Space engineering

Structural design and verification of pressurized hardware

Foreword

This Standard is one of the series of ECSS Standards intended to be applied together for the management, engineering and product assurance in space projects and applications. ECSS is a cooperative effort of the European Space Agency, national space agencies and European industry associations for the purpose of developing and maintaining common standards. Requirements in this Standard are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards.

This Standard has been prepared by the ECSS-E-ST-32-02 Working Group, reviewed by the ECSS Executive Secretariat and approved by the ECSS Technical Authority.

Disclaimer

ECSS does not provide any warranty whatsoever, whether expressed, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item are error-free. In no respect shall ECSS incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this Standard, whether or not based upon warranty, business agreement, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by ECSS.

Published by: ESA Requirements and Standards Division

ESTEC, ,

2200 AG Noordwijk

The

Copyright: 2008 © by the European Space Agency for the members of ECSS

Change log

|

ECSS-E-ST-32-02A

|

Never issued

|

|

ECSS-E-ST-32-02B

|

Never issued

|

|

ECSS-E-ST-32-02C

|

First issue

|

|

ECSS-E-ST-32-02C Rev. 1

|

First issue revision 1.

|

Scope

This Standard defines the structural design verification of metallic and non-metallic pressurized hardware which includes pressure vessels, pressurized structures, pressure components (such as valves, pumps, lines, fittings, and hoses), and special pressurized equipment (e.g. batteries, heat pipes, cryostats, sealed containers, hazardous fluids container). External supports and structural interfaces of pressurized hardware are not covered by this standard. Solid propellant motor cases are not covered by this standard.

Objectives of the associated verification process are primarily to demonstrate the qualification of design and performance, as meeting all specified requirements, and to ensure that the flight hardware is free from workmanship defects and acceptable for flight.

This Standard applies to all space products and in particular to launch vehicles, transfer vehicles, re-entry vehicles, spacecraft, space station, landing probes and rovers, sounding rockets, payloads and instruments.

This standard may be tailored for the specific characteristics and constraints of a space project in conformance with ECSS-S-ST-00.

Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this ECSS Standard. For dated references, subsequent amendments to, or revision of any of these publications, do not apply. However, parties to agreements based on this ECSS Standard are encouraged to investigate the possibility of applying the more recent editions of the normative documents indicated below. For undated references, the latest edition of the publication referred to applies.

|

ECSS-S-ST-00-01

|

ECSS system – Glossary of terms

|

|

ECSS-E-ST-10-02

|

Space engineering – Verification

|

|

ECSS-E-ST-10-03

|

Space engineering – Testing

|

|

ECSS-E-ST-32

|

Space engineering – Structural general requirements

|

|

ECSS-E-ST-32-01

|

Space engineering – Fracture control

|

|

ECSS-E-ST-32-08

|

Space engineering – Materials

|

|

ECSS-E-ST-32-10

|

Space engineering – Reliability based mechanical factors of safety

|

|

ECSS-Q-ST-20

|

Space product assurance – Quality assurance

|

|

ECSS-Q-ST-70

|

Space product assurance – Materials, mechanical parts and processes

|

Terms, definitions, and abbreviated terms

Terms from other standards

For the purpose of this Standard, the terms and definitions from ECSS-S-ST-00-01, ECSS-E-ST-32, and ECSS-E-ST-32-01 apply.

Terms specific to the present standard

autofrettage

vessel sizing operation where pressure driven deflection is used to plastically yield the metal liner into the overlying composite in order to induce initial compressive stress states in the metal liner

Autofrettage is considered to be part of the manufacturing process and is conducted prior to acceptance test.

boss

zone of a pressure vessel or a pressurized structure ensuring functional interfaces (e.g. fluid connections and mechanical interfaces) of the hardware with the pressurized system

burst factor (jburst)

multiplying factor applied to the maximum design pressure (MDP), to obtain the design burst pressure

The burst factor corresponds to an ultimate factor of safety.

burst pressure

pressure level at which collapse, rupture or unstable fracture of the pressurized hardware occurs

composite over-wrap

layers of fibre-based composite material applied onto a liner, sustaining significant pressure and environmental loads

composite over-wrapped pressure vessel (COPV)

pressure vessel with a fibre-based composite structure fully or partially encapsulating a liner

For example:

- the liner can be metallic or not.

- the liner ensures the leak tightness of the vessel.

composite over-wrapped pressurized component (COPC)

pressurized component with a fibre-based composite system fully or partially encapsulating a liner

For example:

- the liner can be metallic or not.

- the liner ensures the leak tightness of the vessel.

composite over-wrapped pressurized structure (COPS)

pressurized structure with a fibre-based composite system fully or partially encapsulating a liner

For example:

- the liner can be metallic or not.

- the liner ensures the leak tightness of the vessel.

composite over-wrapped special pressurized equipment (COSPE)

special pressurized equipment with a fibre-based composite system fully or partially encapsulating a liner

For example:

- the liner can be metallic or not.

- the liner ensures the leak tightness of the vessel.

composite pressure vessel (CPV)

pressure vessel whose structural wall is fully composed with fibre based composite material

For example:

- the permeation barrier can be ensured by a coating on the internal or the external shape of the composite wall, or by the composite wall itself, or by both.

- low-pressure liquid hydrogen tank without liner.

composite pressurized structure (CPS)

pressurized structure whose structural wall is fully composed with fibre based composite material

For example:

- the permeation barrier can be ensured by a coating on the internal or external shape of the composite wall, or by the composite wall itself, or by both.

- low-pressure liquid hydrogen structural tank without liner.

critical flaw

specific flaw with a size such that unstable growth occurs under the specific operating load and environment

cryostat

vacuum-jacketed container designed to keep its contents at a low (cryogenic) temperature

Cryostat is also known as a Dewar, named after its inventor.

design burst pressure

differential pressure to be withstood by the pressurized hardware without burst in the applicable operating environment

The design burst pressure is equal to the product of the MDP and the burst factor.

differential pressure

internal pressure minus external pressure

external pressure

absolute pressure outside the pressurized hardware

fibre failure

rupture or kinking of a bundle of filaments

There are two fibre failure modes: under tension (fibre rupture) and under compression (kinking).

fitting

pressure component of a pressurized system utilized to connect lines, other pressure components or pressure vessels within the system

hazardous fluid container

pressurized container, compartment or housing that is individually sealed to contain a fluid, which can create a hazard if released

hydrogen embrittlement

mechanical and environmental process that results from the initial presence or absorption of excessive amounts of hydrogen in metals

Usually it occurs in combination with residual or applied tensile stresses.

impact damage

induced defect caused by an object strike on the pressurized hardware or pressurized hardware strike on an object

Delamination in the composite over-wrap of a COPV, dent in the metallic liner of a COPV.

inter-fibre failure

micro-cracking in the matrix of a composite material, or at the interface filament-matrix of a composite material

internal pressure

absolute pressure inside the pressurized hardware

leak-before-burst (LBB)

fracture mechanics design concept, showing that any potentially critical flaw grows through the wall of a pressurized system and cause pressure relieving leakage at MDP without burst (catastrophic failure)

liner

part of pressurized hardware serving as a mandrel during the manufacturing of the over-wrap and as fluid permeation barrier when in contact with the stored fluid

For example:

- when the liner is made of metallic material, it can carry significant pressure and environmental loads.

- when the liner is made of homogeneous non metallic material, it usually does not carry significant pressure and environmental loads.

line

tubular pressurized hardware of a pressurized system provided as means for transferring fluids between components of the system

Flex hoses are included.

maximum design pressure (MDP)

See ECSS-E-ST-32.

maximum expected operating pressure (MEOP)

See ECSS-E-ST-32.

mechanical damage

induced flaw in pressurized hardware item which is caused by surface abrasions, cuts or impacts

The pressurized hardware item can be a metallic, homogeneous non metallic or composite item.

metallic pressure vessel (MPV)

pressure vessel fully composed of metallic material

metallic pressurized structure (MPS)

pressurized structure fully composed of metallic material

metallic pressurized component (MPC)

pressurized component fully composed of metallic material

metallic special pressurized equipment (MSPE)

special pressurized equipment fully composed of metallic material

non-hazardous LBB failure mode

leak-before-burst (LBB) behaviour that does not result in a hazard

For example: LBB behaviour with a leak of liquid or gas that is not toxic, reactive or flammable.

pressure component (PC)

component in a pressurized system, other than a pressure vessel, pressurized structure, or special pressurized equipment that is designed largely by the internal pressure

For example:

- lines, fittings, gauges, valves, bellows, and hoses.

- batteries not meeting the pressure vessel definition.

pressure vessel (PV)

pressurized hardware designed primarily for the storage of pressurized fluid with an energy level greater than or equal to 19310 Joules, or with a pressure greater than or equal to 0,69 MPa, or which can create a hazard if released

E.g. the stored energy can be calculated by the formula for the reversible adiabatic (isentropic) expansion of the confined gas:

where:

E is the stored energy;

P1 is the internal pressure;

P2 is the external pressure;

V is the pressurized volume;

is the ratio of specific heat of the gas.

pressurized hardware (PH)

hardware item that primarily contains internal pressure

E.g. included are pressure vessels, pressurized structures, pressure components and special pressurized equipments.

pressurized structure (PS)

structure designed to carry both internal pressure and vehicle structural loads

E.g. launch vehicle main propellant tanks, crew cabins and manned modules.

pressurized system

system which consists of pressure vessels, or pressurized structures, or both, and other pressure components, that are exposed to and structurally designed largely by the acting pressure

For example:

- a pressurized system is often called a pressure system.

- electrical or other control devices for system operations are not included.

proof factor (jproof)

multiplying factor applied to MDP to obtain design proof pressure

proof pressure

product of MDP and proof factor

proof test

test of flight hardware under proof load or pressure to give evidence of satisfactory workmanship and material quality or to establish the initial crack sizes in the hardware

sealed container

pressurized container, compartment or housing that is individually sealed to contain a fluid or to maintain an internal gaseous environment

E.g. electronics housing

sizing pressure

pressure to which composite over-wrapped pressurized hardware is subjected with the intent of yielding its metallic liner or a portion of the liner

E.g. the sizing pressure also refers to the pressure applied during autofrettage.

special pressurized equipment

pressurized hardware that meets the pressure vessel definition, but which is not feasible or cost effective to conform to the requirements applicable to pressure vessels

For example:

- pressurized hardware may be classified as special pressurized equipment with customer approval.

- heat pipes, cryostats, sealed containers and hazardous fluids container.

- sealed nickel-hydrogen batteries meeting the definition of a pressure vessel.

visual damage threshold (VDT)

lowest impact energy level applied to a composite item that creates an indication that is detectable by an inspector using an unaided visual technique

No quantitative reliability nor confidence level is associated with this technique.

Abbreviated terms

For the purpose of this Standard, the abbreviated terms from ECSS-S-ST-00-01 and the following apply:

|

Abbreviation

|

Meaning

|

|

BAI

|

residual burst strength after impact

|

|

COPC

|

composite over-wrapped pressurized component

|

|

COPS

|

composite over-wrapped pressurized structures

|

|

COSPE

|

composite over-wrapped special pressurized equipment

|

|

COPV

|

composite over-wrapped pressure vessel

|

|

CPS

|

composite pressurized structure

|

|

CPV

|

composite pressure vessel

|

|

DLL

|

design limit load

|

|

DUL

|

design ultimate load

|

|

DYL

|

design yield load

|

|

FCI

|

fracture critical item

|

|

FLLI

|

fracture limited life item

|

|

FOS

|

factor of safety

|

|

ISS

|

international space station

|

|

LBB

|

leak-before-burst

|

|

MDP

|

maximum design pressure

|

|

MEOP

|

maximum expected operating pressure

|

|

MPC

|

metallic pressurized component

|

|

MPS

|

metallic pressurized structure

|

|

MPV

|

metallic pressure vessel

|

|

MSPE

|

metallic special pressurized equipment

|

|

NDI

|

non-destructive inspection

|

|

PFCI

|

potential fracture-critical item

|

|

PC

|

pressure component

|

|

PH

|

pressurized hardware

|

|

PV

|

pressurized pressure vessel

|

|

PS

|

pressurized structure

|

|

SPE

|

special pressurized equipment

|

|

VDT

|

visual damage threshold

|

Symbols

jburst value of burst factor

jproof value of proof factor

FOSU value of ultimate factor of safety

FOSY value of yield factor of safety

General requirements

Overview

Content

Clause 4 presents requirements which are general requirements in the sense that:

requirements for all categories of pressurized hardware are specified in clause 4.2;

requirements for all pressure vessels are specified in clause 4.3;

requirements for all pressurized structures are specified in clause 4.4;

requirements for all pressure components are specified in clause 4.5;

requirements for all special pressurized equipments are specified in clause 4.6.

Categories of pressurized hardware

The pressurized hardware treated in this Standard are categorized in Figure 41. A flowchart describing the classification of pressurized hardware is in Figure 42.

Figure 41: Breakdown of PH types covered by this Standard

Figure 41: Breakdown of PH types covered by this Standard

Figure 42: Flowchart describing PH classifications covered by this Standard

Figure 42: Flowchart describing PH classifications covered by this Standard

General

Leak tightness

The maximum leak rates of the pressurized hardware versus pressure values shall be established through a detailed analysis of the pressurized system to which the pressurized hardware belongs.

Leak rate of all pressurized hardware shall conform to the level defined in 4.2.1a.

Leak rate of all pressurized hardware shall be such that operation of the system is ensured throughout the specified lifetime.

Pressurized hardware containing hazardous fluids reach end of safe-life when leakage occurs.

Classification of fracture critical parts

‘Fracture critical item classification’ shall be performed in conformance with ECSS-E-ST-32-01.

When pressurized hardware is classified as fracture critical, it is subjected to the implementation of the fracture critical item tracking, control and documentation procedures specified in ECSS-E-ST-32-01.

Operation and maintenance

Operating procedures

Operating procedures shall be established for all pressurized hardware.

The procedures specified in 4.2.3.1a shall be compatible with the safety requirements and personnel control requirements at the facility where the operations are conducted.

Step-by-step directions shall be written with such a detail to unambiguously describe the operation.

Schematics identifying the location and pressure limits of a relief valve and burst disc, shall be provided.

Procedures to ensure compatibility of the pressurizing system with the structural capability of the pressurized hardware shall be established.

Prior to initiating or performing a procedure involving hazardous operations with pressure systems, practice runs shall be conducted on non-pressurized systems.

Initial tests shall then be conducted at pressure levels not to exceed 50 % of the nominal operating pressure until operating characteristics can be established.

Warning signs with the hazard identified shall be posted at the operations facility prior to pressurization.

Safe operating limit

Safe operating limits shall be established for pressurized hardware based on analysis and testing employed during its design, development and qualification.

The safe operating limits specified in 4.2.3.2a shall be summarized in a format providing visibility of the structural characteristics and capability.

The information in the format specified in 4.2.3.2b shall include as a minimum the following data:

- In a general case

- fabrication materials;

- critical design conditions;

- MDP;

- nominal operating pressure;

- proof pressure;

- design burst pressure;

- pressurization and depressurization sequence;

- operational cycle limits;

- operational system fluid;

- cleaning agent;

- NDI techniques employed;

- extreme thermal and chemical environments;

- maximum leakage levels versus pressure values;

- minimum margin of safety;

- potential failure mode.

- For pressurized hardware with a non LBB failure mode, additionally to the data included in 4.2.3.2c.1:

- the critical flaw sizes;

- the maximum acceptable flaw sizes.

Back-up documentation, including at least applicable references to design drawings, detail analyses, inspection records, and test reports, shall be indicated.

The minimum internal pressure to guaranty structural stabilization shall be identified and included in the acceptance data package.

Inspection and maintenance

The results of stress and safe-life analyses shall be used in conjunction with the results from the structural development and the qualification tests to define quantitative acceptance criteria for inspection and repair.

Damage limits shall be established by the supplier for pressurized hardware so that the inspection interval and repair schedule can be established.

Analyses of operational data developed per clause 5.7 shall include forecast of remaining life and reassessment of inspection intervals.

Repair

All repaired or refurbished hardware shall be submitted to re-acceptance, as specified in clause 4.2.4.3, after each repair and refurbishment to verify their structural integrity.

Storage

When pressurized hardware is put into storage:

- they shall be protected against exposure to adverse environments that can cause corrosion or degrade the material;

- they shall be protected against mechanical damages;

- induced stresses due to storage fixture constraints shall be avoided by storage fixture design. If 4.2.3.5a is not met, the hardware shall be submitted to re-acceptance as specified in clause 4.2.4.3 prior to acceptance for use.

Documentation

Inspection, maintenance, and operation records shall be kept and maintained throughout the life of the pressurized hardware.

As a minimum, the records specified in 4.2.3.6a shall contain the following information:

- temperature, pressurization history, and pressurizing fluid for both tests and operations;

- number of pressurization cycles experienced as well as the maximum number in safe-life analysis or test;

- results of any inspection conducted, including: inspector, inspection dates, inspection techniques employed, location and character of flaws, flaw origin and cause;

- storage condition;

- maintenance and corrective action performed from manufacturing to operational use, including refurbishment;

- sketches and photographs to show areas of structural damage and the extent of repair;

- acceptance and re-acceptance test performed, including test condition and results;

- analyses supporting the repair or modification which can influence future use capability.

Service life extension, reactivation and re-acceptance

Service life extension

In case of safe-life demonstration, required for the hardware, the service life may be extended after performing a complete NDI, and leak test.

In case of fatigue life demonstration, required for the hardware, the service life may be extended without additional test or inspection, if there is available data including at least actual pressure, loads, and environments from the past period of service life, and the evaluation exhibits that the cumulative damage does not reach the specified service life.

The new service life shall be determined by fatigue-life or safe-life demonstration as required for this type of pressurized hardware.

Reactivation

Pressurized hardware which is reactivated for use after an extensive period in either an unknown, unprotected, or unregulated storage environment shall meet the requirements specified in clause 4.2.4.3 to ascertain their structural integrity before commitment to flight.

A specific inspection for corrosion and incidental damage prior to re-acceptance tests shall be performed.

Re-acceptance

All refurbished pressurized hardware shall undergo the same acceptance tests as specified for new hardware in clauses 4.3 to 4.6, in order to verify their structural integrity before commitment to flight.

If the demonstration specified in 4.2.4.3a is not performed, it shall be demonstrated that the refurbished parts of the pressurized hardware are not affected by the corresponding tests.

Pressurized hardware exceeding the specified storage environment (e.g. temperature, humidity, time and storage fixture constraints) shall undergo the acceptance tests specified in clauses 4.3 to 4.6 for new hardware.

If the demonstration specified in 4.2.4.3c is not performed, it shall be demonstrated that all concerned parts of the pressurized hardware are not affected by the exceeded storage environment.

Pressure vessels

Factors of safety

The values in Table 41 shall be applied as minimum values of factors of safety for internal pressure.

For loads different from internal pressure, minimum values of factors of safety for ‘pressurized hardware’ shall be applied in conformance with ECSS-E-ST-32-10.

- 1 Exceptions to the values provided in Table 41 are sometimes specified by the customer or granted with customer approval.

When this is the case for a burst factor, the following relations can be used for determination of the proof factor:

jproof = (1 + jburst) / 2 when jburst < 2,0

jproof = 1,5 when jburst > 2,0

TableTable 41: Factors of safety for PV (unmanned and manned missions)

|

Load

|

FOSY

|

Prooffactor

|

FOSU

|

BurstFactor

|

|

Internal pressure

|

1,0

|

1,25

|

1,0

|

1,5

|

|

Mechanical loads(including external pressure)

|

Values specified in ECSS-E-ST-32-10

| |||

Metallic pressure vessels

Development approach

Clause 5.2 on structural engineering shall be applied.

The failure mode shall be demonstrated by analysis or test or both according to clause 5.3.

Except in the case specified in 4.3.2.1d, ‘safe life item’ demonstration shall be performed by analysis or test in conformance with ECSS-E-ST-32-01.

For pressure vessels with a non-hazardous LBB failure mode, the safe-life demonstration specified in 4.3.2.1c may be replaced by a fatigue life demonstration by analysis or test or both.

This can have an impact on the mission reliability.

In the case specified in 4.3.2.1d, requirements for ‘fatigue analysis’ shall be applied in conformance with ECSS-E-ST-32.

Qualification tests shall be conducted according to clause 4.3.2.2 to demonstrate the structural adequacy of the design.

For corrosion effects (control and prevention), the requirements in ECSS-E-ST-32 shall apply.

For hydrogen embrittlement phenomena, requirements shall be applied in conformance with ECSS-E-ST-32-08.

For material selection, material design allowables and their characterisation, requirements shall be applied in conformance with ECSS-E-ST-32.

For ‘process control’, requirements shall be in conformance with ECSS-Q-ST-70.

Inspections shall be applied according to clause 5.7.

The development approach is illustrated in Figure 43.

Figure 43: Development approach of MPV

Figure 43: Development approach of MPV

Qualification tests

A first qualification test article shall be submitted to the following chronology of operations:

- non-destructive inspection (NDI);

- proof pressure test;

- leak test;

- design burst pressure test;

- burst test.

The first qualification test article specified in 4.3.2.2a may be deleted with customer approval.

A second qualification test article shall be submitted to the following chronology of operations: - NDI;

- proof pressure test;

- leak test;

- vibration tests;

- pressure cycling test;

- leak test;

- design burst pressure test;

- burst test.

The leak test after proof pressure test, specified in 4.3.2.2c, and the final burst test specified in 4.3.2.2c may be deleted with customer approval.

When the vibration loads are enveloped by the other qualification tests, the vibration tests specified in 4.3.2.2c may be deleted with customer approval.

Clause 5.4 shall be applied to the qualification tests.

The need to apply external loads in combination with internal pressure during testing shall be considered taking into account their relative magnitude, the fatigue and destabilizing effects of external loads.

If external cycling loads are applied, the load shall be cycled to limit for four times the predicted number of operating cycles of the most severe design condition.

Destabilizing load with constant minimum internal pressure or maximum additive load with a constant MDP.

Acceptance tests

All hardware shall be submitted to the following chronology of operations:

- initial NDI, in order to establish the initial condition of the hardware;

- proof pressure test;

- leak test;

- final NDI.

For example:

- The NDI prior to proof test can be substituted for that of the manufacturing process.

- Proof test monitoring by acoustic emission is acceptable for composite items instead of post testing NDI, with customer approval.

Clause 5.5 shall be applied to the acceptance tests.

Final NDI shall be performed on the weld-joints of the MPV as a minimum.

COPV with metallic liner

Development approach

Clause 5.2 on structural engineering shall be applied.

A stiffness demonstration shall be performed by analysis and test.

A strength and stability demonstration shall be performed by analysis and test.

The failure mode shall be demonstrated by analysis or test or both according to clause 5.3.

The metallic liner of the COPV shall exhibit a LBB failure mode.

‘Safe life item’ demonstration shall be performed for the metallic liner by analysis or test or both in conformance with ECSS-E-ST-32-01.

Fatigue-life demonstration shall be performed for the composite over-wrap by analysis or test or both in conformance with ECSS-E-ST-32.

Qualification tests shall be conducted according to clause 4.3.3.2 to demonstrate the structural adequacy of the design.

For corrosion effects (control and prevention), the requirements in ECSS-E-ST-32 shall apply.

For hydrogen embrittlement phenomena, requirements shall be applied in conformance with ECSS-E-ST-32-08.

For material selection, material design allowables and their characterisation, requirements shall be applied in conformance with clause 5.6 and ECSS-E-ST-32.

For ‘process control’, requirements shall be in conformance with ECSS-Q-ST-70.

Inspections shall be applied according to clause 5.7.

The development approach is illustrated in Figure 44.

Qualification tests

A first qualification test article shall be submitted to the following chronology of operations:

- non-destructive inspection (NDI);

- proof pressure test;

- leak test;

- design burst pressure test;

- burst test.

The first qualification test article specified in 4.3.3.2a may be deleted with customer approval.

A second qualification test article shall be submitted to the following chronology of operations: - NDI;

- proof pressure test;

- leak test;

- vibration tests;

- pressure cycling test;

- leak test;

- design burst pressure test;

- burst test.

The leak test after proof pressure test specified in 4.3.3.2c, and the final burst test specified in4.3.3.2c may be deleted with customer approval.

When the vibration loads are enveloped by the other qualification tests, the vibration tests specified in 4.3.3.2c may be deleted with customer approval.

NDI operations shall be applied to the over-wrap, in addition to NDI on the liner.

Clause 5.4 shall be applied to the qualification tests.

The need to apply external loads in combination with internal pressure during testing shall be considered taking into account their relative magnitude, the fatigue and destabilizing effects of external loads.

If external cycling loads are applied, the load shall be cycled to limit for four times the predicted number of operating cycles of the most severe design condition.

For example: destabilizing load with constant minimum internal pressure or maximum additive load with a constant MDP.

Acceptance tests

All hardware shall be submitted to the following chronology of operations:

- initial NDI, in order to establish the initial condition of the hardware;

- proof pressure test;

- leak test;

- final NDI.

For example:

- The NDI prior to proof test can be substituted for that of the manufacturing process.

- Proof test monitoring by acoustic emission is acceptable for composite items instead of post testing NDI, with customer approval.

Initial NDI operations shall be applied to the over-wrap, in addition to NDI on the liner.

Clause 5.5 shall be applied to the acceptance tests.

Final NDI shall be performed on the over-wrap of the COPV as a minimum.

Figure 44: Development approach of COPV with metallic liner

Figure 44: Development approach of COPV with metallic liner

COPV with homogeneous non metallic liner and CPV

Development approach

Clause 5.2 on structural engineering shall be applied.

A stiffness demonstration shall be performed by analysis and test.

A strength and stability demonstration shall be performed by analysis and test.

The failure mode shall be demonstrated by test on full-scale article according to the requirements developed per clauses 5.3.1, 5.3.4 and 5.3.5.

The liner of the COPV shall exhibit a LBB failure mode.

The CPV shall exhibit a LBB failure mode.

When the non-metallic liner of the COPV remains in compression up to MDP and flaws do not propagate during the LBB test, the flaws pre-fabricated in the liner of the LBB full-scale specimen may be through cracks.

‘Safe life item’ demonstration shall be performed in conformance with ECSS-E-ST-32-01:

- by test for non-metallic items;

- by analysis or test or both for metallic items (e.g. metallic bosses).

Qualification tests shall be conducted according to clause 4.3.4.2 to demonstrate the structural adequacy of the design.

For corrosion effects (control and prevention), the requirements in ECSS-E-ST-32 shall apply.

For hydrogen embrittlement phenomena, requirements shall be applied in conformance with ECSS-E-ST-32-08.

For material selection, material design allowables and their characterisation, requirements shall be applied in conformance with clause 5.6 and ECSS-E-ST-32.

For ‘process control’, requirements shall be in conformance with ECSS-Q-ST-70.

Inspections shall be applied according to clause 5.7.

The development approach is illustrated in Figure 45.

Qualification tests

A first qualification test article shall be submitted to the following chronology of operations:

- non-destructive inspection (NDI);

- proof pressure test;

- leak test;

- design burst pressure test;

- burst test.

The first qualification test article specified in 4.3.4.2a may be deleted with customer approval.

A second qualification test article shall be submitted to the following chronology of operations: - NDI;

- proof pressure test;

- leak test;

- vibration tests;

- pressure cycling test;

- leak test;

- design burst pressure test;

- burst test.

The leak test after proof pressure test specified in 4.3.4.2c, and the final burst test specified in 4.3.4.2c may be deleted with customer approval.

When the vibration loads are enveloped by the other qualification tests, the vibration tests specified in 4.3.4.2c may be deleted with customer approval.

For COPV, NDI operations shall be applied to the over-wrap, in addition to NDI on the liner.

For CPV, NDI operations shall be applied to the composite wall.

Clause 5.4 shall be applied to the qualification tests.

The need to apply external loads in combination with internal pressure during testing shall be considered taking into account their relative magnitude, the fatigue and destabilizing effects of external loads.

If external cycling loads are applied, the load shall be cycled to limit for four times the predicted number of operating cycles of the most severe design condition.

Destabilizing load with constant minimum internal pressure or maximum additive load with a constant MDP.

Acceptance tests

All hardware shall be submitted to the following chronology of operations:

- initial NDI, in order to establish the initial condition of the hardware;

- proof pressure test;

- leak test;

- final NDI.

For example:

- The NDI prior to proof test can be substituted for that of the manufacturing process.

- Proof test monitoring by acoustic emission is acceptable for composite items instead of post testing NDI, with customer approval.

For COPV, initial NDI operations shall be applied to the over-wrap, in addition to NDI on the liner.

For CPV, NDI operations shall be applied to the composite wall as a minimum.

Clause 5.5 shall be applied to the acceptance tests.

Final NDl shall be performed on the over-wrap of the COPV as a minimum.

Figure 45: Development approach of COPV with homogeneous non metallic liner and CPV

Figure 45: Development approach of COPV with homogeneous non metallic liner and CPV

Pressurized structures

Factors of safety

The values in Table 42 and Table 43 shall be applied as minimum values of factors of safety for internal pressure.

The values specified in ECSS-E-ST-32-10 shall be applied as minimum values of factors of safety for loads different from internal pressure.

Exceptions to the values provided in ECSS-ST-32-10 are sometimes specified by the customer or granted with customer approval.

Requirements for load combination shall be defined with customer approval.

The combined DYL shall be larger or equal than 1,0 times the combined DLL.

The combined DUL shall be larger or equal than 1,25 times the combined DLL in case of an unmanned mission.

The combined DUL shall be larger or equal than 1,4 times the combined DLL in case of a manned mission.

TableTable 42: Factors of safety for PS (unmanned mission)

|

Load

|

FOSY

|

Prooffactor

|

FOSU

|

BurstFactor

|

|

Internal pressure

|

1,1

|

1,1

|

1,25

|

1,25

|

|

Mechanical loads(including external pressure)

|

Values specified in ECSS-E-ST-32-10

| |||

TableTable 43: Factors of safety for PS (manned mission)

|

Load

|

FOSY

|

Prooffactor

|

FOSU

|

Burstfactor

|

|

Internal pressure

|

1,1

|

1,1

|

1,4

|

1,4

|

|

Mechanical loads(including external pressure)

|

Values specified in ECSS-E-ST-32-10

| |||

TableTable 44: Factors of safety for manned modules

|

Load

|

FOSY

|

Prooffactor

|

FOSU

|

Burstfactor

|

|

Internal pressure

|

1,65

|

1,5

|

2,0

|

2,0

|

|

Mechanical loads(including external pressure)

|

Values specified in ECSS-E-ST-32-10

| |||

Metallic pressurized structures

Development approach

Clause 5.2 on structural engineering shall be applied.

The failure mode shall be demonstrated by analysis or test or both according to clause 5.3.

Except in the case specified in 4.4.2.1d, ‘safe life item’ demonstration shall be performed by analysis or test or both in conformance with ECSS-E-ST-32-01.

For pressurized structures with a non-hazardous LBB failure mode, the safe-life demonstration specified in 4.4.2.1c may be replaced by a fatigue life demonstration by analysis or test or both with customer approval.

This can have an impact on the mission reliability.

In the case specified in 4.4.2.1d, requirements for ‘fatigue analysis’ shall be applied in conformance with ECSS-E-ST-32.

Qualification tests shall be conducted according to clause 4.4.2.2 to demonstrate the structural adequacy of the design.

For corrosion effects (control and prevention), the requirements in ECSS-E-ST-32 shall apply.

For hydrogen embrittlement phenomena, requirements shall be applied in conformance with ECSS-E-ST-32-08.

For material selection, material design allowables and their characterisation, requirements shall be applied in conformance with ECSS-E-ST-32.

For ‘process control’, requirements shall be in conformance with ECSS-Q-ST-70.

Inspections shall be applied according to clause 5.7.

The development approach is illustrated in Figure 46.

Figure 46: Development approach of MPS

Figure 46: Development approach of MPS

Qualification tests

The qualification test article shall be submitted to the following chronology of operations:

- NDI;

- proof pressure test;

- leak test;

- pressure cycling test;

- design burst pressure test.

The pressure cycling and design burst pressure tests specified in 4.4.2.2a may be deleted with customer approval.

Clause 5.4 shall be applied to the qualification tests.

The need to apply external loads in combination with internal pressure during testing shall be considered taking into account their relative magnitude, fatigue and destabilizing effects of external loads.

If external cycling loads are applied, the load shall be cycled to limit for four times the predicted number of operating cycles of the most severe design condition.

Destabilizing load with constant minimum internal pressure or maximum additive load with a constant MDP.

Acceptance tests

All hardware shall be submitted to the following chronology of operations:

- initial NDI, in order to establish the initial condition of the hardware;

- proof pressure test;

- leak test;

- final NDI.

The NDI prior to proof test can be substituted for that of the manufacturing process.

Clause 5.5 shall be applied to the acceptance tests.

Final NDI shall be performed on the weld-joints of the MPS as a minimum.

COPS with metallic liner

Development approach

Clause 5.2 on structural engineering shall be applied.

A stiffness demonstration shall be performed by analysis and test.

A strength and stability demonstration shall be performed by analysis and test.

The failure mode shall be demonstrated by analysis or test or both according to clause 5.3.

The metallic liner of the COPS shall exhibit a LBB failure mode.

‘Safe life item’ demonstration shall be performed for the metallic liner by analysis or test or both in conformance with ECSS-E-ST-32-01.

Fatigue-life demonstration shall be performed for the composite over-wrap by analysis or test or both in conformance with ECSS-E-ST-32.

Qualification tests shall be conducted in conformance with clause 4.4.3.2 to demonstrate the structural adequacy of the design.

For corrosion effects (control and prevention), the requirements in ECSS-E-ST-32 shall apply.

For hydrogen embrittlement phenomena, requirements shall be applied in conformance with ECSS-E-ST-32-08.

For material selection, material design allowables and their characterisation, requirements shall be applied in conformance with clause 5.6 and ECSS-E-ST-32.

For ‘process control’, requirements shall be in conformance with ECSS-Q-ST-70.

Inspections shall be applied according to clause 5.7.

The development approach is illustrated in Figure 47.

Qualification tests

The qualification test article shall be submitted to the following chronology of operations:

- NDI;

- proof pressure test;

- leak test;

- pressure cycling test;

- design burst pressure test.

The pressure cycling and design burst pressure tests specified in 4.4.3.2a may be deleted with customer approval.

NDI operations shall be applied to the over-wrap, in addition to NDI on the liner.

Clause 5.4 shall be applied to the qualification tests.

The need to apply external loads in combination with internal pressure during testing shall be considered taking into account their relative magnitude, fatigue and destabilizing effects of external loads.

If external cycling loads are applied, the load shall be cycled to limit for four times the predicted number of operating cycles of the most severe design condition.

Destabilizing load with constant minimum internal pressure or maximum additive load with a constant MDP.

Acceptance tests

All hardware shall be submitted to the following chronology of operations:

- initial NDI, in order to establish the initial condition of the hardware;

- proof pressure test;

- leak test;

- final NDI.

For example:

- The NDI prior to proof test can be substituted for that of the manufacturing process.

- Proof test monitoring by acoustic emission is acceptable for composite items instead of post testing NDI, with customer approval.

Initial NDI operations shall be applied to the over-wrap, in addition to NDI on the liner.

Clause 5.5 shall be applied to the acceptance tests.

Final NDI shall be performed on the over-wrap of the COPS as a minimum.

Figure 47: Development approach of COPS with metallic liner

Figure 47: Development approach of COPS with metallic liner

COPS with homogeneous non metallic liner and CPS

Development approach

Clause 5.2 on structural engineering shall be applied.

A stiffness demonstration shall be performed by analysis and test.

A strength and stability demonstration shall be performed by analysis and test.

The failure mode shall be demonstrated by test on full-scale article according to clauses 5.3.1, 5.3.4 and 5.3.5.

The liner of the COPS shall exhibit a LBB failure mode.

The CPS shall exhibit a LBB failure mode.

When the non-metallic liner of the COPS remains in compression up to MDP and flaws do not propagate during the LBB test, the flaws pre-fabricated in the liner of the LBB full-scale specimen may be through cracks.

‘Safe life item’ demonstration shall be performed in conformance with ECSS-E-ST-32-01:

- by test for non-metallic items;

- by analysis or test or both for metallic items (e.g. metallic bosses).

Qualification tests shall be conducted according to clause 4.4.4.2 to demonstrate the structural adequacy of the design.

For corrosion effects (control and prevention), the requirements in ECSS-E-ST-32 shall apply.

For hydrogen embrittlement phenomena, requirements shall be applied in conformance with ECSS-E-ST-32-08.

For materials selection, material design allowables and their characterisation, requirements shall be applied in accordance with clause 5.6 and ECSS-E-ST-32.

For ‘process control’, requirements shall be in conformance with ECSS-Q-ST-70.

Inspections shall be applied according to clause 5.7.

The development approach is illustrated in Figure 48.

Qualification tests

The qualification test article shall be submitted to the following chronology of operations:

- NDI;

- proof pressure test;

- leak test;

- pressure cycling test;

- design burst pressure test.

For COPS, NDI operations shall be applied to the over-wrap, in addition to NDI on the liner.

For CPS, NDI operations shall be applied to the composite wall.

Clause 5.4 shall be applied to the qualification tests.

The need to apply external loads in combination with internal pressure during testing shall be considered taking into account their relative magnitude, fatigue and destabilizing effects of external loads.

If external cycling loads are applied, the load shall be cycled to limit for four times the predicted number of operating cycles of the most severe design condition.

Destabilizing load with constant minimum internal pressure or maximum additive load with a constant MDP.

Acceptance tests

All hardware shall be submitted to the following chronology of operations:

- initial NDI, in order to establish the initial condition of the hardware;

- proof pressure test;

- leak test;

- final NDI.

For example:

- The NDI prior to proof test can be substituted for that of the manufacturing process.

- Proof test monitoring by acoustic emission is acceptable for composite items instead of post testing NDI, with customer approval.

For COPS, initial NDI operations shall be applied to the over-wrap, in addition to NDI on the liner.

For CPS, NDI operations shall be applied to the composite wall as a minimum.

Clause 5.5 shall be applied to the acceptance tests.

Final NDI shall be performed on the over-wrap of the COPS as a minimum.

Figure 48: Development approach of COPS with homogeneous non metallic liner and CPS

Figure 48: Development approach of COPS with homogeneous non metallic liner and CPS

Pressure components

Metallic pressure components

Factors of safety

The values in Table 45 shall be applied as minimum values of factors of safety for internal pressure.

The values specified in ECSS-E-ST-32-10 shall be applied as minimum values of factors of safety for loads different from internal pressure.

Exceptions to the values provided in Table 45 are sometimes specified by the customer or granted with customer approval.

TableTable 45: Factors of safety for MPC (unmanned and manned missions)

|

Load

|

Application

|

FOSY

|

Prooffactor

|

FOSU

|

Burstfactor

|

|

Internal pressure

|

application 1

|

|

1,5

|

|

4,0

|

|

application 2

|

|

1,5

|

|

2,5

| |

|

application 3

|

|

1,5

|

|

2,5

| |

|

Mechanical loads(including external pressure)

|

Values specified in ECSS-E-ST-32-10

| ||||

|

NOTES:application 1: lines and fittings with diameter < 38 mmapplication 2: lines and fittings with diameter 38 mmapplication 3: other MPC (including batteries not meeting the pressure vessel definition)

| |||||

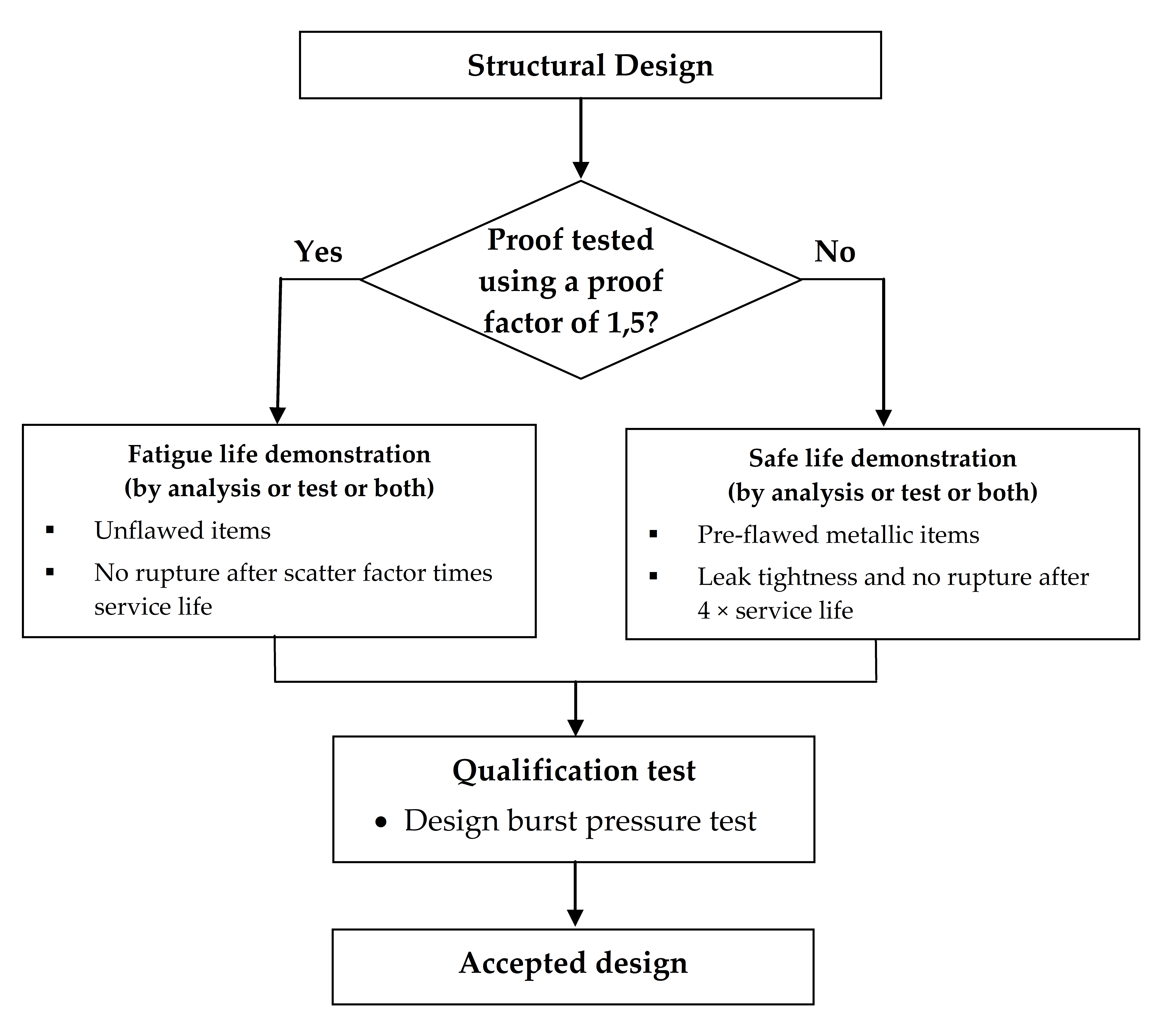

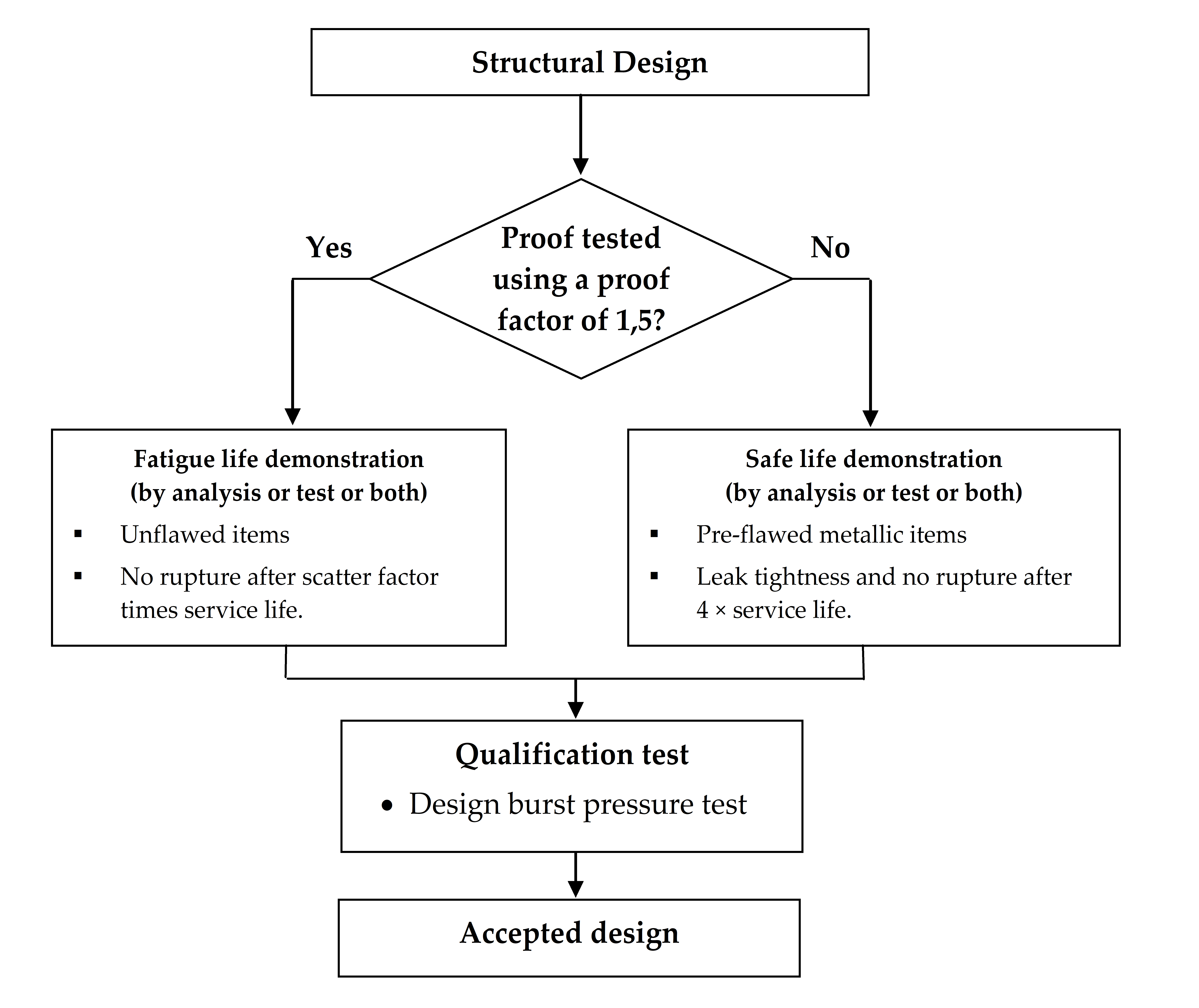

Development approach

Clause 5.2 on structural engineering shall be applied.

Thermal, stress and strain analyses and stiffness, strength and stability demonstrations are sometimes substituted with certification from qualified aerospace suppliers, with customer approval.

Qualification tests shall be conducted according to clause 4.5.1.3 to demonstrate the structural adequacy of the design.

A ‘safe life item’ demonstration shall be performed by analysis or test or both in conformance with ECSS-E-ST-32-01 for pressure components not submitted to a proof pressure test or for which the proof factor used in the proof pressure test is less than 1,5.

Fatigue-life demonstration shall be performed by analysis or test or both in conformance with ECSS-E-ST-32.

For corrosion effects (control and prevention), the requirements in ECSS-E-ST-32 shall apply.

For hydrogen embrittlement phenomena, requirements shall be applied in conformance with ECSS-E-ST-32-08.

For material selection, material design allowables and their characterisation, requirements shall be applied in conformance with ECSS-E-ST-32.

For ‘process control’, requirements shall be in conformance with ECSS-Q-ST-70.

Inspections shall be applied according to clause 5.7.

For example:

- The development approach is illustrated in Figure 49.

- Failure mode demonstration as per clause 5.3 is sometimes specified by the customer.

Qualification tests

Pressure components other than lines and fittings shall be submitted to a design burst pressure test.

No qualification test is specified for lines and fittings on unit level.

Lines and fittings, which are joined to an assembly, shall be submitted to a design burst pressure test on a representative, flight-quality hardware assembly.

For pressure components other than lines and fittings at unit level, clauses 5.4.1 and 5.4.6 shall be applied to the qualification tests.

Acceptance tests

Pressure components shall be submitted to a proof pressure test or a leak test or both according to clause 5.5.

All items with fusion joints shall be submitted to a proof pressure test according to clause 5.5.2.

Proof and leak tests can be performed at the assembled pressurized system level.

All fusion joints shall be 100 % inspected by means of a NDI method, defined with customer approval, prior and after the proof pressure test.

Figure 49: Development approach of MPC

Figure 49: Development approach of MPC

COPC with metallic liner

Factors of safety

The values in Table 46 shall be applied as minimum values of factors of safety for internal pressure.

The values specified in ECSS-E-ST-32-10 shall be applied as minimum values of factors of safety for loads different from internal pressure.

Exceptions to the values provided in Table 46 are sometimes specified by the customer or granted with customer approval.

When this is the case for a burst factor, the following relations can be used for determination of the proof factor:

jproof = (1 + jburst) / 2 when jburst < 2,0

jproof = 1,5 when jburst > 2,0

TableTable 46: Factors of safety for COPC with metallic liner (unmanned and manned missions)

|

Load

|

FOSY

|

Prooffactor

|

FOSU

|

BurstFactor

|

|

Internal pressure

|

1,0

|

1,25

|

1,0

|

1,5

|

|

Mechanical loads(including external pressure)

|

Values specified in ECSS-E-ST-32-10

| |||

Development approach

Clause 5.2 on structural engineering shall be applied.

A stiffness demonstration shall be performed by analysis and test.

A strength and stability demonstration shall be performed by analysis and test.

The failure mode shall be demonstrated by analysis or test or both according to clause 5.3.

The metallic liner of the COPC shall exhibit a LBB failure mode.

‘Safe life item’ demonstration shall be performed for the metallic liner by analysis or test or both in conformance with ECSS-E-ST-32-01.

Fatigue-life demonstration shall be performed for the composite over-wrap by analysis or test or both in conformance with ECSS-E-ST-32.

Qualification tests shall be conducted according to clause 4.5.2.3 to demonstrate the structural adequacy of the design.

For corrosion effects (control and prevention), the requirements in ECSS-E-ST-32 shall apply.

For hydrogen embrittlement phenomena, requirements shall be applied in conformance with ECSS-E-ST-32-08.

For material selection, material design allowables and their characterisation, requirements shall be applied in conformance with clause 5.6 and ECSS-E-ST-32.

For ‘process control’, requirements shall be in conformance with ECSS-Q-ST-70.

Inspections shall be applied according to clause 5.7.

The development approach is illustrated in Figure 44.

Qualification tests

A first qualification test article shall be submitted to the following chronology of operations:

- non-destructive inspection (NDI);

- proof pressure test;

- leak test;

- design burst pressure test;

- burst test.

The first qualification test article specified in 4.5.2.3a may be deleted with customer approval.

A second qualification test article shall be submitted to the following chronology of operations: - NDI;

- proof pressure test;

- leak test;

- vibration tests;

- pressure cycling test;

- leak test;

- design burst pressure test;

- burst test.

The leak test after proof pressure test specified in 4.5.2.3c, and the final burst test specified in 4.5.2.3c may be deleted with customer approval.

When the vibration loads are enveloped by the other qualification tests, the vibration tests specified in 4.5.2.3c may be deleted with customer approval.

NDI operations shall be applied to the over-wrap, in addition to NDI on the liner.

Clause 5.4 shall be applied to the qualification tests.

The need to apply external loads in combination with internal pressure during testing shall be considered taking into account their relative magnitude, the fatigue and destabilizing effects of external loads.

If external cycling loads are applied, the load shall be cycled to limit for four times the predicted number of operating cycles of the most severe design condition.

Destabilizing load with constant minimum internal pressure or maximum additive load with a constant MDP.

Acceptance tests

All hardware shall be submitted to the following chronology of operations:

- initial NDI, in order to establish the initial condition of the hardware;

- proof pressure test;

- leak test;

- final NDI.

For example:

- The NDI prior to proof test can be substituted for that of the manufacturing process.

- Proof test monitoring by acoustic emission is acceptable for composite items instead of post testing NDI, with customer approval

Initial NDI operations shall be applied to the over-wrap, in addition to NDI on the liner.

Clause 5.5 shall be applied to the acceptance tests.

Final NDI shall be performed on the over-wrap of the COPC as a minimum.

COPC with homogeneous non metallic liner

Factors of safety

The values in Table 47 shall be applied as minimum values of factors of safety for internal pressure.

The values specified in ECSS-E-ST-32-10 shall be applied as minimum values of factors of safety for loads different from internal pressure.

Exceptions to the values provided in Table 47 are sometimes specified by the customer or granted with customer approval.

When this is the case for a burst factor, the following relations can be used for determination of the proof factor:

jproof = (1 + jburst) / 2 when jburst < 2,0

jproof = 1,5 when jburst > 2,0

TableTable 47: Factors of safety for COPC with homogeneous non metallic liner (unmanned and manned missions)

|

Load

|

FOSY

|

Prooffactor

|

FOSU

|

BurstFactor

|

|

Internal pressure

|

1,0

|

1,25

|

1,0

|

1,5

|

|

Mechanical loads(including external pressure)

|

Values specified in ECSS-E-ST-32-10

| |||

Development approach

Clause 5.2 on structural engineering shall be applied.

A stiffness demonstration shall be performed by analysis and test.

A strength and stability demonstration shall be performed by analysis and test.

The failure mode shall be demonstrated by test on full-scale article according to the requirements developed per clauses 5.3.1, 5.3.4 and 5.3.5.

The liner of the COPC shall exhibit a LBB failure mode.

When the non-metallic liner of the COPC remains in compression up to MDP and flaws do not propagate during the LBB test, the flaws pre-fabricated in the liner of the LBB full-scale specimen may be through cracks.

‘Safe life item’ demonstration shall be performed in conformance with ECSS-E-ST-32-01:

by test for non-metallic items;

by analysis or test or both for metallic items (e.g. metallic bosses).

Qualification tests shall be conducted according to clause 4.5.3.3 to demonstrate the structural adequacy of the design.

For corrosion effects (control and prevention), the requirements in ECSS-E-ST-32 shall apply.

For hydrogen embrittlement phenomena, requirements shall be applied in conformance with ECSS-E-ST-32-08.

For material selection, material design allowables and their characterisation, requirements shall be applied in conformance with clause 5.6 and ECSS-E-ST-32.

For ‘process control’, requirements shall be in conformance with ECSS-Q-ST-70.

Inspections shall be applied according to clause 5.7.

The development approach is illustrated in Figure 45.

Qualification tests

A first qualification test article shall be submitted to the following chronology of operations:

- non-destructive inspection (NDI);

- proof pressure test;

- leak test;

- design burst pressure test;

- burst test.

The first qualification test article specified in 4.5.3.3a may be deleted with customer approval.

A second qualification test article shall be submitted to the following chronology of operations: - NDI;

- proof pressure test;

- leak test;

- vibration tests;

- pressure cycling test;

- leak test;

- design burst pressure test;

- burst test.

The leak test after proof pressure test specified in 4.5.3.3c, and the final burst test specified in 4.5.3.3c may be deleted with customer approval.

When the vibration loads are enveloped by the other qualification tests, the vibration tests specified in 4.5.3.3c may be deleted with customer approval.

NDI operations shall be applied to the over-wrap, in addition to NDI on the liner.

Clause 5.4 shall be applied to the qualification tests.

The need to apply external loads in combination with internal pressure during testing shall be considered taking into account their relative magnitude, the fatigue and destabilizing effects of external loads.

If external cycling loads are applied, the load shall be cycled to limit for four times the predicted number of operating cycles of the most severe design condition.

Destabilizing load with constant minimum internal pressure or maximum additive load with a constant MDP.

Acceptance tests

All hardware shall be submitted to the following chronology of operations:

- initial NDI, in order to establish the initial condition of the hardware;

- proof pressure test;

- leak test;

- final NDI.

For example:

- The NDI prior to proof test can be substituted for that of the manufacturing process.

- Proof test monitoring by acoustic emission is acceptable for composite items instead of post testing NDI, with customer approval.

Initial NDI operations shall be applied to the over-wrap, in addition to NDI on the liner.

Clause 5.5 shall be applied to the acceptance tests.

Final NDI shall be performed on the over-wrap of the COPC as a minimum.

Special pressurized equipment

Metallic special pressurized equipment

Factors of safety

The values in Table 48 shall be applied as minimum values of factors of safety for internal pressure.

The values specified in ECSS-E-ST-32-10 shall be applied as minimum values of factors of safety for loads different from internal pressure.

Exceptions to the values provided in Table 48 are sometimes specified by the customer or granted with customer approval.

TableTable 48: Factors of safety for MSPE (unmanned and manned missions)

|

Load

|

Application

|

FOSY

|

Prooffactor

|

FOSU

|

Burstfactor

|

|

Internal pressure

|

cryostats

|

|

1,25

|

|

1,5

|

|

heat pipes

|

1,5

|

2,5

| |||

|

sealed containers

|

1,1

|

1,5

| |||

|

hazardous fluids container

|

1,5

|

2,5

| |||

|

batteries meeting the pressure vessel definition

|

Values specified in Table 41

| ||||

|

Mechanical loads(including external pressure)

|

Values specified in ECSS-E-ST-32-10

| ||||

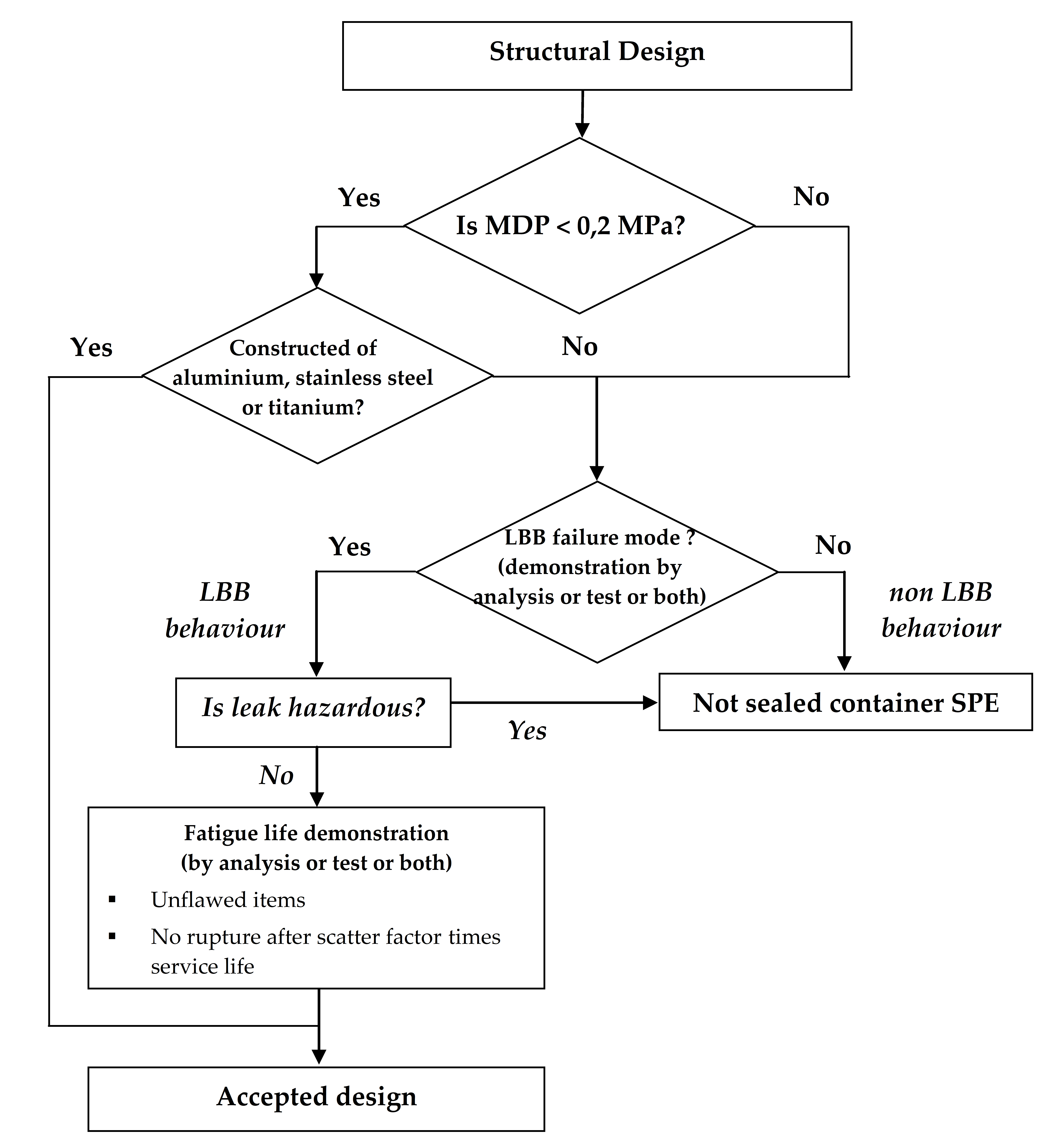

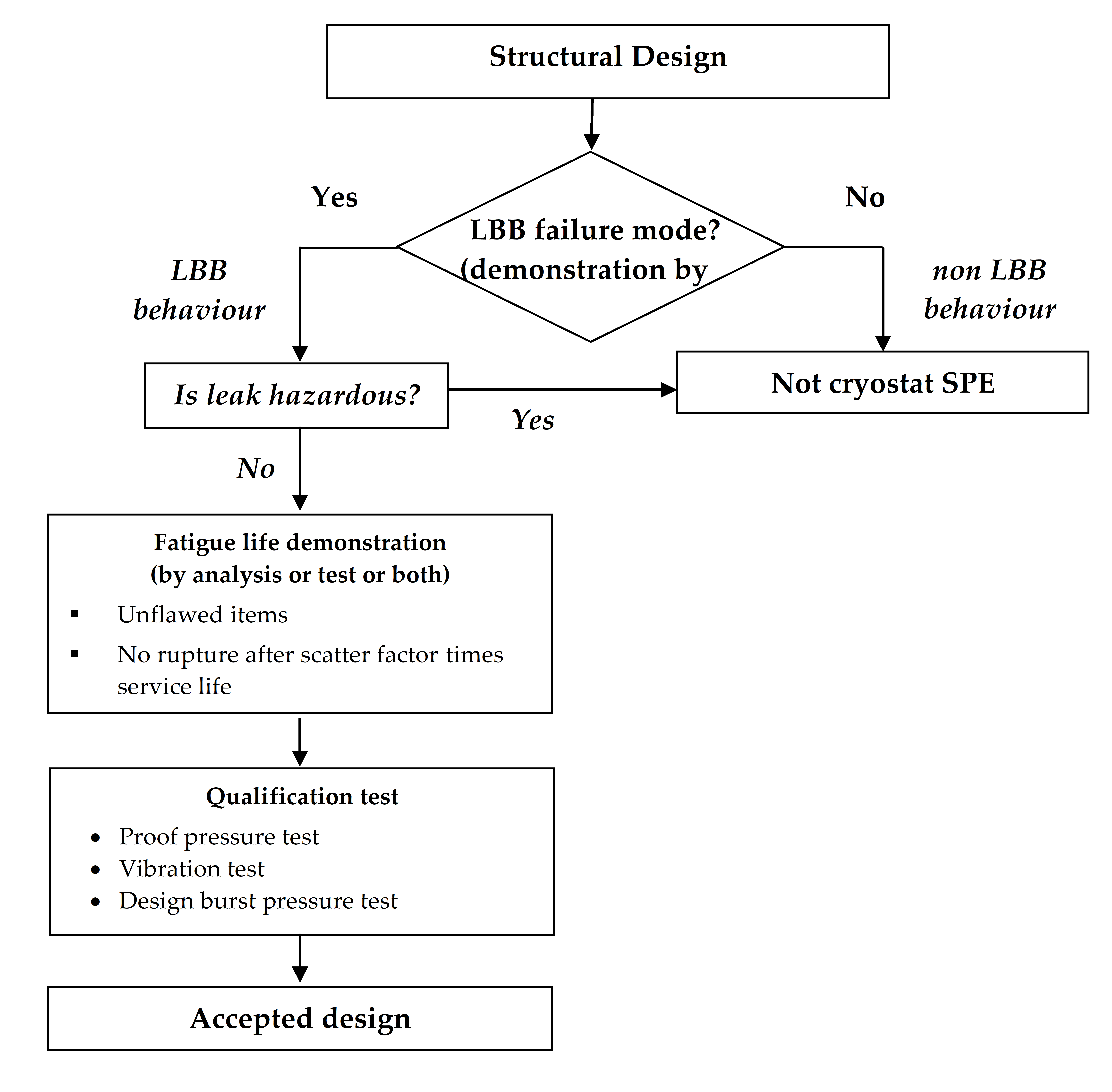

Development approach

Clause 5.2 on structural engineering shall be applied.

Thermal, stress and strain analyses and stiffness, strength and stability demonstrations are sometimes substituted with certification from qualified aerospace suppliers, with customer approval.

The failure mode shall be demonstrated by analysis or test or both, according to clause 5.3, for the following types of special pressurized equipment:

- sealed container whose MDP is greater than or equal to 0,2 MPa;

- sealed container whose MDP is less than 0,2 MPa and that are not made of aluminium alloy, stainless steel or titanium alloy;

- cryostats.

Special pressurized equipment defined in 4.6.1.2b, whose failure mode is not LBB or is LBB hazardous, shall be considered as pressure vessels, and therefore shall meet 4.3.

NOTE Sealed containers with an LBB hazardous failure mode are sometimes designed as hazardous fluids containers.

The development approach for batteries with pressurized cells that meet the definition of a pressure vessel shall conform to clause 4.3.2.1.

Qualification tests shall be conducted according to 4.6.1.3 to demonstrate the structural adequacy of the design.

A ‘safe life item’ demonstration shall be performed by analysis or test or both in conformance with ECSS-E-ST-32-01 for heat pipes and hazardous fluids containers not submitted to a proof pressure test or for which the proof factor used in the proof pressure test is less than 1,5.

Fatigue-life demonstration shall be performed by analysis or test or both in conformance with ECSS-E-ST-32.

For corrosion effects (control and prevention), the requirements in ECSS-E-ST-32 shall apply.

For hydrogen embrittlement phenomena, requirements shall be applied in conformance with ECSS-E-ST-32-08.

For material selection, material design allowables and their characterisation, requirements shall be applied in conformance with ECSS-E-ST-32.

For ‘process control’, requirements shall be in conformance with ECSS-Q-ST-70.

Inspections shall be applied according to clause 5.7.

- 1 The development approach for sealed containers is illustrated in Figure 410.

- 2 The development approach for cryostats (or Dewars) is illustrated in Figure 411.

- 3 The development approach for heat pipes is illustrated in Figure 412.

- 4 The development approach for hazardous fluids containers is illustrated in Figure 413.

- 5 Failure mode demonstration as per clause 5.3 is sometimes specified for heat pipes by the customer.

Figure 410: Development approach of sealed containers

Figure 410: Development approach of sealed containers

Figure 411: Development approach of cryostats (or Dewars)

Figure 411: Development approach of cryostats (or Dewars)

Figure 412: Development approach of heat pipes

Figure 412: Development approach of heat pipes

Figure 413: Development approach of hazardous fluid containers

Figure 413: Development approach of hazardous fluid containers

Qualification tests

All cryostats shall be submitted to the following chronology of operations:

- proof pressure test;

- vibration tests;

- design burst pressure test.

All heat pipes and hazardous fluids containers shall be submitted to a design burst pressure test.

All batteries meeting the pressure vessel definition shall be submitted to the qualification tests as per clause 4.3.2.2.

For batteries meeting the pressure vessel definition, the qualification tests to be performed for functional performance shall be defined with customer approval.

Qualification leak test is sometimes replaced by thermal vacuum test.

Clauses 5.4.1, 5.4.2, 5.4.4 and 5.4.6, shall be applied to the qualification tests.

Acceptance tests

The following SPE shall be submitted to a proof pressure test:

- sealed containers with MDP greater than or equal to 0,2 MPa and exhibiting a LBB failure mode;

- cryostats;

- heat pipes;

- hazardous fluids containers.

Cryostats shall be NDI inspected prior to the proof pressure test.

Fusion joints shall be 100 % inspected by means of a NDI method, defined with customer approval, prior and after the proof pressure test.

All batteries meeting the pressure vessel definition shall be submitted to the acceptance tests as per clause 4.3.2.3.

For batteries meeting the pressure vessel definition, additional acceptance tests shall be defined for functional performance with customer approval.

Clauses 5.5.1, 5.5.2, and 5.5.3 shall be applied to the acceptance tests.

Proof and leak tests can be performed at the assembled pressurized system level.

COSPE with metallic liner

Factors of safety

The values in Table 49 shall be applied as minimum values of factors of safety for internal pressure.

The values specified in ECSS-E-ST-32-10 shall apply as minimum values of factors of safety for loads different from internal pressure.

Exceptions to the values provided in Table 49 are sometimes specified by the customer or granted with customer approval.

When this is the case for a burst factor, the following relations can be used for determination of the proof factor:

jproof = (1 + jburst) / 2 when jburst < 2,0

jproof = 1,5 when jburst > 2,0

TableTable 49: Factors of safety for COSPE with metallic liner (unmanned and manned missions)

|

Load

|

FOSY

|

Prooffactor

|

FOSU

|

Burstfactor

|

|

Internal pressure

|

1,0

|

1,25

|

1,0

|

1,5

|

|

Mechanical loads(including external pressure)

|

Values specified in ECSS-E-ST-32-10

| |||

Development approach

Clause 5.2 on structural engineering shall be applied.

A stiffness demonstration shall be performed by analysis and test.

A strength and stability demonstration shall be performed by analysis and test.

The failure mode shall be demonstrated by analysis or test or both according to clause 5.3.

The metallic liner of the COSPE shall exhibit a LBB failure mode.

‘Safe life item’ demonstration shall be performed for the metallic liner by analysis or test or both in conformance with ECSS-E-ST-32-01.

Fatigue-life demonstration shall be performed for the composite over-wrap by analysis or test or both in conformance with ECSS-E-ST-32.

Qualification tests shall be conducted in conformance with clause 4.6.2.3 to demonstrate the structural adequacy of the design.

For corrosion effects (control and prevention), the requirements in ECSS-E-ST-32 shall apply.

For hydrogen embrittlement phenomena, requirements shall be applied in conformance with ECSS-E-ST-32-08.

For material selection, material design allowables and their characterisation, requirements shall be applied in conformance with clause 5.6 and ECSS-E-ST-32.

For ‘process control’, requirements shall be in conformance with ECSS-Q-ST-70.

Inspections shall be applied according to clause 5.7.

The development approach is illustrated in Figure 44.

Qualification tests

A first qualification test article shall be submitted to the following chronology of operations:

- non-destructive inspection (NDI);

- proof pressure test;

- leak test;

- design burst pressure test;

- burst test.

The first qualification test article specified in 4.6.2.3a may be deleted with customer approval.

A second qualification test article shall be submitted to the following chronology of operations: - NDI;

- proof pressure test;

- leak test;

- vibration tests;

- pressure cycling test;

- leak test;

- design burst pressure test;

- burst test.

The leak test after proof pressure test specified in 4.6.2.3c, and the final burst test, specified in 4.6.2.3c may be deleted with customer approval.

When the vibration loads are enveloped by the other qualification tests, the vibration tests specified in 4.6.2.3c may be deleted with customer approval.

NDI operations shall be applied to the over-wrap, in addition to NDI on the liner.

Clause 5.4 shall be applied to the qualification tests.

The need to apply external loads in combination with internal pressure during testing shall be considered taking into account their relative magnitude, the fatigue and destabilizing effects of external loads.

If external cycling loads are applied, the load shall be cycled to limit for four times the predicted number of operating cycles of the most severe design condition.

Destabilizing load with constant minimum internal pressure or maximum additive load with a constant MDP.

Acceptance tests

All hardware shall be submitted to the following chronology of operations:

- initial NDI, in order to establish the initial condition of the hardware;

- proof pressure test;

- leak test;

- final NDI.

For example:

- The NDI prior to proof test can be substituted for that of the manufacturing process.

- Proof test monitoring by acoustic emission is acceptable for composite items instead of post testing NDI, with customer approval.

Initial NDI operations shall be applied to the over-wrap, in addition to NDI on the liner.

Clause 5.5 shall be applied to the acceptance tests.

Final NDI shall be performed on the over-wrap of the COSPE as a minimum.

COSPE with homogeneous non metallic liner

Factors of safety

The values in Table 410 shall be applied as minimum values of factors of safety for internal pressure.

The values specified in ECSS-E-ST-32-10 shall be applied as minimum values of factors of safety for loads different from internal pressure.

Exceptions to the values provided in Table 410 are sometimes specified by the customer or granted with customer approval.

When this is the case for a burst factor, the following relations can be used for determination of the proof factor:

jproof = (1 + jburst) / 2 when jburst < 2,0

jproof = 1,5 when jburst > 2,0

TableTable 410: Factors of safety for COSPE with homogeneous non metallic liner (unmanned and manned missions)

|

Load

|

FOSY

|

Prooffactor

|

FOSU

|

Burstfactor

|

|

Internal pressure

|

1,0

|

1,25

|

1,0

|

1,5

|

|

Mechanical loads(including external pressure)

|

Values specified in ECSS-E-ST-32-10

| |||

Development approach

Clause 5.2 on structural engineering shall be applied.

A stiffness demonstration shall be performed by analysis and test.

A strength and stability demonstration shall be performed by analysis and test.

The failure mode shall be demonstrated by test on full-scale article according to the requirements developed per clauses 5.3.1, 5.3.4 and 5.3.5.

The liner of the COSPE shall exhibit a LBB failure mode.

When the non-metallic liner of the COSPE remains in compression up to MDP and flaws do not propagate during the LBB test, the flaws pre-fabricated in the liner of the LBB full-scale specimen may be through cracks.

‘Safe life item’ demonstration shall be performed in accordance with ECSS-E-ST-32-01:

- by test for non-metallic items;

- by analysis or test or both for metallic items (e.g. metallic bosses).

Qualification tests shall be conducted according to clause 4.6.3.3 to demonstrate the structural adequacy of the design.

For corrosion effects (control and prevention), the requirements in ECSS-E-ST-32 shall apply.

Embrittlement control shall be applied in accordance with ECSS-E-ST-32-08.

For materials selection, material design allowables and their characterisation, requirements shall be applied in conformance with clause 5.6 and ECSS-E-ST-32.

For ‘process control’, requirements shall be in conformance with ECSS-Q-ST-70.

Inspections shall be applied according to clause 5.7.

The development approach is illustrated in Figure 45.

Qualification tests

A first qualification test article shall be submitted to the following chronology of operations:

- non-destructive inspection (NDI);

- proof pressure test;

- leak test;

- design burst pressure test;

- burst test.

The first qualification test article specified in 4.6.3.3a may be deleted with customer approval.