Space product assurance

Thermal testing for the evaluation of space materials, processes, mechanical parts and assemblies

Foreword

This Standard is one of the series of ECSS Standards intended to be applied together for the management, engineering and product assurance in space projects and applications. ECSS is a cooperative effort of the European Space Agency, national space agencies and European industry associations for the purpose of developing and maintaining common standards. Requirements in this Standard are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards.

This Standard has been prepared by the ECSS-Q-ST-70-04 Working Group, reviewed by the ECSS Executive Secretariat and approved by the ECSS Technical Authority.

Disclaimer

ECSS does not provide any warranty whatsoever, whether expressed, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item are error-free. In no respect shall ECSS incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this Standard, whether or not based upon warranty, business agreement, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by ECSS.

Published by: ESA Requirements and Standards Division

ESTEC, ,

2200 AG Noordwijk

The

Copyright: 2008 © by the European Space Agency for the members of ECSS

Change log

|

ECSS-Q-70-04A

|

First issue

|

|

ECSS-Q-70-04B

|

Never issued

|

|

ECSS-Q-ST-70-04C

|

Second issue

|

Introduction

The deleterious effects to be anticipated during the thermal cycling test under vacuum include:

outgassing,

cracking or fracture of materials or assemblies due to sudden dimensional changes by expansion,

contraction or pressure,

short circuiting of electrical wiring,

overheating of materials or assemblies due to change in convection and conductive heat transfer characteristics.

Scope

This Standard establishes the requirements for the specification, the procedures, the execution and the reporting of a thermal cycling test under vacuum for the evaluation of materials, processes, mechanical parts and assemblies intended for use in the fabrication of spacecraft and associated equipment. This is one of the tests to determine the ability of theses articles to withstand changes of ambient temperature under vacuum.

Typical materials or assemblies that can be evaluated by means of this test method are listed below.

adhesives;

adhesive bonded joints;

coatings (paint, thermal and protective);

insulating materials;

metallic bonded joints;

metallic samples, finished by plating or chemical conversion;

metallized plastic films;

organic or nonorganic bonding;

plated surfaces;

potting compounds;

reinforced structural laminates;

sealants.

This is not an exhaustive list and other products or items can be tested.

This standard may be tailored for the specific characteristic and constrains of a space project in conformance with ECSS-S-ST-00.

Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this ECSS Standard. For dated references, subsequent amendments to, or revisions of any of these publications do not apply. However, parties to agreements based on this ECSS Standard are encouraged to investigate the possibility of applying the most recent editions of the normative documents indicated below. For undated references the latest edition of the publication referred to applies.

|

ECSS-S-ST-00-01

|

ECSS system – Glossary of terms

|

|

ECSS-Q-ST-10-09

|

Space product assurance – Nonconformance control system

|

|

ECSS-Q-ST-20

|

Space product assurance – Quality assurance

|

|

ECSS-Q-ST-20-07

|

Space product assurance – Quality assurance for test centres

|

|

ECSS-Q-ST-70

|

Space product assurance – Materials, mechanical parts and processes

|

Terms, definitions and abbreviated terms

Terms from other standards

For the purpose of this Standard, the terms and definitions from ECSS-S-ST-00-01 and ECSS-Q-ST-70 apply.

Terms specific to the present standard

batch

see “lot”

lot

quantity produced at one operation

- 1 One lot can be divided in several sub-lots.

- 2 The term “batch” is synonymous.

Abbreviated terms

For the purpose of this Standard, the abbreviated terms from ECSS-S-ST-00-01 and the following apply:

|

Abbreviation

|

Meaning

|

|

QCM

|

quartz crystal microbalance

|

|

UV

|

ultraviolet

|

Principles

The principles of the thermal test for the evaluation of space materials and processes is to submit the item to be tested (materials, processes, mechanical parts or assemblies) to a certain number of thermal cycles, oscillating within an defined temperature range in order to anticipate and to evaluate the resistance to deleterious effects as:

outgassing,

cracking or fracture of materials or assemblies due to sudden dimensional changes by expansion,

contraction or pressure,

short circuiting of electrical wiring,

overheating of materials or assemblies due to change in convection and conductive heat transfer characteristics.

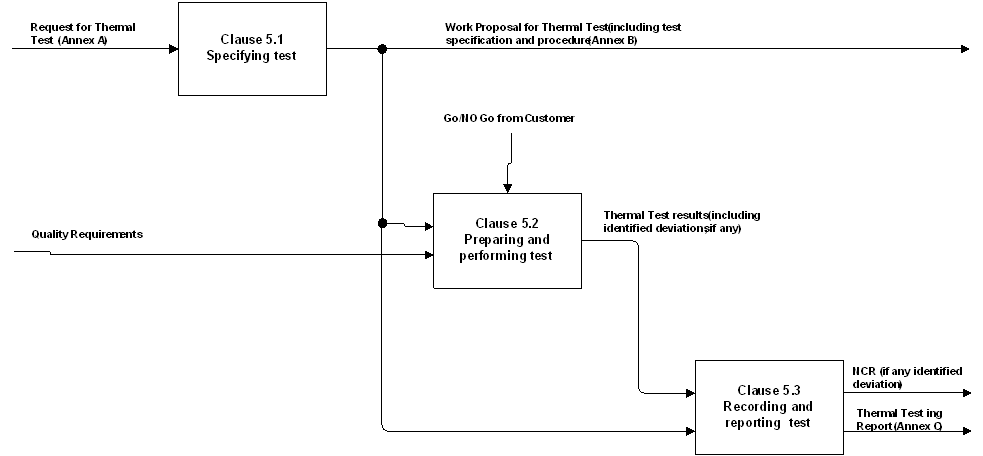

For this purpose the activities related to thermal cycling tests requirements, specifications, procedures and reports are described in Figure 41 and the related requirements are captured in clause 5.

Figure 41: Thermal cycling test process overview

Figure 41: Thermal cycling test process overview

Clause 5.1 provides the specification for the means and procedures of tests (facilities, equipments and special apparatus) and the item to be tested.

Clause 5.2 and 5.3 provide the requirements for preparing, performing, recording and reporting a thermal cycling test.

Requirements

Specifying test

General provision

The customer shall provide a request for thermal test in conformance with the DRD in Annex A.

ECSS-Q-ST-20 shall be made applicable in the request for thermal cycling test.

ECSS-Q-ST-10-09 shall be made applicable in the request for thermal cycling test.

For safety and security, the test centre shall comply with ECSS-Q-ST-20-07, clause 9.

Examples of safety issues are “hazard” and “health”. An example for security issues is “access control”.

The supplier shall provide a thermal cycling test proposal in conformance with the DRD in Annex B for customer approval.

Specifying the test means

Facilities

The work area shall be nominally clean with minimum dust, but not necessarily a cleanroom environment.

Air used for ventilation shall be nominally filtered to prevent contamination of the sample.

The ambient conditions for the process and work areas shall be (22 3) C with a relative humidity of (55 10) %.

Equipment

The supplier shall specify the list of the equipment necessary to set up and run the approved test procedures.

If the test procedure proposed in Annex D is executed by the supplier, the corresponding equipment specification is described in Annex E.

Specifying the thermal cycling test procedures

Test procedures

The test procedures shall address the test conditions control and monitoring of:

- temperature,

- vacuum,

- contamination. The test procedure for controlling and monitoring the temperature shall contain the following information:

- sample temperatures measurement and recording methods,

- temperature data acquisition during testing.

There is a difference between real sample temperature and temperature of the holder.

The test procedure for controlling and monitoring the vacuum shall contain the following information:

- sample vacuum and residual atmosphere measurements and recording methods,

- pressure data acquisition during testing. The test procedure for controlling and monitoring the contamination shall contain the following information:

- contamination check methods used during tests,

- contamination results. ECSS-Q-ST-20 shall apply for the establishment of the test procedures.

Controlling the contamination

In case of optical or thermo-optical properties measurements, contamination effects on the sample shall be controlled.

- 1 Cross contamination can occur between samples or be induced by internal vacuum chamber residual pressure.

- 2 Contamination control evaluation can be performed with any method: witness sample, UV absorption, Infrared analysis of contaminants deposit on CaF2 or ZnSe windows and/or QCM measurements.

Measuring the temperatures

The method used to measure the temperature shall be agreed between customer and supplier.

During thermal testing, the temperature of the sample (test item) shall be measured.

The test temperature range shall be based on the operating temperature range of the material in space

The test supplier shall specify the temperature measurement procedure and accuracy.

Preparing and performing Test

General

The test proposal shall include the thermal cycling test procedures.

Preparing the item to be tested

Identification

Materials, processes and mechanical parts submitted for thermal cycling test shall be clearly identified in order to maintain traceability.

Assemblies submitted for thermal cycling test shall be identified by:

- trade name and batch number;

- name of supplier through whom the purchase was made;

- configuration control status of the assembly.

Preparation

The material samples shall be prepared according to the relevant process specifications or manufacturer’s data.

It shall be agreed with the customer that the material samples are representative of batch variance.

If it is not practicable to test completed assemblies, the supplier shall submit samples made from the same materials and by the same processes as those used in the manufacture of the assemblies.

The sample for testing shall have one flat surface which does not overlap the dimensions of the sample holder to be used in the test.

The flat surface shall be in continuous contact with the sample holder, attached by any form of clamping arrangement which does not cover more than 10 % of the sample’s remaining surfaces.

The maximum thickness of the sample shall be such that, under vacuum of 10-5 Pa, any point of extremity does not differ by more than 5 C from the temperature of the sample holder.

This parameter depends on the thermal conductivity properties of the sample.

Cleaning

The cleaning and other treatments of the sample shall be the same as that applied to the finished article, which the sample is intended to represent, prior to integration into the spacecraft.

Further cleaning or other treatments should be avoided.

Handling and storage

Samples shall only be handled with clean nylon or lint free gloves.

Samples shall be stored in a controlled area, with an ambient temperature of (22 3) C and relative humidity of (55 10) %.

Coated surfaces shall be shielded from contact by using polyethylene or polypropylene bags or sheets.

Physical damage shall be avoided by packing the polyethylene or polypropylene wrapped workpieces in clean, dust and lint free material.

Limited life materials shall be labelled with their shelf lives and dates of manufacture or date of delivery if date of manufacture is not known.

Preparing the facilities and equipment

The work area shall be as defined in clause 5.1.2.1a.

Contamination of the samples shall be avoided (when handling or storing) and monitored.

Monitoring of the sample contamination can be done by witness samples described in ECSS-Q-ST-70-01.

The ambient conditions for the process and work areas shall be (22 ± 3) C with a relative humidity of (55 ± 10) %.

The specific equipments shall be defined in the thermal cycling test proposal.

The supplier shall provide evidence that all test measuring equipment, are calibrated.

Running the thermal cycling test procedures

The supplier shall run the approved thermal cycling test procedures, produced in conformance with the DRD in Annex B.

An example of an approved thermal cycling test procedure is given in Annex D.

Recording and reporting the test results

Test records

The test records of the thermal cycling test shall be retained for at least ten years or in accordance with project business agreement requirements.

The test records shall contain the following:

- trade names and batch numbers of the materials under test;

- name of the supplier through whom the purchase was made;

- summary of the preparation and conditioning schedule;

For example: mixing proportions, coating thickness, cure time and temperature, postcure, cleaning procedure.

- details of the testing room environment conditions and test equipment used for the thermal cycling in vacuum;

- details of the test parameters outlined in the approved thermal cycling test procedures.

Those details also include any variation in working vacuum pressure during the test.

- details of equipment used for visual, mechanical, chemical and physical property measurement or inspection, as outlined in approved thermal cycling test specifications and procedures;

- comments concerning any unusual occurrence during the temperature cycling;

- the list of all samples subjected to thermal cycling under vacuum tests;

- reports of the results, subsequent to visual examination and testing, to the customer;

- number of sample tests;

- results of any failure analysis;

- details of failure mode (if applicable):

- deficient design;

- poor workmanship;

- wrong fabrication or application procedure;

- wrong choice of materials;

- others.

The test records of the thermal cycling test shall be composed of:

- the request for thermal cycling test which conforms to the DRD in Annex A,

- the thermal cycling test proposal which conforms to the DRD in Annex B,

- the thermal cycling test report which conforms to the DRD in Annex C,

- a conclusion with respect to the compliance with the project requirements (acceptance criteria) and any associated nonconformances.

Test report

The supplier shall establish a test report in conformance with the DRD in Annex C, for customer approval.

The supplier shall apply ECSS-Q-ST-20, clause 5.6.3.2 for the establishment of the test.

Acceptance criteria and nonconformance

Acceptance criteria shall be defined (beforehand) in common agreement between the test authority and the customer.

Any suspected or actual equipment failure shall be recorded as project nonconformance report so that previous results can be examined to ascertain whether or not re-inspection and re-testing is needed.

The test procedures shall contain an instantiation or adaptation for the test item of the nonconformance processing flow chart as described in ECSS-Q-ST-10-09 figure 4.1.

In the frame of research and development activities, this is not necessary.

The supplier shall notify the customer of the nonconformance details.

Traceability shall be maintained throughout the process from incoming inspection to final measurements and calculations, including details of the test equipment and personnel employed in performing the task.

Samples which have passed the test criteria and is not damaged by the execution of the approved thermal cycling test procedures shall have passed this test.

During and upon completion of the test sequence the sample shall be investigated for signs of cracking, fracture, overheating and significant electrical degradation.

Photomicrographs shall be taken of the sample to the requirements of the customer.

Evaluation of other properties can be invoked by the customer, such as those indicated in D.2.

ANNEX(normative)Request for thermal cycling test - DRD

DRD identification

Requirement identification and source document

This DRD is called by ECSS-Q-ST-70-04, requirement 5.1.1a.

Purpose and objective

The purpose of the request for thermal testing is to confirm that the materials to be evaluated with respect to the specific thermal test requirements of the project and prior to its validation and approval for selection as item of the “as designed” DML, DPL or DMPL depending on the nature of the item to be tested (e.g. materials, processes or parts) are acceptable for use.

Expected response

Scope and content

The request for thermal test shall include or refer to the following information:

- objective of the test activity,

- background and justification to the test activity,

- material or assemblies to be investigated,

- description of test activity, and

- deliverables.

Special remarks

None.

ANNEX(normative)Thermal cycling test specifications and procedures (Work Proposal) - DRD

DRD identification

Requirement identification and source document

This DRD is called by ECSS-Q-ST-70-04, requirement 5.1.1e.

Purpose and objective

The work proposal (WP) is a document that specifies the test activity for the evaluation of materials and processes. It is proposed by the test house. The work proposal for thermal cycling test is prepared by the supplier who is responsible for the test activity, and it is submitted to the customer for review and approval.

Expected response

Scope and content

The WP shall include or refer to the proposed work description giving:

- the objectives of the test activity,

- test procedure and reference to standards

- materials, processes. or parts number and dimensions of samples

- test conditions (i.e. environment, properties evaluated and measurement techniques),

- expected test output.

The WP shall include or refer to a proposed settlement describing the test procedures and any deviation from the conditions initially requested by the customer.

The WP shall include financial information.

Special remarks

None.

ANNEX(normative)Thermal cycling test report - DRD

DRD identification

Requirement identification and source document

This DRD is called by ECSS-Q-ST-70-04, requirement 5.3.2a.

Purpose and objective

The purpose of the thermal cycling test report is to provide evidence that the materials, processes, mechanical parts or assemblies were screened according to the thermal test specifications and procedures.

Expected response

Scope and content

The thermal cycling test report shall include or refer to the following information:

- description of the purpose, objective, content and the reason prompting its preparation,

- description of the thermal cycling test facility,

- description of the item to be tested or a reference to the document containing its identification characteristics,

For example: request for thermal cycling test.

- calibration tools,

- the actual thermal cycling test procedures or a reference to the document containing the description of the test procedure (e.g. thermal cycling test specifications and procedures DRD),

- the test results,

- discussion about the test results,

- conclusion and recommendations.

Special remarks

None.

ANNEX(informative)Thermal cycling test procedures

General

The test procedure flow is shown in Figure D-1.

Pre and post test

The extent of physical and mechanical properties to be examined before and after testing depends on the intended application of the sample material and assembly.

The inspection and test methods are specified by the customer before each sample undergoes thermal cycling in vacuum.

Visual examination for defects in the sample is initially carried out at ×20 magnification.

Higher magnification is used post test for locating microscopic defects such as surface crazing, embitterment and blistering.

Photomicrographs are taken before and after the thermal cycling sequence at the same magnification.

Thermo optical properties and surface properties are recorded for comparison post test if detailed by the customer.

For mechanical testing and other forms of destructive testing identical samples are supplied for the comparison of results before and after the thermal cycling sequence.

These tests can include the recording of tensile, compression, elongation, hardness and adhesion properties (see ECSS-Q-ST-70-09).

Surface roughness is recorded upon request by the customer.

Electrical measurements can be performed before, during or after the thermal cycling on the sample.

Electrical measurements to be performed are specified before testing by the customer.

One sample of the lot can be kept as a reference or a witness for mechanical, electrical, thermo-optical measurements. In this case, this sample is not submitted to thermal cycles.

Thermal cycling test

The initial characteristics are investigated at (22 3) C and RH (55 10) % within six hours prior to the commencement of the thermal cycling.

The sample is then mounted on the sample holder as described in clause 5.2.2.2.

After insertion of the sample holder, the chamber is evacuated.

Thermal cycling commences after a working vacuum of 1 × 10-5 Pa has been reached.

The chamber is thermally cycled between temperatures of +(100 ± 5) C to -(100 ± 5) C unless otherwise specified, at a nominal heating or cooling rate of (10 ± 2) C per minute between the two temperature extremes with the temperature recorded at the sample as e.g. in Annex E.d to Annex E.h.

The sample dwell time is not less than five minutes, the maximum dwell time determined by the customer, at each of the temperature extremes.

Certain special samples, e.g. electrical circuits, can require a modified cycling sequence with different temperature parameters.

The minimum number of thermal cycles performed on each sample is 100.

Certain samples can require further cycling, e.g. when thermal fatigue conditions exist, but in these cases the number of cycles is specified before tests start.

Final inspection and testing of the sample is conducted at (22 ± 3) C and RH (55 ± 10) % within six hours after the completion of thermal cycling in vacuum.

Figure: Test procedure flow diagram

Handling and packaging of tested samples

For handling and packaging of testes samples the conditions specified in clause 5.2.2.4 are applied, unless other post test disposal instructions are given.

ANNEX(informative)Thermal cycling test equipment

The following test equipment can be used for the thermal cycling test:

Microscope

At least 20 magnification with attachment to enable photomicrographs to be taken.

Electrical instruments (if applicable)

To monitor any electrical degradation of the sample, i.e. insulation, current and other parameters as appropriate.

Monitoring instruments

To fulfil the monitoring requirements of the test process:

Temperature: -150 C to +150 C accurate to 1 C;

Relative Humidity (RH): 40 % to 70 % accurate to 1 %;

Vacuum: 1 10-5 Pa accurate to 5 %.

Additional test equipment can be used if further tests are invoked by the project.

The test is conducted in a thermal vacuum chamber containing a suitable sample holder.

The vacuum capacity of the chamber is capable of maintaining the test vacuum of 1 10-5

The vacuum is monitored by a vacuum gauge mounted in close proximity to the sample under test.

The sample holder and associated heating and cooling systems are capable of cycling, at a nominal rate of (10 2) C/min, the sample between -150 C and +150 C.

The thermal cycling sequence is controlled by the temperature of the sample and is continuously monitored and recorded by a minimum of two thermocouples, having an accuracy of 2 C, in direct contact with the sample holder in close proximity to the sample under test.

Contamination of the samples is avoided (when handling or storing) and monitored.

Monitoring of the sample contamination can be done by witness samples.

The specific equipments are defined in the thermal cycling test proposal.

The supplier provides evidence that all measuring equipments, part of the test set up are calibrated.

Bibliography

|

ECSS-S-ST-00

|

ECSS system – Description, implantation and general requirements

|

|

ECSS-Q-ST-70-01

|

Space product assurance – Cleanliness and contamination control

|

|

ECSS-Q-ST-70-09

|

Space product assurance – Measurement of thermooptical properties of thermal control materials

|