Space engineering

Thermal control general requirements

Foreword

This Standard is one of the series of ECSS Standards intended to be applied together for the management, engineering and product assurance in space projects and applications. ECSS is a cooperative effort of the European Space Agency, national space agencies and European industry associations for the purpose of developing and maintaining common standards. Requirements in this Standard are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards.

This Standard has been prepared by the ECSS-E-ST-31 Working Group, reviewed by the ECSS Executive Secretariat and approved by the ECSS Technical Authority.

Disclaimer

ECSS does not provide any warranty whatsoever, whether expressed, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item are error-free. In no respect shall ECSS incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this Standard, whether or not based upon warranty, business agreement, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by ECSS.

Published by: ESA Requirements and Standards Division

ESTEC, P.O. Box 299,

2200 AG Noordwijk

The

Copyright: 2008 © by the European Space Agency for the members of ECSS

Change log

|

ECSS-E-30 Part 1A

|

First issue

|

|

ECSS-E-ST-31B

|

Never issued

|

|

ECSS-E-ST-31C

|

Second issue

|

Scope

ECSS-E-ST-31 defines requirements for the discipline of thermal engineering.

This Standard defines the requirements for the definition, analysis, design, manufacture, verification and in-service operation of thermal control subsystems of spacecraft and other space products.

For this Standard, the complete temperature scale is divided into three ranges:

Cryogenic temperature range

Conventional temperature range

High temperature range.

The requirements of this Standard are applicable to the complete temperature scale. However, where applicable, requirements are stated to be applicable only for the cryogenic or high temperature range. References to these specific requirements have been summarized in Annex G and Annex H.

This standard is applicable to all flight hardware of space projects, including spacecraft and launchers.

This standard may be tailored for the specific characteristic and constrains of a space project in conformance with ECSS-S-ST-00.

Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this ECSS Standard. For dated references, subsequent amendments to, or revision of any of these publications do not apply, However, parties to agreements based on this ECSS Standard are encouraged to investigate the possibility of applying the more recent editions of the normative documents indicated below. For undated references, the latest edition of the publication referred to applies.

|

ECSS-S-ST-00-01

|

ECSS system – Glossary of terms

|

|

ECSS-E-ST-10-02

|

Space engineering – Verification

|

|

ECSS-E-ST-10-03

|

Space engineering – Testing

|

|

ECSS-E-ST-10-04

|

Space engineering – Space environment

|

|

ECSS-M-ST-40

|

Space project management – Configuration and information management

|

|

ECSS-Q-ST-20

|

Space product assurance – Quality assurance

|

|

ECSS-Q-ST-40

|

Space product assurance – Safety

|

|

ECSS-Q-ST-70

|

Space product assurance – Materials, mechanical parts and processes

|

|

ECSS-Q-ST-70-01

|

Space product assurance – Cleanliness and contamination control

|

Terms, definitions and abbreviated terms

Terms from other standards

For the purpose of this Standard, the terms and definitions from ECSSST0001 apply, in particular for the following terms:

acceptance test (system level)

assembly

item

part

For the purpose of this Standard, the following terms and definitions from ECSS-E-ST-10-03 apply:

temperature cycle

Terms specific to the present standard

General

acceptance margin

contingency agreed between system authority and TCS to account for unpredictable TCS-related events

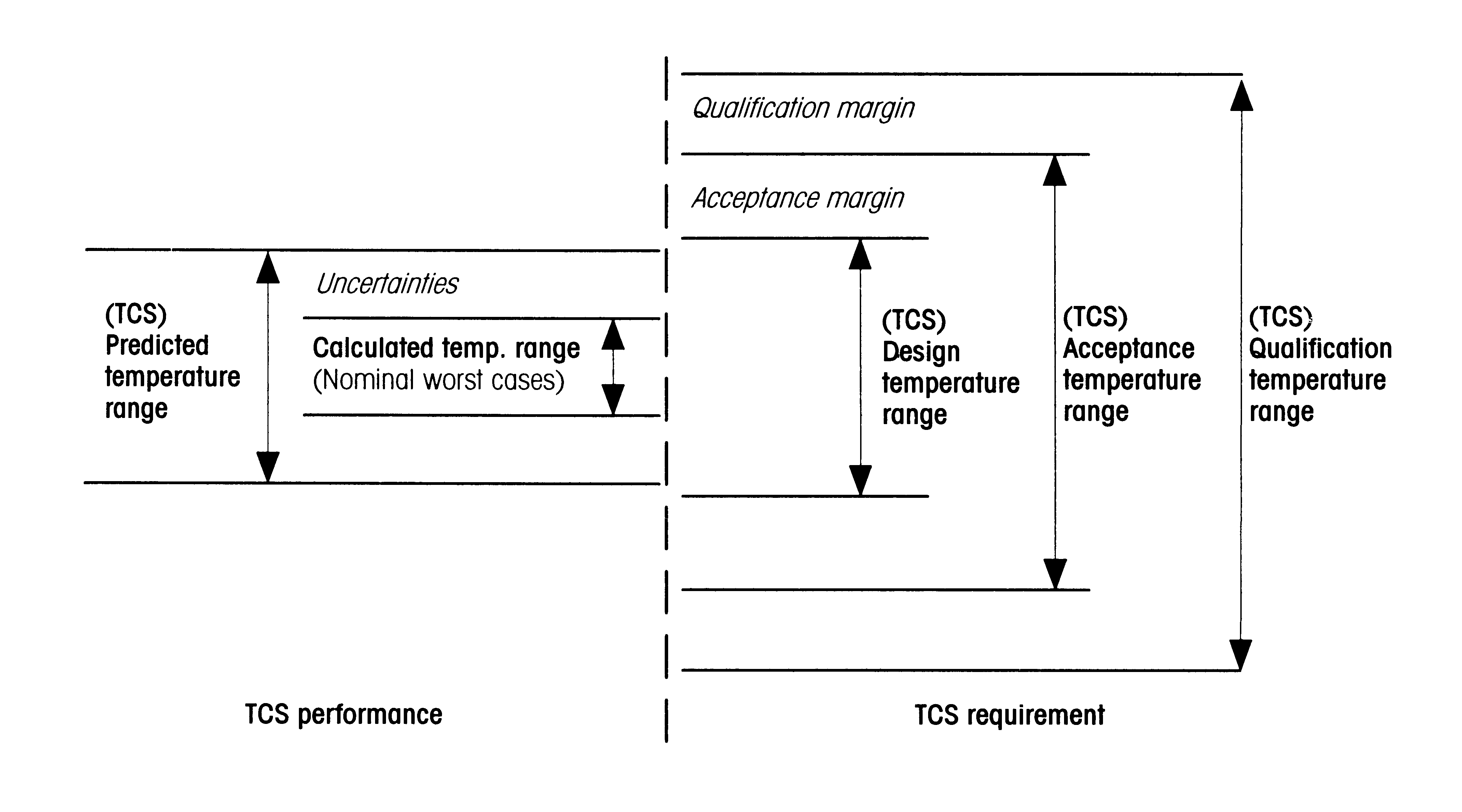

The acceptance margin is the difference between the upper or lower acceptance temperature and the upper or lower design temperature (for both operating and non -operating mode). See Figure 31.

Figure 31: Temperature definitions for thermal control system (TCS)

Figure 31: Temperature definitions for thermal control system (TCS)

acceptance temperature range

temperature range obtained from the qualification temperature range after subtraction of qualification margins specified for the operating and non-operating mode and the switch-on condition of a unit

- 1 The acceptance temperature range is the extreme temperature range that a unit can reach, but never exceed, during all envisaged mission phases (based on worst case assumptions). See Figure 31.

- 2 Temperature range used during acceptance tests to verify specified requirements and workmanship

calculated temperature range

temperature range obtained by analysis or other means for the operating and non-operating mode and the minimum switch-on condition of a unit, based on worst case considerations (i.e. an appropriate combination of external fluxes, materials properties and unit dissipation profiles to describe hot and cold conditions) excluding failure cases

See Figure 31. The calculated temperature range plus any uncertainties is limited to the specified design temperature range. During the course of a project these uncertainties change from initial estimates into a value determined by analysis.

climatic test

test conducted to demonstrate the capability of an item to operate satisfactorily or to survive without degradation under specific environmental conditions at predefined hot and cold temperatures, temperature gradients and temperature variations

Examples of environmental conditions are: pressure, humidity and composition of atmosphere.

thermal component

piece of thermal hardware which by further subdivision loses its functionality, but is not necessarily destroyed

correlation

correspondence between analytical predictions and test results

design temperature range

temperature range specified for the operating and non-operating mode and the switch-on condition of a unit, obtained by subtracting acceptance margins from the acceptance temperature range

- 1 Temperature range representing the temperature requirement for the TCS design activities.

- 2 The terms “operating temperature range” or “operational temperature range” should not be used for the design temperature range. The term “operating or non-operating temperature limits” is acceptable.

geometrical mathematical model (GMM)

mathematical model in which an item and its surroundings are represented by radiation exchanging surfaces characterised by their thermo-optical properties

The GMM generates the absorbed environmental heat fluxes and the radiative couplings between the surfaces.

heat dissipation

thermal energy divided by time produced by a source

heat flux

thermal energy (heat) divided by time and unit area perpendicular to the flow path

Heat flux is also referred to as heat flow rate density.

heat leak

unwanted heat exchange between a thermally protected item and the environment

The heat leak can be a heat gain or a heat loss depending of the environmental temperature

heat lift

transfer of a specified heat flow rate from a lower to a higher temperature

For example: Heat pump.

heat storage

capability to store heat at a defined temperature or within a defined temperature range

For example: Heat storage can be performed by sensible heat, latent heat as a PCM, by heat conversion into chemical energy.

induced environment

set of environmental conditions for a given item created by the operation or movement of the item itself

For example: Set of loading conditions due to atmospheric flight.

infrared test

thermal test method in which the solar and planetary radiation and aerodynamic heating are simulated by locally heating the spacecraft surface to the predicted input level using infrared techniques

For example: Infrared lamps and heaters.

minimum switch-on temperature

minimum temperature at which a unit can be switched from the non-operating mode to the operating mode and functions nominally when the unit temperature is brought back to the relevant operating mode temperatures

Also referred to as start-up temperature.

natural environment

set of environmental conditions defined by the external physical surrounding for a certain mission

For example: Heat flux by sun and planet, gas composition and pressure of planet atmosphere.

predicted temperature range

temperature range obtained from the calculated temperature range increased by the uncertainties

See Figure 31

qualification margin

contingency approved by the system authority to account for any unexpected events

For temperatures, the qualification margin is the difference between the upper or lower qualification temperature and the upper or lower acceptance temperature (for operating and non - operating mode). See Figure 31.

qualification temperature range

temperature range specified for the operating and non-operating mode and the switch-on condition of a unit, for which this unit is guaranteed to fulfil all specified requirements

See Figure 31.

qualification test (system level)

verification process that demonstrates that hardware fulfil all specified requirements under simulated conditions more severe than those expected during the mission

During the qualification tests, unit temperature reference points (TRP) are exposed to temperatures within but not exceeding the qualification temperature range.

radiative sink temperature

virtual black body radiation temperature used to define the equivalent radiative thermal load on an item

- 1 The radiative sink temperature includes both the natural environment load (solar, planetary albedo and infrared fluxes) and the radiative exchanges with other items.

- 2 The radiative sink temperature is typically used to provide a simplified interface for an item, to provide a means for parameter studies thus avoiding extensive calculations or to define adequate radiative boundary conditions for thermal tests.

- 3 The sink temperature TSink of an item i with a temperature Ti in radiative exchange with n items j and submitted to external radiative environmental fluxes is calculated according to the formula:

where

emissivity of item i

Ps absorbed solar flux on item i

PA absorbed (planetary) albedo flux on item i

PIR absorbed infrared (planetary) flux on item i

Rij radiative coupling between item i and item j

Tj temperature of item j

Stefan-Boltzmann constant

Ai radiative exchange area of item i

- 4 The radiative sink temperature formula is defined for steady state and transient conditions. Depending on the degree of interaction between the item i (via its temperature, surface properties, dimensions, heat dissipation) and the radiative sink, the simplified approach using the radiative sink temperature is performed in an iterative way during the course of a project.

sensitivity analysis

analysis, which uses a variation of input parameters in order to evaluate the influence of inaccuracies on the analysis results

solar simulation test

test method in which the intensity, spectral distribution, uniformity and collimation angle of the solar radiation are reproduced within acceptable limits

success criteria

predefined value or set of values used for verification of a requirement and based on one or several parameters

- 1 Success criteria can be defined for verification by analysis and test.

- 2 Examples of such parameters are temperature, and temperature gradient.

system authority

organization responsible for the system

The "system authority" can be the "customer" as defined in ECSS-S-ST-00-01.

system interface temperature point

physical point appropriately located on the structure of the system which can be used to evaluate the heat exchanged by conduction between a unit and the spacecraft system

temperature difference

difference in temperature of two points at a given time

temperature gradient

spatial derivation of temperature in a point at a given time

It is expressed by a temperature divided by unit length.

temperature mean deviation (Tmean)

sum of temperature differences (measured minus analysed values) divided by the number of correlated temperatures

Tmean can be positive or negative.

where

Tmean = temperature mean deviation

TMi = measured temperature

TPi = temperature predicted by analysis

N = number of samples

temperature reference point (TRP)

physical point located on a unit and defined in the unit ICD to provide a simplified representation of the unit temperature

- 1 The TRP is used for coherent verification at unit, subsystem and system level.

- 2 Depending on the unit dimensions and interface complexity, more than one temperature reference point can be defined.

temperature stability

condition when the temperature variation for a defined period of time is less than a defined (small) value

temperature standard deviation ()

measure of statistical dispersion of temperature deviations, measuring how widely spread the values of temperature differences in a data set are

Temperature standard deviation is given by:

where

TMi = measured temperature

TPi = temperature predicted by analysis

Tmean = temperature mean deviation (see 3.2.1.30)

N = number of samples.

temperature uniformity

condition when the temperature difference or the temperature gradient at a given time is less than a defined (small) value

temperature variation

change of temperature at a given point with respect to time

It is expressed by a temperature divided by time.

thermal balance test

test conducted to verify the adequacy of the thermal model and the adequacy of the thermal design

thermal design case

set of parameters used for the definition and sizing of the thermal control subsystem

For example: environmental, material properties and dissipation profiles are typical set of parameters.

thermal mathematical model (TMM)

numerical representation of an item and its surroundings represented by concentrated thermal capacitance nodes or elements, coupled by a network made of thermal conductors (radiative, conductive and convective)

- 1 For thermo - hydraulic modelling enthalpy and fluidic conductors are used in addition.

- 2 A TMM generates for all nodes / elements a temperature history, an energy balance; in addition pressure drops and mass flow rates for thermo - hydraulic modelling.

- 3 Numerical representation can be performed by lumped parameter, finite difference or finite element methods.

thermal node

representation of a specific volume of an item with a representative temperature, representative material properties and representative pressure (diffusion node) used in a mathematical lumped parameter approach

thermal vacuum test

test conducted to demonstrate the capability of the test item to operate according to requirements in vacuum at predefined temperature condition

Temperature conditions can be expressed as temperature level, gradient and variation.

uncertainties

inaccuracies in temperature calculations due to inaccurate physical, environmental and modelling parameters

unit

finished product with a given internal design

- 1 The only interaction between a unit and TCS is via the control of external means (e.g. surface coatings, mounting method) and temperature information is derived from the temperature at the unit temperature reference point

- 2 All data relevant for TCS are included in an interface control document (ICD).

Unit internal thermal design

unit acceptance test temperature range

extreme range which is used for acceptance at unit level

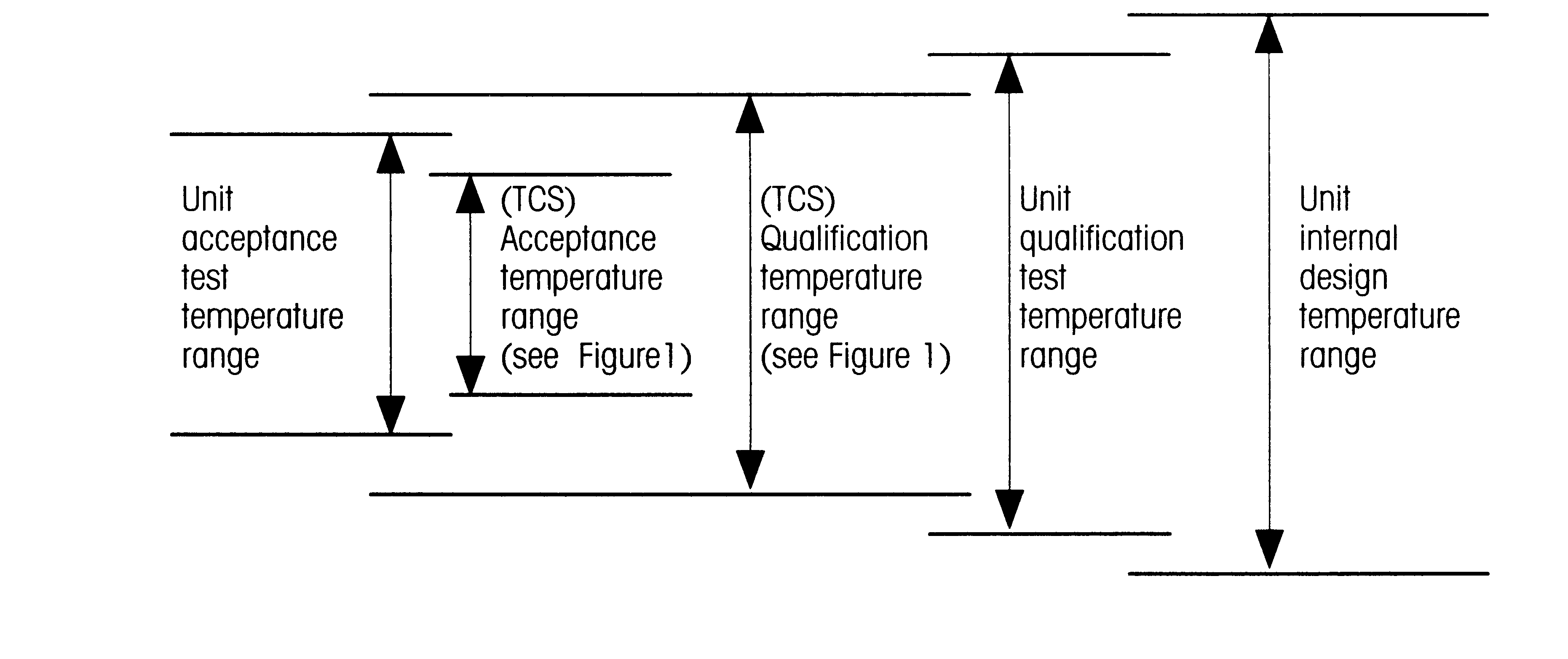

See Figure 32. The unit acceptance temperature range is obtained from the (TCS) acceptance temperature range as defined in Figure 31 after the addition of a suitable value to account for test inaccuracies.

Figure 32: Temperature definitions for unit thermal design

Figure 32: Temperature definitions for unit thermal design

unit internal design temperature range

extreme range for which components or parts are selected

See Figure 32. Unit internal design temperatures are derived from unit thermal calculations including uncertainties and margins.

unit qualification test temperature range

extreme range used for unit qualification at unit level

See Figure 32. The unit qualification temperature range is obtained from the qualification temperature range as defined in Figure 31 after addition of a suitable value to account for test inaccuracies.

Cryogenic temperature range

cryogenic temperature range

temperature range below 200 K

cryogenic control system (CCS)

system which provides thermal control in the cryogenic temperature range

The CCS provides either bulk or point cooling with defined interfaces for assessing the cryogenic heat load on the CCS.

maximum cryogenic heat load

sum of all heat flowing into the cold side of the CCS for the most unfavourable conditions

For example: All heaters and sensors energized and mechanisms operating.

maximum cryogenic temperature

temperature of a defined item when the total heat load flowing into the CCS is the maximum cryogenic heat load and considering the worst case performance of the CCS

nominal cryogenic heat load

sum of all heat flowing into the cold side of the CCS in a nominal steady state operation

nominal cryogenic temperature

temperature of a defined item when the total heat load flowing into the CCS in nominal steady state conditions is the nominal cryogenic heat load and considering a nominal performance of the CCS

ultimate cryogenic heat load

maximum cryogenic heat load multiplied by a safety coefficient agreed by the system authority and depending on the design status

ultimate cryogenic temperature

maximum cryogenic temperature increased by the temperature margins agreed by the system authority and depending on the design status

High temperature range

high temperature range

temperature range above 470 K

ablation

chemical change and removal of surface material due to the action of external high temperature heating

Ablation consumes energy and provides a cooling effect in the underlying material level.

aerodynamic heating

intense heating by convection, radiation and re-combination effects, caused by fluid compression, typically occurring during atmospheric entry

allowable temperatures

maximum temperatures specified for thermally protected items to ensure the structure integrity

For example: Protected items are primary and secondary structures.

arc-jet test

testing method using electric discharge to produce a plasma

combined loads

combination of thermal and mechanical loads acting simultaneously on the TPS

hot structure

primary mechanical load carrying structure which is directly exposed to the high temperatures caused by aerodynamic flow

For example: Heat shield, nose cap, wing leading edges, control surfaces such as winglet, rudder and body-flap.

limit aero-thermal heat flux

maximum or minimum local heat flux values, or the most unfavourable simultaneous combination of the constituting terms (in the sense of maximizing or minimizing these heat fluxes) liable to be attained in the different areas of the vehicle during the normal service life for the corresponding mission instant

- 1 Limit aero-thermal heat flux applies to TPS and hot structures only.

- 2 Aero-thermal fluxes can be caused by molecular flow and can also act after fairing jettisoning or at very low attitudes at orbital velocities.

limit temperatures

maximum or minimum local temperatures of an exposed surface for a defined item resulting from the application of the least favourable heat fluxes histories expected on nominal missions inside the boundaries of limit fluxes

nominal aero-thermal heat fluxes

nominal local heat flux values expected for nominal mission and nominal atmospheric conditions

Nominal aero-thermal heat flux applies to TPS and hot structures only.

nominal temperatures

local temperatures of an exposed surface for a defined item resulting from the application of the nominal heat flux histories

plasma wind-tunnel

test method using a high temperature ionized medium flowing over the test item

protected structure

primary mechanical load carrying structure which is covered by a thermal protection layer exposed to the aerodynamic flow

thermal protection subsystem (TPS)

thermal control system to protect the spacecraft against aerodynamic heating

For example: Ablative materials, ceramic tile and shingle, CMC stand-off panel TPS, metallic TPS, flexible external insulation blanket, internal insulation, high temperature static and dynamic seals, high temperature assembly systems (i.e. tribology, hot fasteners).

ultimate aero-thermal heat fluxes

heat fluxes deduced from the limit heat fluxes upper boundary values through aero-convective upper boundary limit heat fluxes (launch and re-entry) multiplied by a safety coefficient

Ultimate aero-thermal heat flux applies to TPS and hot structures only.

ultimate temperature

local instantaneous temperature of an exposed surface for a defined item resulting from the application of ultimate flux histories

Abbreviated terms

For the purpose of this Standard, the abbreviated terms from ECSSSST-0001 and the following apply:

|

Abbreviation

|

Meaning

|

|

ABM

|

apogee boost motor

|

|

AIT

|

assembly, integration and test

|

|

AOCS

|

attitude and orbit control system

|

|

CCS

|

cryogenic control system

|

|

CMC

|

ceramic matrix composites

|

|

DRD

|

document requirements definition

|

|

DRL

|

document requirements list

|

|

ECLS

|

environmental control and life support system

|

|

EEE

|

electronic, electrical, electromechanical

|

|

EM

|

engineering model

|

|

EMC

|

electromagnetic compatibility

|

|

ESD

|

electrostatic discharge

|

|

FAR

|

flight acceptance review

|

|

FEM

|

finite element methods

|

|

FM

|

flight model

|

|

FOV

|

field of view

|

|

GMM

|

geometrical mathematical model

|

|

GSE

|

ground support equipment

|

|

H/W

|

hardware

|

|

HS

|

hot structure

|

|

I/F

|

interface

|

|

ICD

|

interface control document

|

|

LEO

|

low Earth orbit

|

|

LHP

|

loop heat pipe

|

|

LPM

|

lumped parameter method

|

|

MLI

|

multi layer insulation

|

|

OBDH

|

onboard data handling

|

|

PA

|

product assurance

|

|

PCM

|

phase change material

|

|

PMP

|

parts, materials, process

|

|

QA

|

quality assurance

|

|

QM

|

qualification model

|

|

RLV

|

reusable launch vehicle

|

|

RV

|

re-entry vehicle

|

|

S/C

|

spacecraft

|

|

S/W

|

software

|

|

STM

|

structural thermal model

|

|

TBT

|

thermal balance test

|

|

TC

|

thermocouple

|

|

TCS

|

thermal control (sub)system

|

|

TM

|

thermal model

|

|

TM/TC

|

telemetry, telecommand

|

|

TMM

|

thermal mathematical model

|

|

TPS

|

thermal protection system

|

|

TRP

|

temperature reference point

|

|

TV-Test

|

thermal-vacuum test

|

|

VCHP

|

variable conductance heat pipe

|

|

w.r.t.

|

with respect to

|

Requirements

General

The design of the TCS shall meet requirements of all mission phases, up to the end of the operating lifetime.

The specified environmental conditions are usually found in the system environmental specification.

Ground and pre-launch

The following conditions shall apply:

- integration and ground testing;

- storage, transport;

- functional checkout;

- waiting on launch pad;

- launch abort.

Thermal constraints related to the ground and pre-launch phases shall be agreed with the system authority and specified in Phase A of a project.

Space vehicle and GSE design shall accommodate specific requirements for thermal conditioning.

For example: thermal conditioning, heat pipe panel levelling fixtures, auxiliary fluid cooling loops, pre-launch conditioning of launcher.

Launch and ascent

The following conditions shall apply:

- worst case launcher boundary conditions (launch time and season; external environment);

- impact of depressurization;

- launch abort conditions;

- spacecraft under fairing;

- environment after fairing jettisoning up to separation (aero-thermal fluxes, solar and planetary fluxes, eclipses);

- ABM firing. Thermal requirements related to the launch and ascent phases shall be specified.

Planetary orbital phases

The TCS design shall use the following parameters, which relate to transfer, drift, commissioning and operational orbits:

- orbit radii (or heights) and eccentricity including its evolution in time;

- inclination and its evolution in time;

- ascending node angle and its evolution in time;

- maximum eclipse duration or argument of perigee;

- spacecraft orientation, w.r.t. sun, planet;

- relative movement of spacecraft items with respect to the main spacecraft body.

Examples of main spacecraft bodies are: solar array, and antennae.

Interplanetary phases

The TCS design shall use the following parameters for interplanetary phases:

- Spacecraft orientation w.r.t. external heat sources

Example of external heat sources are: sun, and planets.

- Relative movement of spacecraft items with respect to the main spacecraft body.

Examples of such spacecraft items are: solar array, and antennae.

Planetary natural environment

For earth and sun the natural environment as specified in ECSS-E-10-04, clause 6 shall apply.

For bodies other than the earth, the applicable natural environment shall be agreed with the system authority.

Docking, docked and separation phases

The TCS shall be designed for mission aspects during docking and separation manoeuvre as well as during a docked phase, including the following conditions:

- spacecraft orientation;

- firing of thrusters;

- shadowing effects;

- mutual radiative heat exchanges;

- reflected environmental fluxes;

- multiple reflections.

Descent, entry and landing

The TCS shall be designed for heat flux effects as well as transient phenomena during descent, entry and landing including:

- loss of MLI efficiency due to re-pressurization;

- heating and cooling effects due to the inlet of air and gas for re-pressurization;

- requirement for special heat sinks during descent.

Post-landing phases

The TCS design shall conform to the environmental conditions occurring at the landing site.

The TCS design shall include thermal conditioning during the post-landing phases.

For example: specific GSE.

The TCS design shall account for the heat load stored by the TPS during entry phases.

Performance

General

TCS performance requirements for all mission phases shall be specified and agreed with the system authority.

The mission phases shall be represented by a coherent set of thermal design cases covering the extreme range of conditions experienced by an item during its lifetime.

Dimensioning environmental design cases shall be defined and used for the development of the TCS design.

For the dimensioning environmental design cases hot and cold worst cases shall be used.

Minimum and maximum values for design temperatures shall be provided by the system authority.

Acceptance and qualification margins as defined in Figure 31 shall be defined by the system authority.

The TCS shall conform to the following requirements to be specified in the TCS specification:

- Temperature gradients

- Temperature stability

- Temperature uniformity

- Heat flux

- Heat storage

- Heat lift

- Electrical power allocation for heating and cooling

- TM/TC allocation for TCS parameter;

For requirements on TM/TC, see 4.3.5.

- Mass allocation for TCS.

High temperature range

Temperatures of all protected items shall not exceed the allowable temperatures defined by the system authority and specified in the TCS specification.

A TPS in the high temperature range shall:

- Respect the aero thermodynamic shape of the space vehicle.

For example: Steps, gaps, and roughness tolerances.

- Insulate the space vehicle to withstand the outer temperature range, limit temperature levels, temperature gradients and heat flows on the protected elements.

- Support mechanical and thermo-mechanical loads.

- Include venting in order to withstand the pressure decrease and increase encountered during ascent and re-entry.

- Avoid hot gas ingress (i.e. aero thermodynamic sneak flows) into structure and internal equipments.

- Withstand on-ground and in-orbit natural environments.

- 1 For reusable re-entry vehicles additional requirements for on-ground and in-orbit maintenance (inspection, repair and replacement) can be specified at system level.

- 2 For fracture control requirements see ECSS-E-ST-32-01 and fracture control DRDs in ECSS-E-ST-32.

- 3 For re-usable TPS cases the number of ascent/entry cycles need to be specified.

Cryogenic temperature range

The Cryogenic Control System (CCS) shall meet the allowable temperatures defined by the system authority and specified in the CCS specification.

For the design of the CCS radiators, the ultimate cryogenic temperature shall be applied.

For the design of the CCS stirling and pulse tube coolers, the ultimate cryogenic heat load shall be applied.

For the design of the CCS all other coolers and cooling chains, the application of the ultimate cryogenic heat load or ultimate cryogenic temperature shall be defined for each thermal I/F and agreed with the system authority.

The CCS design shall meet requirements for cool down from non-operating maximum temperature down to nominal cryogenic temperatures

Functionality

Functional requirements for the TCS shall be specified at system level.

For example: Function in any orientation, under specified gravity and acceleration environment.

Requirements towards other subsystems

General

The following requirements shall be agreed and included in the TCS specification:

- requirements from other subsystems affecting the TCS;

- requirements from TCS on other subsystems.

Requirements shall be defined in the TCS interface control document in conformance with the DRD of Annex D.

The TCS interface control document shall be delivered to the system authority for approval.

Mechanical

The TCS shall be designed respecting spacecraft configuration and layout, including the following information for each item in the applicable ICD:

- Dimension and mass

- Materials and heat capacities

- Fixation and mounting techniques

- Contact area

- Surface characteristics

For example: Treatment, planarity and roughness.

- Alignment requirements

- Forbidden zones

For example: instrument FOV and operational range of mechanism.

- Connector locations

- Available area for fixation of thermal hardware

For example: heaters and MLI.

- Spacecraft harness.

In case of an unacceptable or unbalanced concentration of heat dissipation, the TCS can propose changes to the spacecraft configuration layout.

The TCS shall conform to mechanical loads during mission phases as identified by structural analysis.

Mechanical stability requirements are specified at system level.

The TCS hardware configuration and layout shall be defined in the thermal ICD, including TCS specific forbidden zones.

- 1 For example, unobstructed radiation to space, and radiator deployment range.

- 2 For the TCS ICD, see Annex D.

Electrical

The TCS shall fulfil specific requirements considering the heat dissipation profiles of all items on the spacecraft including energy dissipated in any cabling;

The TCS shall fulfil specific requirements considering type and routing of the harness, grounding, electrical conductivity.

Propose changes to the layout, routing, and external wrapping of any harness and cabling, so as to avoid unacceptable or unbalanced concentration of heat dissipation;

The TCS shall specify for electrical TCS items the power consumption, peak and average power, duty cycle

The TCS shall comply with the specified voltage and voltage variation;

The TCS shall meet grounding and EMC requirements for TCS items.

AOCS

Propulsion

The TCS design shall fulfil requirements considering heat fluxes due to plume interaction and the temperature profiles of the thruster components during operation of a thrusters.

Examples of thruster components are: nozzle, and heat shield.

The TCS shall be designed for effects of heat soak after firing of thrusters.

TCS shall agree with the system authority modifications of thruster operation for the case that temperatures of thruster components are predicted to be not acceptable.

Attitude control

Attitude requirements affecting the TCS design shall be specified at system level.

For example: Specified momentum for mechanical pumps in fluid loops.

In case of a thermally unacceptable attitude, the TCS shall agree with the system authority alternative attitudes and lay out.

TM/TC

TM/TC channel requirements allocated to the TCS shall be specified at system level.

Requirements can include accuracy, measurement frequency, downlink or uplink frequency, on-board or ground data handling and override capability

The TCS shall specify:

- The telemetry channels to monitor spacecraft temperatures, TCS temperatures, pressures, flow rates, voltages. currents, and switch status.

For example: Voltage for heaters, or currents for Peltier elements.

- All ground or onboard controlled telecommand channels for the operation of the TCS.

OBDH and S/W

TCS related OBDH and software requirements, and requirements to implement TCS features into the data handling subsystem, shall be specified by the TCS and agreed with the system authority.

For example: Heater control laws, and temperature sensor calibration data.

Launcher

TCS shall derive and agree with the system authority requirements related to the launcher interface based on the launcher ICD.

This is particularly important for:

- launcher envelope both for static and dynamic conditions, including ventilation effects;

- accessibility requirements;

- launch-pad air - conditioning requirements;

- launcher depressurization profile;

- heat fluxes from the fairing and to the launcher interface;

- heat flux from the spacecraft to the launcher.

GSE

GSE interface requirements related to TCS shall be specified in the GSE specification of the project.

TCS specific requirements for ground support equipment shall be specified by the thermal control subsystem.

The TCS design shall permit GSEs to interface the S/C at the specified locations.

ECLS

The TCS shall conform to requirements of ECLS.

Design

General

The TCS design shall meet the thermal mission requirements of clause 4.1, the thermal performance requirements of clause 4.2, the interface requirements to other subsystems of 4.3.

The TCS design shall make use of materials and design features compatible with the environmental factors expected during all mission phases including possible effects and degradations.

Degradation can be caused by wear, mechanical loads, test environment, and in-orbit environment (e.g. ATOX, UV, and radiation).

The TCS design shall be documented in the TCS detailed design document in conformance with the DRD of Annex F.

Reliable properties of materials and their degraded values under the specified environment shall be used in the design.

If suitable data are not available, then a material test programme shall be implemented.

Budget allocation

The TCS shall define for system approval budgets for mass, size, power, energy, TM/TC channels and operational aspects throughout the TCS life cycle.

Parts, materials and processes (PMP)

The TCS design shall use space qualified parts, materials and processes.

For example: Preferred PMP list.

An acceptance or qualification programme shall be performed in agreement with the system authority for parts, materials or processes, which have not yet reached a space-qualification status.

Declared materials, mechanical parts and processes lists shall be produced according to the Declared material list (DML) DRD specified in ECSS-Q-ST-70.

EEE components

The TCS design shall use space qualified EEE components.

An acceptance or qualification programme shall be performed in agreement with the system authority for EEE components, which have not yet reached a space-qualification status.

Lifetime

The TCS design shall conform to the total lifetime covering expected combinations of the mission phases.

Predictability and testability

The TCS shall be designed such that conformance to performance requirements of clause 4.2 can be demonstrated by thermal analyses and thermal test.

Modularity of the TCS design can facilitate its predictability and testability.

Flexibility

The TCS design shall incorporate flexibility to

- accommodate modifications of requirements imposed on the TCS during the project development phase;

- offer trimming capabilities to accommodate late requirement updates.

Integration and accessibility

Layout and design of the TCS hardware shall provide without performance degradation accessibility to allow for integration, mounting / de-mounting, inspection and maintenance of items, during AIT and during flight.

Reliability

The allocated reliability figure for the TCS shall be specified at system level.

The TCS shall demonstrate by analysis and test that the allocated reliability figure is met.

Reliability requirements for the design of individual TCS items shall be specified and verified.

These reliability requirements can be met by introducing adequate redundancy features;

The TCS shall meet system requirements w.r.t. single point failures.

For the reduction of risk at subsystem level, see ECSS-M-ST-80 “Risk management”.

Interchangeability

Interchangeability requirements to be met by TCS shall be specified at system level.

Maintenance

The TCS shall specify maintenance procedures.

Operational maintenance during in-orbit phases shall be avoided.

Safety

For safety, see ECSS-Q-ST-40.

For hazard analysis, see ECSS-Q-ST-40-02.

Availability

A plan for an in-time availability of resources, including long lead items and items with limited lifetime shall be agreed with the system authority.

Verification

Overview

For general requirements on verification of the TCS, see ECSS-E-ST-10-02 and ECSS-E-ST-10-03.

Verification requirements specific to TCS

All temperature ranges

Verification by analysis shall be performed through thermal analytical modelling and corresponding performance predictions.

The cases to be verified by analysis shall be agreed with the system authority.

- 1 Verification by analysis is the selected verification method for cases where fully representative testing cannot be performed.

- 2 For example: Environmental and dimensional limitations of the test facilities.

- 3 For example: Behaviour of TCS items under reduced or increased gravity.

Verification by analysis shall take into account uncertainties.

Uncertainties of lower than 10 K are generally not applied before verification by a TBT is performed.

Thermal and geometrical models shall be defined in a Mathematical Model Specification in conformance with the DRD of Annex A.

Thermal and geometrical models used for analysis shall be documented in the Thermal and Geometrical Model Description in conformance with the DRD of Annex B.

For each thermal analysis a TCS analysis report shall be produced in conformance with the DRD of Annex C.

Conformance to specified performance shall be demonstrated by performing thermal balance, thermal vacuum and climatic tests.

Test conditions shall be agreed with the system authority and included in the system test plan.

Verification testing of the TCS shall include, mechanical, electrical and hydraulic testing to be defined in test specifications.

Temperatures at the TRP shall be used to verify requirements by analysis and test.

CCS

A CCS shall be verified by testing at instrument and subsystem level.

Objectives and set-up for tests on CCS shall be agreed with the system authority and specified in the Verification Plan according to ECSS-E-ST-10-02.

- 1 Important inputs for the test objectives are the CCS interfaces.

- 2 Testing at cryogenic temperatures is usually first performed in a specialized laboratory.

High temperature TPS

Thermal tests on thermal protection items shall be agreed with the system authority and specified in the Verification Plan in conformance with its DRD specified in ECSS-E-ST-10-02.

Thermal protections shall be tested in association with the supporting structure and equivalent mock-ups (sub-element), in order to provide representative thermal interface conditions.

For the cases where full verification by test is not performed the following requirements shall apply and agreed with the system authority:

- Introduction of simplified and separated test cases including nominal and worst case scenarios.

- Clear identification of unknown data and justification of assumptions taken for test prediction.

Examples of unknown data: Heat flux, catalycity, emissivity.

- The methods and processes to use test results and extrapolate to actual flight conditions.

- 1 In addition to classical means, plasma wind-tunnel (e.g. arc-jet) and high temperature radiation test methods may be used.

- 2 This applies to cases, for which flight conditions are not sufficiently specified and where verification by test is not appropriate (e.g. due to the size of the test object or lack of environment representativity).

Thermal balance test (TBT)

Test performance

TBT requirements shall be defined in the TCS thermal balance test specification in conformance with the DRD of Annex E.

TBT test procedures and test report shall be produced in conformance with its DRDs specified in ECSS-E-ST-10-03 and ECSS-ST-E-10-02, respectively.

For TCS items controlled by radiative and conductive heat exchange, a thermal balance test shall be performed in order to:

- provide data for the verification of the thermal mathematical model as part of the TCS qualification,

- demonstrate the suitability of the TCS design,

- verify the performance of TCS hardware, and

- provide data about sensitivity of the TCS design with respect to parameter changes.

- 1 For example, heat dissipation

- 2 TB testing is generally performed on items at high integration levels, such as spacecraft, service module, payload module or instruments.

The test instrumentation and the test set-up to be used shall be defined in the test specification (in conformance with Annex E) and agreed with the system authority;

For example: Temperature sensors and heaters with adequate number and position.

The TBT shall provide accurate and reliable input data for the thermal model correlation.

Analysis shall be performed to predict the thermal balance test results, and documented in an analysis report in conformance with the DRD of Annex C.

Two different steady-state test cases shall be performed.

A transient case shall be included for items sensible to dynamic behaviour.

The solar environment to be applied for solar simulation, and the cases where solar simulation is used, shall be agreed with the system authority.

- 1 Generally this is performed when the thermal behaviour is governed by the solar environment and the analytical verification poses unknown uncertainties.

- 2 For example: Items with complex geometry, shape, apertures and with specular reflective coatings.

Critical hardware items and interfaces shall be flight representative.

Parasitic radiative and conductive heat loads between test item and test surroundings shall be determined and the influence on the test results analytically verified.

Test success criteria

For TBT the following test success criteria shall be applied:

- Test conditions defined in the TBT specification specified in Annex E, and TBT Procedure specified in the test procedure DRD of ECSS-E-ST-10-03 are met.

- Performance parameters as predicted by analysis for the TBT are verified.

Example of performance parameters are temperatures, temperature levels, gradients, differences, and variations.

- Resources specified in the TCS specification have not been exceeded.

For example, heater power, battery energy in an eclipse case.

Steady-state condition shall be declared when for stable dissipation modes temperature sensor readings meet a temperature variation over a period of time defined in the TBT test procedure and agreed by the system authority.

- 1 Besides the classical TBT with steady state conditions additional tests can be performed with operating active heating / cooling regulation.

- 2 For the TBT test procedure, see Table 51.

Correlation success criteria

Test correlation shall be performed for

- Steady – state modes

- Transient modes.

For test correlation of transient modes specific success criteria and mathematical rules need to be defined.

Test correlation for units shall be based on each TRP as defined in the ICD.

This requires that temperature sensors be placed on each TRP.

A correlation shall be declared successful, when the following requirements are met after test correlation:

- Deviations between measured and predicted temperatures are within specification.

This can include temperature gradients, temperature differences, temperature variations

- The temperature mean deviation is as specified.

- The temperature standard deviation is as specified.

- 1 Temperature mean and standard deviations are defined in clauses 3.2.1.30 and 3.2.1.33.

- 2 Temperature deviations are specified in the TCS specification. Typical values are:

- Temperature deviation for internal units <5K, for external units <10K

- Temperature mean deviation within ±2K

- Temperature standard deviation <3K, 1

- 3 In order to obtain statistically meaningful results the number of correlated temperatures for calculation of mean and standard deviations is typically >25.

- Deviations between measured and predicted heating/cooling power are within specifications

Production and manufacturing

Procurement

Procurement shall be performed against purchase orders, conforming to requirements of system authority specifications.

Successful manufacture of space thermal hardware relies on the supply of qualified and approved materials, parts and processes.

For procurement of materials, the requirements of ECSS-Q-ST-70 clause 5.6 shall apply.

For procurement of mechanical parts, the requirements of ECSS-Q-ST-70 clause 6.6 shall apply.

Quality assurance requirements for procurement as specified in ECSS-Q-ST-20 clause 5.4 shall apply.

The thermal hardware shall be procured in accordance with the specifications provided by the TCS to lower-level supplier(s) or manufacturer(s).

Integration of hardware at system and sub-system level can be part of the procurement process.

Manufacturing process

Manufacturing procedures approved by the customer shall be used.

The number of samples to be manufactured for evaluation and testing shall be agreed with the customer.

The number of prototypes, components, representative sections or whole thermal hardware to be manufactured shall be agreed with the customer, in order to

- prove manufacturing processes and procedures;

- test and evaluate;

- determine and prove the adequacy of applied inspection procedures.

Quality assurance requirements for manufacturing as specified in ECSS-ST-Q-20 clause 5.5 shall apply;

Requirements for production of design and manufacturing drawings shall be specified at system level.

For example: Identification, configuration control.

Quality management

Requirements for implementation of a quality assurance programme as specified in ECSS-Q-ST-20, clause 5.1.1.shall apply.

Cleanliness and Contamination

Requirements for implementing a cleanliness and contamination control programme as specified in ECSS-Q-ST-70-01 clause 5.1 shall apply.

Requirements for contamination control during the product life cycle as specified in ECSS-Q-ST-70-01 clause 5.2 shall apply.

Requirements for TCS cleanliness and contamination control can be part of the system cleanliness and contamination control plan.

TCS shall define cleanliness requirements for TCS H/W.

Integration

Procedures for all levels of integration shall be defined, including:

- integration instructions;

- preparation;

- support equipment and tooling;

- method;

- cleaning;

- verification;

Identification and Marking

Marking of thermal hardware shall be performed according to ECSS-M-ST-40, clause 5.3.1.5.

Packaging, handling, transportation

Requirements for packaging, handling, transportation and monitoring shall be specified and implemented in order to prevent any degradation of thermal hardware.

Items containing hazardous material or those subjected to special packaging, handling and transportation shall be identified.

Storage

Storage conditions shall not cause any degradation to the thermal hardware.

Storage devices and storage procedures shall be defined.

For example: Periodical inspections, and functional checks.

Repair

Repair procedures shall be established.

Repair tools and material shall be defined.

In-service requirements

The TCS shall support the system during spacecraft commissioning and operational phases, special events and in-orbit anomalies and shall provide input to the operational documentation.

For example:

- Thermal mathematical models for thermal simulation of the spacecraft;

- De-freezing of fluid systems.

The CCS shall support in-orbit operations by providing capabilities to: - adjust cooler operational parameters to compensate for any degradation of the CCS and change in environment.

- de-contaminate cryogenic areas where condensables lead to deterioration of the CSS and affect the system performance.

For example: Radiators at cryogenic temperatures

Product assurance

Product assurance requirements for TCS are specified at system level and agreed with the system authority based on requirements of ECSS-Q-ST-20, ECSS-Q-ST-40, and ECSS-Q-ST-70.

Deliverables

General

Items to be delivered during the course of a project shall be specified in the subsystem statement of work.

- 1 For example, hardware, software, models and documents.

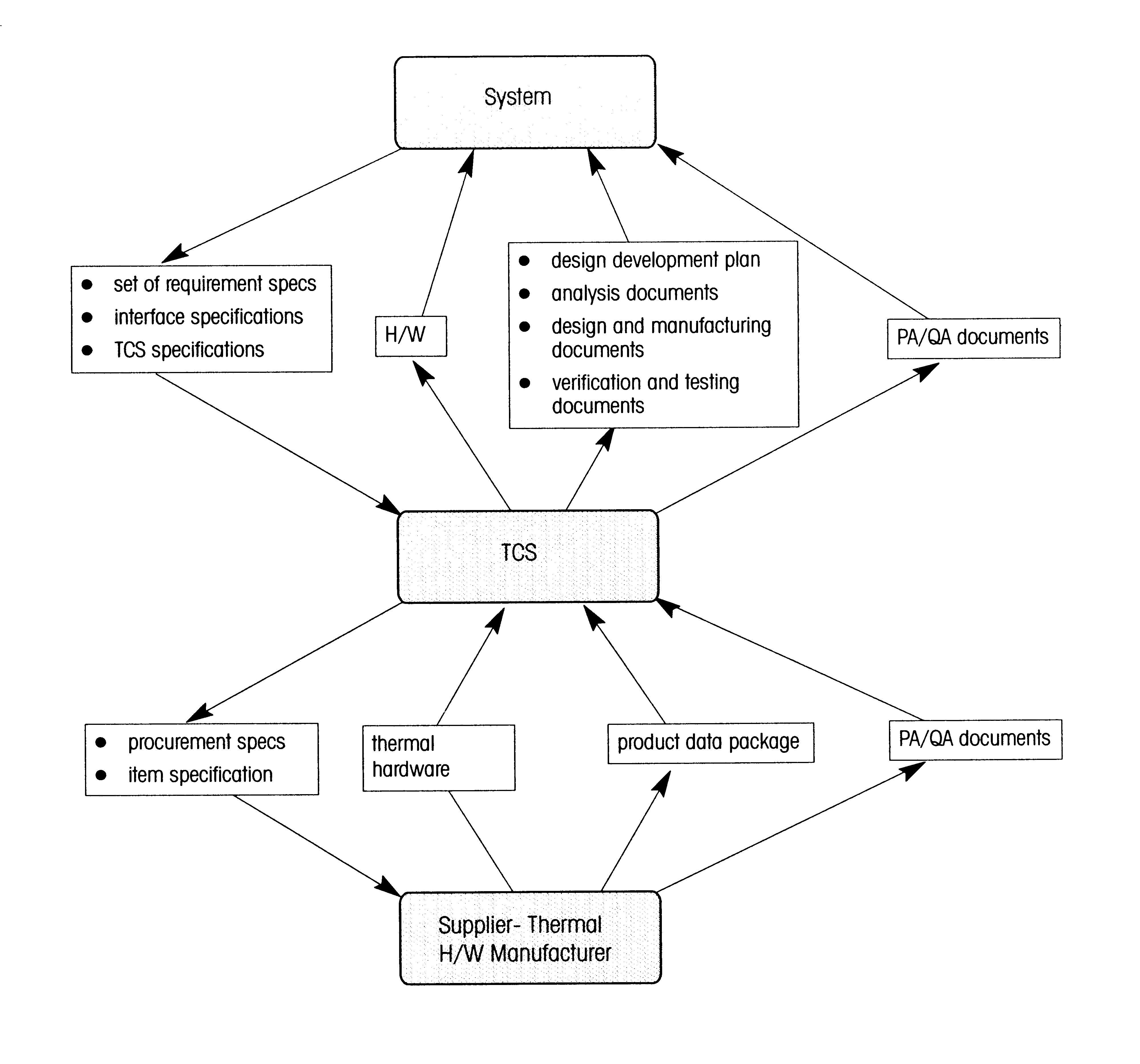

- 2 Figure 41 shows schematically the product exchange between different levels of a project, i.e. system, TCS, supplier and thermal hardware manufacturer.

Hardware

Hardware shall be delivered according to specification provided by the TCS responsible and approved by the system authority at the beginning of the project.

Example of hardware to be delivered:

- thermal hardware for different models (e.g. STM, EM, QM and FM);

- hardware for sample tests;

- spare and repair thermal hardware;

- ground or integration support hardware.

Documentation

The TCS shall be documented in accordance with the approved TCS specification and statement of work.

The TCS supplier shall deliver the documentation as detailed in Table 51.

The TCS shall provide following inputs to higher level documents:

- AIV plan;

- design and development plan;

- drawings;

- interface requirements document;

- technical specifications for other S/S and components;

- test plan;

- verification control document;

- PMP lists;

- Operation Documentation (user manual, ground segment and on-board software user requirement documents);

- Budgets / resources;

- Design Justification File;

- Design Definition File.

Figure 41: Product exchange between the system, TCS and the supplier or manufacturer

Figure 41: Product exchange between the system, TCS and the supplier or manufacturer

Mathematical models

Mathematical models shall be delivered according to TCS mathematical model specification.

For the TCS mathematical model specification, see Annex A.

Mathematical models shall be provided to the system authority for approval.

The thermal and geometrical model description shall be delivered in conformance with Annex B.

Document requirements definitions (DRD) list

ECSS Standards specify the production and use of project documents. Document requirements definitions are defined to control the content of the project documents.

Document requirements definitions serve to ensure:

completeness and consistency of information within the documents,

that the information contained in the document conforms to its defined scope, and correctly implements its interfaces with other documents, and

that portions of a document can be generated or maintained by separate organizational groups and seamlessly integrated into a coherent whole.

Table 51 lists and summarizes the DRDs that are called up in the previous clauses and that are defined in annexes of this Standard or other relevant Standards.

Table 51: ECSS-E-ST-31 DRD list

|

Document title

|

Summary

|

Phase

|

DRD ref.

|

Remarks

| ||||||||

|

0

|

A

|

B

|

C

|

D

|

E

|

F

| ||||||

|

MDR

|

PRR

|

SRR

|

PDR

|

CDR

|

QR

|

AR

|

|

MCR

| ||||

|

Mathematical Model Specification

|

Specifies requirements for development and delivery of thermal mathematical models to be used for thermal analysis at system level

|

|

|

|

X

|

X

|

|

|

|

|

E-ST-31

|

|

|

Thermal and geometrical model description

|

Describes the TMM and GMM to be used as input for the sub-system thermal analysis cases

|

|

X

|

X

|

X

|

X

|

X

|

X

|

|

|

E-ST-31

|

To be updated before each analysis campaign

|

|

TCS analysis report

|

Contains a full mathematical analysis of the thermal control system leading to the thermal subsystem definition including redundancy strategy, operational concept and hardware definition

|

|

X

|

X

|

X

|

X

|

X

|

X

|

X

|

|

E-ST-31

|

Document to be updated or re-issued for CDR, AR, TBT prediction, TBT evaluation, Flight prediction

|

|

TCS interface control document

|

Describes the thermal control subsystem interfaces to other subsystems and to the system

|

|

X

|

X

|

X

|

X

|

X

|

X

|

|

|

E-ST-31

|

To be updated at CDR and AR

|

|

TCS thermal balance test specification

|

Describes the requirements applicable for the thermal balance test including purpose, test approach and test article

|

|

|

|

|

X

|

|

|

|

|

E-ST-31

|

Can be combined with the system thermal vacuum (TV) test specification

|

|

TCS detailed design description

|

Describes the detailed design of the thermal control subsystem

|

|

|

X

|

X

|

X

|

|

|

|

|

E-ST-31

|

Possible update for phase D

|

|

TCS thermal balance test procedure

|

Gives directions for conducting the thermal balance test in terms of description, resources, constraints and step-by-step procedure

|

|

|

|

|

X

|

|

|

|

|

E-ST-10-02

|

Before TBT

|

|

TCS thermal balance test report

|

Describes the execution of the thermal balance test and the results obtained

|

|

|

|

|

X

|

|

|

|

|

E-ST-10-02

|

After TBT

|

|

TCS declared materials list

|

Establishes the detailed record of all the materials used to produce the products of the thermal control subsystem

|

|

X

|

X

|

X

|

X

|

|

|

|

|

Q-ST-70

|

First formal delivery at PDR

|

|

TCS declared mechanical parts list

|

Establishes the detailed record of all the mechanical parts used to produce the products of the thermal control subsystem

|

|

X

|

X

|

X

|

X

|

|

|

|

|

Q-ST-70

|

First formal delivery at PDR

|

|

TCS declared process list

|

Establishes the detailed record of all the processes used to produce the products of the thermal control subsystem

|

|

X

|

X

|

X

|

X

|

|

|

|

|

Q-ST-70

|

First formal delivery at PDR

|

ANNEX(normative)TCS mathematical model specification - DRD

DRD identification

Requirement identification and source document

This DRD is called from ECSS-E-ST-31, requirement 4.5.2.1d.

Purpose and objective

The TCS mathematical model specification specifies requirements for development and delivery of mathematical models to be used for thermal analysis.

Expected response

Scope and content

Introduction

The TCS mathematical model specification shall contain a description of the purpose, objective, content and the reason prompting its preparation.

For example:

- This document specifies the requirements for the delivery of subassembly mathematical models to the system authority to be used for system analysis.

- This document specifies requirements for reduced thermal mathematical models to be delivered by sub-contractors and unit suppliers. The models are introduced in the global mathematical model of the spacecraft in order to calculate satellite thermal performance at system level.

Any open issue, assumption and constraint relevant to this document shall be stated and described.

Applicable and reference documents

The TCS mathematical model specification shall list the applicable and reference documents in support to the generation of the document.

Definitions and abbreviations

The TCS mathematical model specification shall list the applicable directory or glossary and the meaning of specific terms or abbreviations utilized in this document.

Definition of subassemblies, interfaces and nodal breakdown

The TCS mathematical model specification shall specify the subassemblies, for which mathematical models are required.

The TCS mathematical model specification shall define conductive, convective and radiative interface nodes and their characteristics.

Node number and node identification

The maximum number of nodes for a subassembly model shall be given.

A method of identification and numbering of nodes shall be presented.

For example: Each node is identified by 5 digits with the following meaning:

- X indicates the type of hardware, i.e. 1 for MLI, 2 for primary structure, 3 for secondary structure, etc.

- Y indicates the subassembly or the external element, to which the node belongs;

- ZZZ indicates the sequence of nodes in the mathematical model.

Modelling rules

The model hierarchy shall be described.

For example: Level 1 satellite, level 2 subsystem, level 3 assembly, level 4 units

The document shall describe the applied modelling rules for thermal items

For example: Dissipative items (e.g. number of nodes), MLI, thermal protection, fluid piping, and heat pipes.

Control algorithms for thermal components shall be described.

- 1 For example, delivery of thermal data necessary to simulate the deported items in the System TMM.

- 2 Example of such thermal components are thermostats, heater, pumps, and coolers.

Software tools

The software tools to be used for development of the mathematical models shall be described.

- 1 The software to be used for the preparation and delivery of GMM's should be ESARAD or THERMICA.

- 2 The software to be used for the preparation and delivery of TMM's should be ESATAN.

Test cases

The thermal mathematical model shall be delivered together with the definition and results of representative test cases.

Special remarks

None.

ANNEX(normative)Thermal and geometrical model description - DRD

DRD identification

Requirement identification and source document

This DRD is called from ECSS-E-ST-31, requirement 4.5.2.1e.

Purpose and objective

The objective of this document is to describe the thermal mathematical models (GMM and TMM) used for thermal analysis.

Expected response

Scope and content

Introduction

The thermal and geometrical model description shall contain a description of the purpose, objective, content and the reason prompting its preparation.

Any open issue, assumption and constraint relevant to this document shall be stated and described.

Status and limitations of the models shall be described in detail.

Applicable and reference documents

The thermal and geometrical model description shall list the applicable and reference documents in support to the generation of the document.

Definitions and abbreviations

The thermal and geometrical model description shall list the applicable directory or glossary and the meaning of specific terms or abbreviations utilized in this document.

Geometrical mathematical model

The document shall describe geometrical models used for thermal analysis (including identification of surfaces, external geometry, model lay out).

The document shall describe input data and modelling assumptions for view-factor and external flux calculation.

For example: Environment, geometry description, thermo-optical properties, insulated and non-insulated areas, moving bodies.

The document shall describe input data referenced to a coordinate system as agreed in relevant system ICDs.

Heat input shall be presented separately for

- Solar radiation

- Planet albedo radiation

- Planet infrared emission. Geometrical interfaces between spacecraft and appendices or bodies used in the radiative calculation and not directly related to the spacecraft shall be described.

For example: Module and ISS, spacecraft and solar array, spacecraft and test facility.

Tools (including version) and computer environment used for establishing geometrical models shall be described.

Thermal mathematical model

A complete set of input data for a thermal mathematical model (including additional heat fluxes not derived by the GMM) shall be described including all passive and active thermal control features.

The Modelling characteristics of active components and interfaces of sub-models to the main spacecraft model shall be described.

For example: Mechanical pump, two-phase loops, varying conductance devices, heater control

The model description shall contain in detail

- Model breakdown structure

- Node numbering hierarchy

- Node properties

E.g. heat capacity, area, and dissipation

- Conductive, radiative and convective couplings

- Graphical representation of the model

In case model reduction techniques are being applied, these techniques shall be described and the validity of the reduced model justified.

Tools (including version) and computer environment used for establishing thermal models shall be described.

Modelling constraints and critical implementation issues shall be described and their relevance on analysis shall be indicated.

Model checks

Results of performed checks of TMM and GMM shall be presented.

Files and lists

The following information, in a format as agreed with the system authority, shall be attached to the document as annexes:

- Identification of delivered computer files,

- GMM and TMM source lists based on applied tools. Documentation

Model descriptions for GMM and TMM shall be delivered, which contain:

- General description of the models

- Diagrams allowing better understanding of the models

For example, external geometry and views of the model layout.

- Test case description

- Number of rays used for radiative coupling calculation

- Average and maximum accuracy obtained by the radiative coupling calculation

- Number of rays used for external fluxes calculation

- Number of orbital positions for external fluxes calculation

- Relaxation factor for TMM

- Time step used in the transients

- Listings containing all the models data (model input files)

- Test calculation results

- Convergence criteria for TMM calculation. Models data and test calculation results shall be delivered as electronic file.

Special remarks

None.

ANNEX(normative)TCS analysis report - DRD

DRD identification

Requirement identification and source document

This DRD is called from ECSS-E-ST-31, requirement 4.5.2.1f and 4.5.3.1f.

Purpose and objective

The TCS analysis report is produced by the thermal control subsystem supplier to gather and document the results of analysis. The first issue is produced for the Phase A and updated throughout the project as further thermal control subsystem analysis and testing is carried out. The present DRD is also used to present test prediction and correlation with respect to major subsystem tests, such as Thermal Balance Test as well as for thermal control system flight prediction.

The results of all analysis including test prediction and correlation carried out at subsystem level are reported in TCS analysis report. The documents are therefore critical for tracking the development of the thermal control subsystem throughout the project, ensuring that the TCS continues to meet the functional and performance requirements as the design and implementation are elaborated.

Expected response

Scope and content

Introduction

The TCS analysis report shall contain a description of the purpose, objective, content, assumption and constraint and the reason prompting its preparation.

Any open issue relevant to the TCS analysis report shall be stated and described..

Applicable and reference documents

The TCS analysis report shall list the applicable and reference documents in support to the generation of the document.

Definitions and abbreviations

The TCS analysis report shall list the applicable directory or glossary and the meaning of specific terms or abbreviations utilized in this document.

Subsystem status

Each issue of the TCS analysis report shall define the underlying design status of the TCS (development-, test-, qualification-, protoflight-, flight- model).

Each issue of the TCS analysis report shall identify / evaluate analysis constraints with respect to in-orbit configuration.

Requirements review

The report shall contain a list of subsystem requirements to be met by analysis.

Overview of analysis approach

The TCS analysis report shall provide an overview of the analysis approach applied to the TCS.

The TCS analysis report shall describe the different analysis techniques used.

The TCS analysis report shall include a description of tools used to carry out the analysis.

The TCS analysis report shall refer to GMM and TMM used for each analysis case.

Description of thermal analysis cases

The description shall include a list of assumptions made concerning the thermal control subsystem and its environment during the analysis.

The description shall include a list of all input data including starting conditions for the analysis cases.

The description shall include a justification of assumed uncertainties.

Results of analysis

The TCS analysis report shall include the results of the analyses represented as diagrams, temperature mapping, detailed comparison to requirements, heat balance.

The TCS analysis report shall include a compliance matrix for applicable requirements.

The results of the analysis shall be presented as electronic file as agreed with the system authority.

Assessment and conclusions

The TCS analysis report shall summarize the analysis results and the comparison with the requirements.

The TCS analysis report shall provide an overall assessment.

The requirement closeout may be summarized in dedicated tables to be prepared for each involved requirement or a group of requirements.

For examples see ECSS-E-HB-10-02.

Any open issue shall be clearly stated and described.

Based on analysis results recommendations for design changes and adaptations at subsystem and system level shall be formulated.

Special remarks

None.

ANNEX(normative)TCS interface control document - DRD

DRD identification

Requirement identification and source document

This DRD is called from ECSS-E-ST-31, requirement 4.3.1b.

Purpose and objective

The TCS interface control document specifies interfaces of thermal control hardware to other subsystems and to the system. It contains mechanical, electrical, operational, handling, accommodation and safety requirements and constraints.

The first draft version of the TCS interface control document is produced for the PDR and updated issues follow for major project reviews (CDR, FAR). Tailored TCS interface control document versions are derived for spacecraft development and test models.

The content of this document can be merged with the TCS design description of Annex F.

Expected response

Scope and content

Introduction

The TCS interface control document shall contain a description of the purpose, objective, content and the reason prompting its preparation.

Any open issue, assumption and constraint relevant to this document shall be stated and described.

Applicable and reference documents

The TCS interface control document shall list the applicable and reference documents in support to the generation of the document (in particular thermal item ICDs at lower level).

Definitions and abbreviations

The TCS interface control document shall list the applicable directory or glossary and the meaning of specific terms or abbreviations utilized in this document.

Presentation of interface control requirements

TCS interfaces shall be defined in an interface control document (ICD), which includes interface control drawings.

Interface control drawings

Reference shall be given to subsystem specific ICDs to be delivered as separate package.

The thermal interface control drawing shall contain:

- location of thermal hardware within the spacecraft,

- identification of thermally relevant surface properties,

- identification of insulated areas including insulation fasteners,

- location of heaters, thermostats, sensors (test, flight configuration),

- thermally dictated mounting provisions (identification of interface filler, number of mounting bolts and torque, MLI mounting provisions),

- location of temperature reference points,

- definition of specific interfaces of thermal fluidic systems,

- mechanical, electrical, handling and accommodation requirements as far as presentable in drawings,

- critical interfaces to other subsystems, to the system and the launcher. Thermal interfaces

The TCS interface control document shall list thermal interface data, including:

- temperature ranges, gradients and variations for mission phases;

- environmental loads (external fluxes and environmental temperatures);

- boundary temperatures and heat fluxes;

- thermal interface conductance. Mechanical interfaces

The TCS interface control document shall list mechanical interface data including:

- Dimensions, mass, material and surface properties of thermal hardware

- Quality of thermally relevant surfaces

For example: Roughness, flatness.

- Properties of thermally relevant components, which are under the responsibility of other subsystems

For example: Brackets, face sheets of sandwich.

- Subsystem mass budget. Electrical interfaces

The TCS interface control document shall list the following electrical interface data:

- Power consumption of thermal components and electrical subsystem budget

- Interfaces of thermal control electrical units

For example: Redundancy, voltage, resistance, feed wire characteristic of heaters, pumps, temperature sensor and Peltier elements.

- Layout schematics for thermal control electrical circuitry.

For example: Heater circuits, switches, feedback control, sensors.

Data handling and monitoring interfaces

The TCS interface control document shall identify TM / TC interfaces and provide a list of on-board and ground control parameters.

For example: Temperature range, precision, resolution, regulation thresholds, alarm settings.

Operation, handling, maintenance and safety

The TCS interface control document shall identify the following thermal hardware constraints with respect to operation, handling and maintenance:

- Operational constraints of thermal control components.

For example: Heat pipe unit and heat pipe system operation at different temperatures and tilt, minimum start-up power of two-phase loops, dry-run capabilities of mechanical pumps.

- Accommodation constraints of thermal control hardware.