Space product assurance

Adhesive bonding for spacecraft and launcher applications

Foreword

This Standard is one of the series of ECSS Standards intended to be applied together for the management, engineering, product assurance and sustainability in space projects and applications. ECSS is a cooperative effort of the European Space Agency, national space agencies and European industry associations for the purpose of developing and maintaining common standards. Requirements in this Standard are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards.

This Standard has been prepared by the ECSS-Q-ST-70-16C Working Group, reviewed by the ECSS Executive Secretariat and approved by the ECSS Technical Authority.

Disclaimer

ECSS does not provide any warranty whatsoever, whether expressed, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item are error-free. In no respect shall ECSS incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this Standard, whether or not based upon warranty, business agreement, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by ECSS.

Published by: ESA Requirements and Standards Section ESTEC, P.O. Box 299, 2200 AG Noordwijk The NetherlandsCopyright: 2020© by the European Space Agency for the members of ECSS## Change log

|

ECSS-Q-ST-70-16C

|

First issue

|

Introduction

Adhesive materials have a wide range of uses within the space domain however they are often qualified as a minor or negligible part of a large subsystem or system. This frequently results in unforeseen effects arising directly from the adhesive selection which impacts either the functionality, integrity or AIT activities. As a consequence whilst the adhesive is often the lowest cost element of the system it frequently has a high cost associated with the necessary recovery and delta qualification activities need to ensure the system level functionality. Both the system level qualification and any recovery actions are further complicated by the intrinsic relationship between the adhesive performance, the adherend and all the processes associated with the manufacture of the adhesive bond.

European space agencies and the space industry at present have a general handbook available for adhesive bonding (ECSS-E-HB-32-21) however there is no fixed scheme detailing the minimum requirements for verification of adhesive bonding process nor validation of an adhesive material.

Standardisation of the verification processes for adhesives and adhesive bonding across the European space industry is allowing a harmonised and consistent approach.

The generic approach facilitates the correct selection of data thus allowing streamlining of the industrial development activities and enabling the validation of adhesives and verification of adhesive bonding process at an early stage of a programmes lifetime.

This standard is further justified because of the high level of non-conformances (NCR) identified across industry due to limited early programmatic qualification programmes related to adhesive bonding and characterisation of adhesive materials.

Scope

The scope of the document addresses the generic verification for all types of adhesive bonding for space applications including evaluation phases. This standard covers all aspects of the adhesive bonding lifetime such as assembly, integration and testing, on-ground acceptance testing, storage, transport, pre-launch, launch and in-flight environments.

This standard does not cover requirements for:

Adhesive bonding used in EEE mounting on printed circuit boards (for this subject see ECSS-Q-ST-70-61)

Adhesive bonding used in hybrid manufacturing (for this subject see ESCC 2566000)

Adhesive bonding for cover-glass on solar cell assemblies (for this subject see ECSS-E-ST-20-08)

Design of adhesive joints (for this subject see ECSS-E-ST-32)

Long term storage and long term storage sample testing

Performance of adhesive bonds

Functional properties of adhesive joints

Co-curing processes

Life-time aging prediction, neither on ground (humidity) nor in-orbit (thermal cycling)

This standard may be tailored for the specific characteristics and constrains of a space project in conformance with ECSS-S-ST-00.

Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this ECSS Standard. For dated references, subsequent amendments to, or revision of any of these publications do not apply. However, parties to agreements based on this ECSS Standard are encouraged to investigate the possibility of applying the more recent editions of the normative documents indicated below. For undated references, the latest edition of the publication referred to applies.

|

ECSS-S-ST-00-01

|

ECSS system - Glossary of terms

|

|

ECSS-E-ST-32

|

Space engineering - Structural general requirements

|

|

ECSS-Q-ST-10

|

Space product assurance -Product assurance management

|

|

ECSS-Q-ST-10-09

|

Space product assurance -Nonconformance control system

|

|

ECSS-Q‐ST‐20

|

Space product assurance - Quality assurance

|

|

ECSS-Q-ST-40

|

Space product assurance - Safety

|

|

ECSS-Q-ST-70

|

Space product assurance - Materials, mechanical parts and processes

|

|

ECSS-Q-ST-70-02

|

Space product assurance - Thermal vacuum outgassing test for the screening of space materials

|

|

ECSS-Q-ST-70-09

|

Space product assurance - Measurements of thermo-optical properties of thermal control materials

|

|

ECSS-Q-ST-70-22

|

Space product assurance - Control of limited shelf-life materials

|

|

ECSS-Q-ST-70-71

|

Space product assurance - Materials, processes and their data selection

|

|

ISO 472:2013/ Amd 1:2018

|

Plastics - Vocabulary - Amendment 1: Additional items

|

|

ISO 3696:1987

|

Water for analytical laboratory use - Specification and test methods

|

|

ISO 15785:2002

|

Technical drawings - Symbolic presentation and indication of adhesive, fold and pressed joints

|

Terms, definitions and abbreviated terms

Terms from other standards

For the purpose of this Standard, the terms and definitions from ECSS-S-ST-00-01 apply.

For the purpose of this Standard, the terms and definitions from ECSS-Q-ST-70 apply, in particular for the following terms:

critical process

critical material

special process

request for approval

For the purpose of this Standard, the terms and definitions from ECSS-Q-ST-40 apply, in particular for the following term:

criticality

Terms specific to the present standard

adherend

body that is, or is intended to be, held to another body

[ISO 472:2013/Amd 1:2018]

adhesion

state in which two surfaces are held together by interfacial forces which can consist of chemical or mechanical or physical interfacial forces

adhesive bond

see “adhesive joint”

The term “adhesive joint” is commonly used, but for the process the term “bonding”.

adhesive bonding procedure

detailed instructions, equipment and tools needed to perform the adhesive bonding

Refer to Annex A for the detailed content.

adhesive bonding process

material joining process where an adhesive material is added in order to maintain chemical, mechanical or physical interfacial forces between bonded parts

The joining mechanism between adhesive and bonded parts, also called “adherend”, is adhesion-based. According to ECSS-Q-ST-70, adhesive bonding belongs to category of “special processes”.

adhesive joint

joint of two or more parts of similar or different materials made using adhesives

[ISO 15785:2002]

The term “adhesive bond” is synonymous

adhesive material

substance with the capability of holding two surfaces together by either chemical, physical or mechanical interfacial forces or a combination of them

The concept of adhesive materials is addressed in ECSS-E-HB-32-21.

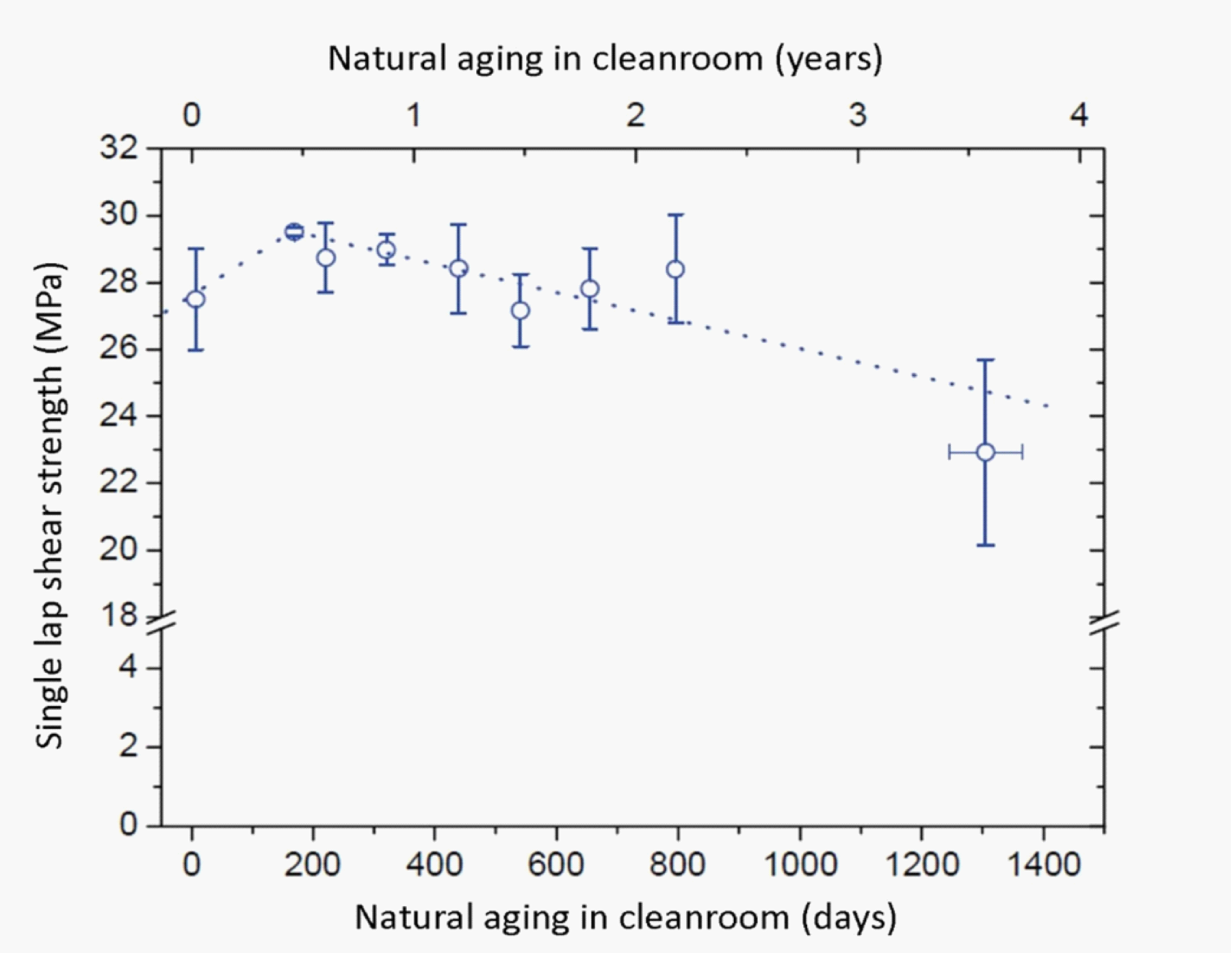

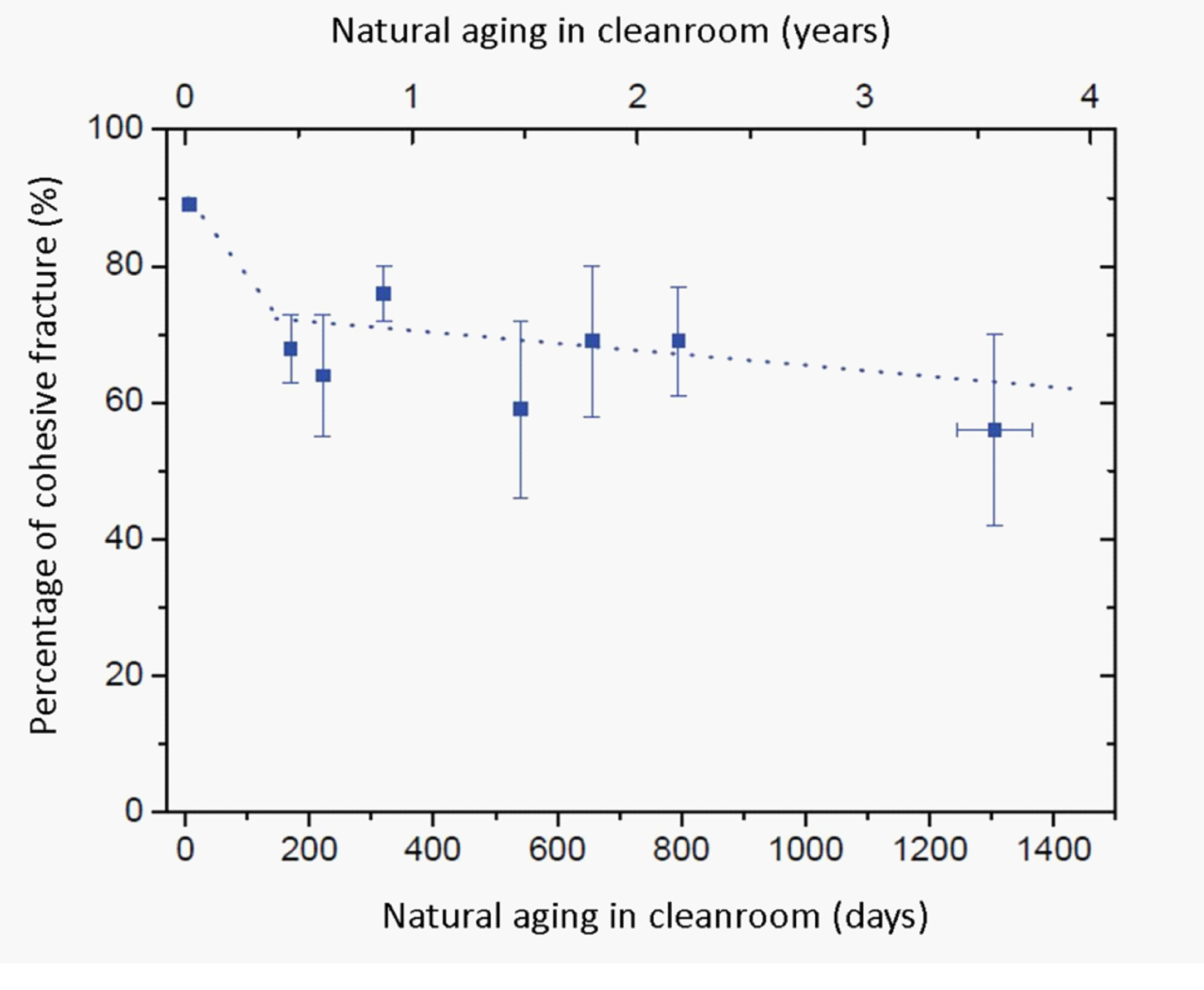

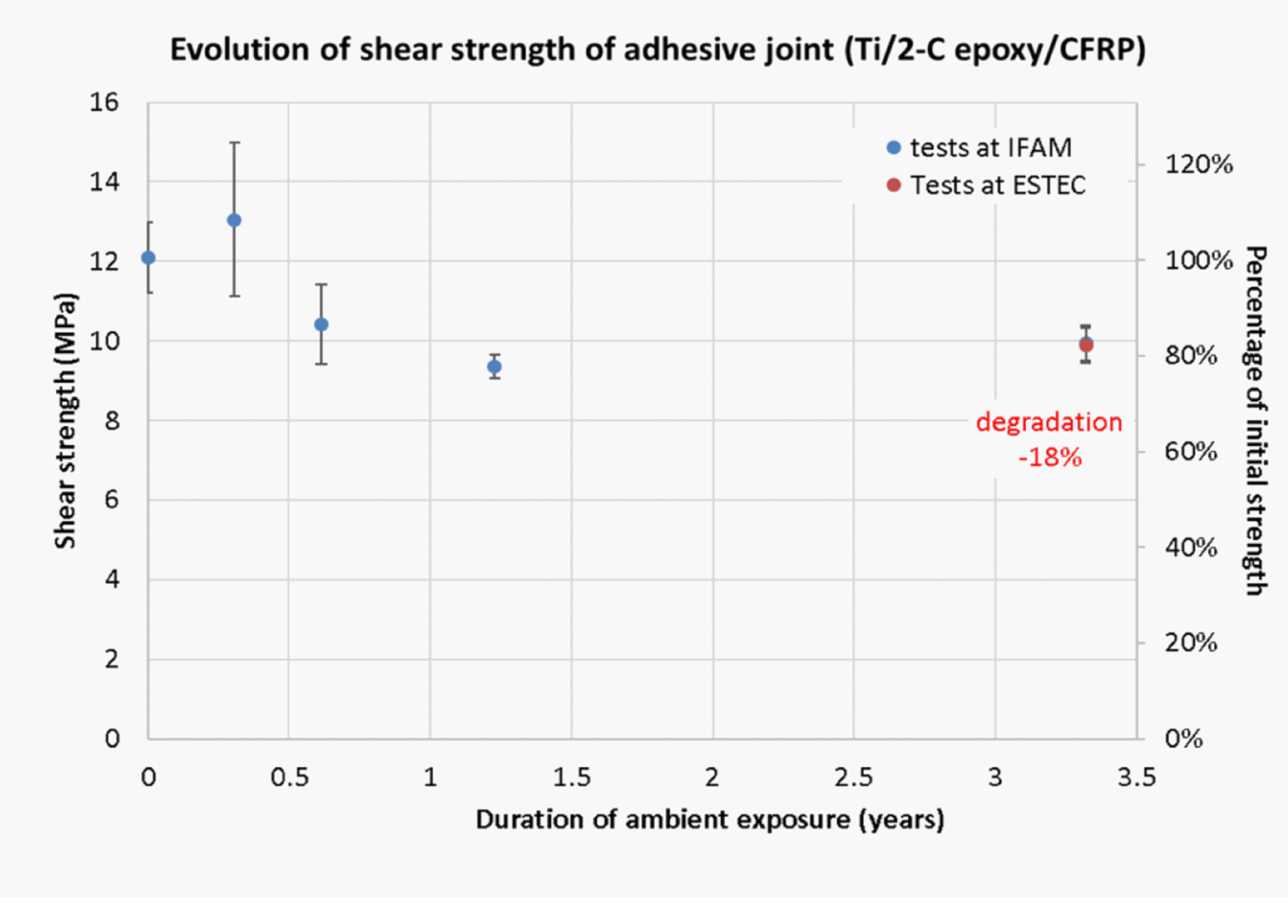

ambient exposure in a controlled environment

item is exposed to ambient air with temperature in the range of (22 ± 3) °C, and relative humidity (55 ± 10) %

-

1 Long term exposure to these conditions can cause degradation of the adhesive joint’s performance.

-

2 Contributes to “intrinsic ageing” of the joints.

co-curing

earliest stage of the manufacturing process, resulting in a fully integrated component -

1 The joining mechanism is chemical cross-linking. Both adherends are undergoing chemical reaction.

-

2 This standard does not cover requirements for the verification of co-curing processes.

co-bonding

intermediate stage of a manufacturing process when an uncured part is joined with one or more cured parts, typically with an additional layer of uncured adhesive -

1 The joining mechanism between the adhesive and the cured part is adhesion. Between the un-cured part and uncured adhesive layer chemical cross-linking is taking place.

-

2 Further text refers only to adhesive bonding or co-bonding (uncured adhesive, cured adherend) or to bonding with pressure sensitive tapes (PSAs).

degradation

undesired change of property of interest in a given time interval

hot-wet exposure

exposure where the test item is subjected to synergistic effect of gaseous water phase and temperature

-

1 The test item is exposed to conditions where temperature and water vapour pressure, typically >25 °C and >65 % RH), are higher than in a controlled environment

-

2 Performed in frame of simulation of on-ground environment within adhesive bonding verification test sequence or as part of independent hot-wet testing

-

3 Inspection and verification of the test item before and after hot-wet exposure is non-destructive and does not prevent test item to be submitted for further testing in frame of verification test sequence

-

3 Also known as “humidity exposure”

hot-wet testing

test where the test item is subjected to hot-wet exposure and the effect of hot-wet exposure is verified after hot-wet exposure is performed -

1 Hot-wet exposure can be performed in combination with other additional stresses, e.g. mechanical, chemical or electrical

-

2 Functional properties of test item can be verified during hot-wet exposure “in-situ” conditions

-

3 In hot-wet testing of the adhesively bonded joints, hot-wet exposure is typically followed by mechanical tests to verify degradation of the joint and reduction factor associated with hot-wet exposure

-

4 Also known as “damp-heat” testing or “humidity testing”

knock-down factor (KDF)

overall factor that is applied to the material property to account for variations in material composition, service environment and structural geometry

It can consist of several reduction factors.

reduction factor

ratio between mean value of given material property of exposed test item set and of reference (unexposed) test item sets

Can be expressed as fraction or as percentage of initial reference value (remaining percentage of the property of interest).

representativeness level of test item

definition of how well or accurately the test item reproduces the similarity to flight model configuration

structural bond

bond which is capable of sustaining in a structure a specified strength level under a combination of stresses for a specified period of time

- 1 to entry: The combination of stresses can, for example, include peel and shear forces, fluctuating loads, environmental exposure and steady load. An adhesive that is capable of forming a structural bond is commonly referred to as a “structural adhesive”.

- 2 The term “structural joint” is synonymous

[ISO 472:2013]

test item

manufactured assembly undergoing verification test sequence

The test item can be standard test sample, component or part fully representative to the flight hardware.

test item population

group of test items sets manufactured to complete specific test sequence, including all reference test items, on-ground simulation test items, mission simulation test items and launch simulation test items and spare test items

Group of items with same manufacturing history.

test item set

test items that follow an identical test sequence

Abbreviated terms

For the purpose of this Standard, the abbreviated terms and symbols from ECSS-S-ST-00-01 and the following apply:

|

Abbreviation

|

Meaning

|

|

AIT

|

assembly, integration and test

|

|

CME

|

coefficient of moisture expansion

|

|

CTE

|

coefficient of thermal expansion

|

|

DMA

|

dynamic mechanical analysis

|

|

DPL

|

declared process list

|

|

DRD

|

document requirements definition

|

|

DSC

|

differential scanning calorimetry

|

|

MLI

|

multi-layer insulation

|

|

MMPP

|

materials, mechanical parts and processes

|

|

NDI

|

non-destructive inspection

|

|

PA

|

product assurance

|

|

PPE

|

personal protective equipment

|

|

PSA

|

pressure sensitive adhesive

|

|

RFA

|

request for approval

|

|

RH

|

relative humidity

|

|

SDS

|

safety data sheet

|

|

Tg

|

glass transition temperature

|

|

TDS

|

technical data sheet

|

|

TGA

|

thermo-gravimetric analysis

|

|

TMA

|

thermo-mechanical analysis

|

|

TVC

|

thermal vacuum cycling

|

|

UV

|

ultraviolet

|

Nomenclature

The following nomenclature applies throughout this document:

The word “shall” is used in this Standard to express requirements. All the requirements are expressed with the word “shall”.

The word “should” is used in this Standard to express recommendations. All the recommendations are expressed with the word “should”.

It is expected that, during tailoring, recommendations in this document are either converted into requirements or tailored out.

The words “may” and “need not” are used in this Standard to express positive and negative permissions, respectively. All the positive permissions are expressed with the word “may”. All the negative permissions are expressed with the words “need not”.

The word “can” is used in this Standard to express capabilities or possibilities, and therefore, if not accompanied by one of the previous words, it implies descriptive text.

In ECSS “may” and “can” have completely different meanings: “may” is normative (permission), and “can” is descriptive.

The present and past tenses are used in this Standard to express statements of fact, and therefore they imply descriptive text.

Principles of adhesive bonding

Overview

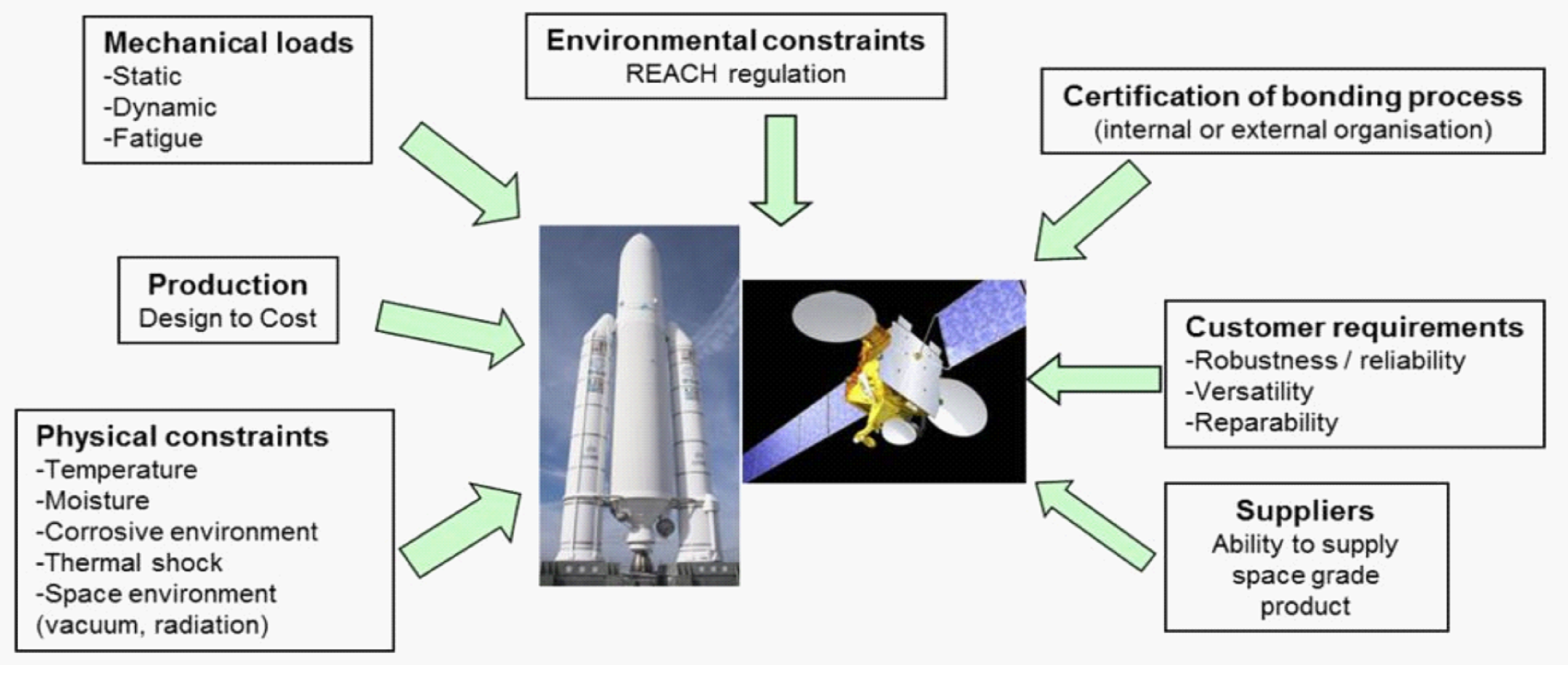

Adhesive bonding for space hardware varies from bonding of for example cable ties, to the complex structural bonding of load bearing parts. Some adhesive bonds can be inside the spacecraft, while others are exposed to space conditions including sometimes large temperature variations and radiation. Therefore the lifetime of each adhesive bond is carefully assessed before starting the bonding process. An overview of the different factors affecting the adhesive bonding performance is given in Figure 41.

Figure 41: Overview of the constrains linked to adhesive bonds for space applications (not exhaustive)

Figure 41: Overview of the constrains linked to adhesive bonds for space applications (not exhaustive)

Design of hardware

The design of bonded hardware involves parameters such as load direction and magnitude, CTEs, bonding gaps, accessibility. A detailed overview on how to design an adhesive joint can be found in sections 8 to 11 of ECSS-E-HB-32-21.

Designers or sizing engineers have a good understanding of how stresses are distributed across the joint when loads (mechanical and thermal) are applied to it. Typically they consider the general guideline for adhesive bonds to:

Maximize shear and minimize peeling and cleavage load

Maximize compression and minimize tensile loads

Optimize the bond length to width ratio for shear loading

Increase the bond width is more efficient than to increase the bond length.

In case of using fibre composite adherends the fibre orientation of the first ply is taken into account to optimize the joint performance.

Performance of the adhesive bond

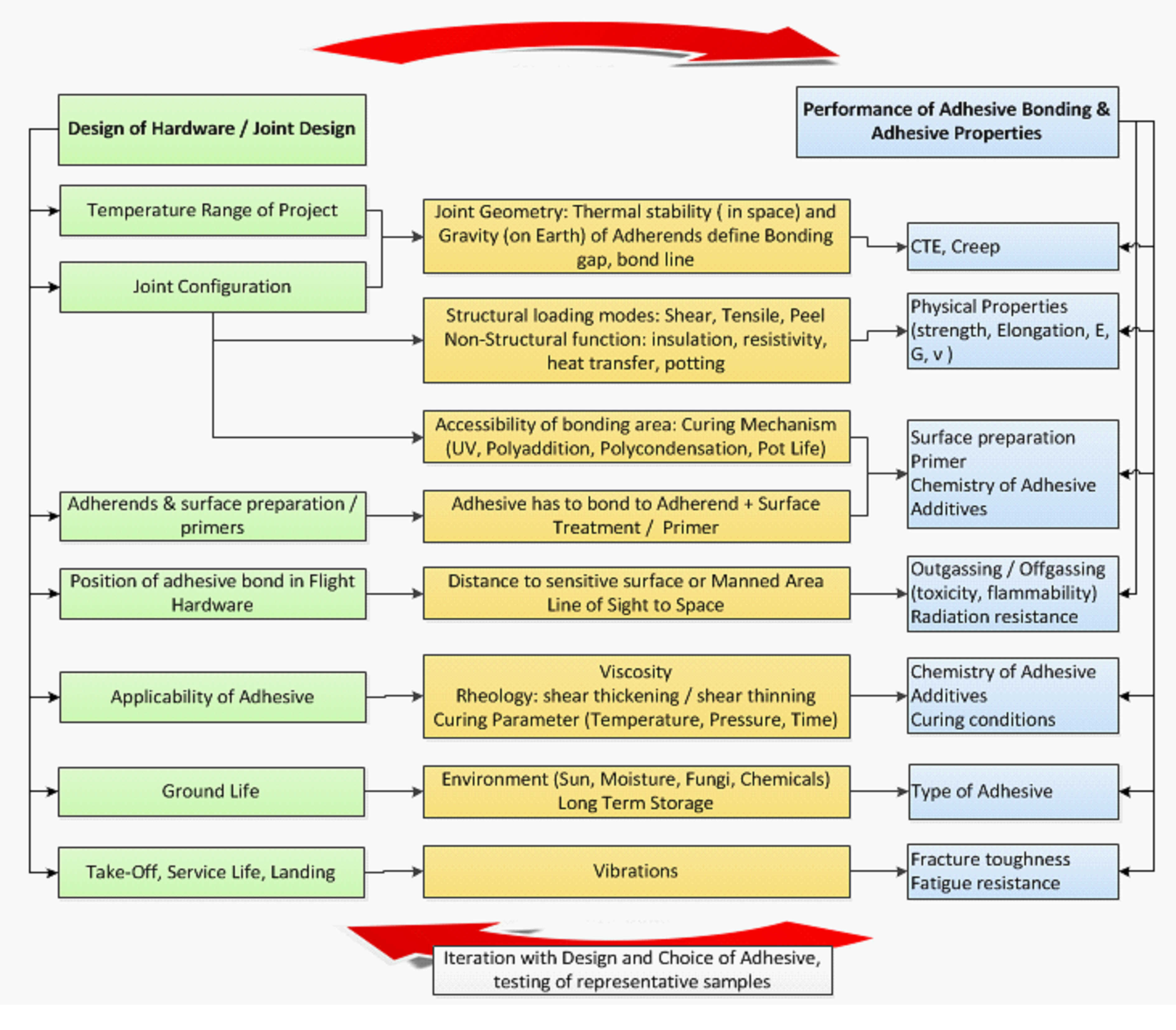

After having defined the basic design of the hardware and the parts that are bonded, the analysis of the adhesive bond is performed. This analysis can focus on joint design, adhesive material properties and environmental constraints, see Figure 42.

The needed performance of the adhesive bond has an influence on the choice of the adhesive itself, regarding for example strength, curing process, surface treatment of the adherend and temperature stability.

More information on surface treatments of the adherends can be found in section 12 of ECSS-E-HB-32-21 and in ISO 17212:2012.

In case the needed performance cannot be achieved with the adhesives and surface preparations available, the design is changed to generate a more bonding-friendly setup (see Figure 42) or changed to another (for example mechanical) joining method.

Adhesive bonding process

The adhesive bonding process is considered as a “special process” in accordance with ECSS Q-ST-70 and generally taken into account in the early stages of the project.

The amount of time and personnel needed to perform the bonding depends on parameters like, the overall surface area, type of surface preparation, treatment, possible primer application, pot life and curing of the adhesive.

The bonding process steps can be described in individual procedures. For example the adhesive bonding procedure can refer to sub- procedures.

Examples of adhesive bonding process steps:

Preparation of bonded parts (degreasing, cleaning, ultrasonic bath with organic solvents, drying condition)

Surface treatment (by mechanical, chemical and physical means)

Surface post-treatment (incl. final surface cleaning, surface protection and conditions of storage if not bonded immediately)

Surface activation (by mechanical, chemical and physical means)

Adherends such as polymers can need a dedicated surface treatment to increase their surface energy.

Surface quality verification (for example surface energy, roughness, wettability)

Positioning and alignment of adherends

Adherend priming (if any)

Adhesive preparation (including conditioning and mixing)

Adhesive application

Adhesive curing in bonded assembly

Bonded assembly verification (NDI inspection after cure – visual, dimensional check, mechanical load proof test)

- 1 The same process steps are applicable for in-process samples.

- 2 This list with examples is not exhaustive and steps are not mentioned in a strict chronological order.

In the case of adherends that are sensitive to ageing in storage conditions (UV, humidity, temperature over time) a specific surface preparation process can be applied to remove the affected surface layer.

Figure 42: Overview on some parameters influencing the adhesive bond and its design

Figure 42: Overview on some parameters influencing the adhesive bond and its design

For a more detailed design chart see Figure 10.16‐1 in ECSS-E-HB-32-21.

Selection of adhesive

Overview

The selection of an appropriate adhesive depends on a wide range of factors from early stage of manufacturing over service life till the end of mission. The ECSS Adhesive Bonding Handbook ECSS-E-HB-32-21 gives information about adhesive characteristics and properties and adhesive selection.

Analysis of adhesive application

ECSS-Q-ST-70-16_1460001Selection of materials for adhesives shall be in compliance with requirements from clause 5 of ECSS-Q-ST-70.

Requirements from clause 5 of ECSS-Q-ST-70 include: for example: vacuum, radiation, moisture.

ECSS-Q-ST-70-16_1460002Selection of adhesives shall be in compliance with clause 4.2.11 of ECSS-Q-ST-70-71.

ECSS-Q-ST-70-16_1460003Depending on the cured adhesive properties, selection of adhesives shall be in compliance with requirements from clauses 4.2.17, 4.2.18 and 4.2.19 of ECSS-Q-ST-70-71.

Adhesive materials can be also grouped to elastomers (clause 4.2.17), thermoplastic (4.2.18) and thermosets (4.2.19).

ECSS-Q-ST-70-16_1460004Selection of adhesive tapes shall be in compliance with clause 4.2.12 of ECSS-Q-ST-70-71.

ECSS-Q-ST-70-16_1460005The outgassing characteristics of selected adhesive material in cured state shall be in compliance with requirements from clause 5 of ECSS-Q-ST-70-02.

For launcher applications when the adhesive material is not facing the spacecraft (for example lower stagers of launcher, ground segment support applications), the requirements on cleanliness and contamination and outgassing specified in clause 5 of ECSS-Q-ST-70-02 can be tailored.

ECSS-Q-ST-70-16_1460006An assessment of the bonding application shall be performed as basis for the adhesive selection.

ECSS-Q-ST-70-16_1460007The assessment should include, but is not limited to:

- Joints design

- Mechanical loads

- Thermo-mechanical loads

- Adherends

- Geometrical Configuration

- Shape of the bondline

- Need of NDI

- Adhesives properties

- Mechanical properties

- Thermo-mechanical properties

- Offgassing

- Moisture sensitivity

- Appearance

- Specific properties

- Processing

- Surface preparation of adherends

- Curing conditions: time to full cure, temperature, pressure, humidity, time to handling strength

- Adhesive conditioning

- Viscosity

- Pot life

- Manual or machine processing

- Adhesive filet removal (excess adhesive)

- Packaging and storage

- Ground, launch, and in-orbit environment

- Radiation

- Vacuum

- Temperature range

- Thermal cycling

- Chemical compatibility

- Storage time and storage conditions

- Procurement

- Cost factors

- Lead time

- Export control

- Obsolescence risk

- Health and safety

- 1 For requirement 5.2g.1(e): The shape of the bondline refers, for example, to the presence/absence of an outer fillet (excess glue)

- 2 For requirement 5.2g.2(d): Sensitivity can be related to water absorption, water content in the adhesive, water desorption, CME, water diffusion.

- 3 For requirement 5.2g.2(d): Accelerated hot-wet tests can be performed within screening activities in order to determine the moisture sensitivity of representative assembly.

- 4 For requirement 5.2g.2(e): Optical applications can require either transparent or dark glues.

- 5 For requirement 5.2g.2(f): Specific properties include electrical, thermal, optical, thermo-optical properties.

- 6 For requirement 5.2g.3(g)variations in adhesive processing can modify final adhesive properties

- 7 Further information about selection of adhesives can be found in section 7 of ECSS-E-HB-32-21.

ECSS-Q-ST-70-16_1460008Adhesives properties should be analysed based on: - Supplier information

- Materials data bases

- Data of tests relevant to the specific application

- 1 Examples of Materials databases are: MAPTIS (NASA), MATREX (CNES), Granta MI, ESMDB (ESA), MIL handbooks.

- 2 Examples of tests can be found in Annex D, Annex E and section 15 of ECSS-E-HB 32-21.

- 3 Further information on adhesive characteristics and properties can be found in a section 6 of ECSS-E-HB-32-21.

- 4 Tests applied for generation of missing data are based on national or international standards, list of tests can be found in Annex D, Annex E.

ECSS-Q-ST-70-16_1460009For application of adhesive tape for passive thermal control requirements from clause 4 of ECSS-Q-ST-70-09 shall apply for thermo-optical measurements.

Tape application procedure can have an impact on the tape thermo-optical properties.

Definition of adhesive bonding process

Adhesive bonding process requirements

ECSS-Q-ST-70-16_1460010The adhesive bonding process shall be in compliance with the requirements specified as in clause 4.3.1 of ECSS-Q-ST-70-71.

ECSS-Q-ST-70-16_1460011Process control of adhesive bonding shall be performed in compliance with the requirements from clause 7 of ECSS-Q-ST-70.

ECSS-Q-ST-70-16_1460012The adhesive bonding process shall be performed according to the adhesive bonding procedure specified in DRD Annex A.

ECSS-Q-ST-70-16_1460013Adherends and adhesive materials shall have the same temperature as the processing environment in order to avoid condensation during the bonding process.

- 1 This means conditioning to the working temperature of materials taken from colder or warmer places than the bonding area.

- 2 This can be described by an additional step: conditioning prior to bonding.

Adhesive bonding procedure

ECSS-Q-ST-70-16_1460014An adhesive bonding procedure shall be issued by the supplier according to DRD Annex A.

- 1 Preparation of the bonding procedure is considered as a multidisciplinary task.

- 2 The bonding procedure can be a single document or split into several documents.

ECSS-Q-ST-70-16_1460015The references relevant to adhesive bonding procedure shall be listed in the Declared Process List (DPL)

ECSS-Q-ST-70-16_1460016The operators executing the bonding process shall proceed according to the adhesive bonding procedure.

ECSS-Q-ST-70-16_1460017Training of the operators shall be done in accordance to the requirements in clause 8.11.

Adhesive bonding process traceability

ECSS-Q-ST-70-16_1460018For process traceability the requirements from clause 5.2.5 of ECSS-Q-ST-20 shall apply.

ECSS-Q-ST-70-16_1460019Date of the bonding process steps shall be recorded.

ECSS-Q-ST-70-16_1460020Batch (production lot) number of primer and adhesive material used for bonding process shall be recorded.

ECSS-Q-ST-70-16_1460021Operator identification shall be recorded.

ECSS-Q-ST-70-16_1460022Records of requirements 6.3b, 6.3c and 6.3d shall be kept in the manufacturing file.

For requirement 6.3b the information about the execution time for bonding process steps can be useful.

Verification of adhesive bonding

Overview

The adhesive bonding of the flight hardware needs a careful analysis to determine its verification status with respect to the mission requirements. When verification is missing or not complete then a test plan is established.

The test plan is defined - to verify the performance of the flight hardware. Defined tests are therefore representative of flight conditions with, for example, representative loads being applied in representative directions.

Adhesive bonding test plan

ECSS-Q-ST-70-16_1460023The supplier shall issue an adhesive bonding test plan according to the DRD in Annex B for customer approval for critical processes as defined in ECSS-Q-ST-70.

Customer approval is processed through a RFA.

ECSS-Q-ST-70-16_1460024The adequacy and reliability of a bonding configuration and its associated process shall be demonstrated through a verification programme.

A bonding configuration is defined as a minimum by the adherends, the adhesive and the bonding process, see clause 7.7.

ECSS-Q-ST-70-16_1460025Adhesive bonding performance properties to be tested shall be selected according to application needs.

- 1 The bonding application assessment as described in clause 5.2 can be used to determine these parameters.

- 2 The test item configuration is linked to the properties to be characterized.

ECSS-Q-ST-70-16_1460026In the adhesive bonding test plan the supplier shall list all tests and inspections used during sub-sequential steps of verification test sequence in conformance with requirements from clause 7.7.

ECSS-Q-ST-70-16_1460027The pass-fail criteria of the verification test sequence shall be specified by the supplier and submitted as part of the adhesive bonding test plan for customer approval.

Adhesive bonding test report

ECSS-Q-ST-70-16_1460028The results of the test shall be documented in the adhesive bonding test report in conformance with the DRD from Annex C.

Test item bonding procedure

ECSS-Q-ST-70-16_1460029The bonding procedure shall be in compliance with the DRD from Annex A.

ECSS-Q-ST-70-16_1460030The bonding procedure used for test item shall be representative of flight hardware manufacturing.

ECSS-Q-ST-70-16_1460031Any deviation between test items and flight hardware bonding procedure shall be justified and submitted for the customer approval.

Deviations can be related to differences in adhesive application, tooling manufacturing environment and to upscaling of in production.

Test item configuration

ECSS-Q-ST-70-16_1460032Test items shall be representative of flight hardware configuration as a minimum for the following:

- Adhesive preparation and curing

- Adhesive application

- Primer preparation and curing

- Primer application

- Adherend materials

- Adhesive thickness

- Surface finishing of adherends

- Geometry

- Dimensions

- Surface preparation

- 1 to item 7.5a.5: The precise chemical composition and material manufacturing process can be important for any type of material.

- 2 to item 7.5a.7: Surface finishing is state of the surface before surface preparation prior adhesive bonding.

ECSS-Q-ST-70-16_1460033Any deviation between test items and flight hardware configuration shall be justified and submitted for customer approval.

The justification rational can be included in the adhesive bonding test plan.

ECSS-Q-ST-70-16_1460034Deviations in test item from flight hardware shall be justified for following:

- Adherends materials

- Adhesive preparation method

- Adhesive application

- Adhesive thickness

- Curing cycle

- Surfaces finishing of adherends

- Geometry

- Dimensions

- Sandwich panel configuration

- Surface preparation ECSS-Q-ST-70-16_1460035In case a repair process of adhesive bond exists, the test items shall be manufactured and tested according to the verification sequence.

Typical examples of repairs are : debonding/breakage of MLI studs, bonding of additional fixtures in cabling.

Test item identification

ECSS-Q-ST-70-16_1460036The supplier shall mark all test items with identification to maintain traceability in a way not to degrade the quality of the test item during testing.

This includes also untested spare test items.

ECSS-Q-ST-70-16_1460037The supplier shall maintain the traceability of the following details of the test items submitted for testing:

- Identification code of the test item

- Applicable documentation

- Details of the supplier of the assembly

- Type of product

- Adherend and adhesive materials

- Processing details, reference to the adhesive bonding procedure

- Batch numbers

- Test item quantity

- Test item manufacturing date

- Prepared by

- Any deviation to test item definition

Verification test sequence

General

ECSS-Q-ST-70-16_1460038For the purpose of the verification test sequence the supplier shall identify the parameters affecting the performance of the adhesive bond within its life cycle.

Figure 42 shows some parameters from the on ground-life phase, pre-launch, launch and early orbit phase as well as the mission.

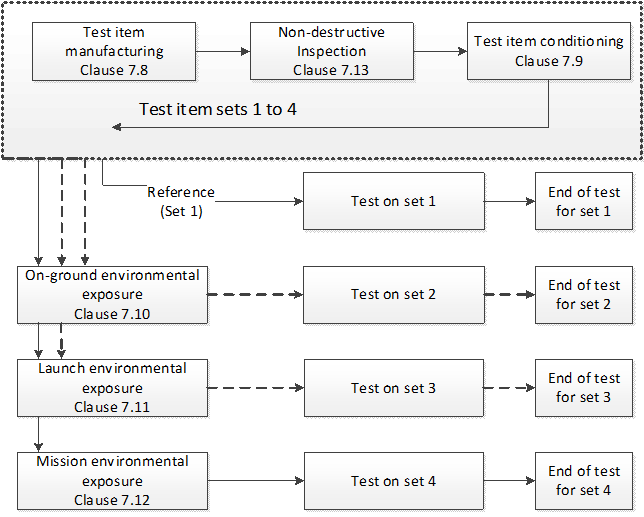

ECSS-Q-ST-70-16_1460039The verification test sequence shall be in accordance with the flow chart from Figure 71.

- 1 The verification sequence based on the flow chart from Figure 71 can be tailored depending on the application needs. For example it is not always necessary to have intermediate verification steps (Set of Test Items “2” tested after on-ground exposure simulation test and “3” tested after launch environmental exposure can be optional, represented by dashed lines with arrows in Figure 71).

- 2 The need to perform optional steps in Figure 71 is discussed in clauses 7.10 and 7.11.

ECSS-Q-ST-70-16_1460040After each environmental exposure step, inspection of the test item set should be performed.

ECSS-Q-ST-70-16_1460133Figure 71: Flow chart with adhesive bonding verification sequence

ECSS-Q-ST-70-16_1460133Figure 71: Flow chart with adhesive bonding verification sequence

Test item manufacturing

ECSS-Q-ST-70-16_1460041Test items shall be manufactured in accordance with requirements from clause 7.5.

ECSS-Q-ST-70-16_1460042The number of test items in a test item set shall be as a minimum five.

ECSS-Q-ST-70-16_1460043The number of test items may be reduced upon customer agreement.

ECSS-Q-ST-70-16_1460044For the determination of design allowables the number of test items shall be agreed with the design authority.

ECSS-Q-ST-70-16_1460045The test items sets should originate from the same test item population.

For 7.8d for the determination of design allowables refer to clauses 4.5.8 and 4.5.12 from ECSS-E-ST-32.

Test item conditioning

ECSS-Q-ST-70-16_1460046Any conditioning step performed on flight hardware shall be applied to test items.

Examples of conditioning steps are:

- Heat treatments performed in manufacturing steps after bonding

- Bake-out

- Thermal cycling performed in screening activities

- Conditioning between environmental exposure and performance test

ECSS-Q-ST-70-16_1460047Thermal cycling tests performed as conditioning steps specified in requirement 7.9a may be combined with simulation of mission environmental exposure specified in the requirements from clause 7.12.

Simulation of on-ground environmental exposure

ECSS-Q-ST-70-16_1460048The supplier shall demonstrate the robustness of the adhesive bonding in the relevant on-ground environment.

- 1 Relevant on-ground environment is the environment representative of the exposure period between bonding and launch.

- 2 Exposure to humidity or other chemical substances can contribute to the degradation of the adhesive bond.

ECSS-Q-ST-70-16_1460049On-ground robustness demonstration may be based on experience, adhesive bonding process heritage or test.

The term heritage is defined in Table 5-1 of ECSS-E-ST-10-02.

ECSS-Q-ST-70-16_1460050For launcher applications the hot-wet exposure shall be part of the verification sequence of structural bonds.

For a list with examples of conditioning and durability standards see Table F-4 and Table F-5 respectively.

ECSS-Q-ST-70-16_1460051For spacecraft applications the sensitivity to atmospheric humidity shall be assessed.

- 1 Sensitivity of an adhesive bond’s performance to humidity can be interpreted as negative impact on the key property: for example mechanical, electrical, dimensional, thermo-optical properties.

- 2 For criticality of the adhesive bonding application see Table F-1.

- 3 For the sensitivity assessment of adhesive bonds to humidity see Table F-2.

- 4 Necessity to implement the hot-wet exposure into the verification sequence can be found in Table F-3.

ECSS-Q-ST-70-16_1460052For spacecraft applications exposed to cleanroom-controlled environments the hot-wet exposure need not to be always performed. - 1 Cleanroom-controlled environments are defined in ECSS-Q-ST-70-01, with temperature in the range of (22 ± 3) °C, and relative humidity (55 ± 10) %.

- 2 Examples of humidity highly-sensitive, sensitive and non-sensitive applications are presented in Table F-2.

- 3 An example of assessment for necessity to implement the hot-wet exposure into the verification sequence can be found in Table F-3.

ECSS-Q-ST-70-16_1460053In case the hot-wet exposure is performed, the temperature, relative humidity and duration of the exposure shall be agreed with the customer.

Examples of conditioning and durability standards are given in Table F-4.

ECSS-Q-ST-70-16_1460054For the hot-wet exposure specified in 7.10f water condensation on the test item shall be prevented.

- 1 An efficient way to avoid condensation is to increase the relative humidity only after the test items are at the given exposure temperature.

- 2 An inclined cover can help prevent condensed water accidentally dropping down onto the test items from the ceiling of the test chamber.

ECSS-Q-ST-70-16_1460055For the hot-wet exposure specified in 7.10f purified water of a quality ISO Grade II, or better, as defined in ISO 3696:1987 or equivalent, should be used.

The detailed water purity can be also found in ASTM D1193-06:2011.

Simulation of launch environmental exposure

Overview

Launch environmental exposure means mechanical loads, thermal exposure or a combination of both, that act on the flight hardware during launch.

Test definition

ECSS-Q-ST-70-16_1460056Launch environment test conditions shall be agreed with the customer.

ECSS-Q-ST-70-16_1460057Launch environment test conditions should be derived from system level requirements.

ECSS-Q-ST-70-16_1460058Thermal exposure relevant to launch phase may be combined with simulation of mission environmental exposure.

ECSS-Q-ST-70-16_1460059Mechanical load testing may consist of:

- Static and quasi-static load testing

- Dynamic load testing: sinus, random, acoustic

- Shock testing.

Dynamic mechanical load testing at test item level is usually not necessary. It is generally performed when adhesive bonds are submitted to complex loads which are difficult to model.

Simulation of mission environmental exposure

Overview

In-orbit environmental exposure is mainly related to thermal vacuum cycling of the adhesive bond.

In special applications, radiation (UV, electrons, protons) tests, ATOX tests as well as long-term exposure to high or cold temperatures can be necessary. Tests are generally performed in the frame of a dedicated verification test flow.

- 1 Radiation testing is addressed in ECSS-Q-ST-70-06.

- 2 Thermal cycling tests are not applicable for launchers except of in-orbit upper parts.

Thermal cycling test conditions

ECSS-Q-ST-70-16_1460060Thermal cycling test conditions shall be agreed with the customer.

Test conditions are e.g. thermal range, number of cycles, atmosphere.

ECSS-Q-ST-70-16_1460061A minimum of 25 thermal cycles shall be performed.

- 1 Generally 25 cycles cover on ground thermal cycling testing at unit level with margin.

- 2 ECSS-Q-ST-70-04 can be used as a guideline.

- 3 The atmosphere in the test chamber can have an impact on adhesive joint performance.

ECSS-Q-ST-70-16_1460062For ambient pressure thermal cycling water condensation shall be avoided.

An inert gas atmosphere can be used to avoid water condensation and prevent oxidation.

ECSS-Q-ST-70-16_1460063As a minimum the first five thermal cycles shall be performed in vacuum for vacuum sensitive configurations.

Vacuum sensitive configurations include but are not limited to:

- Adhesive tapes

- Foil heaters

- Thin or flexible adherends

- Radiator foils

- Solar reflectors

- Any assembly crossing Tg temperature of its adhesive material during the thermal cycling

- Assemblies for which moisture desorption has an impact on the bonding performance (CME effect)

ECSS-Q-ST-70-16_1460064Thermal vacuum cycling may be omitted in case the robustness of the adhesive bonding to thermal vacuum can be demonstrated by experience from former projects.

Thermal vacuum experience can be gained by unit level testing, spacecraft level testing, flying heritage, sample level testing

ECSS-Q-ST-70-16_1460065In addition to requirement 7.12.2b additional thermal cycles shall be performed to cover mission lifetime.

- 1 The additional thermal cycles are typically performed to simulate ageing effects (thermo-chemical, creep and fatigue phenomena).

- 2 The additional thermal cycles can contain long term thermal endurance exposure, for example cruise phases of probes.

ECSS-Q-ST-70-16_1460066For thermal vacuum cycles, the pressure level shall be less than 1 Pa (10-2 mbar).

ECSS-Q-ST-70-16_1460067For thermal vacuum cycling, the pressure shall be recorded.

ECSS-Q-ST-70-16_1460068The temperature range shall cover the mission qualification thermal requirements.

Mission specific qualification temperature for the bonding, taking into account all phases on ground, launch and during the mission.

ECSS-Q-ST-70-16_1460069Heat generating adherends should be powered in their mission operational temperature range to replicate the thermal loads at the joint in vacuum.

This is related to potential additional temperature loads on the joint, due to limited temperature conductance of the adherends.

ECSS-Q-ST-70-16_1460070Temperature extremes shall be maintained during the dwell time within the intervals Tmax -0/+5 °C and Tmin +0/-5 °C.

ECSS-Q-ST-70-16_1460071The minimum dwell time at each temperature extreme, as measured on the test items, shall be not less than five minutes.

ECSS-Q-ST-70-16_1460072The heating and cooling rate should be less than 12 °C per minute.

- 1 Maximum rate is specified in order to avoid thermal shock.

- 2 A high heating or cooling rate can induce unwanted thermal gradients and hence increase thermo-elastic stresses.

- 3 The temperature rate can be tailored in case of thermal shock simulation.

ECSS-Q-ST-70-16_1460073The test item temperature shall be recorded to verify that the specified temperature is achieved.

ECSS-Q-ST-70-16_1460074The temperature sensor should be placed as close as possible to the adhesive bond.

An additional test item, slightly modified to accommodate a temperature sensor, can be used if it is not possible to place a sensor directly on the verification test item.

Inspection before, during and after environmental exposure

ECSS-Q-ST-70-16_1460075The supplier shall perform the inspection according to requirements in clause 8.10.

Test before, during and after environmental exposure

ECSS-Q-ST-70-16_1460076Test of test item set shall be performed according to adhesive bonding test plan specified in the 7.2.

- 1 Examples of tests are included in Annex D and Annex E.

- 2 The monitoring of the functional performance of the test items can be important: for example infrared monitoring of foil heaters during thermal vacuum exposure; temperature measurement of bonded thermistors, thermo-optical performance of thermal control materials, electrical performance.

ECSS-Q-ST-70-16_1460077For mechanical test samples static performance test shall be performed at least for test item sets 1 and 4.

Examples of standard mechanical tests are given in Annex E.

Quality assurance

Overview

The role of quality assurance in adhesive bonding is to ensure that:

Materials stipulated in the design are obtained, stored and used correctly; as stated in the procurement specification and confirmed by incoming inspection.

Each joint made meets the materials and process specification(s) and is fully documented, test data are accumulated and that the bonded structure is qualified for space use,

Bonded‐joint data acquired from testing, inspection or in‐service experience are ‘fed‐back’ into manufacturing documentation. Previously accumulated data can aid the design process for all subsequent, similar, structures.

The performance of adhesive bonds is strongly linked to the application and strict control of every manufacturing process step. Adequate training, along with regular monitoring and documentation, of personnel involved in any bonding‐related process is an essential part of the quality assurance system.

Besides all the materials and processes needed for the adhesive bonding, the training of personnel is a key factor for successful adhesive bonding. There are many possible causes for human error like for example bad mixing, exceeding of pot life, insufficient surface preparation and many more.

General information regarding quality control of adhesive bonding can be found in section 14 of ECSS-E-HB-32-21.

General

ECSS-Q-ST-70-16_1460078The quality assurance requirements specified in clause 5 of ECSS-Q-ST-20 shall apply.

Procurement

ECSS-Q-ST-70-16_1460079Procurement of all materials needed for adhesive bonding shall be in conformance with clause 5.6.1 of ECSS-Q-ST-70.

Materials to be considered are for example raw materials, adhesives, filler materials, as well as adherends manufactured and pre-treated (for example plated, conversion coated) for bonding.

ECSS-Q-ST-70-16_1460080The user shall request the information about change of material composition, material testing and stop of production from material supplier.

- 1 Further information on possible parameters to be checked can be found in section 14.4 of ECSS-E-HB-32-21.

- 2 Technical Data Sheets (TDS) and Safety Data Sheets (SDS) can undergo changes because of obsolescence, production variation over the years or new information about the material.

Hazard, health and safety precautions

ECSS-Q-ST-70-16_1460081The supplier shall identify, manage and process materials and parts with hazardous characteristic according to requirements from clause 5 to clause 8 of ECSS-Q‐ST‐40.

ECSS-Q-ST-70-16_1460082The supplier shall keep the health and safety precautions according to the supplier’s national safety regulations.

ECSS-Q-ST-70-16_1460083The details of hazards for each material used in the process shall be known to all personnel involved in the application.

ECSS-Q-ST-70-16_1460084Operators and supervising staff shall have access to the Material Safety Data Sheets of the materials that are used in the adhesive bonding process.

ECSS-Q-ST-70-16_1460085Hazards to personnel, equipment, environment and materials shall be controlled and reduced to the risk specified in supplier’s in-house procedures.

Hazards can be reduced by using personal protective equipment (PPE).

Incoming inspection

ECSS-Q-ST-70-16_1460086All materials used in adhesive bonding process shall be submitted to an incoming inspection.

ECSS-Q-ST-70-16_1460087Incoming inspection shall be performed on each batch in compliance with clause 5.4.4. from ECSS-Q-ST-20.

ECSS-Q-ST-70-16_1460088In-coming inspection may include:

- Check of material reference

- Transportation and packing conditions

- Surface finish of adherends

- Expiry dates of adhesive components and primers

- Expiry date of applied surface treatments

- Visual criteria

- Chemical composition

- Microstructural analysis of adherends

- Crosscheck of relevant properties stated in certificate of analysis (CoA) of adhesive materials with results of in-house analysis.

Further information on possible parameters to be checked can be found in section 14.4 of ECSS-E-HB-32-21.

Traceability

ECSS-Q-ST-70-16_1460089Traceability of materials shall be handled in conformance with clause 5.7.2 of ECSS-Q-ST-70.

ECSS-Q-ST-70-16_1460090Supplier executing the bonding process shall establish a control system to verify before use the validity of the involved materials with limited shelf life in compliance with requirements from clause 4 of ECSS-Q-ST-70-22.

- 1 This applies for surface treatment agents, adhesives, additives, primers, sealants or potting compounds.

- 2 The shelf life can be reduced after opening the material’s original package or container.

ECSS-Q-ST-70-16_1460091Traceability of the bonding processes shall be performed in accordance with clause 6.3.

ECSS-Q-ST-70-16_1460092Traceability of the bonding inspection shall be recorded in the manufacturing file.

Tooling and equipment control

ECSS-Q-ST-70-16_1460093The supplier shall ensure that manufacturing equipment and tooling has no detrimental effect on the bonding process.

For example cleanliness provisions, no contamination with unwanted chemicals, no visual defects

ECSS-Q-ST-70-16_1460094Calibration control shall comply with the requirement from clause 5.2.6 of ECSS-Q-ST-20.

ECSS-Q-ST-70-16_1460095The supplier shall ensure that all automated adhesive application systems are calibrated.

ECSS-Q-ST-70-16_1460096Selection of tooling and equipment shall conform to the requirements from clause 5.2.6 of ECSS-Q-ST-20.

Workmanship

ECSS-Q-ST-70-16_1460097The quality of the workmanship shall be monitored.

ECSS-Q-ST-70-16_1460098Bonded assemblies shall be free of defects that affect the intended use.

For example cracks, entrapped air, kissing bonds, discoloration and particles can all affect bonding performance.

ECSS-Q-ST-70-16_1460099The supplier shall ensure quality of workmanship by implementing defined workmanship checks based on the dedicated bonding configuration.

For example check of visibility of adhesive at bond line edges, measurement of adhesive mass, control of temperature of the mixture, bond line thickness control, bonded area verification

ECSS-Q-ST-70-16_1460100The supplier shall specify adhesive bonding in-process control.

For example proof testing, in-process samples, visual inspection, adhesive cure check.

ECSS-Q-ST-70-16_1460101Adhesive bonding assembly shall not lose any macroscopic particles contributing to particulate contamination of the spacecraft.

The example of particulate release can be adhesives not covered by adherends after exposure to mechanical environment.

ECSS-Q-ST-70-16_1460102Cross-contamination between different chemical families shall be avoided.

- 1 For example cross-contamination between silicones and other adhesives, between hardener and resin pots.

- 2 Cross-contamination can be avoided for example by using dedicated tooling for different products, or by thoroughly cleaning tooling before using the next product.

- 3 Change of gloves can be useful to avoid cross contamination.

- 4 Separate rooms can be useful to avoid cross contamination between for example silicone adhesives and epoxy adhesives.

Handling and storage

ECSS-Q-ST-70-16_1460103The conditions for handling and storage of materials used in adhesive bonding process shall be available to all operators and supervising staff.

Storage conditions can be found in the Safety Data Sheets (SDS) of the used materials.

ECSS-Q-ST-70-16_1460104The test item shall only be handled with clean, powder‐free and lint‐free gloves compatible with all compounds used.

For example the chemical compatibility between solvents, cleaning agents, adhesives, primer and manufacturing tools can play an important role.

ECSS-Q-ST-70-16_1460105Test items shall be stored in a controlled area, with an ambient temperature of (22 ± 3) °C and relative humidity of (55 ± 10) %.

ECSS-Q-ST-70-16_1460106When test items are handled, contamination shall be avoided.

ECSS-Q-ST-70-16_1460107A protective material may be used to avoid contamination on sensitive surfaces.

A sensitive surface can be:

- Surface treated prior priming,

- Primed surface prior bonding,

- The fracture surface of analysed joint after functional or destructive test.

ECSS-Q-ST-70-16_1460108A protective material shall not degrade sensitive surfaces.

Particulate or molecular contamination can impair adhesion properties.

ECSS-Q-ST-70-16_1460109Use of a protective material is part of the handling procedure and shall be included in the verification sequence.

ECSS-Q-ST-70-16_1460110To avoid any damage the test items may be packed in clean, dust‐ and lint‐free material.

ECSS-Q-ST-70-16_1460111Limited‐life time materials shall be labelled with their expiry date and lot number.

ECSS-Q-ST-70-16_1460112In case the expiry date of life limited materials is not known then the supplier shall trace the date of shipment

Inspection and bonding process control

ECSS-Q-ST-70-16_1460113The supplier shall perform an inspection on all qualification and flight hardware bonding.

- 1 The inspection can be non-destructive or destructive (dedicated samples).

- 2 For large number of identical bonded joints, inspection can be performed on a sampling basis.

ECSS-Q-ST-70-16_1460114Inspection shall meet the requirements for inspection procedures from clause 4.3.16 of ECSS-Q-ST-70-71.

ECSS-Q-ST-70-16_1460115The acceptance criteria for the inspection of bonded joints shall be specified by the supplier and agreed with the customer. - 1 Depending on the process and the configuration, different acceptance criteria can be necessary.

- 2 Supplier can introduce in-process samples.

ECSS-Q-ST-70-16_1460116The inspection shall be performed by an inspector independent of the operators executing the bonding process.

ECSS-Q-ST-70-16_1460117Visual standards of bonded joints such as photos, drawings or other visual aids and clearly illustrating the quality characteristics needed should be available to each inspector. - 1 The visual standards can be examples of acceptable and unacceptable bond lines.

- 2 Typical defects can be reported in a defect catalogue.

ECSS-Q-ST-70-16_1460118Personnel involved in the inspection and non-destructive testing of adhesive bonds shall have an appropriate qualification and valid certificate. - 1 Appropriate qualification schemes of Non-Destructive Inspection can be found in ECSS-Q–ST-70-15 (For example visual inspection, Ultrasonic inspection, X-ray tomography, Microscopic inspection and other methods).

- 2 Inspection can be part of the bonding process but also an independent process.

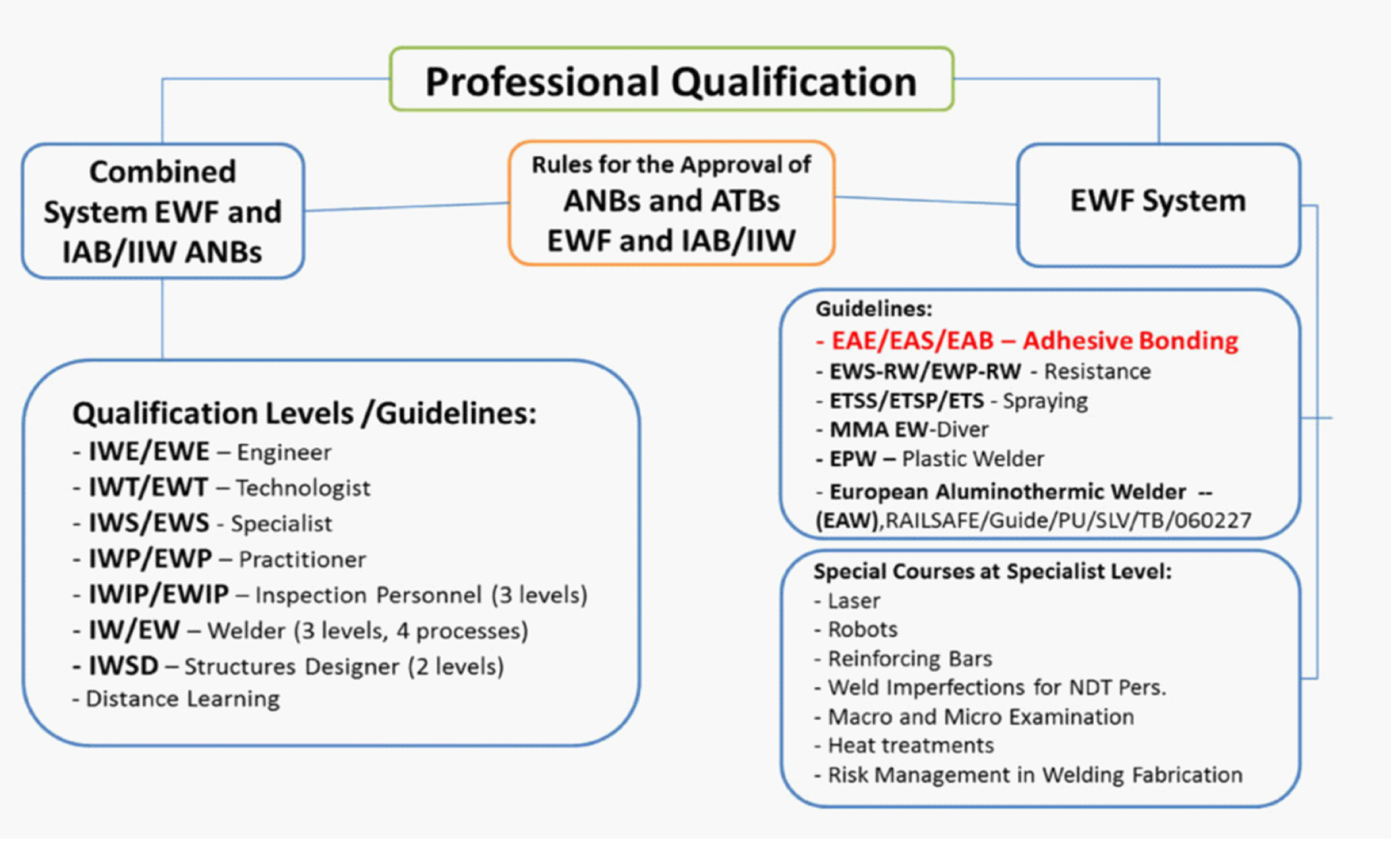

Operator and inspector training

ECSS-Q-ST-70-16_1460119Operators performing adhesive bonding processes shall be trained and certified.

ECSS-Q-ST-70-16_1460120Inspectors for adhesive bonding shall be trained and certified.

ECSS-Q-ST-70-16_1460121Training shall be performed at an adhesive bonding school or by certified external bodies or by approved in-house instructors.

ECSS-Q-ST-70-16_1460122In-house instructors shall be nominated by the company with involvement of quality assurance responsible.

ECSS-Q-ST-70-16_1460123Training and certification may be performed according to in-house standards or external training and certification scheme

External certification scheme and certification bodies for bonding operators can be found in Annex G.

ECSS-Q-ST-70-16_1460124Training shall include at least the following points:

- Adhesive bonding process

- Complexity of configurations

- Reproducibility

- Handling of raw materials, process chemicals and equipment

- Cleanliness and contamination control of environment, materials and equipment

- Safety‐related aspects of materials and process chemicals.

Examples of complexity of configurations are complex shapes, fragile or sensitive materials, multi-step integration processes.

ECSS-Q-ST-70-16_1460125Training specified in requirements 8.11f.4, 8.11f.5 and 8.11f.6 may be implemented in a dedicated training.

ECSS-Q-ST-70-16_1460126Skills status of all operators for adhesive bonding shall be traced in suppliers’ internal system.

ECSS-Q-ST-70-16_1460127The supplier shall specify the conditions of validity of the internal training and internal certification of the bonding operators.

Re-certification can be needed in the event of a new process, a modification to an existing process or a long inactivity period.

ECSS-Q-ST-70-16_1460128The supplier shall specify the conditions of validity of the internal training and internal certification of inspectors.

Re-certification can be needed in the event of a new inspection procedure, a modification to an existing inspection procedure or a long inactivity period.

Nonconformance

ECSS-Q-ST-70-16_1460129Nonconformances shall be managed in conformance with requirements from the clause 5 and 6 of the ECSS-Q-ST-10-09 and clause 5.2 of ECSS-Q-ST-10.

ANNEX(normative) Adhesive bonding procedure – DRD

DRD identification

Requirement identification and source document

This DRD is called from ECSS-Q-ST-70-16, requirements 6.1c and 6.2a.

Purpose and objective

The purpose of this document is to provide a detailed adhesive bonding procedure containing all steps necessary to perform adhesive bonding.

Expected response

Scope and content

ECSS-Q-ST-70-16_1460130The following adhesive bonding parameters shall be documented in the adhesive boding procedure:

- List of adherend, adhesive and primer materials

- List of equipment to be used during overall bonding process

- Environmental working conditions

- Positioning and blank mating of adherends to be bonded, dimensional verification

- Surface preparation of adherends

- Definition of time delay between surface preparation and execution of bonding

- Storage conditions after surface preparation of adherends

- Preparation of primer

- Preparation of adhesive

- Means of application of adhesive

- Fixture load or pressure applied during curing

- Curing schedule, including temperature, dwell time

- Adhesive bonding process control

- 1 to item A.2.1a.3: Examples of environmental working conditions are relative humidity, temperature, pressure and cleanliness of work place.

- 2 to item A.2.1a.5: surface preparation include cleaning, sanding, chemical treatments, priming.

- 3 to item A.2.1a.6: surface chemistry of adherend parts can evolve within few hours after surface preparation.

- 4 to item A.2.1a.8: preparation of primer includes mixing ratio, pot life, evaporation or curing time.

- 5 to item A.2.1a.9: preparation of adhesive includes mixing ratio, pot life, degassing of the mixture.

- 6 to item A.2.1a.10: means of application of adhesive are for example airbrush, foil adhesive roller or dispenser, brush, syringe, spatula, injector.

- 7 to item A.2.1a.12: heating and cooling rates can be key parameters for some type of adhesive systems.

- 8 to item A.2.1a.12: the minimum time for safe handling can be different compared to full curing.

- 9 to item A.2.1a.13: for contents refer to clauses 8.10and 8.11

Special remarks

None.

ANNEX(normative) Adhesive bonding test plan - DRD

DRD identification

Requirement identification and source document

This DRD is called from ECSS-Q-ST-70-16, requirement 7.2a.

Purpose and objective

The purpose of this document is to provide a detailed adhesive bonding test plan containing all steps necessary to perform the verification of the adhesive bonding process.

Expected response

Scope and content

ECSS-Q-ST-70-16_1460131The adhesive bonding test plan shall contain the following information

- Test objective

- Test items

- Adhesive and adherend materials

- Representativeness of test items vs flight configuration

- Reference to the adhesive bonding procedure in conformance with DRD in Annex A

- Number of test sets and test items quantity in each set

- Verification Test sequence

- List and designation of test item sets

- Applicable test procedures

- Applicable test standards

- Applicable inspection procedures

- Sequence of consecutive exposures

- Inspections performed during verification sequence on each item set

- Pass-fail criteria

Special remarks

None.

ANNEX(normative) Adhesive bonding test report -DRD

DRD identification

Requirement identification and source document

This DRD is called from ECSS-Q-ST-70-16, requirement 7.3a

Purpose and objective

The purpose of this document is to provide a detailed adhesive bonding test report containing all steps performed for the verification of the adhesive bonding process including all obtained results and conclusions of the test.

Expected response

Scope and content

ECSS-Q-ST-70-16_1460132The adhesive bonding test report shall contain the following information

- Test objective

- Reference to the applicable adhesive bonding test plan in conformance with DRD in Annex B

- Test items

- Adhesive and adherend materials

- Representativeness of test items vs flight configuration

- Reference to adhesive bonding procedure in conformance with DRD in Annex A

- Number of individual test items and test item sets tested during verification test sequence

- Verification test sequence

- List and designation of test item sets

- Applicable test procedures

- Applicable test standards

- Applicable inspection procedures

- Sequence of consecutive exposures and inspections performed during verification sequence on each item set

- Individual test item test results

- List of nonconformances

- Status of the process verification and definition of the process validity

Reference for adhesive bonding procedure can include the reference to record from manufacturing of bonded assembly or to manufacturing report.

Special remarks

None.

ANNEX(informative)Examples of techniques used for adhesive material characterization (bulk)

Overview

This Annex presents a list of analytical methods and associated test standards which can be used to characterize bulk adhesive properties. These properties are suitable in order to select the best adhesives candidates for use at a dedicated bonding assembly.

The list of recommended test standards is given in the Table D-1 is not exhaustive. Relevant test standards can be found in ECSS-E-HB-32-21 Table 15.1-2 and the book written by G. Habenicht, 2009.

Rheology

Viscosity evaluation is of prime concern for manufacturing and for quality control in transfer of liquid adhesives.

Viscosity of paste adhesive in uncured conditions can be evaluated by any appropriate means relevant to the bonding application.

-

1 For bonding in vertical positions, the viscosity of adhesive can play an important role.

-

2 If found relevant the injection capability can be evaluated.

Viscosity is useful to determine the ability of the adhesive to be injected or to be dispensed. -

1 For some dispensing systems it is important to take also the thixotropic characteristic into account.

-

2 Some adhesive manufacturers determine the product’s “pot life” as the duration after which the viscosity is twice the initial one.

-

3 Determination of the viscosity is of primary concern w.r.t. manufacturing constraints.

-

4 It is also important to determine gel point and pot life.

The following standards can be used for rheological measurements :

EN 12092:2001 Adhesives. Determination of viscosity

ASTM D 1824-16 Standard Test Method for Apparent Viscosity of Plastisols and Organosols at Low Shear Rates

ISO 11443:2014 Plastics -- Determination of the fluidity of plastics using capillary and slit-die rheometers

ISO 2555:2018 Plastics — Resins in the liquid state or as emulsions or dispersions — Determination of apparent viscosity using a single cylinder type rotational viscometer method

ISO 2535:2001 Plastics — Unsaturated-polyester resins — Measurement of gel time at ambient temperature

Rheological test methods exist to determine the G’ G’’ crossing point to assess workability times, gel-points, evolution of complex viscosity during RT curing, thermally-accelerated curing (see Table D-1).

Adhesive density and shrinkage

Adhesive volume shrinkage due to polymerisation can be evaluated by the difference of density between the uncured and cured adhesive.

The following standard can be used:

ISO 1183-1:2019 Plastics — Methods for determining the density of non-cellular plastics — Part 1: Immersion method, liquid pycnometer method and titration method

ISO 3521:1997 Plastics — Unsaturated polyester and epoxy resins — Determination of overall volume shrinkage

Note: thermal vacuum exposure can enhance overall shrinkage by “outgassing” effects by losing mass; for outgassing see D.4.

Outgassing

Screening outgassing tests provide the following values:

Total Mass Loss (TML)

Recovered Mass Loss (RML)

Collected Volatile Condensable Material (CVCM)

These data are mandatory and need to be provided when an organic material is intended to be used for a space vacuum application (on orbit or in ground inside vacuum facilities).

The screening outgassing test methods and generic acceptance criteria are covered in ECSS-Q-ST-70-02.

Sometimes kinetic outgassing parameters are needed for cleanliness sensitive applications, associated test methods can be found in ECSS-Q-TM-70-52.

The adhesive materials are tested in such conditions which are representative of the flight hardware. For example a two-component epoxy adhesive is tested after curing process representative to flight hardware application.

Differential Scanning Calorimetry (DSC)

Differential Scanning Calorimetry (DSC) analysis can be used on non-polymerized product and on polymerized product.

On non-polymerized product, DSC analysis provides polymerisation enthalpy (generally exothermic). This can be useful:

To compare or optimize curing schedule (temperature and duration),

In case of extension of product shelf life.

On polymerized product, DSC analysis allows to:

Quantify potential residual polymerisation enthalpy (not fully cured product),

determine glass transition temperature (Tg), melting temperature (Tm),

Evaluate the product degradation temperature.

The following standards can be used for DSC measurements:

ISO 11357-2:2013 Plastics - Differential scanning calorimetry (DSC) - Part 2: Determination of glass transition temperature and glass transition step height

ASTM D3418-15 Transition Temperatures of Polymers By Differential Scanning Calorimetry

For other suitable standards see Table D-1

Thermogravimetric analysis (TGA)

To determine thermo-chemical stability of individual components in uncured state, mixed, multicomponent adhesives under curing conditions or cured adhesive materials.

Thermogravimetric Analysis (TGA) allows measurement of:

Product Mass loss

Product degradation temperature

The following standards can be used for TGA measurements:

ISO 11358-1:2014 Plastics - Thermogravimetry (TG) of polymers - Part 1: General principles

ISO 11358-2:2014 Plastics -- Thermogravimetry (TG) of polymers -- Part 2: Determination of activation energy

For other suitable standards see Table D-1

TGA can be coupled with other analytical techniques (for example FTIR or GC-MS) to analyse thermally evolved products.

Dilatometry and Thermomechanical Analysis (TMA)

Dilatometry or TMA is suitable for the determination of:

Coefficient of Thermal Expansion (CTE)

Glass transition temperature (Tg)

Dimensional stability of the polymers

The following standards can be used for TMA measurements:

ISO 11359-2:1999 Plastics — Thermomechanical analysis (TMA) — Part 2: Determination of coefficient of linear thermal expansion and glass transition temperature

ASTM D696 - 16 Standard Test Method for Coefficient of Linear Thermal Expansion of Plastics Between −30°C and 30°C with a Vitreous Silica Dilatometer

For other suitable standards see Table D-1

Dynamic Mechanical Analysis (DMA)

Dynamic Mechanical Analysis (DMA) can be performed under several mechanical loading modes :

Tensile

Compression

3 point bending

Shear and other modes

The following properties can be determined:

Glass transition temperature (Tg)

Young's Modulus

Coulomb's Modulus (shear modulus)

Damping Factor

The ASTM D4065-12 Standard Practice for Plastics: Dynamic Mechanical Properties: Determination and Report of Procedures, can be used for DMA measurements.

For other suitable standards see Table D-1

Tensile strength and Young's modulus

Tensile strength testing on adhesive dog-bone shaped samples allow the measurement of:

Young's modulus

Yield strength (elastic limit)

Ultimate tensile strength

Elongation at break

Poisson ratio

Suitable test standards: ISO 527-1:2019 Plastics - Determination of tensile properties -- Part 1: General principles, ISO 527-2:2012 Plastics - Determination of tensile properties - Part 2: Test conditions for moulding and extrusion plastics, ASTM D638-14 Standard Test Method for Tensile Properties of Plastics

Other techniques for the determination of the tensile strength and modulus are often used, where the adhesive material is cured in test joint or assembly configuration, see in Table E-1 of Annex E.

Shear strength and shear modulus (adhesive material)

To address the shear properties in bulk, the materials are tested in non-bonded configuration. Dedicated tests serve to determine the bulk shear properties of the polymer:

Shear elastic modulus

Shear strength

Elongation at break

ASTM E143-13 Standard Test Method for Shear Modulus at Room Temperature

Other techniques for determination of the shear strength and shear modulus are often used, where the adhesive material is cured in test joint or assembly configuration, see Table E-1 of Annex E

Compression strength and modulus

To address the compression properties in the bulk, the materials are tested in non-bonded configuration. Dedicated tests serve to determine the bulk compression properties of the polymer:

Compression elastic modulus

Compression strength

Deformation at break

ASTM D 695-15 Standard Test Method for Compressive Properties of Rigid Plastics

Other techniques for determination of the compression properties can be used, where the adhesive material is cured in test joint assembly configuration, see in Table E-1 of Annex E

Electrical resistivity

Electrical resistance measurement allows to determine :

Surface electrical resistance or resistivity and so respectively surface electrical conductivity

Volume electrical resistance or resistivity and so respectively volume electrical conductivity

The following standards can be used :

ASTM D257-14 Standard Test Method for DC Resistance or Conductance of Insulating Materials

ASTM D4496-13 Standard Test Method for DC Resistance or Conductance of Moderately Conductive Materials

Thermal conductivity

Thermal resistance measurement allows to determine volume thermal resistance or resistivity and so respectively volume thermal conductivity

The following standards can be used:

ASTM C17713 Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded-Hot-Plate Apparatus

ASTM� D593017 Standard Test Method for Thermal Conductivity of Plastics by Means of a Transient Line-Source Technique

For other suitable standards see Table D-1

Thermo-optical properties

Thermo-optical properties are the following:

Solar absorptance

Infra-red emissivity

These properties are necessary in thermal analysis models if thermal radiative exchanges are not negligible. ECSS-Q-ST-70-09: Measurements of Thermo-Optical Properties of Thermal Control Materials provides different test methods that can be used.

Transmittance

Transmittance measurement can be necessary for bonding in optical systems.

The following standards can be used :

ISO 15368:2001 Optics and optical instruments -- Measurement of reflectance of plane surfaces and transmittance of plane parallel elements

ASTM D1746–15 Standard Test Method for Transparency of Plastic Sheeting

Water absorption

Methods cover the determination of the relative rate of absorption of water by plastics when immersed. The following standards can be used:

ASTM D57098(2010)e1 Standard Test Method for Water Absorption of Plastics

ISO 62:2008 Plastics — Determination of water absorption

ASTM D5229/D5229M–14 Standard Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite Materials

Table: Summary of relevant test standards for determination of bulk properties of adhesive material

|

Type of technique or material property

|

Relevant standards

|

|

Rheological measurements

|

EN 12092:2001, ASTM D1824-16, ISO 11443:2014, ISO 2535:2001, ISO 2555:2018 ISO 6721-10:2015

|

|

Adhesive Shrinkage and density

|

ISO 1183-1:2019, ISO 3521:1997

|

|

Outgassing

|

ECSS-Q-ST-70-02, ASTM E595-15, ECSS-Q-TM-70-52

|

|

DSC techniques (Glass transitions, phase transition temperature)

|

ISO 11357-2:2013, ASTM D3418-15, ISO 11357-1:2016, ISO 11357-3:2018, ISO 11357-4:2014, ISO 11357-5:2013

|

|

Thermo-chemical stability (TGA)

|

ASTM E1131-08(2014), ISO 11358-2:2014, ISO 11358-1:2014

|

|

Thermo-mechanical (CTE by TMA or dilatometer)

|

ISO 11359-2:1999, ISO 11359-1:2014, ISO 11359-3:2002, ASTM D696-16, ASTM E831-03, ASTM E2113-04

|

|

Thermo-elastic properties (DMA)

|

ASTM D4065-12, ISO 6721-1:2011

|

|

Tensile properties

|

ISO 527-1:2012, ISO 527-2:2012, ASTM D638-14

|

|

Shear strength and modulus

|

ASTM E143-13

|

|

Compression strength and modulus

|

ASTM D695-15

|

|

Electrical Resistivity

|

ASTM D4496-13, ASTM D257-14

|

|

Thermal Conductivity

|

ASTM D5930-17, ASTM C177-13, ISO 22007-4:2017

|

|

Thermo-optical

|

ECSS-Q-ST-70-09

|

|

Transmittance

|

ISO 15368:2001, ASTM D1746-15

|

|

Water absorption

|

ASTM D5229 / D5229M-14, ASTM D570-98(2010)e1, ISO 62:2008

|

ANNEX(informative) Characterisation of adhesive in bonded assembly configuration

Overview

There are a considerable number of test methods used to evaluate adhesive joints and to characterize the behaviour of adhesives in different loading configurations. Most of those that are of interest to the users are described in numerous test standards, for example from ASTM or ISO. The aim of this clause is to provide a brief overview of commonly evaluated properties and standardized test methods that can be applied in order to obtain comparable results.

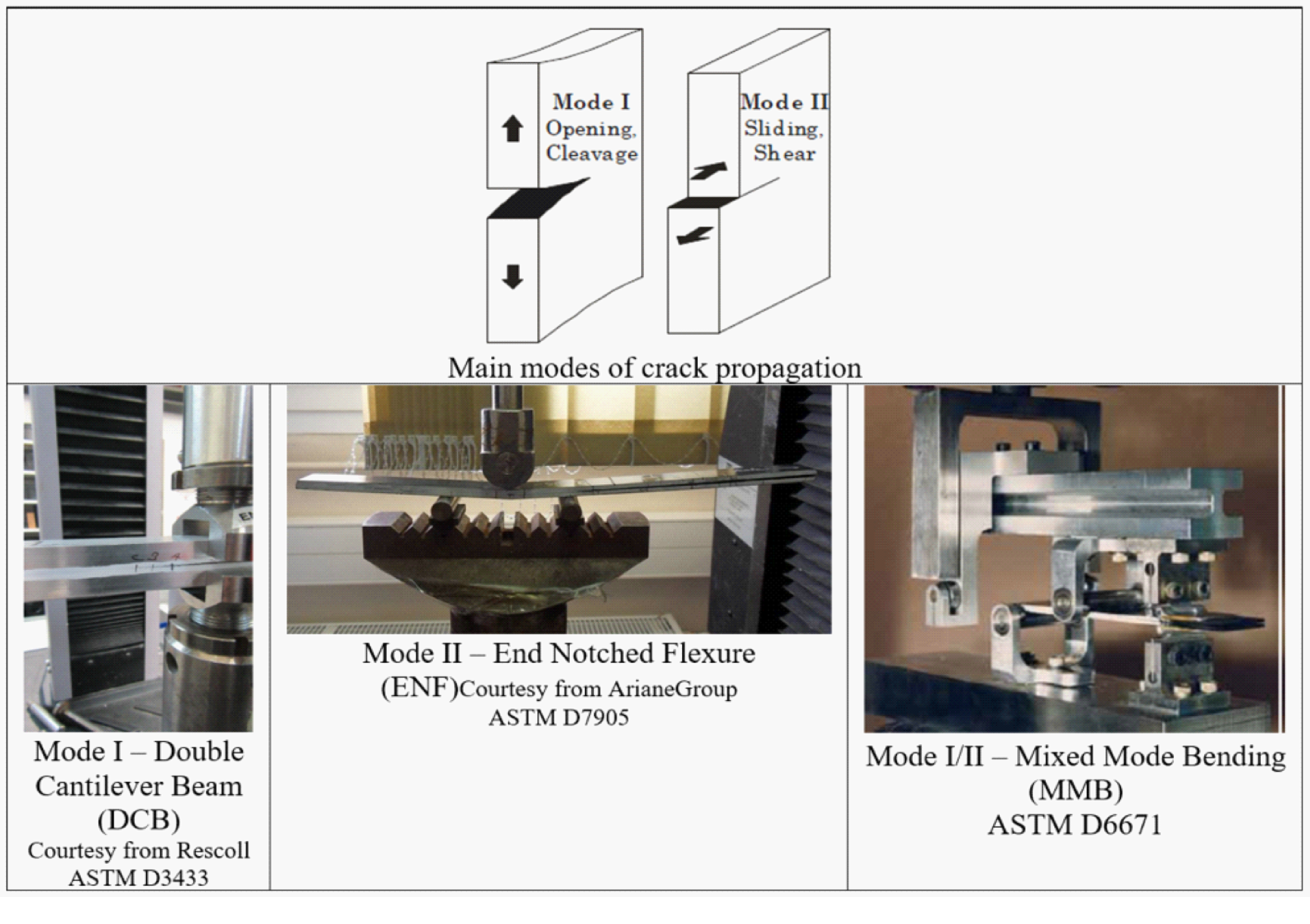

To characterise individual adhesives, there are various test methods which assess fracture characteristics relevant to joint design.

Fracture mechanics concepts characterise the strength of adhesively bonded joints in terms of a critical value of an appropriate fracture parameter. This list is not exhaustive.

Adhesive bonding test

The properties of adhesives affect the static joint strength and durability in fatigue.

Adhesive bonding test includes:

Static joint strength

Durability in fatigue

Fracture toughness

Environmental durability of the joints

- 1 to item 3: Examples of standard tests for the fracture toughness relevant to adhesive joints can be found in Table E-1.

- 2 to item : Examples of standard tests for durability of the joints and test conditions can be found in Table F-4 and Table F-5 in Annex F.

Strength of bonded joints

Single Lap Shear Strength – thin adherends

This test is regularly used by the adhesive bonding industry for adhesive screening purposes, selection of adhesive, selection of surface treatment and optimisation of bonding processes. Due to its significant stress non-uniformity and complex loading mode (thin adherends which deform during loading and possess peel stresses) this test is typically not used for definition of design allowables.

The list of relevant standards can be found in Table E-1.

See single lap shear standards in Table E-1.

Lap shear –thick adherend test

In comparison to the thin adherend test, this test method also determines the shear modulus of the adhesive. The results are typically less affected by deformation of the adherend pieces and are of a lower scatter when compared with thin adherend test methods.

ISO 11003-2:2001 Adhesives -- Determination of shear behaviour of structural adhesives -- Part 2: Tensile test method using thick adherends

ISO 1827:2016 Rubber, vulcanized or thermoplastic -- Determination of shear modulus and adhesion to rigid plates -- Quadruple-shear methods

See standards listed in Table E-1.

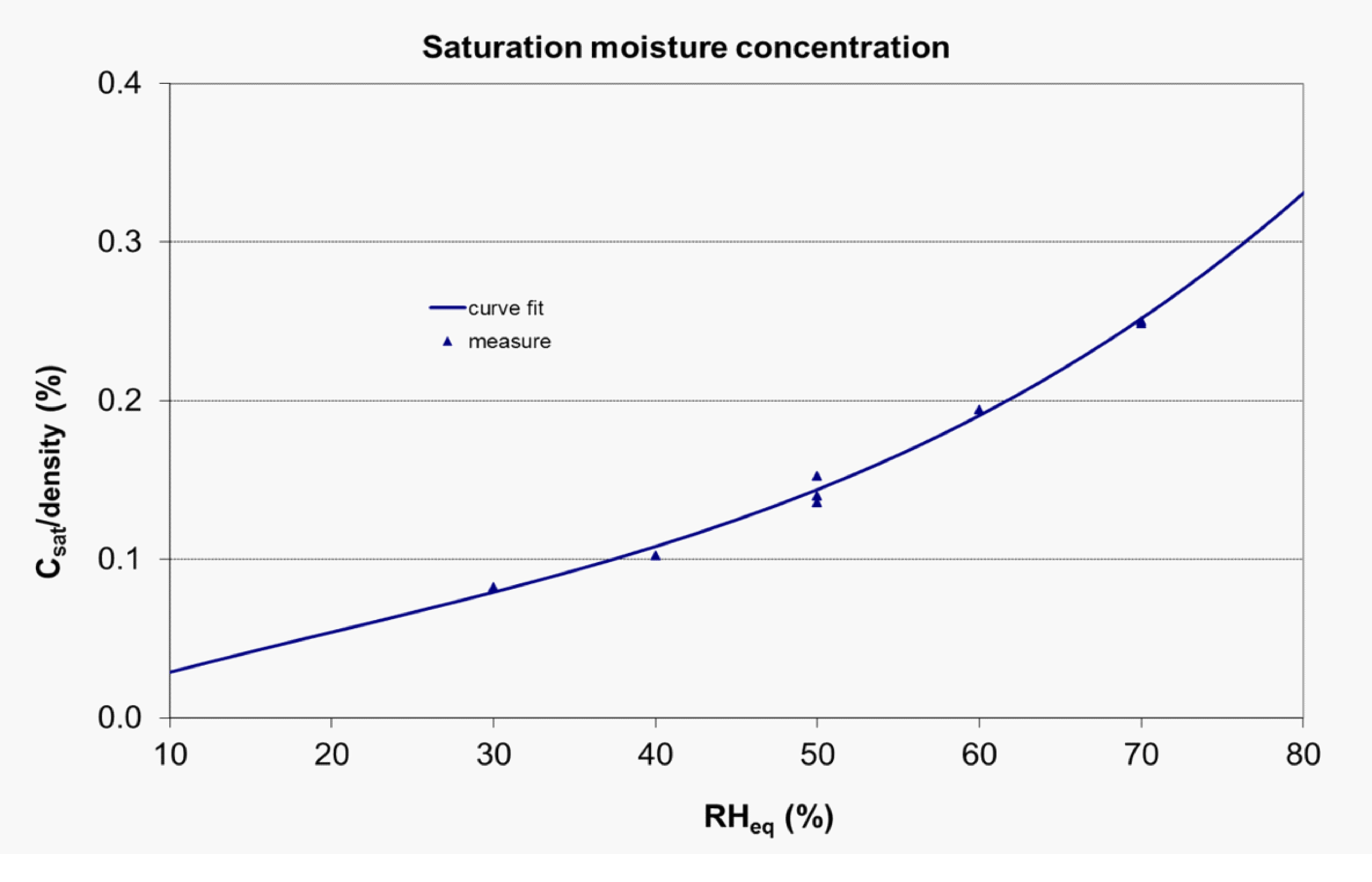

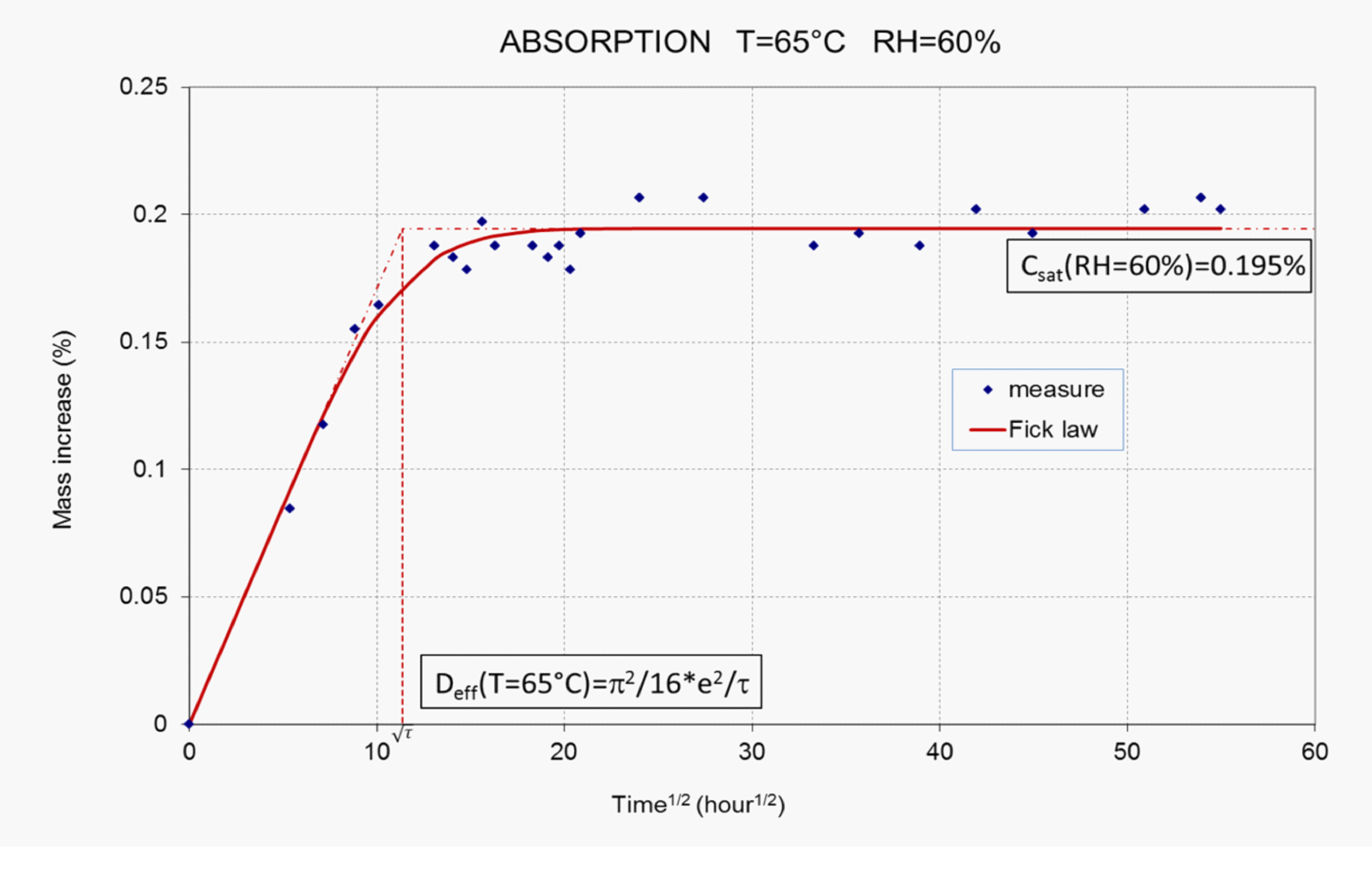

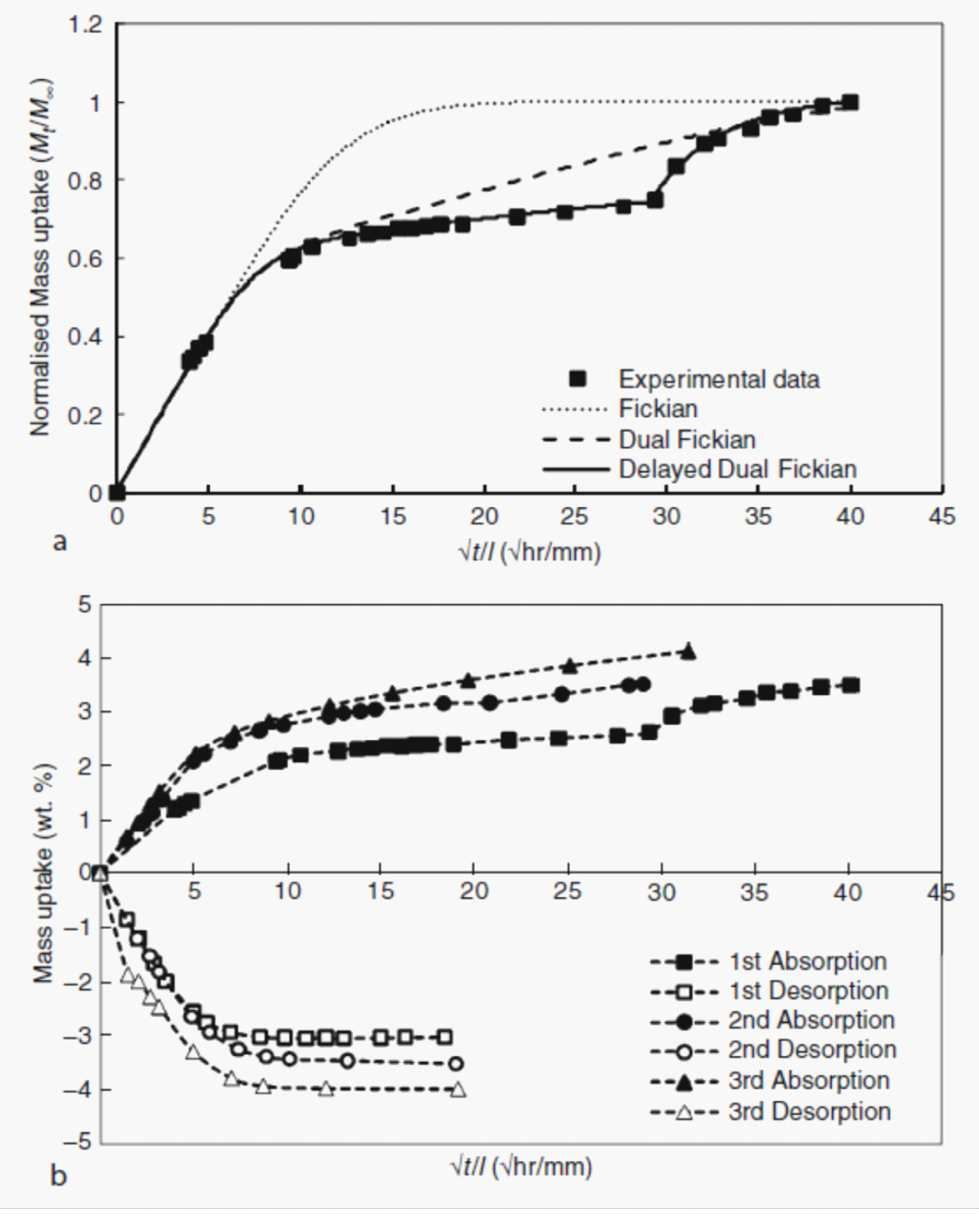

Peel strength test