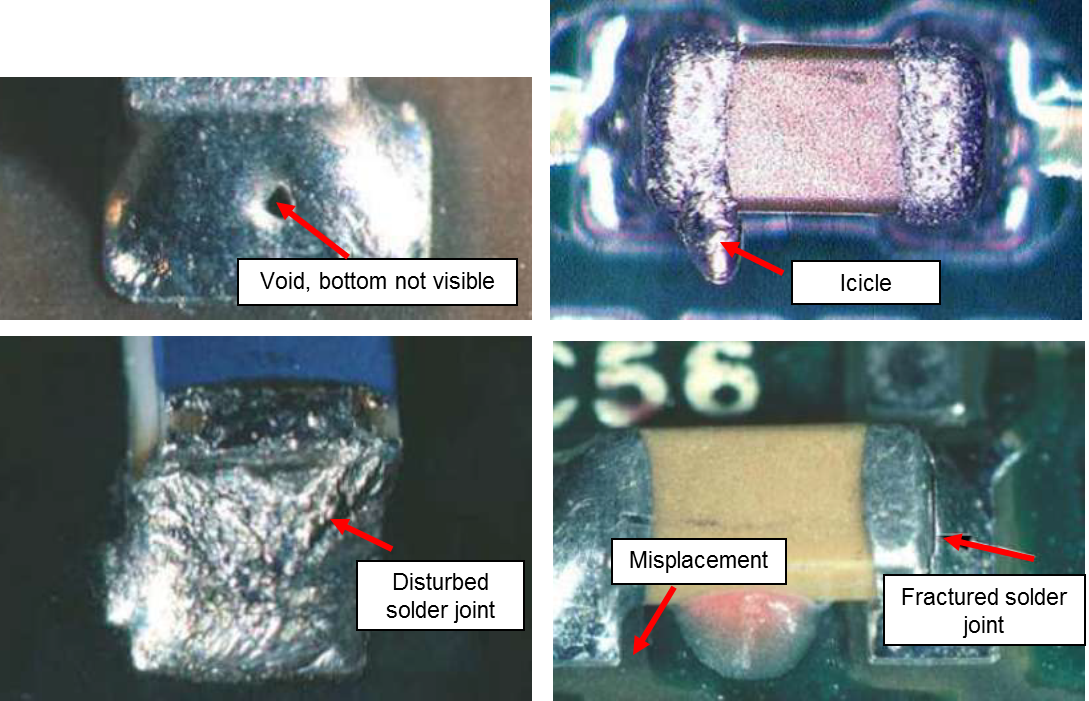

Annex I includes examples of acceptable and unacceptable workmanship.

The assembly shall be visually inspected in two steps with the following methodology:

- Visual inspection of the assembly is aided by magnification appropriate to the size of the connections between 4x and 10x.

- Detailed inspection is performed with a minimum magnification 20x.

Additional magnification shall be used to resolve suspected anomalies or defects up to 40x.

X-ray inspection shall be applied when there are hidden solder joints that are not visually accessible.

Acceptance criteria

Acceptable solder connections shall be characterised by:

- clean, smooth, satin to bright undisturbed surface,

- solder fillets between conductor and termination areas as described in clause 11.5,

- visible contour of wires and leads such that their presence, direction of bend and termination end can be determined,

- complete wetting as evidenced by a low contact angle between the solder and the joined surfaces,

- acceptable amount and distribution of solder in accordance with clause 11.5,

- absence of any of the defects mentioned in clauses 13.3 and 13.4.

Annex I includes examples of acceptable and unacceptable workmanship.

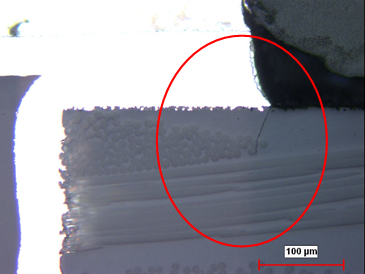

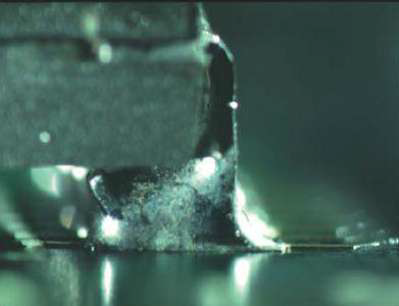

Visual rejection criteria

The following are some characteristics of unsatisfactory conditions, any of which shall be cause for rejection:

- charred, burned or melted insulation of devices,

- conductor pattern separation from circuit board,

- burns on base materials,

- <<deleted>>

- excessive solder (including peaks, icicles and bridging), see clause 11.5,

- flux residue, solder splatter, solder balls, or other foreign matter on circuitry, beneath devices or on adjacent areas,

- dewetting,

- insufficient solder, see clause 11.5,

- pits, holes or voids where bottom is not visible,

- granular or disturbed solder joints,

- fractured or cracked solder connection,

- cut, nicked, gouged or scraped conductors or conductor pattern,

- <<deleted>>

- <<deleted>>

- damaged conductor pattern,

- bare copper or base metal, excluding the ends of cut wire or leads or sides of tracks and soldering footprints on substrate,

- soldered joints made directly to gold-plated terminals or gold-plated conductors using tin-lead solders,

- cold solder joints,

- device body embedded within solder fillet,

- open solder joints (e.g. tombstoning),

- probe marks present on the metallization of chip devices caused by electrical testing after assembly,

- glass seal does not conform to MIL-STD-883 Method 2009,

- any nonconformance with clause 11.5,

- measling which violates the minimum insulation distance,

- delamination, except within region of the breakout regions for multi-panel processed,

- exposed base metal excluding area of cut leads in the soldered connection,

- cracks detected in glass diodes outside the relevant devices procurement standard,

- bent connector pins outside the relevant devices procurement specification,

- damage of the lead, device or PCB beyond that defined in the procurement standard of the item,

- degraded insulation material of the connector in contact area,

- bubble or void in the conformal coating or potting that are bridging conductive elements,

- bubble, void or delamination in conformal coating and or potting between high voltage conductors,

- lack of intended conformal coating,

- unintended and continuous adhesive forming a bridge in contact with terminals, component body or solder joints,

- excessive degolding,

- insufficient degolding,

- direct bonding on glass device body with epoxy,

- separation of adhesive from the bonded surface,

- separation of conformal coating from the surface,

- any longitudinal misalignment on sensitive devices,

- longitudinal misalignment of end capped and end metallized devices,

- presence of cracks in the ceramic of devices or cover of device.

- 1 For requirement 13.3a.29, end cap metallization peeling crack in device, missing metallization are examples of damage.

- 2 For requirement 13.3a.29, cracks in ceramics mainly occur in chip capacitors, and leadless device with thermal plane termination.

- 3 For the requirement 13.3a.32, high voltage applications are defined in ECSS-E-HB-20-05.

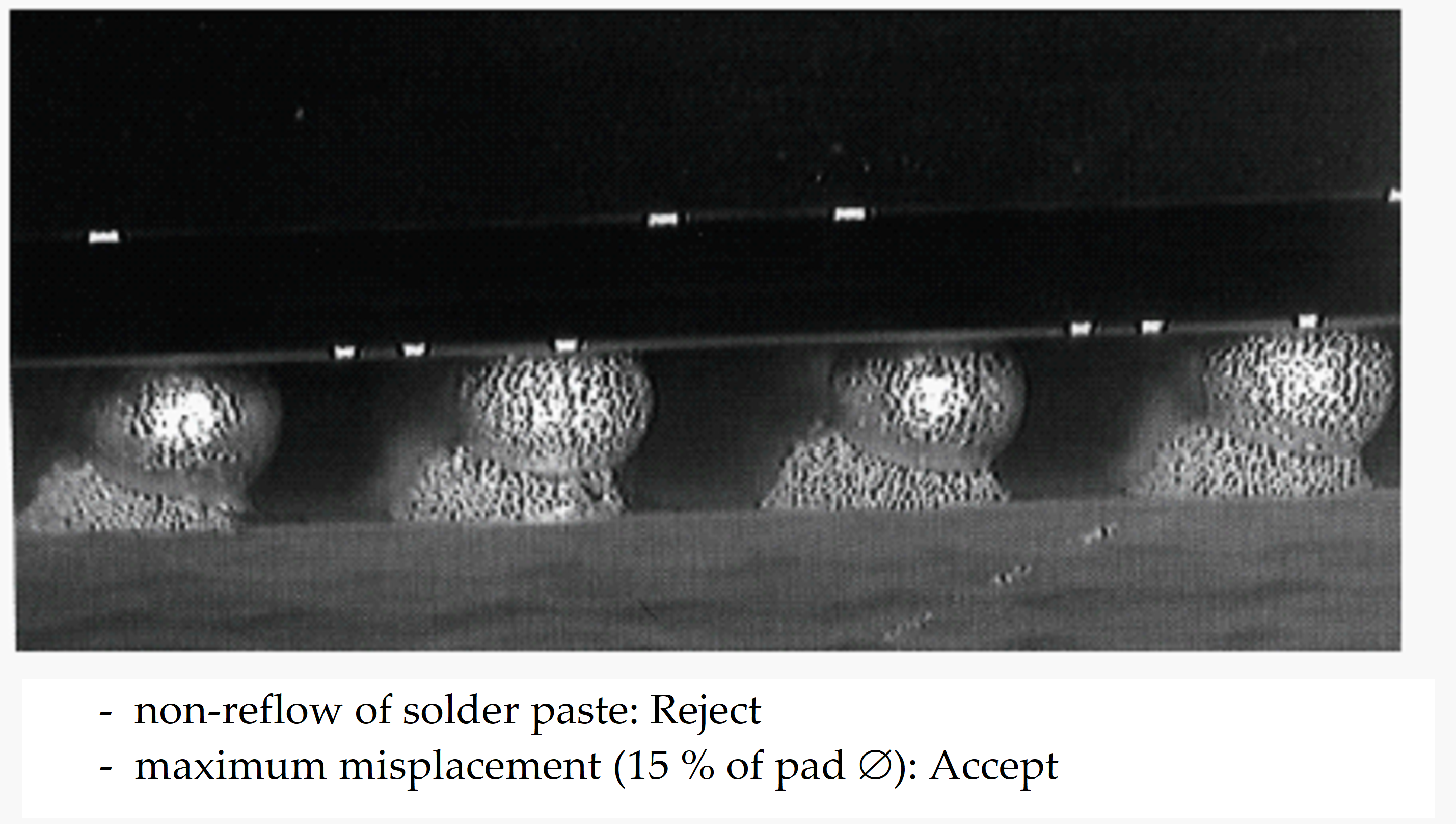

X-ray rejection criterion

The following are some characteristics of not acceptable conditions from X-ray inspection, utilizing equipment defined in clause 6.8.7, any of which shall be cause for rejection:

- criteria and dimensions outside the limits given in Table 118 for area array devices,

- bridges and other unintended metallic materials,

- non-wetting of the solder,

- cumulative voids greater than 25 % by area of the solder joint,

- a single void which traverses either length or width of the terminal and exceed 10 % of the total area.

For the requirement 13.4a.2 solder balls are a typical example of unintended metallic material.

Any deviation to requirement 13.4a.4 shall be demonstrated by verification in compliance with requirements from clause 14.

Warp and twist of populated boards

<<deleted>>

The PCB assembly shall be supported during handling and transportation in order to avoid any mechanical stress on the assembly or component damage.

Mechanical support can be provided by spacer and frame.

The PCB shall not be forced during integration to compensate warp and twist.

Shims or spacers can be used to accommodate warp and twist during integration.

Inspection records

The result of the final inspection shall be recorded on the shop traveller.

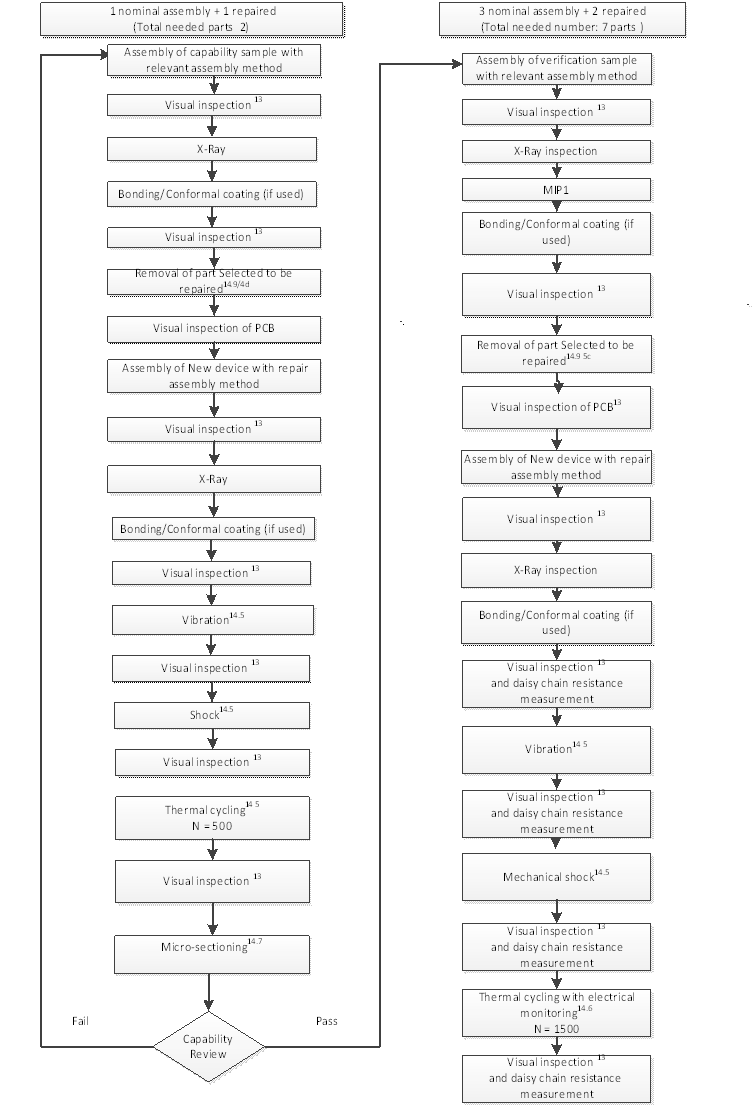

Verification procedure

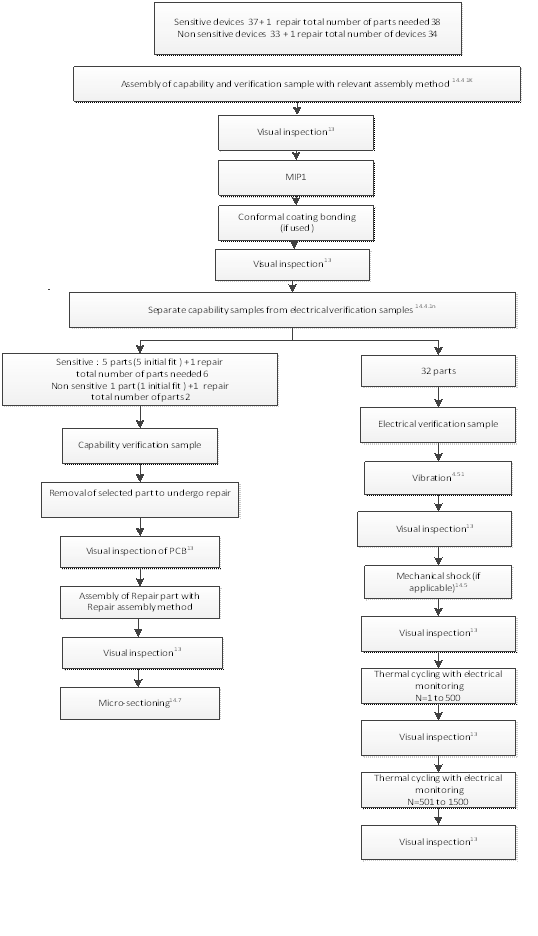

General

The supplier shall establish a verification programme in accordance with the DRD from Annex G for approval by the Approval Authority.

Requirement G.2.1b gives possibility to tailor verification programme.

The supplier shall demonstrate verification for each combination of substrate material, PCB footprint, SMD type, soldering technique applied, stacking and bonding, lead forming configuration, , solder mask and conformal coating as used on FM.

Substrate materials are defined in Table 6-1 of ECSS-Q-ST-70-12.

<<deleted>>

<<deleted>>

<<deleted>>

The verification shall be performed on at least three devices except for the sensitive devices where five parts are used per configuration in the verification programme.

- 1 For the devices listed in the ESCIES sensitive list that have not been demonstrated to be none sensitive by the supplier the first verification test plan is with five devices.

- 2 Machine reflow, hand soldering are examples of different assembly methods.

The supplier’s repair process including removing and replacing of one of each type of mounted device shall be submitted to verification testing. - 1 Verification of the number of repairs as permitted in ECSS-Q-ST-70-28.

- 2 The supplier has the option to perform more than one repair for each type of device.

<<deleted>>

<<deleted>>

<<deleted>>

Verification testing of commercial devices shall be performed for each lot in conformance with this clause.

A repair, not included in ECSSQST70-28, shall be submitted to a verification programme.

Verification of the assembly shall be performed with a nominal method and a repair method for each device.

Standard manual method can cover a range of processes in addition to hand soldering e.g. hot gas station, IR station.

Collective assembled devices shall not be reworked neither repaired.

The PCB verification test vehicle shall be representative of the FM footprint configuration and connections of the hardware.

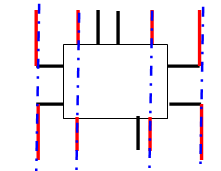

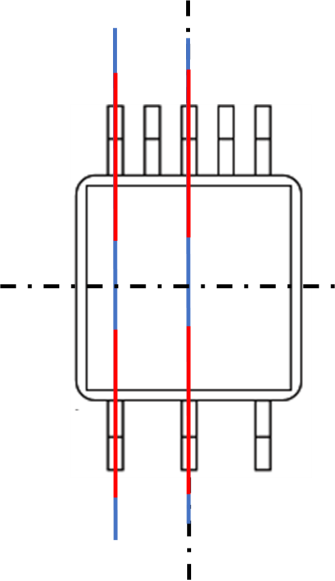

Terminations to be microsectioned shall be connected to the internal PCB layers.

The terminations to be microsectioned are described in Table 142.

The verification of area array devices shall meet the requirements of clause 14.9.

For each type of device, the repair shall be performed on the largest device.

The repair shall be performed only on the devices being assembled by standard manual method.

No repair verification is needed on the devices being assembled by machine method as this is covered under the standard manual soldering verification method.

The supplier shall maintain a list of sensitive devices.

Sensitive devices shall be submitted to re-verification every four years to monitor the stability of the assembly.

The re-verification of sensitive devices specified in the requirement 14.1u may be performed on limited verification programme performed on worst case configuration identified during initial verification.

- 1 One substrate, one package per device type, three samples per device.

- 2 For leadless devices, mechanical testing can be omitted.

- 3 Non-destructive characterization can be proposed as alternative to microsection.

The verification sample shall be submitted to two nominal soldering method reflows when reflow is performed on the both PCB sides of the FM.

The supplier has the option to flip the board for the second reflow to demonstrate the flight configuration.

The device type classification shall be in accordance with Table 141.

Table 141: Device type classification

|

Device type

|

Classification

|

|

Rectangular and square end-capped or end-metallized device with rectangular body

|

Leadless chip

|

|

Cylindrical and square end-capped devices with cylindrical body

|

Leadless chip

|

|

Bottom terminated chip device

|

Leadless

|

|

Castellated chip carrier device

|

Leadless

|

|

Flat pack and Gull-wing leaded device with round, rectangular, ribbon leads

|

Leaded

|

|

Moulded magnetics

|

Leaded

|

|

“J” leaded device

|

Leaded

|

|

Area array devices

|

AAD

|

|

Devices with ribbon terminals without stress relief (flat lug leads)

|

Leaded

|

|

Device with Inward formed L-shaped leads

|

Leaded

|

|

Stacked modules devices with leads protruding vertically from bottom

|

Leaded

|

|

Leaded device with plane termination

|

Leaded

|

Verification by similarity

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

<<deleted>>

General

A package shall be identified as the same family in case the following conditions are met:

- the lead pitch, nominal thickness, nominal width and materials composition are identical,

- the coated lead finishes on the termination are identical,

- the bending dimensions and shape are identical,

- the packages are constructed from the same materials.

- 1 Glass to metal sealed, glass sealed side-brazed, top-brazed, and bottom-brazed packages are different families.

- 2 Dual side pin arrangements are different to quad side pin families.

For flat pack, verification by similarity may apply even if the lead materials are different.

Conditions for similarity

Verification by similarity shall not apply to commercial devices.

Verification by similarity shall not apply to castellated devices.

Some resistors networks and LCCs are castellated devices examples

Verification by similarity for leadless chip devices shall not be declared successful until the following conditions are met:

- device size is between the length Lmax and the width Wmax of verified component,

- the device is thinner than the maximum height verified,

- the ceramic material type is identical,

- the metallization of the termination and the barrier layers on devices is identical,