Space engineering

Multipactor design and test

Foreword

This Standard is one of the series of ECSS Standards intended to be applied together for the management, engineering, product assurance and sustainability in space projects and applications. ECSS is a cooperative effort of the European Space Agency, national space agencies and European industry associations for the purpose of developing and maintaining common standards. Requirements in this Standard are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards.

This Standard has been prepared by the ECSS-E-ST-20-01C Working Group, reviewed by the ECSS Executive Secretariat and approved by the ECSS Technical Authority.

Disclaimer

ECSS does not provide any warranty whatsoever, whether expressed, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item are error-free. In no respect shall ECSS incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this Standard, whether or not based upon warranty, business agreement, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by ECSS.

Published by: ESA Requirements and Standards Office ESTEC, P.O. Box 299, 2200 AG Noordwijk The NetherlandsCopyright: 2020© by the European Space Agency for the members of ECSS ## Change log

|

ECSS-E-20-01A

|

First issue

|

|

ECSS-E-ST-20-01A Rev.1

|

First issue, Revision 1

|

|

ECSS-E-ST-20-01C

|

Second issue

|

Introduction

In the context of increased RF power and equipment or component miniaturization, more and more attention shall be paid to multipactor which is critical for space missions based on satellite telecommunication or navigation payloads, or active microwave instruments for Earth Observation or Science. The multipactor phenomenon is an electron avalanche discharge occurring in high vacuum initiated by primary electrons inside a RF component in presence of a high local RF voltage or electric field.

In order to verify by analysis that a RF equipment or component is multipactor free, accurate EM modelling tools are required. These tools need more and more computation resources to cope with RF equipment or components with complex geometries, advanced manufacturing techniques, new materials and processes, and complex RF signals. The verification by test also requires some up-to-date test facilities, that provide high power amplification, electron seeding techniques, multiple and accurate detection methods, ability to generate complex signals, and the ability to reproduce the space representative environment conditions.

This standard is an update of previous version of ECSS-E-20-01A Rev.1, that includes the state-of-art of new verification approaches, and associated margins.

Scope

This standard defines the requirements and recommendations for the design and test of RF components and equipment to achieve acceptable performance with respect to multipactor-free operation in service in space. The standard includes:

verification planning requirements,

definition of a route to conform to the requirements,

design and test margin requirements,

design and test requirements, and

informative annexes that provide guidelines on the design and test processes.

This standard is intended to result in the effective design and verification of the multipactor performance of the equipment and consequently in a high confidence in achieving successful product operation.

This standard covers multipactor events occurring in all classes of RF satellite components and equipment at all frequency bands of interest in high vacuum conditions (pressure lower than 10-5 hPa). Operation in single carrier CW and pulse modulated mode are included, as well as unmodulated multi-carrier operations. A detailed clause on secondary emission yield is also included.

This standard does not include breakdown processes caused by collisional processes, such as plasma formation.

This standard is applicable to all space missions.

This standard may be tailored for the specific characteristic and constrains of a space project in conformance with ECSS-S-ST-00.

Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this ECSS Standard. For dated references, subsequent amendments to, or revision of any of these publications do not apply. However, parties to agreements based on this ECSS Standard are encouraged to investigate the possibility of applying the more recent editions of the normative documents indicated below. For undated references, the latest edition of the publication referred to applies.

|

ECSS-S-ST-00-01

|

ECSS system – Glossary of terms

|

|

ECSS-E-ST-10-02

|

Space engineering – Verification

|

|

ECSS-E-ST-10-03

|

Space engineering – Testing

|

|

ECSS-Q-ST-20

|

Space product assurance – Quality assurance

|

|

ECSS-Q-ST-20-08

|

Space product assurance – Storage, handling and transportation of spacecraft hardware

|

|

ECSS-Q-ST-70-01

|

Space product assurance – Cleanliness and contamination control

|

|

ECSS-Q-ST-70-02

|

Space product assurance – Thermal vacuum outgassing test for the screening of space materials

|

|

ESCC-20600

|

Preservation, packaging and despatch of ESCC component

|

|

ISO 14644–1:2015

|

Cleanrooms and associated controlled environments – Part 1: Classification of air cleanliness by particle concentration

|

Terms, definitions and abbreviated terms

Terms and definitions from other standards

For the purpose of this standard, the terms and definitions from ECSS-S-ST-00-01 apply, in particular the following terms:

acceptance

assembly

bakeout

batch

component

development

equipment

integration

uncertainty

validation

verification

For the purpose of this standard, the terms and definitions from ECSS-E-ST-10-02 apply, in particular the following terms:

acceptance stage

analysis

inspection

model philosophy

qualification stage

review of design

test

verification level

For the purpose of this standard, the terms and definitions from ECSS-E-ST-10-03 apply, in particular the following terms:

acceptance margin

qualification margin

For the purpose of this standard, the terms and definitions from ECSS-Q-ST-70-02 apply, in particular the following terms:

outgassing

Terms and definitions specific to the present standard

analysis margin

required margin of the nominal power with respect to the theoretical threshold power resulting from a Multipactor analysis

assembly

process of mechanical mating of hardware after the manufacturing process

backscattered electron

incident electron that was re-emitted from the material surface with or without energy loss.

batch

group of equipment or component produced in a limited amount of time with the same manufacturing tools, that originates from the same manufacturing lot, and followed the same manufacturing processes

This definition is more specific than the one from the ECSS Glossary ECSS-S-ST-00-01.

batch acceptance margin

allowance of the power level above the nominal power over the specified equipment or component lifetime, excluding testing, to be applied to equipment or component of the same batch

critical gap

Vacuum region within a component or equipment, surrounded by surfaces of any material at which the discharge occurs at the lowest input power for a given frequency within the operating frequency band.

Critical gap does not correspond necessarily to the smallest gap.

discharge

<CONTEXT: multipactor testing> simultaneous response on two or more independent detection methods

The term "multipactor discharge" is synonymous.

event

<CONTEXT: multipactor testing> short time response on one detection method

ferromagnetic material

substances which have a large, positive susceptibility to an external magnetic field, exhibit a strong attraction to magnetic fields and are able to retain their magnetic properties after the external magnetic field has been removed.

gap voltage

voltage over the critical gap

heritage

status of verification based on previously verified reference component or equipment including all relevant parameters

The relevant parameters are listed in Table 41.

multicarrier average power

sum of the average power of each carrier

where:

Pi is the average power of each individual carrier

N is the number of carriers

minimum inflexion point

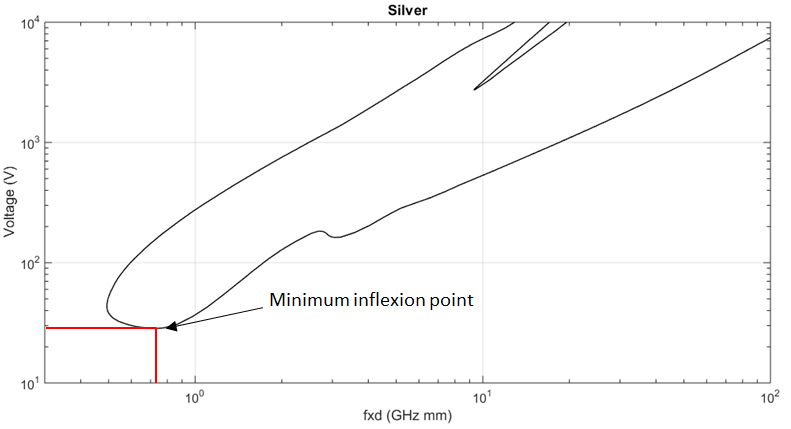

frequency times gap distance product, corresponding to multipactor order one, at which there is a change in the slope of the breakdown voltage curve and the breakdown voltage is minimized

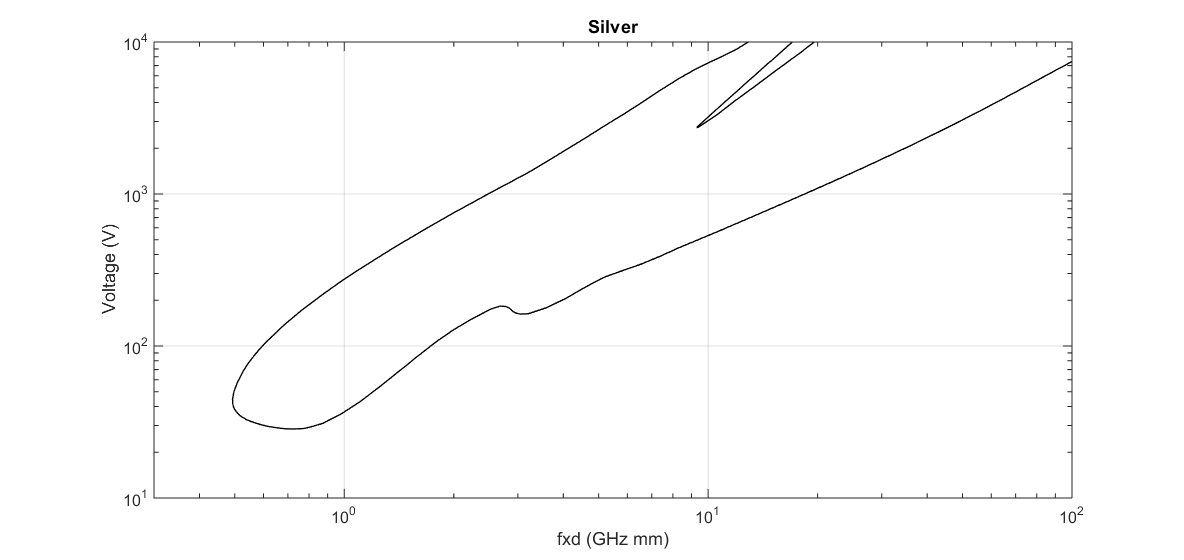

Figure 31 is given as example. See for more information the Multipactor handbook ECSS-E-HB-20-01.

Figure 31: Minimum inflexion point for Silver multipactor chart.

Figure 31: Minimum inflexion point for Silver multipactor chart.

multipactor discharge

see "discharge"

multipactor threshold

<CONTEXT: multipactor testing> lowest power level for which a multipactor discharge has occurred

multicarrier signal

<CONTEXT: multipactor testing> signal composed of a number of independent CW signals at different frequencies

qualification test

test performed on a single unit for establishing that a suitable margin exists in the design and built standard

Such suitable margin is the qualification margin.

RF boundary conditions

impedance matching conditions at all RF ports of the equipment or component

secondary electron emission yield (SEY)

see "total secondary electron emission coefficient"

total secondary electron emission coefficient

ratio of the number of all emitted electrons to the number of incident electrons of defined incident kinetic energy and angle, specific of a material surface under electron irradiation under high vacuum conditions

- 1 The total secondary electron coefficient is the sum of the true secondary electron coefficient and the backscattered electron coefficient.

- 2 The term "secondary electron emission yield" is synonymous.

Abbreviated terms

For the purpose of this Standard, the abbreviated terms from ECSS-S-ST-00-01 and the following apply:

|

Abbreviation

|

Meaning

|

|

AC/DC

|

alternating current/direct current

|

|

BAT

|

batch acceptance test

|

|

BSE

|

back-scattered electron emission

|

|

CDR

|

Critical Design Review

|

|

CFRP

|

carbon-fibre-reinforced plastic

|

|

CW

|

continuous wave

|

|

DC

|

direct current

|

|

DML

|

declared materials list

|

|

DPL

|

declared processes list

|

|

DRD

|

documents requirements definition

|

|

DUT

|

device under test

|

|

EQSR

|

equipment qualification status review

|

|

ECSS

|

European Cooperation for Space Standardization

|

|

EM

|

electromagnetic

|

|

EMC

|

electromagnetic compatibility

|

|

ERS

|

European remote sensing satellite

|

|

ESCC

|

European Space Components Coordination

|

|

FM

|

flight model

|

|

HPA

|

high power amplifier

|

|

IF

|

intermediate frequency

|

|

LNA

|

low noise amplifier

|

|

OMUX

|

output multiplexer

|

|

PDR

|

preliminary design review

|

|

PIC

|

particle in cell

|

|

PID

|

process identification document

|

|

PIMP

|

passive intermodulation product

|

|

RF

|

radio frequency

|

|

SEE

|

secondary electron emission

|

|

SRR

|

system requirements review

|

|

REG

|

regulated electron gun

|

|

RS

|

radioactive source

|

|

SEY

|

secondary emission yield

|

|

TEM

|

transverse electromagnetic mode

|

|

TRB

|

test review board

|

|

TRP

|

temperature reference point

|

|

TRR

|

test readiness review

|

|

TVAC

|

thermal vacuum chamber

|

|

TWTA

|

travelling wave tube amplifier

|

|

UAT

|

unit acceptance test

|

|

UV

|

ultraviolet

|

|

VSWR

|

voltage standing wave ratio

|

|

WG

|

wave guide

|

|

WOCA

|

worst case analysis

|

Nomenclature

The following nomenclature applies throughout this document:

The word “shall” is used in this Standard to express requirements. All the requirements are expressed with the word “shall”.

The word “should” is used in this Standard to express recommendations. All the recommendations are expressed with the word “should”.

It is expected that, during tailoring, recommendations in this document are either converted into requirements or tailored out.

The words “may” and “need not” are used in this Standard to express positive and negative permissions, respectively. All the positive permissions are expressed with the word “may”. All the negative permissions are expressed with the words “need not”.

The word “can” is used in this Standard to express capabilities or possibilities, and therefore, if not accompanied by one of the previous words, it implies descriptive text.

In ECSS “may” and “can” have completely different meanings: “may” is normative (permission), and “can” is descriptive.

The present and past tenses are used in this Standard to express statements of fact, and therefore they imply descriptive text.

Verification

Verification process

ECSS-E-ST-20-01_1450001The process of verification of the equipment with respect to multipactor performance shall demonstrate conformance to the margin requirements defined in clauses 4.6 and 4.7.

ECSS-E-ST-20-01_1450002Verification of the equipment with respect to multipactor shall be performed as part of the overall verification process specified in ECSS-E-ST-10-02, by applying Table 41.

ECSS-E-ST-20-01_1450003Each equipment shall have a dedicated multipactor verification plan as specified in 4.2.2a.

It can involve a combination of design analyses, inspections, development testing, qualification testing, batch acceptance testing and equipment or component acceptance testing.

ECSS-E-ST-20-01_1450004Multipactor performance shall be verified at equipment level.

ECSS-E-ST-20-01_1450005If multipactor performance cannot be verified at equipment level, as specified in 4.1d, then verification may be performed at component level.

ECSS-E-ST-20-01_1450006The process of verification of the component with respect to multipactor performance shall demonstrate conformance to the margin requirements defined in clauses 4.6 and 4.7.

ECSS-E-ST-20-01_1450007Verification of the component with respect to multipactor shall be performed as part of the overall verification process specified in ECSS-E-ST-10-02, by applying Table 41.

ECSS-E-ST-20-01_1450008Each component shall have a dedicated multipactor verification plan as specified in 4.2.2a.

It can involve a combination of design analyses, inspections, development testing, qualification testing, batch acceptance testing and equipment or component acceptance testing.

ECSS-E-ST-20-01_1450009Multipactor performance shall be verified at component level.

ECSS-E-ST-20-01_1450010Table 41: Classification of equipment or component type according to the qualification status and heritage from a multipactor point of view (adapted from Table 5-1 of ECSS-E-ST-10-02)

|

Category

|

Description

|

Comments

|

Verification type

|

|

Am

|

Off the shelf equipment or component without modifications and:

|

|

Review of design

|

|

Bm

|

Off the shelf equipment or component without modifications. However:

|

For this document, modification of project specifications apply to power only

|

Review of design, analysis margin evaluation and if necessary test

|

|

Cm

|

Existing equipment or component with modifications. Modification includes:

|

In case the equipment or component with modification includes a change of materials and processes, the materials and processes subject to change see requirement 9.2a.

|

Review of design, analysis margin evaluation and if necessary test

|

|

Dm

|

Newly designed and developed equipment or component or use of non-already qualified material or process.

|

No analysis and test heritage for the new design or material and process

|

Review of design, analysis margin evaluation and if necessary test

|

Multipactor verification plan

Generation and updating

ECSS-E-ST-20-01_1450011A multipactor verification plan shall be produced at EQSR and, if necessary, updated at the PDR and the CDR at the latest.

ECSS-E-ST-20-01_1450012The multipactor verification plan specified in 4.2.2a shall be kept up-to-date and under configuration control.

The detailed verification plan adopted for any particular project can depend on the qualification status of the equipment and on the model philosophy or production philosophy adopted.

ECSS-E-ST-20-01_1450013The inputs for the multipactor verification plan shall include as a minimum:

- equipment or component requirements specification,

- proposed design,

- equipment or the component qualification status as per Table 41,

- equipment or component type as per Table 42.

Description

ECSS-E-ST-20-01_1450014The multipactor verification plan shall be in conformance with the Verification Plan DRD specified in Annex A of ECSS-E-ST-10-02 plus the following items:

- the verification route as per Figure 41,

- list of the multipactor deliverable documents per review,

- description of tests or analysis to be performed.

The list of Multipactor deliverable documents is given in Table A-1.

ECSS-E-ST-20-01_1450015The multipactor verification plan shall present a coherent sequence of activities that are proposed in order to provide adequate evidence that the requirement specifications for the product are achieved for each delivered item.

ECSS-E-ST-20-01_1450016The multipactor verification plan shall state the criteria for successful completion of each of the verification activities.

Power requirements

General power requirements

Nominal power

ECSS-E-ST-20-01_1450017The nominal power shall be the specified input power for which the equipment or component is designed and verified to be multipactor free.

ECSS-E-ST-20-01_1450018The nominal power shall be the RF power level to which the analysis margin and test margin refers.

ECSS-E-ST-20-01_1450019The nominal power specified at equipment or component level shall exclude RF boundary conditions, neither from payload assembly nor from test bed.

The nominal power for multicarrier signal can be given as power per carrier, or a list of power per carrier.

Increased power P due to payload mismatch

ECSS-E-ST-20-01_1450020The increased power P of the Table 43, Table 44, Table 46 and Table 47 shall be calculated including the mismatch at the RF boundaries of the equipment or the component.

Further details can be found in the Handbook ECSS-E-HB-20-01A.

Failure

ECSS-E-ST-20-01_1450021At payload level, the design and the verification of the equipment or component identified as critical shall include failure modes.

ECSS-E-ST-20-01_1450022As a minimum, the failure modes shall include the following:

- failed equipment

- hot switching

- overdrive scenario

- unexpected thermal variations

- unexpected full or partial RF power reflection

- unexpected increase of input power

ECSS-E-ST-20-01_1450023For multipactor design and verification, the failures modes shall be included only if the equipment recovery is possible.

ECSS-E-ST-20-01_1450024For multipactor design and verification, failure modes that are not recoverable should not be taken.

ECSS-E-ST-20-01_1450025At equipment or component level, the multipactor design and verification shall include the impact of the applicable failure modes identified at payload level.

ECSS-E-ST-20-01_1450026The increased power P shall be determined by taking the change of RF boundary conditions due to the failure mode that yields the worst case among the ones defined in 4.3.1.3c.

Classification of equipment or component type

General classification of equipment or component type

ECSS-E-ST-20-01_1450027The classification of equipment or component types given in Table 41 and in Table 42 shall be used to determine the applicable multipactor margin.

This requirement defines a classification of equipment or component types according to the materials employed in the construction and the geometry and according to the qualification status from a multipactor point of view.

ECSS-E-ST-20-01_1450028In case of doubt when determining the classification of any particular equipment or component, the type with a higher number and a lower level of qualification status shall be used.

ECSS-E-ST-20-01_1450029An equipment consisting of several components shall have the type of the component with the highest number and the lowest level of qualification status.

ECSS-E-ST-20-01_1450030An RF equipment assembly consisting of equipment shall have the type of the equipment with the highest number and the lowest level of qualification status.

ECSS-E-ST-20-01_1450031In case the equipment or component has multiple potential critical gaps of different nature, each one shall be classified as P1 or P2 and follow the verification approach as defined in 4.2.

Examples of potential critical gaps of different nature are metal/metal, metal/dielectric or dielectric/dielectric.

ECSS-E-ST-20-01_1450032In case SEY characterization of materials present in an equipment or component including dielectrics materials is not performed, it shall be considered as P3 equipment or component.

ECSS-E-ST-20-01_1450033Table 42: Classification of equipment or component type according to the material and the geometry

|

Type

|

Characteristics

|

Parameters for equipment or component knowledge

|

|

P1

|

Equipment or component with metal only in the critical gap area. Metal(s) and geometry of equipment or component are known.

|

Minimum parameters: RF path dimensions of the equipment or component Tuning range of the equipment or component (if applicable) SEY of the metal(s) CTE of the material(s) (if applicable) DC EM field (if applicable) |

|

P2(1)

|

Equipment or component with dielectric and possibly metal in the critical gap area. Dielectric material(s), metal(s) and geometry of the equipment or component are known.

|

Minimum parameters:

|

|

P3(1)

|

Any equipment or components not classified as Type P1 or Type P2.

|

If any of the parameters needed for P1 or P2 is unknown, the component or equipment is classified as P3.

|

|

(1) Any P2/P3 component/equipment with a geometry involving 3 media (dielectric, metal and vacuum) and with a sharp edge in the metallic part exhibiting high RF field are prone to generate breakdown phenomena such as “triple-point” discharge which are difficult to analyse and predict. (For more information, see the corresponding clause of the Multipactor handbook ECSS-E-HB-20-01).

| ||

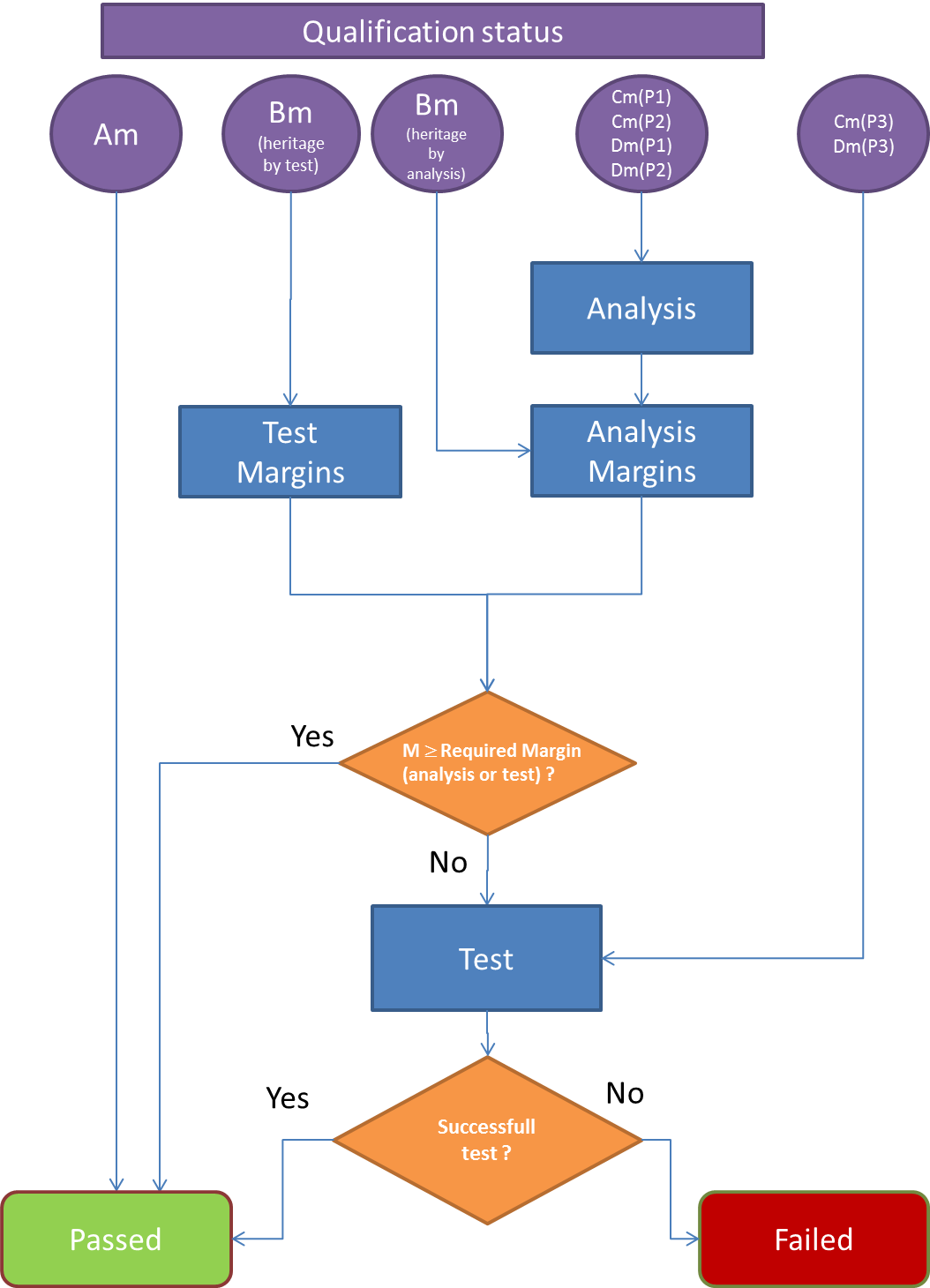

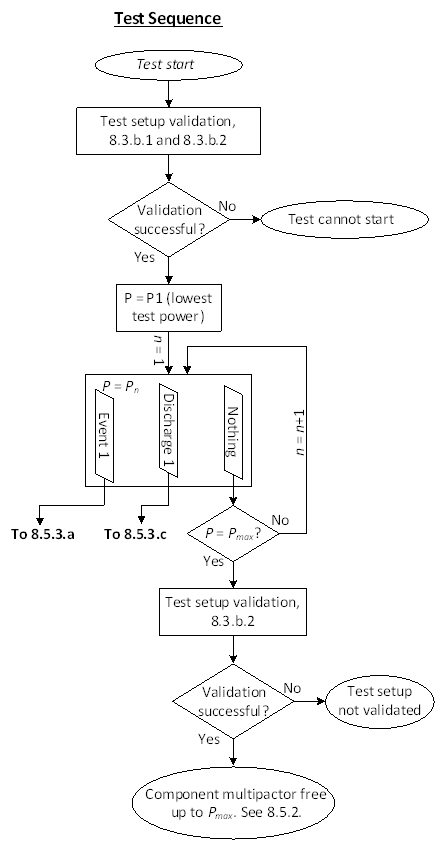

Verification routes

ECSS-E-ST-20-01_1450034Verification shall be accomplished by one of the verification routes shown in Figure 41.

ECSS-E-ST-20-01_1450035Figure 41: Verification routes per component/equipment type and qualification status for multipactor conformance

ECSS-E-ST-20-01_1450035Figure 41: Verification routes per component/equipment type and qualification status for multipactor conformance

Single carrier

General

Clause 4.6 states the numerical values of the margins to be used for CW and pulsed systems.

Verification by analysis

Analysis types

ECSS-E-ST-20-01_1450036The Multipactor analysis shall be performed following one of the two possible design analysis levels, L1 and L2, as per clause 5.3.2.

Analysis margins

ECSS-E-ST-20-01_1450037The nominal margins shown in Table 43 and Table 44 for the different contributions and equipment or component types according to the heritage shall be applied.

ECSS-E-ST-20-01_1450038The reduced margins, as indicated in Table 43 and Table 44, may be used if justification is given by the supplier.

The nominal and reduced margins as indicated in Table 43 and Table 44 include modelling error.

ECSS-E-ST-20-01_1450039Table 43: Analysis margins w.r.t. nominal power applicable to P1 and P2 equipment or components with Bm or Cm category verified by analysis

|

Justification type

|

|

L1 analysis

|

L2 analysis

|

L2 analysis

|

L2 analysis

|

|

|

P1 equipment or component

|

P1 equipment or component

|

P1 equipment or component

|

P2 equipment or component(1)

| |

|

Margin type

|

Margin

|

Margin

|

Margin

|

Margin

| |

|

Nominal dimension & ECSS SEY

|

Nominal margin |

6+ΔP |

7+ΔP |

8+ΔP |

N/A |

|

Manufacturing tolerance/thermal stability dimension & ECSS SEY

|

Reduced margin |

5+ΔP |

6+ΔP |

7+ΔP |

N/A |

|

Nominal dimension & WOCA SEY (ageing, temperature) justified by measurement (2)

|

Reduced margin |

4+ΔP |

5+ΔP |

6+ΔP |

8+ΔP(3) |

|

Manufacturing tolerance/thermal stability dimension & WOCA SEY (ageing, temperature) justified by measurement (1) (2)

|

Reduced margin |

3+ΔP |

4+ΔP |

5+ΔP |

7+ΔP(3) |

|

(1) Worst case analysis combining both as-built/thermal stability dimension and real SEY characterized by measurement.

| |||||

ECSS-E-ST-20-01_1450040Table 44: Analysis margins w.r.t. nominal power applicable to P1 and P2 equipment or components with Dm category verified by analysis

|

Justification type

|

|

L1 analysis

|

L2 analysis

| ||

|

|

P1 equipment or component

|

P1 equipment or component

|

P1 equipment or component (other cases)

|

P2 equipment or component(1)

| |

|

Margin type

|

Margin

|

Margin

|

Margin

|

Margin

| |

|

Manufacturing tolerance/thermal stability dimension & WOCA SEY (ageing, temperature) justified by measurement (1) (2) |

Reduced margin |

6+ΔP |

8+ΔP |

10+ΔP |

12 +ΔP(3) |

|

(1) Worst case analysis combining both as-built/thermal stability dimension and real SEY characterized by measurement.

| |||||

Verification by test

Test margins

ECSS-E-ST-20-01_1450041The test margin shall be defined according to the equipment or component type and the heritage.

ECSS-E-ST-20-01_1450042The test margins as shown in Table 45 shall be applied.

Margins shown in Table 45 are those for a payload mismatch of -12 dB. Further discussions regarding the payload mismatch can be found in the Multipactor handbook ECSS-E-HB-20-01.

ECSS-E-ST-20-01_1450043Any deviation from requirement 4.6.3.1b shall be proposed by the supplier and agreed with the customer.

ECSS-E-ST-20-01_1450044Multipactor tests shall be conducted at the temperature range defined in clause 6.3.

ECSS-E-ST-20-01_1450045For P1 equipment or component of type Bm and Cm, the test at ambient temperature may be performed if justifications are provided of the non-impact of temperature over any parameter affecting the breakdown threshold.

Discussions regarding test at ambient can be found in the Multipactor handbook ECSS-E-HB-20-01.

ECSS-E-ST-20-01_1450046Table 45: Test margins w.r.t. nominal power applicable to P1, P2 and P3 equipment or components verified by test

|

Equipment or component type

|

P1

|

P2 or P3

| |

|

Heritage

|

All

|

Bm(1)

|

Bm(2), Cm, Dm

|

|

Qualification Test

|

6

|

6

|

6

|

|

Batch Acceptance Test

|

4

|

4

|

5

|

|

Unit Acceptance Test

|

3

|

3

|

4

|

|

(1) Heritage by test

| |||

Multicarrier

General

Clause 4.7 states the numerical values of the margins to be used for multicarrier systems.

The margins by analysis and test are defined with respect to either the power per carrier of the multicarrier signal, or the multicarrier average power, or the equivalent CW power as specified in 6.4.3.2a.

Verification by analysis

Analysis types

ECSS-E-ST-20-01_1450047The Multipactor analysis shall be performed following one of the two possible levels L1 and L2 as per clause 5.3.2.

Analysis margins

ECSS-E-ST-20-01_1450048The nominal margins shown in Table 46 and Table 47 for the different contributions and equipment or component types according to the heritage shall be applied in addition to the nominal power.

ECSS-E-ST-20-01_1450049The reduced margins as indicated in Table 46 and Table 47 may be used if justification is given by the supplier and agreed by the customer

The nominal and reduced margins as indicated in Table 46 and Table 47 include modelling error.

ECSS-E-ST-20-01_1450050Table 46: Analysis margins applicable to P1 and P2 equipment or components with Bm or Cm category verified by analysis

|

Justification type

|

|

L1 analysis

|

L2 analysis

| ||

|

|

P1 equipment or component

|

P1 equipment or component

|

P1 equipment or component

|

P2 equipment or component(1)

| |

|

Margin type

|

Margin

|

Margin

|

Margin

|

Margin

| |

|

Nominal dimension & ECSS SEY (3)

|

Nominal Margin

|

6+ΔP

|

7+ΔP

|

8+ΔP

|

N/A

|

|

Manufacturing tolerance/thermal stability dimension & ECSS SEY (3)

|

Reduced Margin

|

5+ΔP

|

6+ΔP

|

7+ΔP

|

N/A

|

|

Nominal dimension & WOCA SEY (ageing, temperature) justified by measurement (2)

|

Reduced Margin

|

4+ΔP

|

5+ΔP

|

6+ΔP

|

8+ΔP(3)

|

|

Manufacturing tolerance/thermal stability dimension & WOCA SEY (ageing, temperature) justified by measurement(1) (2)

|

Reduced Margin

|

3+ΔP

|

4+ΔP

|

5+ΔP

|

7+ΔP(3)

|

|

(1) Worst case analysis combining both as-built/thermal stability dimension and real SEY characterized by measurement.

| |||||

ECSS-E-ST-20-01_1450051Table 47: Analysis margins applicable to P1 and P2 equipment or components with Dm category verified by analysis

|

Justification type

|

|

L1 analysis

|

L2 analysis

| ||

|

|

P1 equipment or component

|

P1 equipment or component

|

P1 equipment or component

|

P2 equipment or component(1)

| |

|

Margin type

|

Margin

|

Margin

|

Margin

|

Margin

| |

|

Manufacturing tolerance/thermal stability dimension & WOCA SEY (ageing, temperature) justified by measurement(1) (2)

|

Reduced Margin

|

6+ΔP

|

8+ΔP

|

10+ΔP

|

12+ΔP(3)

|

|

(1) Worst case analysis combining both as-built/thermal stability dimension and real SEY characterized by measurement.

| |||||

Verification by test

Test margins

ECSS-E-ST-20-01_1450052The test margin shall be defined according to the equipment or component type and the heritage.

ECSS-E-ST-20-01_1450053The test margins as shown in Table 48 shall be applied for test performed in single carrier with an equivalent single carrier CW power determined in 6.4.3.2.

- 1 Margins shown in Table 48 are those for a payload mismatch of -12 dB.

- 2 If a single carrier test is not possible, see requirement 6.4.3.1b.

ECSS-E-ST-20-01_1450054Any deviation from Table 48 shall be proposed by the supplier and agreed with the customer.

ECSS-E-ST-20-01_1450055Multipactor tests shall be conducted at the temperature range defined in the clause 6.3.

ECSS-E-ST-20-01_1450056For P1 equipment or component of type B and C, the test at ambient temperature may be performed if justifications are provided of the non-impact of temperature over any parameter affecting the breakdown threshold.

Discussions regarding test at ambient can be found in the Multipactor handbook ECSS-E-HB-20-01.

ECSS-E-ST-20-01_1450057Table 48: Test margins w.r.t. nominal power applicable to P1, P2 and P3 equipment or components verified by test

|

Equipment or component type

|

P1

|

P2 or P3

| |

|

Heritage

|

All

|

Bm(1)

|

Bm(2), Cm, Dm

|

|

Qualification Test

|

6

|

6

|

6

|

|

Batch Acceptance Test

|

4

|

4

|

5

|

|

Unit Acceptance Test

|

3

|

3

|

4

|

|

(1) Heritage by test

| |||

Design analysis

Overview

Clause 5 defines the minimum requirements for performing a satisfactory design analysis with respect to multipactor. These requirements are applicable for all cases where the chosen route to conformance includes analysis. Implementation of such an analysis can vary from sophisticated three-dimensional multipactor simulations to a much simpler estimation process. The analysis represents the application under the specified conditions.

Field analysis

ECSS-E-ST-20-01_1450058An analysis of the electromagnetic fields within the complete equipment or component shall be performed before establishing the worst case multipactor threshold under the specified conditions.

- 1 Multipactor analysis is performed with a proper understanding of the electric fields within the whole equipment or component.

- 2 Specified conditions include parameters such as operational frequency bandwidth, temperature extremes, mismatch conditions, which are applicable to the equipment or component.

- 3 Field analysis without electron tracking solver and surface modelling is used in L1 analysis as described in 5.3.2.2.

- 4 Field analysis with electron tracking solver and surface modelling is used in L2 analysis described in 5.3.2.3.

ECSS-E-ST-20-01_1450059The analysis shall be accomplished by using one of the following methods: - RF EM software,

- estimations from the appropriate use of equivalent circuit models,

- analytical solution of canonical geometries.

ECSS-E-ST-20-01_1450060All regions shall be analyzed to identify the multipactor critical gap.

ECSS-E-ST-20-01_1450061If ferrite materials are present in the equipment or component the following two analyses shall be performed: - an EM field analysis based on the knowledge of the magnetic properties of such ferrite materials, and

- a multipactor analysis including the DC magnetic field applied to the ferrite.

DC magnetic fields applied to ferrite equipment or components include permanent magnets and coils.

Multipactor design analysis

Frequency selection

ECSS-E-ST-20-01_1450062The Multipactor design analysis shall be performed at the frequency within the full bandwidth, at which the EM fields yield the lowest breakdown power.

ECSS-E-ST-20-01_1450063For multicarrier analysis, the carrier frequencies of each of the specified channels shall be used.

Carrier frequency is chosen for multicarrier analysis in order to obtain representative signal envelope characteristics.

Design analysis levels

General design analysis requirements

ECSS-E-ST-20-01_1450064Design analysis shall be applied to equipment or components P1 and P2, according to clause 4.6.2 for single carrier and clause 4.7.2 for multicarrier.

ECSS-E-ST-20-01_1450065The level of analysis shall be selected and performed according to Table 43 and Table 44 for single carrier analysis and to Table 46 and Table 47 for multi-carrier analysis.

ECSS-E-ST-20-01_1450066Depending on the design analysis level, margin shall be adequately applied according to clause 4.6.2.2 or 4.7.2.2.

Analysis level 1 (L1)

General requirements for analysist level 1 (L1)

ECSS-E-ST-20-01_1450067Analysis level 1 shall be applied on equipment or components of type P1.

Criteria for geometry and material

ECSS-E-ST-20-01_1450068The critical gap shall be similar to a parallel surface or coaxial geometry, and the electron trajectory is only possible between two-surfaces.

ECSS-E-ST-20-01_1450069The material, in terms of SEY, shall be selected according to criteria specified in clause 5.3.3.3

ECSS-E-ST-20-01_1450070In case the analysis includes fringing field effect for iris-like geometries, then analyses may be modified based on relevant heritage or studies on such effect if agreed between the supplier and customer on the degree of similarity of the proposed studies.

Fringing field effect can increase the multipactor threshold power level (see respective clause in the Multipactor handbook ECSS-E-HB-20-01).

Analysis methodology for single-carrier case

ECSS-E-ST-20-01_1450071The analysis level 1 with single-carrier signals shall consist of the following steps:

- Computation of the voltage inside the critical region, Vgap, through analytical formula or an electromagnetic software, for a given input power Pin, using the definition of the voltage to power ratio as

- Computation of the multipactor threshold at the corresponding frequency gap distance product, by either:

- using one of the dedicated charts for the list of ECSS materials of clause 5.3.3.4, or

- using a multipactor theory or numerical method for parallel surfaces or coaxial geometry.

- Computation of input power corresponding to the Multipactor threshold voltage computed in point b as

The voltage to power ratio of item 1 is equivalent to the voltage magnification factor defined in the handbook.

ECSS-E-ST-20-01_1450072The customer and supplier shall agree on the method to follow regarding requirement 5.3.2.2.3a.2.

ECSS-E-ST-20-01_1450073Different analysis methodologies may be used in agreement with the customer.

ECSS-E-ST-20-01_1450074The resulting threshold shall be compared with the nominal power increased with the dedicated margin of Table 43 and Table 44.

Analysis methodology for multi-carrier case

ECSS-E-ST-20-01_1450075The analysis level 1with multi-carrier signals shall consist of the following steps:

- Computation of the voltage inside the critical region, Vgap, through analytical formula or an electromagnetic software, for a given input power Pin, giving the EM fields solved for a frequency equal to the mean frequency of all carriers and using the definition of the voltage to power ratio as

This ratio is equivalent to the voltage magnification factor defined in the Multipactor handbook ECSS-E-HB-20-01.

- Compute the breakdown voltage threshold per carrier by either:

- Using the pulsed model approximation in combination with single-carrier analysis.

- Using the envelope sweep approach in combination with a full multicarrier multipactor theory or numerical method for L1, to find the worst-case pulse width that leads to the minimum breakdown power.

ECSS-E-ST-20-01_1450076The pulsed model approximation, specified in 5.3.2.2.4a.2(a), shall consist of the following steps:

- Approximate the multicarrier signal by a pulsed signal, consisting of an on-off rectangular signal, with a frequency of the signal equal to the mean frequency of all carriers, and a period equal to that of the envelope of the multicarrier signal.

- Select the single carrier multipactor theory employed in item 3 in agreement with the customer that allows for analytically computing the electron growth during the "on" interval, and electron absorption during the "off" interval.

- Compute the electron growth during a period by employing the theory selected in item 2.

- Select the worst-case as the combination of the duration and amplitude of the pulse, that produces a discharge with the lowest voltage per carrier, by:

- Using the long-term discharge criterion, where the number of produced electrons is higher than the number of absorbed electrons during a period of the multicarrier signal.

- Determining the computation of the voltage per carrier, given the amplitude of the pulse, by the use of a multicarrier envelope fitting function.

Specific analytical formulas, methodology and different envelope fitting functions are given in the Multipactor handbook ECSS-E-HB-20-01.

ECSS-E-ST-20-01_1450077The envelope sweep, specified in 5.3.2.2.4a.2(b), shall consist of the computation of the Multipactor threshold voltage per carrier given by a full-multicarrier multipactor theory or numerical method for parallel plates, as follows:.

- Selection of M different time intervals of duration i, i varying from 1 to M, in order to fully cover the duration range between 0 and T, where T is the multi-carrier envelop period by ensuring that the number of time intervals is large enough for the convergence.

- Optimization of the carrier phases for each value of i in order to maximize the minimum value of the envelope voltage amplitude during the respective time interval of duration i.

- Computation of the Multipactor voltage threshold for each phase scenario resulting from step 2, considering a long-term discharge, where the number of produced electrons is higher than the number of absorbed electrons during a period of the multicarrier signal.

- Selection of the minimum Multipactor voltage threshold.

A full-multicarrier theory is able to compute the multipactor dynamics (electron growth in time) for an arbitrary combination of frequencies, amplitudes and phases with no simplification of the signal.

ECSS-E-ST-20-01_1450078The customer and supplier shall agree on the method for the computation of the multipactor threshold voltage, specified in 5.3.2.2.4c.

ECSS-E-ST-20-01_1450079The input power corresponding to the Multipactor threshold voltage computed in 5.3.2.2.4a.2 shall be computed as

ECSS-E-ST-20-01_1450080Different analysis methodologies may be used in agreement with the customer.

ECSS-E-ST-20-01_1450081The resulting threshold shall be compared with the nominal power increased with the dedicated margin of Table 46 and Table 47.

Analysis level 2 (L2)

General requirements for analysist level 2 (L2)

ECSS-E-ST-20-01_1450082Analysis level 2 shall be applied on equipment or components of type P1 or P2.

Criteria for geometry and material

ECSS-E-ST-20-01_1450083The secondary emission properties used shall be selected according to criteria specified in clause 5.3.3.3.

ECSS-E-ST-20-01_1450084According to the geometry of the critical gap, any equipment or component type 1 (P1) which cannot be analysed through L1, shall be analysed through L2.

This includes for instance multiple electron trajectories, complex 3D structures where the critical cannot be locally approximated by a parallel plate or coaxial cases.

ECSS-E-ST-20-01_1450085Type 2 equipment or components (P2) shall be analysed through L2, considering the DC electric field created by the dielectric charging in order to determine the worst case of Multipactor threshold.

Analysis methodology for single-carrier case

ECSS-E-ST-20-01_1450086The analysis level 2 shall be characterized by the computation of the Multipactor threshold with a 3D coupled RF EM and electron tracking and surface modelling software.

ECSS-E-ST-20-01_1450087A convergence study of the mesh density and of the initial number of electrons shall be performed until the Multipactor threshold is stabilized.

ECSS-E-ST-20-01_1450088The resulting threshold shall be compared with the nominal power increased with the dedicated margin of Table 43 and Table 44.

Analysis methodology for multi-carrier case

ECSS-E-ST-20-01_1450089The analysis L2 with multi-carrier signals shall be done by using the envelope sweep approach to find the worst-case pulse width that leads to the minimum breakdown power in the following sequence:

- Computation of the Multipactor threshold power per carrier given by a 3D coupled RF EM and electron tracking and surface modelling software.

- Comparison of the obtained power threshold per carrier with the nominal power per carrier increased with the dedicated margin of Table 46 and Table 47. ECSS-E-ST-20-01_1450090The computation of the multipactor threshold power per carrier, as specified in 5.3.2.3.4a.1, shall consist of:

- Selection of M different time intervals of duration i, i varying from 1 to M, in order to fully cover the duration range between 0 and T, where T is the multi-carrier envelop period by ensuring that the number of time intervals is large enough for the convergence.

- Optimization of the carrier phases for each value of i in order to maximize the minimum value of the envelope voltage amplitude during the respective time interval of duration i.

- Computation of the Multipactor power threshold for each phase scenario resulting from step 2, considering a long-term discharge, where the number of produced electrons is higher than the number of absorbed electrons during a period of the multicarrier signal.

- Selection of the minimum Multipactor power threshold. ECSS-E-ST-20-01_1450091Different analysis methods may be used in agreement with the customer.

Alternative methods are described in the handbook.

ECSS-E-ST-20-01_1450092A convergence study of the mesh density and of the initial number of electrons shall be performed until the Multipactor threshold is stabilized.

Validation of theory and software

ECSS-E-ST-20-01_1450093For parallel-plate theory and both 3D EM and electron trajectory computation, any technique shall be validated by either:

- demonstrable heritage, or

- multipactor breakdown computation of representative sample and comparison with experimental results or results coming from a validated theory or software.

Examples of representative samples are given in the Multipactor handbook ECSS-E-HB-20-01.

Available data for Multipactor analysis

General

ECSS-E-ST-20-01_1450094The analysis margin strategy to be applied shall depend on the available data for two parameters, dimensions and SEY:

- Dimensional accuracy and stability:

- Nominal values

- Worst case, including manufacturing tolerances and thermal effect.

- SEY available data

- ECSS SEY data

- Measured SEY, including ageing and temperature effect and charging (if applicable)

ECSS-E-ST-20-01_1450095For each case specified in 5.3.3.1a, the dedicated margin of Table 43, Table 44, Table 46 or Table 47 shall be applied depending on the level analysis and the type of equipment or component.

Dimensional accuracy and stability

ECSS-E-ST-20-01_1450096The worst case dimension shall be determined using following steps:

- include the accuracy and stability of the dimensions of the equipment or component, including manufacturing tolerances and the thermal effect.

- study the effect of the thermo-elastic distortion on the qualification temperature range.

- use the smallest dimension of the critical gap, provided that the RF equipment or component remains compliant with the electrical performance specifications.

- evaluate the lowest breakdown power within the whole gap dimensional variation range, if the fxd product is lower than the minimum inflexion point of the curve, and select the gap yielding the lowest breakdown power.

- compute the dimensional variation over the iris length in the presence of short irises, and select the longest iris length as the worst-case for all cases.

ECSS-E-ST-20-01_1450097For the nominal dimension, the analysis shall be performed without including the manufacturing tolerances and the thermal effect.

ECSS-E-ST-20-01_1450098In case tuning elements are present in P1 or P2 equipment or component, the predicted worst and best case threshold power shall be derived by applying the range of the tuning elements.

SEY available data

ECSS-E-ST-20-01_1450099SEY data used in the analysis shall be representative of the material in the critical part of the equipment and come from either measured SEY or ECSS SEY.

ECSS-E-ST-20-01_1450100For measured SEY, the SEY curve shall be the worst case including the ageing, contamination and temperature and charging properties as specified in requirement9.3a.

ECSS-E-ST-20-01_1450101If no ad-hoc SEY measurement data are available, and the material is listed in Table 91, the corresponding material data from this table shall be taken.

ECSS-E-ST-20-01_1450102If no ad-hoc SEY measurement data are available, and the material is not listed in Table 91, no analysis is possible and the equipment or component shall be classified as P3.

ECSS-E-ST-20-01_1450103P1 equipment or components shall be analysed with either measured SEY or ECSS SEY data.

ECSS-E-ST-20-01_1450104P2 equipment or components shall be analysed with measured SEY data.

ECSS-E-ST-20-01_1450105If different materials are present at the critical gap, the material with the worse SEY envelope curve shall be taken for analysis level 1.

ECSS Multipactor charts

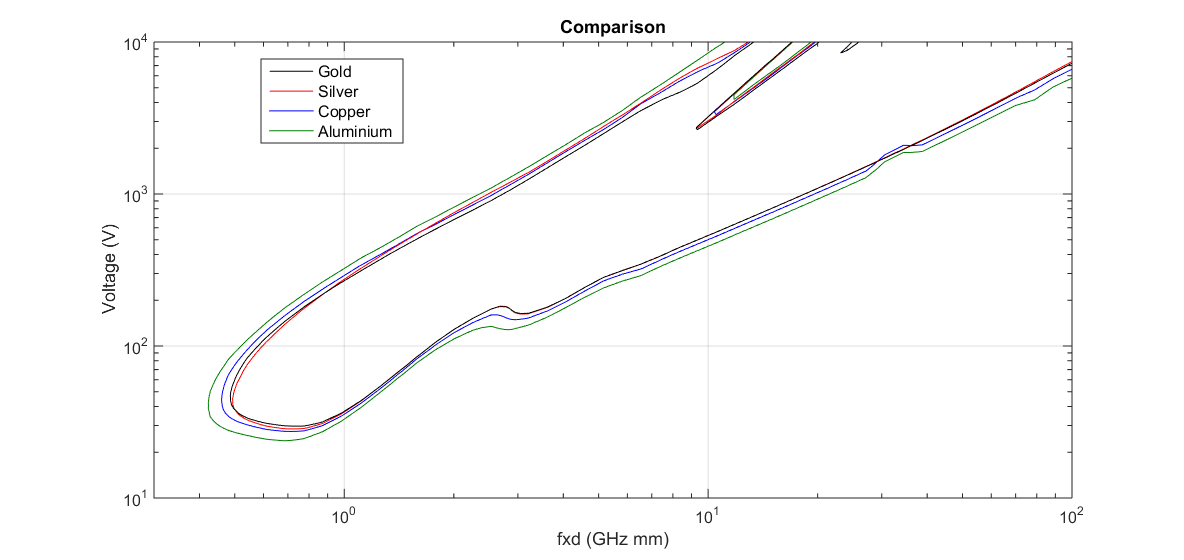

ECSS-E-ST-20-01_1450106To compute the threshold level for L1 analysis according to clause 5.3.2.2 the values of Table 51 shall be taken.

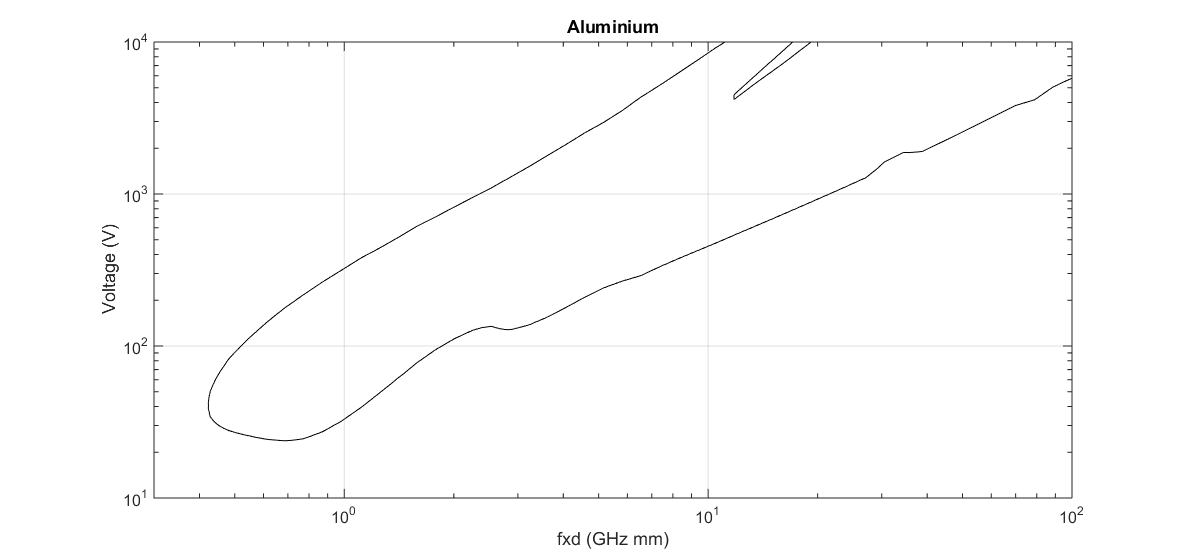

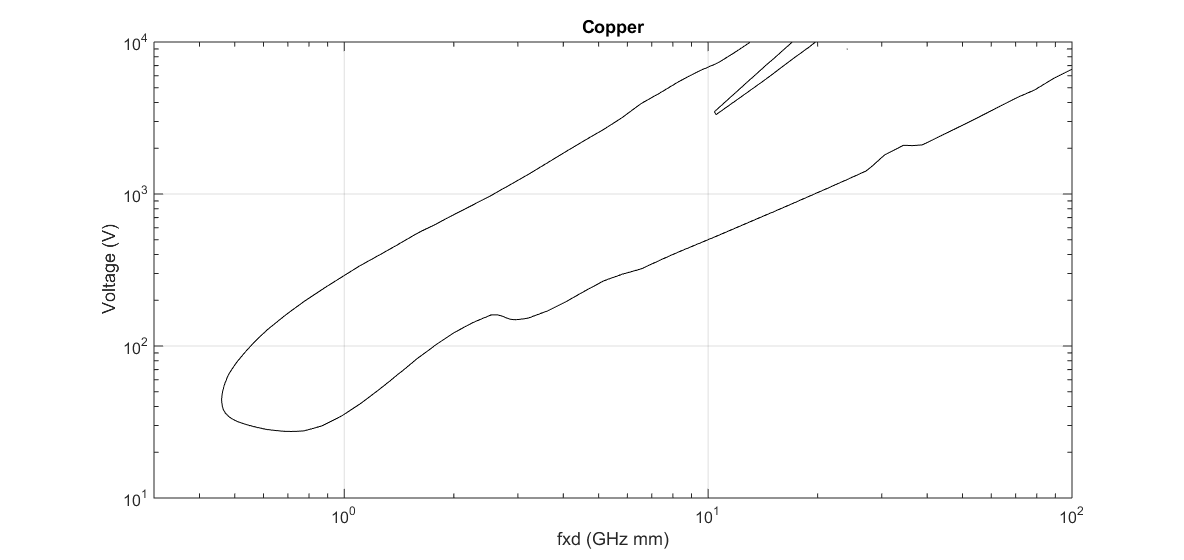

The multipactor charts in Figure 51 to Figure 55 are a visual representation of breakdown voltage for each of the metals listed in Table 91.

ECSS-E-ST-20-01_1450107Table 51: Tabulated values of the lowest breakdown voltage threshold boundary of the multipactor charts, computed with the SEY data of Table 91

|

fxd

|

Breakdown Voltage (V)

| |||

|

Aluminium

|

Copper

|

Silver

|

Gold

| |

|

0,43

|

33,8

|

|

|

|

|

0,47

|

28,5

|

36,6

|

|

|

|

0,49

|

27,4

|

33,4

|

|

41,0

|

|

0,50

|

27,0

|

32,5

|

38,3

|

38,1

|

|

0,53

|

26,1

|

30,8

|

33,7

|

34,5

|

|

0,56

|

25,4

|

29,7

|

31,7

|

32,8

|

|

0,59

|

24,7

|

28,8

|

30,4

|

31,6

|

|

0,62

|

24,2

|

28,1

|

29,5

|

30,8

|

|

0,66

|

24,0

|

27,7

|

28,9

|

30,2

|

|

0,70

|

23,8

|

27,4

|

28,5

|

29,8

|

|

0,74

|

24,1

|

27,5

|

28,5

|

29,7

|

|

0,78

|

24,7

|

27,7

|

28,7

|

29,8

|

|

0,82

|

25,9

|

28,7

|

29,7

|

30,6

|

|

0,87

|

27,2

|

29,9

|

30,9

|

31,6

|

|

0,92

|

29,3

|

31,9

|

32,9

|

33,5

|

|

0,97

|

31,5

|

34,0

|

35,2

|

35,7

|

|

1,02

|

34,4

|

37,0

|

38,3

|

38,6

|

|

1,08

|

37,7

|

40,3

|

41,7

|

42,0

|

|

1,14

|

41,6

|

44,4

|

45,9

|

46,0

|

|

1,21

|

46,2

|

49,0

|

50,8

|

50,8

|

|

1,28

|

51,3

|

54,2

|

56,2

|

56,2

|

|

1,35

|

56,9

|

60,3

|

62,5

|

62,4

|

|

1,43

|

63,4

|

67,0

|

69,5

|

69,3

|

|

1,51

|

70,5

|

74,8

|

77,2

|

77,0

|

|

1,59

|

78,4

|

83,3

|

86,0

|

85,8

|

|

1,68

|

86,1

|

91,9

|

95,4

|

95,3

|

|

1,78

|

94,3

|

101,4

|

105,6

|

105,6

|

|

1,88

|

102,0

|

110,8

|

116,0

|

116,0

|

|

1,99

|

110,1

|

120,9

|

126,9

|

127,0

|

|

2,10

|

117,4

|

130,1

|

137,5

|

137,6

|

|

2,22

|

124,8

|

139,7

|

148,5

|

148,7

|

|

2,34

|

130,5

|

148,2

|

159,4

|

159,4

|

|

2,48

|

133,7

|

156,7

|

170,6

|

170,3

|

|

2,62

|

131,8

|

160,2

|

179,7

|

179,2

|

|

2,77

|

128,4

|

154,3

|

182,2

|

181,3

|

|

2,92

|

129,6

|

149,2

|

167,6

|

168,7

|

|

3,09

|

134,0

|

150,6

|

162,4

|

163,6

|

|

3,27

|

139,7

|

155,2

|

165,4

|

166,3

|

|

3,45

|

147,8

|

163,0

|

172,8

|

173,6

|

|

3,65

|

156,6

|

171,7

|

181,4

|

181,8

|

|

3,85

|

167,8

|

183,4

|

193,5

|

193,9

|

|

4,07

|

179,6

|

195,8

|

206,3

|

206,6

|

|

4,30

|

193,1

|

211,2

|

222,9

|

223,2

|

|

4,55

|

207,5

|

227,6

|

240,4

|

240,7

|

|

4,81

|

221,7

|

244,6

|

258,2

|

258,5

|

|

5,08

|

236,5

|

262,5

|

276,9

|

277,2

|

|

5,37

|

249,5

|

277,3

|

292,2

|

292,7

|

|

5,67

|

261,8

|

290,7

|

306,4

|

307,1

|

|

5,99

|

273,1

|

302,9

|

321,1

|

321,8

|

|

6,33

|

284,0

|

314,4

|

336,2

|

336,9

|

|

6,69

|

298,3

|

329,6

|

353,4

|

354,0

|

|

7,07

|

317,5

|

350,3

|

373,3

|

373,9

|

|

7,47

|

337,5

|

372,1

|

394,8

|

395,4

|

|

7,90

|

357,3

|

394,5

|

419,2

|

419,7

|

|

8,34

|

378,3

|

418,0

|

444,8

|

445,3

|

|

8,82

|

399,9

|

441,6

|

469,9

|

470,5

|

|

9,32

|

422,4

|

466,6

|

496,5

|

497,1

|

|

9,85

|

446,2

|

493,1

|

525

|

525

|

|

10,41

|

471,4

|

521

|

554

|

555

|

|

11,00

|

498,9

|

551

|

586

|

587

|

|

11,62

|

528

|

583

|

621

|

621

|

|

12,28

|

559

|

617

|

657

|

657

|

|

12,98

|

592

|

653

|

695

|

695

|

|

13,71

|

626

|

691

|

736

|

736

|

|

14,49

|

662

|

731

|

779

|

779

|

|

15,31

|

700

|

773

|

825

|

825

|

|

16,18

|

742

|

819

|

874

|

873

|

|

17,10

|

786

|

867

|

925

|

924

|

|

18,07

|

832

|

919

|

981

|

980

|

|

19,10

|

881

|

974

|

1039

|

1038

|

|

20,18

|

934

|

1032

|

1102

|

1100

|

|

21,32

|

990

|

1093

|

1168

|

1166

|

|

22,53

|

1050

|

1160

|

1240

|

1236

|

|

23,81

|

1113

|

1229

|

1315

|

1311

|

|

25,16

|

1181

|

1305

|

1397

|

1392

|

|

26,59

|

1254

|

1385

|

1483

|

1478

|

|

28,10

|

1370

|

1512

|

1577

|

1570

|

|

29,69

|

1532

|

1704

|

1677

|

1668

|

|

31,38

|

1682

|

1870

|

1783

|

1773

|

|

33,16

|

1797

|

2000

|

1897

|

1885

|

|

35,04

|

1875

|

2089

|

2019

|

2006

|

|

37,03

|

1885

|

2087

|

2152

|

2136

|

|

39,13

|

1926

|

2129

|

2293

|

2274

|

|

41,35

|

2052

|

2269

|

2448

|

2425

|

|

43,70

|

2186

|

2418

|

2611

|

2585

|

|

46,18

|

2332

|

2581

|

2791

|

2761

|

|

48,80

|

2486

|

2753

|

2981

|

2946

|

|

51,57

|

2654

|

2941

|

3191

|

3150

|

|

54,49

|

2833

|

3141

|

3414

|

3367

|

|

57,59

|

3026

|

3359

|

3659

|

3604

|

|

60,85

|

3232

|

3593

|

3921

|

3858

|

|

64,31

|

3453

|

3845

|

4206

|

4132

|

|

67,95

|

3690

|

4115

|

4514

|

4430

|

|

71,81

|

3894

|

4383

|

4846

|

4752

|

|

75,88

|

4050

|

4642

|

5208

|

5101

|

|

80,19

|

4283

|

4952

|

5595

|

5474

|

|

84,74

|

4698

|

5368

|

6014

|

5878

|

|

89,55

|

5117

|

5798

|

6458

|

6306

|

|

94,63

|

5440

|

6200

|

6936

|

6767

|

|

100,00

|

5782

|

6624

|

7440

|

7254

|

Figure 51: Multipactor chart for standard Aluminium obtained with parameters from Table 91

Figure 51: Multipactor chart for standard Aluminium obtained with parameters from Table 91

Figure 52: Multipactor chart for standard Copper obtained with parameters from Table 91

Figure 52: Multipactor chart for standard Copper obtained with parameters from Table 91

Figure 53: Multipactor chart for standard Silver obtained with parameters from Table 91

Figure 53: Multipactor chart for standard Silver obtained with parameters from Table 91

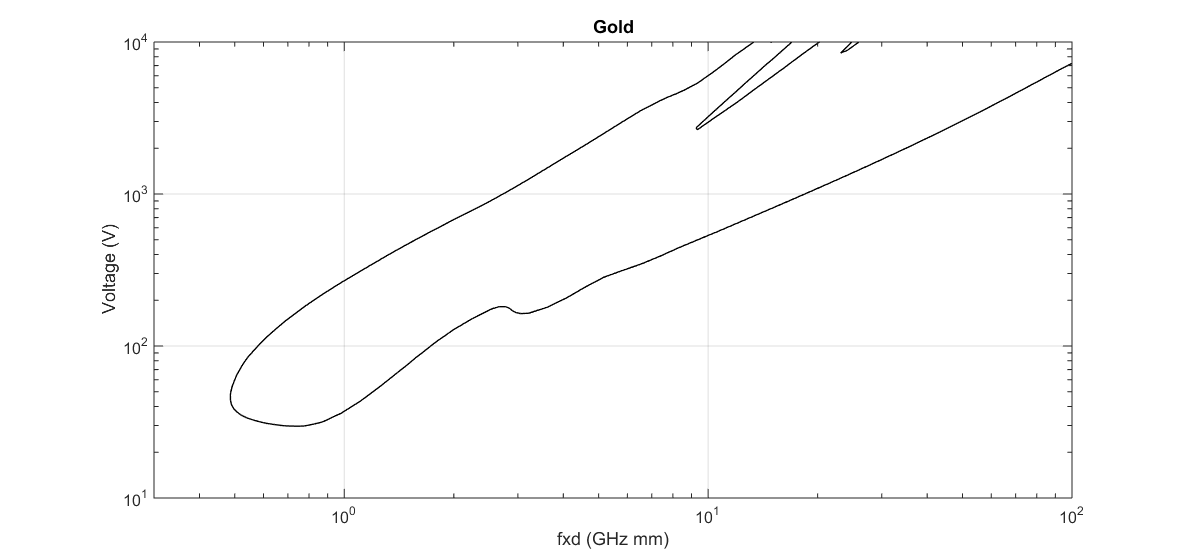

Figure 54: Multipactor chart for standard Gold obtained with parameters from Table 91

Figure 54: Multipactor chart for standard Gold obtained with parameters from Table 91

Figure 55: Comparison of Multipactor charts for all standard materials obtained with parameters from Table 91

Figure 55: Comparison of Multipactor charts for all standard materials obtained with parameters from Table 91

Multipactor - Test conditions

Cleanliness

ECSS-E-ST-20-01_1450108Airborne particulate cleanliness class 8 as per ISO 14644-1 or better conditions, shall be maintained throughout the equipment or component assembly, test, delivery and post-delivery phases.

ECSS-E-ST-20-01_1450109In addition, standard clean room practices for handling flight equipment and for general prevention of contamination, agreed with the customer, shall be strictly applied.

ECSS-E-ST-20-01_1450110Protective covers to prevent the ingress of contaminants shall be used.

ECSS-E-ST-20-01_1450111If surfaces are vulnerable to contamination the surface molecular and particle contamination shall be monitored in accordance with clause 5.4.2 of ECSS-Q-ST-70-01.

ECSS-E-ST-20-01_1450112If the contamination monitoring, specified in 6.1d, shows that the specified levels are exceeded, the surface shall be cleaned according to the requirement of clause 5.4.1 of ECSS-Q-ST-70-01.

Contamination is any unwanted molecular or particulate matter, including microbiological matter, on the surface or in the environment of interest that can affect or degrade the relevant performance or life time.

Pressure

ECSS-E-ST-20-01_1450113A vacuum bake-out shall be performed on all equipment or components before multipactor testing.

ECSS-E-ST-20-01_1450114The combination of maximum temperature and time duration used for the bake-out shall be equivalent to that which is present in the operational environment of the spacecraft payload.

The above requirement allows for accelerated bake-out at higher temperatures over relatively short time periods, where the maximum allowable temperature has been approved by the customer. Refer to the ECSS Multipactor handbook ECSS-E-HB-20-01, for further details on determining equivalence of outgassing conditions.

ECSS-E-ST-20-01_1450115Multipactor testing shall be performed at pressures below 1,0 × 10-5 hPa in the thermal vacuum chamber.

A lower pressure inside the critical regions of the equipment or component can be achieved by providing an adequate combination of:

- pressure in the vacuum chamber,

- venting design for the equipment or component, and

- time for moisture to outgas from the equipment or component.

ECSS-E-ST-20-01_1450116The pressure in the thermal vacuum chamber shall be monitored continuously during the test.

ECSS-E-ST-20-01_1450117If, as a consequence of the monitoring specified in 6.2d, any unexpected pressure increases are detected, these events shall be noted in the test report and correlated against the readings of the multipactor detection methods.

Temperature

ECSS-E-ST-20-01_1450118Multipactor tests shall be performed at the temperature extremes defined for the DUT at the critical gap.

Thermal analysis results can be used to ensure that the required temperature is met in the critical region (including thermal stability)

ECSS-E-ST-20-01_1450119For P1 equipment or component of type Bm and Cm, test at ambient temperature may be performed if justifications are provided and agreed with the customer, of the non-impact of temperature over any parameter affecting the breakdown threshold.

Discussions regarding test at ambient can be found in the corresponding clause ECSS Multipactor handbook ECSS-E-HB-20-01.

ECSS-E-ST-20-01_1450120A equipment or component tested at extreme temperatures as described in 6.3a shall be tested at the hot and cold extremes with reference to the relevant temperature range:

- For qualification tests, the qualification temperature range for EQM and QM.

- For batch- and unit tests, the acceptance temperature range for PFM and FM.

ECSS-E-ST-20-01_1450121In the case that a reduced temperature range is agreed with the customer, the new temperature limits may be used for the tests specified in 6.3a.

ECSS-E-ST-20-01_1450122As a minimum the Temperature Reference Point (TRP) of the DUT shall be monitored during the complete test duration, for ambient tests as well as for tests performed at extreme temperatures.

ECSS-E-ST-20-01_1450123A maximum acceptable temperature of the TRP shall be specified by the customer.

ECSS-E-ST-20-01_1450124The thermal dissipation in the DUT caused by the selected multipactor test signal profile, CW, pulsed or multi-carrier, shall be analysed.

ECSS-E-ST-20-01_1450125The maximum average power applied during multipactor testing shall be no greater than the value used in the thermal analysis.

Signal characteristics

Applicable bandwidth

ECSS-E-ST-20-01_1450126The applicable bandwidth for a multipactor test shall be defined as follows:

- For a qualification test, the applicable bandwidth is the full bandwidth for which the equipment or component is designed.

- For a batch- or unit test, the applicable bandwidth is the bandwidth, which is applicable for the current project or application.

Single-frequency test case

ECSS-E-ST-20-01_1450127The test frequency shall be determined in accordance with 5.3.1.

Multi-frequency test case

General

ECSS-E-ST-20-01_1450128A test with a single carrier, applying an equivalent power as specified in clause 6.4.3.2. shall be performed.

ECSS-E-ST-20-01_1450129If a single carrier test is not possible, a test with a multi-carrier signal, subjected to a frequency multiplex with CW carriers located in accordance with the operational frequency plan and with free-running phase per carrier may be performed under the condition that the test margins and test conditions, including the duration, are agreed between supplier and customer.

ECSS-E-ST-20-01_1450130If the two tests specified in 6.4.3.1a and 6.4.3.1b are not possible a test with a reduced number of carriers applying an equivalent power as specified in clause 6.4.3.3 may be performed with free-running phase per carrier under the condition that the test margins and test conditions, including the duration are agreed between supplier and customer.

Multi-frequency test with a single carrier applying an equivalent power

ECSS-E-ST-20-01_1450131For the multi-carrier tests performed with an equivalent CW single carrier, test margins of Table 45 shall be applied.

ECSS-E-ST-20-01_1450132A single carrier equivalent power for a test as described under 6.4.3.2a above shall be defined as follows:

- perform a single carrier analysis at the average frequency of the multicarrier signal in accordance with clause 5.3.2.1 and 5.3.2.2.3 for L1 or 5.3.2.3.3 for L2 where the threshold power in Watts is denoted Pth,sc,

- perform a multicarrier analysis on the same analysis level, L1 or L2,as the single carrier analysis specified in 1 above,

- calculate the average threshold power in Watts, sum of all carrier power values, found in the multicarrier analysis, denoted Pth,mc with m the number of carriers, using for both, the single carrier and the multi carrier analysis, identical design charts, identical electromagnetic computational model as well as identical material parameters and geometry definitions,

- calculate the equivalent power for a single carrier test of a multicarrier device using following formula: Peq,sc = P0 · Pth,sc/Pth,mc, where P0 is the nominal multicarrier average power in Watts, sum of all carrier power values, of the input signal,

- verify that the computed equivalent power from step 4 for a single carrier test of a multicarrier device is always bounded by P0 ≤ Peq,sc ≤ NP0, where N is the number or of carriers,

- The single carrier test frequency is the average frequency of the multi-carrier signal as for the single carrier analysis in step 1.

- 1 If the single carrier analysis was an L1 analysis performed according to clause 5.3.2.1 and 5.3.2.2.3, the multicarrier analysis is performed according to clauses 5.3.2.1 and 5.3.2.2.4.

- 2 If the single carrier analysis was an L2 analysis performed according to clauses 5.3.2.1 and 5.3.2.3.3, the multicarrier analysis is performed according to clauses 5.3.2.1 and 5.3.2.3.4.

Multi-frequency test with reduced number of carriers applying an equivalent power

ECSS-E-ST-20-01_1450133A reduced number of carrier equivalent power for a test as described under 6.4.3.2 shall be defined as follows:

- Select the reduced frequency plan in order to have the same average frequency and the same voltage envelope period as the original multi-carrier signal.

- If item 1 is not possible due to test facility constraints, a different frequency plan with a reduced number of carriers can be used in agreement with the customer.

- Perform a multicarrier analysis for both frequency plans, with reduced number of carrier or not, with the same analysis level in accordance with clause 5.3.2.2.4 for L1 and clause 5.3.2.3.4 for L2,

- calculate the threshold power found in the multicarrier analysis, denoted Pth,mc,n, with n being the reduced number of carriers compared to Pth,mc,m, with m being the original number of carriers, using for both cases identical simulation models.,

- calculate the equivalent power for a multicarrier test with a reduced number of carriers using following formula: Equation Where:

Equation P0,mc,n is the nominal power of the input signal for n carriers

Equation P0,mc,m is the nominal power of the input signal for m carriers

Equation P0,mc,n is the nominal power of the input signal for n carriers

Pulsed testing

ECSS-E-ST-20-01_1450134Pulsed testing may be applied in the cases of equipment or components operating in CW mode.

For equipment or components operating in CW mode, pulsed testing is an alternative commonly used to avoid thermal effects, which could generate temperature levels in the unit beyond the maximum allowed limits. For this reason, the duty cycle is proportionally and gradually reduced to keep the average CW level constant as the peak power is increased towards the required test margin. This is achieved by varying the PRF between each power step to allow the mean power to be maintained, such that it does not exceed the maximum permitted level.

ECSS-E-ST-20-01_1450135The pulse width shall be equal or greater than 20 microseconds with a duty cycle of at least 2% to ensure sufficient electron seeding as per 6.5.3.

Shorter pulsed width and lower duty cycles can be used if they are representative of the operational signal characteristics.

ECSS-E-ST-20-01_1450136The pulse duration used to test equipment or component that experience pulsed excitation in service shall be between 20 microseconds and the longest pulse duration that the equipment or component experiences in service.

ECSS-E-ST-20-01_1450137The suitability of the proposed pulse width and duty cycle as well as compliance with the definition of sensitivity and rise time for the detection methods as described in 7.3.2 and 7.3.3 shall be demonstrated through the reference sample multipactor test according to 8.3b.2.

Electron seeding

General

ECSS-E-ST-20-01_1450138If seeding is proven to be inefficient on the real DUT at the critical area, the verification by test may be performed on a dedicated BB or EM unit where the design of outer parts and structures is modified in such a way that the critical gaps can be properly seeded.

Multipactor test in CW operation

ECSS-E-ST-20-01_1450139An electron seed source shall be used for CW Multipactor test.

ECSS-E-ST-20-01_1450140Electron seeding may not be used, if the test site demonstrates according to 8.3b.2, with a known reference sample representative of the DUT with respect to the material, the surface properties, the wall thickness – if applicable to the seeding method – and the gap dimensions that the same multipactor threshold as with electron seeding is achieved.

Multipactor test in pulsed operation

ECSS-E-ST-20-01_1450141An electron seed source shall be used in pulsed testing.

ECSS-E-ST-20-01_1450142In those test cases where electron seeding is ineffective due to restricted access to the critical areas, the test signal shall be in CW mode and validated in accordance with 6.5.2b.

ECSS-E-ST-20-01_1450143If, in a test case as described in 6.5.3b, it is not possible to perform CW test, the pulsed test may be performed using a longer pulse width and higher duty cycle than what is defined in 6.4.4, pending customer approval on a case by case basis.

Multipactor test in multi-carrier operation

ECSS-E-ST-20-01_1450144An electron seed source shall be used in the multi-carrier environment.

ECSS-E-ST-20-01_1450145If the test site demonstrates with a reference sample according to 8.3b.2 that the expected multipactor threshold is achieved, electron seeding may not be used.

Seeding sources

ECSS-E-ST-20-01_1450146Any applied method or technique of electron seeding shall be implemented aiming at the critical gap where multipactor breakdown can occur during the test.

ECSS-E-ST-20-01_1450147If the DUT has more than one critical gap, where a seeding source is required according to 6.5.5a, at least one seeding source shall be used at each critical gap, simultaneously or consecutively.

ECSS-E-ST-20-01_1450148The seeding electrons shall have a direct path to the critical gap where seeding is required.

For a radioactive βsource according to 6.5.5d.4, the direct path requirement is applicable to the secondary low energy electrons.

ECSS-E-ST-20-01_1450149At least one of the following seeding sources shall be used: