Space product assurance

Relifing procedure – EEE components

Foreword

This Standard is one of the series of ECSS Standards intended to be applied together for the management, engineering and product assurance in space projects and applications. ECSS is a cooperative effort of the European Space Agency, national space agencies and European industry associations for the purpose of developing and maintaining common standards. Requirements in this Standard are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards.

This Standard has been prepared by the ECSS-Q-60-14 Working Group, reviewed by the ECSS Executive Secretariat and approved by the ECSS Technical Authority.

Disclaimer

ECSS does not provide any warranty whatsoever, whether expressed, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item are error-free. In no respect shall ECSS incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this Standard, whether or not based upon warranty, business agreement, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by ECSS.

Published by: ESA Requirements and Standards Division

ESTEC, P.O. Box 299,

2200 AG Noordwijk

The

Copyright: 2008 © by the European Space Agency for the members of ECSS

Change log

|

ECSS-Q-ST-60-14A

|

Never issued

|

|

ECSS-Q-ST-60-14B

|

Never issued

|

|

ECSS-Q-ST-60-14C

|

First issue

|

Scope

This standard specifies the requirements, also known as “relifing requirements”, for the planned, intentional storage, control, and removal from storage of electronic, electrical and electromechanical parts which are intended to be used for space applications.

The relifing process is a lot quality control activity. The inspections and tests defined do not constitute an up-screening or up-grading of components to a higher level of quality than procured to.

This standard is applicable to all EEE parts covered by ECSS-Q-ST-60 and used in space programmes.

This standard is not applicable to naked dice.

This standard does not cover the relifing of commercial parts.

Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this ECSS Standard. For dated references, subsequent amendments to, or revision of any of these publications do not apply, However, parties to agreements based on this ECSS Standard are encouraged to investigate the possibility of applying the more recent editions of the normative documents indicated below. For undated references, the latest edition of the publication referred to applies.

|

ECSS-S-ST-00-01

|

ECSS system – Glossary of terms

|

|

ECSS-Q-ST-10-09

|

Space product assurance – Nonconformance control system

|

|

ECSS-Q-ST-60

|

Space product assurance – Electrical, electronic and electromechanical (EEE) components

|

|

ECSS-Q-ST-70-01

|

Space product assurance – Cleanliness and contamination control

|

|

ESCC 24900

|

Minimum Requirements for Controlling Environmental Contamination of Components

|

|

IPC/JEDEC J-STD-033

|

Standard for Handling, Packing, Shipping and Use of Moisture/ re-flow Sensitive Surface Mount Devices

|

|

ESCC 20600

|

Preservation, Packaging and dispatch of SCC Electronic Components

|

Terms, definitions and abbreviated terms

Terms from other standards

For the purpose of this Standard, the terms and definitions from ECSS-S-ST-00-01 and ECSS-Q-ST-60 apply.

For the purposed of this Standard the following terms from ECSS-Q-ST-70-01 apply:

clean area

cleanroom

Terms and definitions specific to the present standard

antistatic material

material that minimizes the generation of static charges

- 1 This term refers to the reduction of triboelectric charge generation.

- 2 This property is not dependent upon material resistivity.

conductive material

<ESD protection> material with the following characteristics:

surface conductive type: materials with a surface resistivity less than 105 /.

volume conductive type: materials with a volume resistivity less than 104 -cm.

contaminant

unwanted molecular or particulate matter (including microbiological matter) on the surface or in the environment of interest that can affect or degrade the relevant performance or life time

container

receptacle which holds, restrains or encloses an item

(original) date code

code used by the EEE part manufacturer at assembly step that indicates the production date

- 1 Generally four-figure codes; two for the year and two for the week.

- 2 Special lot number can also identify the date code.

(relifing) date code:

code indicating the date an item is submitted to relifing

Four-figure code, two for the year and two for the week.

dissipative material

<ESD protection> material with the following characteristics:

surface conductive type: materials with a surface resistivity equal to or greater than 105 / but less than 1012 /.

volume conductive type: materials with a volume resistivity equal to or greater than 104 -cm but less than 1011 -cm.

electrostatic charge

negative or positive electrical charge present on the material or item surface, at rest

electrostatic discharge (ESD)

transfer of electrostatic charge between objects at different potentials caused by direct contact or induced by an electrostatic field

electrostatic discharge sensitive (ESDS)

tendency of the performance of EEE parts to be affected or damaged by an ESD event

ESD protected area

area which is constructed and equipped with the necessary ESD protective materials, equipment, and procedures, to limit ESD voltages below the sensitivity level of ESDS items handled therein

ESD protective material

material with one or more of the following properties: limits the generation of electrostatic charge, dissipates electrostatic charge, and provides shielding from electric fields

ESD protective packaging

packaging with ESD protective materials to prevent ESD damage to ESDS items

electrostatic shield

barrier or enclosure that prevents or attenuates the penetration of an electric field

handled or handling

actions during which items are hand manipulated or machine processed

identification

application of appropriate markings to ensure that the identity of an item is unfailingly indicated after preservation and each stage of packing

isolating material

<ESD protection> material not defined as conductive or dissipative are considered to be isolating

package

support used for enveloping, protecting or containing materials

Different types of packages are normally used: Primary, intermediate and final packages

(primary) package

container, envelope or wrap holding an individual item

(intermediate) package

container holding two or more primary packages

(final) package

container holding one or more intermediate packages, used for transportation of supplies to the orderer

packaging

operations consisting in the preparation of supplies for transit and delivery.

The term includes preservation, identification and packing

packing

operation by which supplies are placed in container or wrapped and placed in containers

particle

unit of matter with observable length, width and thickness

A particle can be object of solid or liquid composition, or both, and generally between 0,001 μm and 1000 μm in size

preservation

cleaning of a item and the application of a suitable temporary protective, where necessary, to maintain the item in prime condition

relifing procedures

set of tests performed on an item previously stored to verify that its initial quality and reliability have not been affected by time

storage area

area in the storage site where EEE parts are stored and which contains one or more storage zones.

storage long duration

storage for which duration exceeds 3 years

storage site

geographical location where EEE parts are stored for a short, medium or long term period

For this site the requirements given in this standard apply: EEE parts manufacturer’s premises, procurement Agency, EEE part user.

storage zone

defined space in which EEE parts are stored and which is equipped for the monitoring and the control of storage conditions.

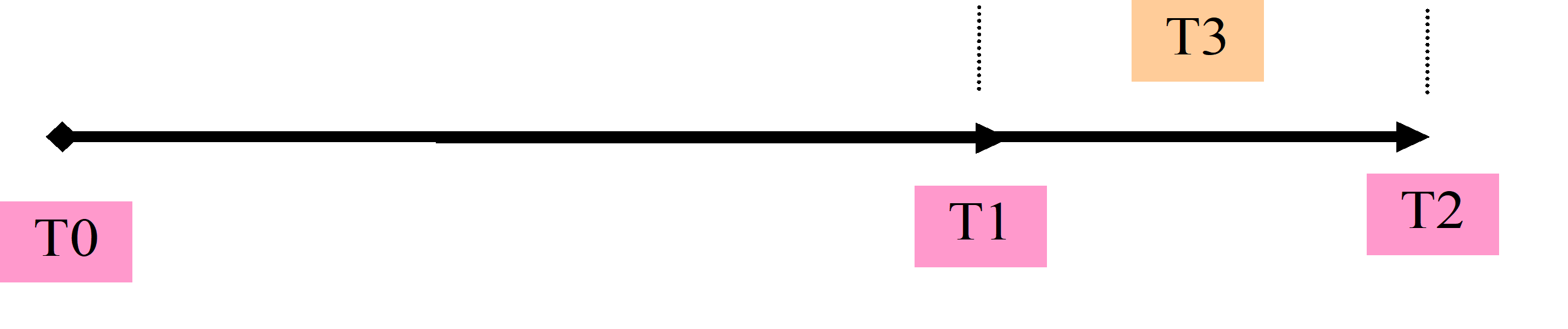

timing parameters

One of the following parameters:

T0 : Original date code

T1 : Maximum allowed storage period from T0 with no relifing control

T2 : Maximum duration between the original date code of part and its mounting

T3 : Maximum allowed storage period after a relifing control.

Figure 31: Timing parameters

Figure 31: Timing parameters

triboelectric effect

generation of electrostatic charge on an object by rubbing or other type of contact.

Abbreviated terms

For the purpose of this Standard, the abbreviated terms from ECSS-S-ST-00-01 and the following apply:

|

Abbreviation

|

Meaning

|

|

ASIC

|

application specific integrated circuit

|

|

CCD

|

charge coupled device

|

|

CDM

|

charge device model

|

|

DPA

|

destructive physical analysis

|

|

DSP

|

digital signal processor

|

|

EEE

|

electronic, electrical and electromechanical

|

|

ESCC

|

European space components coordination

|

|

ESD

|

electrostatic discharge

|

|

FPGA

|

field programmable gate arrays

|

|

HBM

|

human body model

|

|

JEDEC

|

joint electronic devices engineering council

|

|

MM

|

machine model

|

|

MMIC

|

microwave monolithic integrated circuit

|

|

NA

|

not applicable

|

|

NCR

|

nonconformance report

|

|

NSA

|

national space agency

|

|

RH

|

relative humidity

|

|

SCSB

|

space components steering board

|

|

VLSI

|

very large scale integration

|

Symbols

|

Ω

|

ohm

|

|

Ω/

|

ohm per square

|

|

Ω-cm

|

ohm centimetre

|

|

μm

|

micrometer

|

|

V

|

volt

|

Environmental parameters for storage

General rules and requirements

Introduction

This clause defines the rules for storing EEE parts used on space programs.

Those rules are in line with the requirements defined in ESCC Basic Specification 24900.

Procedures

The following domains shall be covered and documented by procedures sent to the customer for information, on request:

- Storage area and storage zone

- Cleanliness

- ESD protection

- Packing and Packaging

- Handling

- Quality assurance.

Storage area and storage zone

It shall be demonstrated that storage areas and storage zones provide such protection against vibration, electromechanical fields, radiation fields and against light so that possible degradation of organic packaging material is prevented.

Cleanliness

Rules for cleanliness efficiency shall be implemented.

The working areas and the contained equipment shall be maintained as visually clean with no loose material.

Access rules shall apply for personnel, materials and equipment.

Storage areas shall conform to a cleanliness level as defined in ECSS-Q-ST-70-01 clause 5.3.1.4.

This cleanliness level is often called and known as “grey zone”.

ESD protection

The efficiency of ESD protection measures in storage, handling and testing areas shall be demonstrated.

Guidelines in Annex B can be used for this demonstration.

Packing – Packaging – Handling

ESCC 20600 or IPC/JEDEC J-STD-033 shall apply for packing, packaging and handling.

Best practice is to pay attention to ESD sensitivity as described in Annex B.

Quality assurance requirements for storage areas

The storage responsible entity shall establish and document the following:

- Prohibited materials

- Personnel access rules

- Prohibited personnel actions

- Measures and facilities to segregate and protect components during receiving, inspection, storage and delivery

- Control measures to ensure that electrostatic discharge susceptible components are identified and handled only by trained personnel using anti static packaging and tools.

Storage conditions

Air

Normal air is used.

Temperature

Temperature in the immediate vicinity of stored components shall at all times be maintained between a minimum temperature of 17 °C and a maximum temperature of 27 °C.

This is to avoid chemical reactions catalysis when it is too high or electronic reactions on certain technologies when it is too low.

Relative humidity (RH)

RH in store cupboards shall be kept in the range defined by ESCC 24900 section 7.

This is to avoid, when combined with temperature, corrosion phenomena. The lower is the Relative Humidity the greater is the probability for ESD damage.

Package

The packages used during storage shall ensure protection against ESD as defined in clause 4.1.6 and against any form of corrosion or contamination.

Parts shall be stored in packages such that it can be demonstrated that they offer protection against ESD, corrosion and contamination including the contamination induced by the package itself.

Their primary packages can be used as long as they meet this requirement.

CCDs and opto-electronic sensors shall be stored in dry air or in neutral ambience, to prevent risks of cover glass pollution and moisture ingress.

Timing parameters

When used, relifing shall be performed anywhere between T1 and T2 according to the timing parameters definition as given in clause 3.2.31 and specified in Table 51.

For parts not planned to be mounted and to be kept in stock, relifing is not mandatory.

Table 51: Timing parameters

|

|

T1

|

T2

|

T3

|

|

All components (except savers)

|

7 years

|

10 years

|

3 years

|

|

Savers

|

10 years

|

NA

|

NA

|

In case of parts procured through an external procurement entity, the customer should require the supplier to state the minimum period of validity of parts (w.r.t. T1 or T3) after delivery.

Control parameters

Test requirements

General requirements per EEE parts family:

For relifing, the following tests, as specified in Table 61 shall be performed:

- External Visual Inspection

- Electrical measurements

- Seal test

- Specific test Component families not covered in Table 61 shall be subject to special procedures to be defined by the program.

The relifing procedure can be applied on a sub-lot containing only the quantity of components immediately needed for production. In this case, the relifing date-code is applicable only to parts actually tested. The time limits specified in Table 51 remain applicable for the residual sub-lot.

When sampling is specified in Table 61, it shall be performed in accordance to the following criteria, with a minimum of 80 parts, calculated with respect to the number of relifed parts.

- < 80 parts : 100%, with 0 defect allowed

- 81 -> 280 parts : sampling is 80 parts, with 0 defect allowed

- > 280 parts : sampling is 80 parts, with 1 defect allowed The specifications and methods to be used during relifing shall be those that were in effect for the initial procurement or, if demonstrated that they are not applicable, the most recent updated issues.

Specific requirements per EEE parts family:

Seal test shall be performed when applicable (hermetic cavity package).

See (1) in Table 61.

For ceramic chip or moulded capacitors, electrical measurement shall be done after 4 hours of stabilisation at 125°C for Type II ceramic.

See (2) in Table 61.

Multi-chips (staked) capacitors shall be submitted to 100% visual inspection and electrical testing.

See (3) in Table 61.

For all type of tantalum capacitors (solid and non-solid), the following specific tests shall be performed before the parametrical measurement:

- Apply 9 discharges and 8 charges with a cycle time of 2 seconds and under nominal voltage.

- Perform a burn-in tests (96 hours, rated voltage, 85°C).

- Monitor the current during both charge and discharge tests to detect short circuit.

See (4) in Table 61.

For film capacitors using the polycarbonate technology, a DPA test shall be performed on three pieces ,including:

- external visual inspection

- sealing test after insulate sleeve removal

- microsection on two pieces

- decaping on third part.

See (5) in Table 61.

For programmed parts, the total duration (storage and mission) shall not exceed data retention duration given by the manufacturer (when applicable).

See (6) in Table 61.

For VLSI, hybrids and CCD, when electrical test is not practicable because of test program or product complexity, the validation may be transferred to use step (functional test, programming).

- 1 See (7) in Table 61.

- 2 For example, VLSI can be ASIC, FPGA, MMIC, DSP, microprocessors, microcontrollers.

For electromagnetic relays of latching and non-latching type, 10 switching shall be run before electrical measurements.

See (8) in Table 61.

For low frequency and radio-frequency wires and cables, at least 0.5 m shall be inspected and insulating material shall be removed on 0.2 m.

See (9) in Table 61.

Electrical test shall be optional for cavity hermetically sealed qualified parts when the qualification level is in line with the quality level defined by the applicable annex: A-1, A-2 or A-3 of ECSS-Q-ST-60.

See (10) in Table 61.

Electrical testing

The DC parameters as given in table 2 of the applicable ESCC detail specification (or equivalent in another specification system) shall be measured.

- 1 It is important to pay attention to the test and set up procedures which can have changed since the initial date code.

- 2 Additional burn-in and drift calculation to be performed are only those specified in Table 6.1.of the applicable ESCC detail specification.

External visual inspection

In case of doubt or anomaly regarding any surface contamination, one part shall be sampled in order to make a solderability test according to the applicable test method.

The solderability test results shall be recorded in the relifing report.

The part tested for solderability shall be considered destroyed.

Seal test

The sealing tests shall be recorded as "pass" where the results meet the requirements of the original procurement specification Sealing tests include fine leaks or gross leaks or both, depending on the applicable specification.

The measurement values of leaks on non-conforming components shall be recorded in the relifing report.

Nonconformance

ECSS-Q-ST-10-09 shall apply for the handling and processing of nonconformances.

The processing of nonconformances is identical for both relifing and normal procurement procedures.

Any components not satisfying at least one of the requirements included in this standard shall be considered as not conform.

When sampling test (as per Table 61), any batch of components failing the sampling rule defined in clause 6.1.1 shall be considered as not conform.

In the cases specified in 6.2c, the test shall be performed on a 100% basis on the whole lot and the causes of the nonconformance shall be determined.

In the case specified in 6.2c, the test shall be performed on a 100% basis on the whole lot and the causes of the nonconformance investigated and recorded in the relifing report.

In case of 100% test (as per Table 61), any batch of components shall be declared as not conform when failing the following requirement:

* lot size < 100 parts : 0 defect allowed

* lot size > 100 parts : 1 defect allowed

Relifing datecode

The relifing date code shall correspond to the week code of the first test performed on the lot.

This date code shall be assigned independent of the report conclusions.

The relifing date code shall not be marked on the component and no other additional marking added.

Relifing report

When relifing a component, a relifing report shall be established in conformance with the DRD in Annex A and sent, on request, to the customer for information.

Certificate of Conformity

Once a batch is accepted, supported by a relifing report giving an “acceptable” decision or as a result of NCR processing, the original Certificate of Conformity shall be annotated with the relifing date code.

The Certificate of Conformity shall be attached with the components during their delivery.

Discarded batches shall be processed internally by the relevant reject system of the supplier.

Table 61: Control parameters and detailed application of categories

|

|

External Visual Inspection

|

ELECTRICAL (10)

|

SEAL (1)

|

SPECIFIC

|

|

capacitors, chip, ceramic

|

sampling

|

sampling (2)

|

no

|

no

|

|

capacitors, moulded, ceramic

|

sampling (3)

|

sampling (2), (3)

|

no

|

no

|

|

capacitors, glass (CYR, …)

|

100 %

|

100 %

|

no

|

no

|

|

capacitors, mica (HTxx, …)

|

100 %

|

100 %

|

no

|

no

|

|

capacitors, chip, solid tantalum

|

sampling

|

100 %

|

no

|

(4) charge/

|

|

capacitors, leaded, solid tantalum

|

sampling

|

100 %

|

no

|

(4) charge/

|

|

capacitors, leaded,

|

100 %

|

100 %

|

no

|

(4) Charge

|

|

capacitors, film

|

sampling

|

100 %

|

no

|

DPA on 3p (5)

|

|

capacitors, variable

|

sampling

|

no

|

no

|

no

|

|

connectors, non filtered, rectangular

|

100 %

|

no

|

100 %

|

no

|

|

connectors, filtered, rectangular

|

100 %

|

100 %

|

100 %

|

no

|

|

connectors, non filtered, circular

|

100 %

|

no

|

100 %

|

no

|

|

connectors, filtered, circular

|

100 %

|

100 %

|

100 %

|

no

|

|

contacts & accessories

|

No

|

no

|

no

|

no

|

|

crystals

|

100 %

|

100 %

|

100 %

|

no

|

|

diodes

|

100 %

|

sampling

|

100 %

|

no

|

|

diodes, microwave

|

100 %

|

sampling

|

100 %

|

no

|

|

Filters

|

100 %

|

100 %

|

100 %

|

no

|

|

fuses, "cermet"

|

sampling

|

sampling

|

no

|

no

|

|

fuses, wire link

|

sampling

|

sampling

|

no

|

no

|

|

heaters, flexible

|

100 %

|

100 %

|

no

|

no

|

|

inductors, coils, moulded

|

sampling

|

sampling

|

no

|

no

|

|

inductors, coils, non moulded

|

sampling

|

sampling

|

no

|

no

|

|

integrated circuits

|

100 %

|

sampling (6), (7)

|

100 %

|

no

|

|

integrated circuits, microwave

|

100 %

|

sampling (7)

|

100 %

|

no

|

|

µwave passive parts (isolators, circulators)

|

100 %

|

sampling

|

no

|

no

|

|

µwave passive parts

|

100 %

|

sampling

|

no

|

no

|

|

µwave passive parts (attenuators, loads)

|

100 %

|

sampling

|

no

|

no

|

|

oscillators (hybrids)

|

100 %

|

100 %

|

100 %

|

no

|

|

relays, electromagnetic,

|

100 %

|

100 % (8)

|

100 %

|

no

|

|

resistors, fixed, film

|

sampling

|

100 %

|

no

|

no

|

|

resistors, high precision,

|

sampling

|

100 %

|

no

|

no

|

|

resistors, network, thick and thin film

|

sampling

|

100 %

|

no

|

no

|

|

resistors, current sensing (RLV, ...)

|

sampling

|

100 %

|

no

|

no

|

|

resistors, power, fixed, wirewound

|

sampling

|

sampling

|

no

|

no

|

|

resistors, power, fixed, wirewound, chassis mounted (RER, ...)

|

sampling

|

sampling

|

no

|

no

|

|

resistors, precision, fixed,

|

sampling

|

100 %

|

no

|

no

|

|

resistors, fixed, film, high voltage

|

sampling

|

sampling

|

no

|

no

|

|

resistors, fixed, thick and thin film, chip

|

sampling

|

100 %

|

no

|

no

|

|

switches, electromechanical

|

100 %

|

100 %

|

100 %

|

no

|

|

switches, thermostatic

|

100 %

|

100 %

|

100 %

|

no

|

|

thermistors

|

100 %

|

100 %

|

no

|

no

|

|

transformers

|

sampling

|

100 %

|

no

|

no

|

|

transistors

|

100 %

|

sampling

|

100 %

|

no

|

|

transistors, microwave

|

100 %

|

sampling

|

100 %

|

no

|

|

wires and cables, low frequency

|

sampling (9)

|

no

|

no

|

no

|

|

cables, coaxial, radio frequency

|

sampling (9)

|

no

|

no

|

no

|

|

hybrids

|

100 %

|

100 % (7)

|

100 %

|

no

|

|

surface acoustic waves

|

100 %

|

100 %

|

100 %

|

no

|

|

charge coupled devices

|

100 %

|

100 % (7)

|

100 %

|

no

|

|

opto discrete devices

|

100 %

|

100 %

|

100 %

|

no

|

|

NOTE: For applicable notes, see clause 6.1.2.

| ||||

ANNEX(normative)Relifing report - DRD

DRD identification

Requirement identification and source document

This DRD is called from ECSS-Q-ST-60-14C requirement 6.4a.

Purpose and objective

The purpose of this document is:

to give the detailed references of the lot tested

to describe the relifing tests performed

to give the results obtained

to give the date of tests

Expected response

Scope and content

The relifing report shall give the following generic information:

- part style

- detailed specification (with issue and variant)

- item identification by the supplier

- quantity stored

- original datecode

- date of storage For each test, the relifing report shall indicate:

- operator

- date of test

- quantity tested

- quantity rejected

- comments

The relifing report shall include a conclusion (accepted / rejected).

The relifing report shall indicate the new datecode (after relifing).

Special remarks

Figure A-1 shows a proposed template to be used for the relifing report.

|

Part Style:

| |

|

Detailed specification: Issue: Var:

| |

|

Item identification at User:

| |

|

Quantity Stored: Date code: Date of Storage:

| |

|

TESTS

|

RELIFING

|

|

1. External visual

|

|

|

Operator

|

|

|

Date

|

|

|

Quantity tested

|

|

|

Quantity rejected

|

|

|

Comments

|

|

|

2. Electrical tests

|

|

|

Operator

|

|

|

Date

|

|

|

Quantity tested

|

|

|

Quantity rejected

|

|

|

Comments

|

|

|

3. Hermeticity

|

|

|

Operator

|

|

|

Date

|

|

|

Quantity tested

|

|

|

Quantity rejected

|

|

|

Comments

|

|

|

4. DPA (if any)

|

|

|

Operator

|

|

|

Date

|

|

|

Quantity tested

|

|

|

Results

|

|

|

DPA Report number

|

|

|

5. Other tests

|

|

|

Conclusion:

|

|

|

New date code

|

|

Figure: Example of a relifing traveller sheet

ANNEX(informative)ESD

Generalities and nature of static electricity

Static electricity is electrical charges at rest.

The electrical charges can be created by two events, which are:

The transfer of electrons within a body resulting in polarization and a net overall charge of zero. The polarization is caused by Induction, that is the body enters an electrostatic field or lines of force around another charged body but without contacting the charged body

The transfer of electrons from one body to another resulting in Conductive Charging and in net positive or negative charge. Triboelectric effects cause the conductive charging

ESD control program

Scope of ESD control program

Tasks, activities and procedures necessary to protect ESDS items

Identification of organizations responsible for the tasks and activities

Listings of directive or guidance documents in the ESD control program

Description of ESD control requirements imposed on subcontractors and suppliers

Listing of the specific ESD protection tools materials and equipment

ESD protections

Protective areas

ESD protective areas are required when handling ESDS parts, assemblies and equipment outside of their ESD protective covering or packaging.

Dispositions are taken to limit static voltage levels below the damage threshold of the most sensitive ESDS part.

Implementation of protective areas leads to requirements for adequate grounding procedures, personnel electrical safety, Tools materials and equipment specification, operating procedures and development of handling procedures.

The following document may be used as guideline: MIL-HDBK-263 appendix F.

Protective covering and packaging materials

|

Personnel

|

Wearing of ESD protective smocks or clothing footwear (list not exhaustive) when handling ESDS items

|

|

Work areas, protected areas

|

Use of conductive materials or dissipative materials

|

|

EEE parts packaging

|

Use and control of antistatic materials for primary packages like dry-packs, plastic rails or tubes.

|

The following document can be used as guideline : MIL-HDBK-263 appendix I.

Materials are normally classified as conductive, dissipative and isolative. The classification depends upon the material resistivity. Isolative materials are not ESD protective and special attention is recommended.

Surface treated isolative material is used as antistatic materials if their resistivity is compliant to the definition of clause 3.2.1.

Warning: Antistatic materials loose their antistatic properties after a certain time due to the fact that only the surface is impregnated with charges. So, special attention is recommended to control it.

Handling

The following document can be used as guideline: MIL-HDBK-263 appendix H.

EEE parts sensitivity to ESD classification

Parts are classified function of their sensitivity to ESD and 3 main models: HBM model, MM model and CDM model (Table B-1)

|

HBM:

|

The principal source of ESD damage is the human body

|

|

MM:

|

The prime source of damage for the MM is a charge machine or device.

|

|

CDM;

|

The prime source of damage for the CDM is the rapid discharge of a charged part

|

Table: ESD classes

|

ESD MODEL

|

ESD CLASS: Sensitivity (S) versus Voltage range

|

|

HBM

|

1 0 V < S < 1999 V

|

|

MM

|

1 0 V < S < 100 V

|

|

CDM

|

1 0 V < S < 124 V

|

Bibliography

|

ECSS-S-ST-00

|

ECSS system – Description, implementation and general requirement.

|

|

MIL-HDBK-263

|

Electrostatic Discharge Control Handbook for protection of Electronic Parts, Assemblies and Equipment (excluding Electrically Initiated Explosive Devices)

|