Space product assurance

Determination of the susceptibility of silver-plated copper wire and cable to "red-plague" corrosion

Foreword

This Standard is one of the series of ECSS Standards intended to be applied together for the management, engineering and product assurance in space projects and applications. ECSS is a cooperative effort of the European Space Agency, national space agencies and European industry associations for the purpose of developing and maintaining common standards. Requirements in this Standard are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards.

This Standard has been prepared by the ECSS Executive Secretariat, endorsed by the Document and Discipline Focal Points, and approved by the ECSS Technical Authority.

Disclaimer

ECSS does not provide any warranty whatsoever, whether expressed, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item are error-free. In no respect shall ECSS incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this Standard, whether or not based upon warranty, business agreement, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by ECSS.

Published by: ESA Requirements and Standards Division

ESTEC, ,

2200 AG Noordwijk

The

Copyright: 2008 © by the European Space Agency for the members of ECSS

Change log

|

ECSS-Q-70-20A

|

First issue

|

|

ECSS-Q-70-20B

|

Never issued

|

|

ECSS-Q-ST-70-20C

|

Second issue

|

|

Redrafting of ECSS-Q-70-20A according to ECSS drafting rules and new template.

|

Scope

This Standard gives details of an accelerated screening test method and acceptance criteria to determine the suitability of silverplated wire and cable materials for use on spacecraft and associated equipment. The test method, which also determines the suitability of the associated fabrication processes, is based on the work of Anthony and Brown (1965). They established that “redplague” originates at breaks in the silverplating of copper wire strands in the presence of moisture and oxygen. The environmental test system artificially promotes “redplague” corrosion under controlled laboratory conditions as a result of galvanic corrosion of the copper conductor core.

This standard may be tailored for the specific characteristics and constraints of a space project in conformance with ECSS-S-ST-00.

Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this ECSS Standard. For dated references, subsequent amendments to, or revisions of any of these publications do not apply. However, parties to agreements based on this ECSS Standard are encouraged to investigate the possibility of applying the most recent editions of the normative documents indicated below. For undated references the latest edition of the publication referred to applies.

|

ECSS-S-ST-00-01

|

ECSS system – Glossary of terms

|

|

ECSS-Q-ST-10-09

|

Space product assurance – Nonconformance control system

|

|

ECSS-Q-ST-20

|

Space product assurance – Quality assurance

|

|

ECSS-Q-ST-70

|

Space product assurance – Materials, mechanical parts and processes

|

Terms, definitions and abbreviated terms

Terms defined in other standards

For the purpose of this Standard, the terms and definitions from ECSSSST0001 apply, in particular for the following terms:

corrosion

Terms specific to the present standard

batch

quantity produced at one operation

One batch can be subdivided into several lots.

redplague

redcoloured cuprous oxide (possibly with some black cupric oxide) corrosion product that forms when a galvanic cell is formed between copper and silver

The presence of humidity or moisture is a prerequisite.

Abbreviated terms

The abbreviated terms defined in ECSS-S-ST-00-01 apply.

Principles

The principles of the corrosion test to determine the susceptibility of silver plate copper wire and cable to red-plague corrosion is to submit the item to be tested (wire and cable) for to a certain period of time to an oxygen rich atmosphere at elevated temperature in order to evaluate the resistance of the item to deleterious effects as copper removal as a result of corrosion

For this purpose the activities related to corrosion test standardization requirements are specified in clause 5.

It is important to perform the work taking into account health and safety regulations, and in particular the national standards on this subject.

Requirements

Preparatory conditions

Handling and storage

The supplier shall handle all samples of wires and cables only with clean nylon or lintfree gloves.

The supplier shall store the samples before and after testing in a clean area.

Identification

The samples of wires and cables submitted for testing shall be identified by the following:

- Trade name

- Source

- Manufacturer’s code number

- Batch number

- Date of manufacture The construction details of wires or cables shall include the following details:

- Form

- Principal dimensions

- Description of insulation and conductor materials

- Plating materials and their nominal thicknesses

Test equipment

The supplier shall use the following test equipment for the test method:

- Microscope, at least 20 magnification with attachment to enable photomicrograph.

- Conical glass flasks

For example: Erlenmeyer > 250 ml.

- Natural two holed rubber stoppers

- Glass tubing having 3 mm - 6 mm internal diameter

- Supply of oxygen gas

- Gas flow regulator

For example: Hoffman clips

- Stock of deionized water

- Length of copper wire having 1 mm - 2 mm diameter

- Water trough, or other suitable temperaturecontrol bath

- Heater with temperature regulator

- Thermometers

- Scalpel and wire cutters that produce a shear 90° end cut

- Any additional equipment enabling metallurgical analysis to be performed when called up by 5.3.1b.

Test procedure

Preparation of test samples

The supplier shall take the wire or cable to be submitted to this test procedure from stock with minimum handling.

The supplier shall remove any particles or contamination visible on the outer insulation under a magnification of 10 with a clean, lintfree cloth.

The supplier shall cut two adjacent test samples from the midlength of the submitted wire or cable. Each test sample shall have a length of (200 50) mm.

The supplier shall strip off insulation of one test sample and shall inspect the exposed (silver)plated braid or strands visually for corrosion and contamination at a magnification of 20.

In case of shielded cable, the supplier shall remove all inner conductors, strip off insulation and inspect the cable.

The supplier shall photograph any unusual features such as contamination or corrosion products present on the exposed (silver)plated strands for control reference.

The supplier shall prepare the second test sample for the corrosion test by removing the outer insulation jacket partially by using the scalpel blade.

The incisions either circumferential or longitudinal, shall not damage the metal conductors.

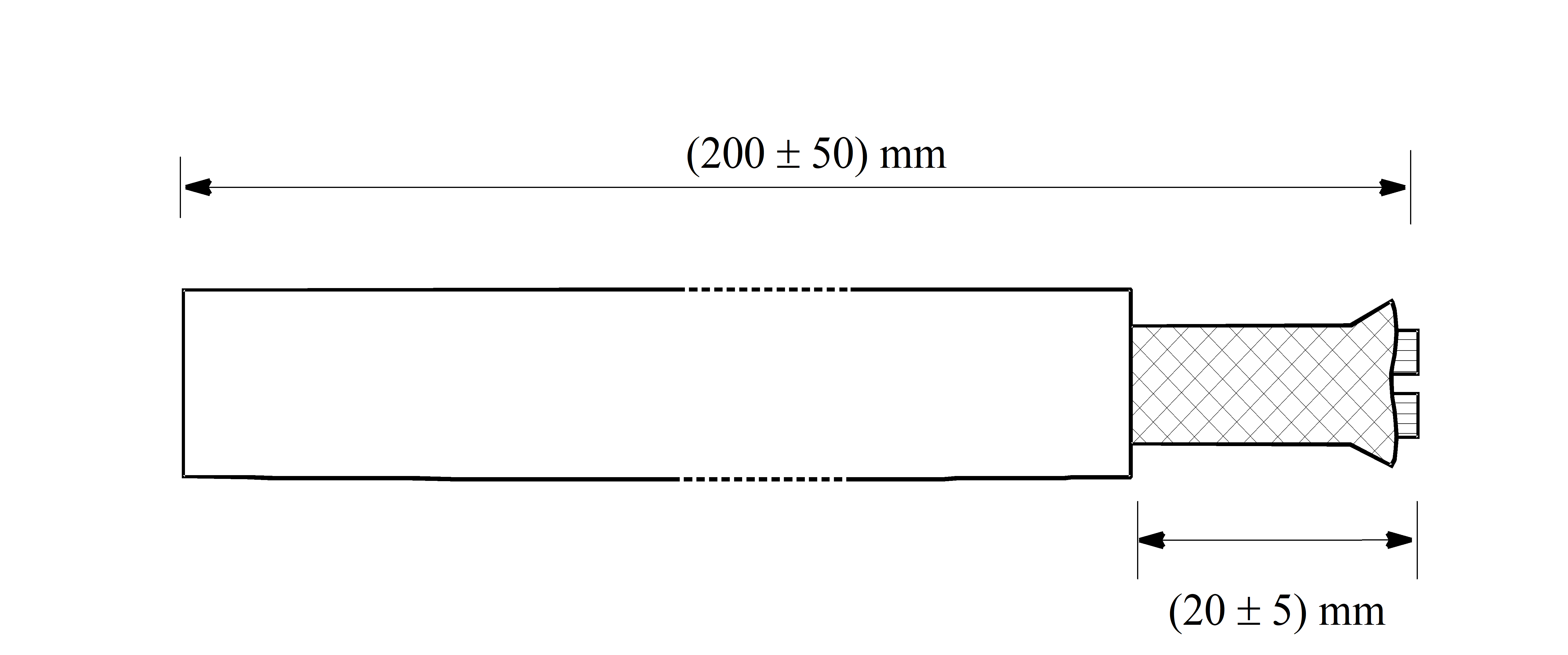

The length of outer insulation to be removed shall be (20 5) mm from the sample end as shown in Figure 51.

The supplier shall splay the outer braid when inner conductors are present to give clear exposure of the cut ends of all inner strands.

The supplier shall use sharp cutters to trim the inner conductors to ensure that the insulation has not sealed off the wires.

Figure 51: Sketch of prepared test cable

Figure 51: Sketch of prepared test cable

Test sequence

The test procedure shall be as follows:

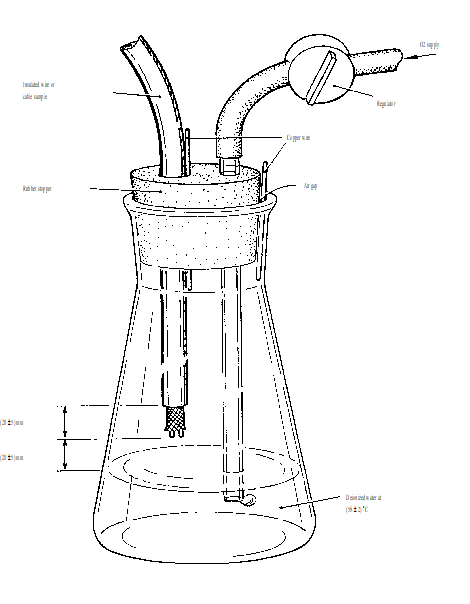

- Pour 200 ml of deionized water into the clean glass flask.

- Insert the wire or cable sample into one hole of the twohole stopper.

Fix the wire in place with a short length of copper wire.

- Insert a glass tube into the second hole, as shown in Figure 52.

- Fit the stopper into the neck of the flask, together with a short length of copper wire to provide an air flow between flask and stopper.

- Ensure that the glass tube extend into the deionized water.

- Ensure that the end of the wire or cable sample is at a distance of (20 5) mm above the water surface.

- Supply oxygen by connecting the glass tube with a plastic tube and a Hoffman clip (or other regulator) that controls the passage of oxygen into the water to maintain a flow rate of (50 10) bubbles per minute.

- Place the test flask in a water trough or bath maintained at a temperature of (58 2) C.

- Always test only one wire or cable sample per flask.

If more than one test is performed at the same time, place the flasks and oxygen flow in parallel to each other.

The wire or cable sample shall be exposed for a duration of 240 hours.

After completion of the test, the sample shall be removed from the flask and stopper.

Figure 52: Example of test equipment

Figure 52: Example of test equipment

Acceptance criteria

Inspection of sample

The inspection procedure shall be as follows:

- Inspect the sample within three hours of being removed from the test apparatus.

- Remove all insulation from the outer braid (when present) and at least from one of the inner conductors.

- Inspect the silverplated strands that make up braiding or inner conductor at a magnification of 20 for signs of contamination and corrosion.

- Photograph specific areas of interest.

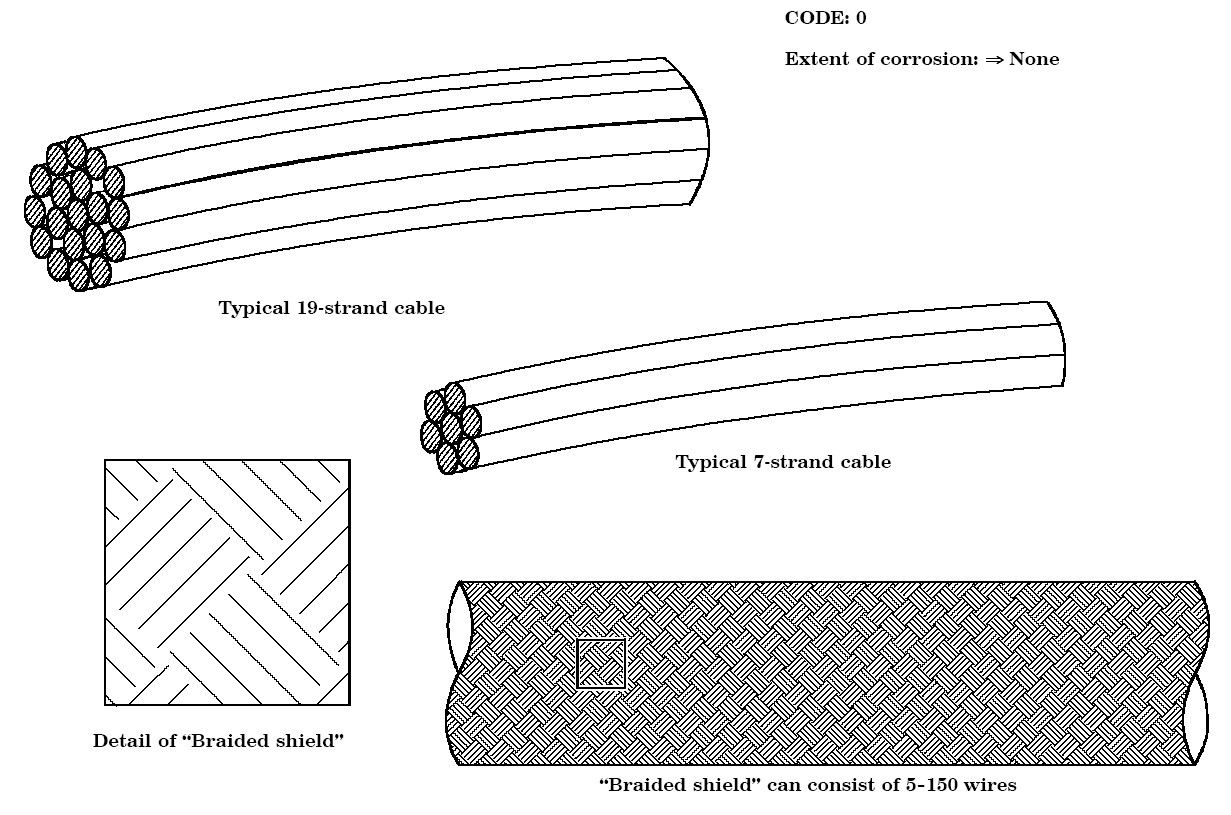

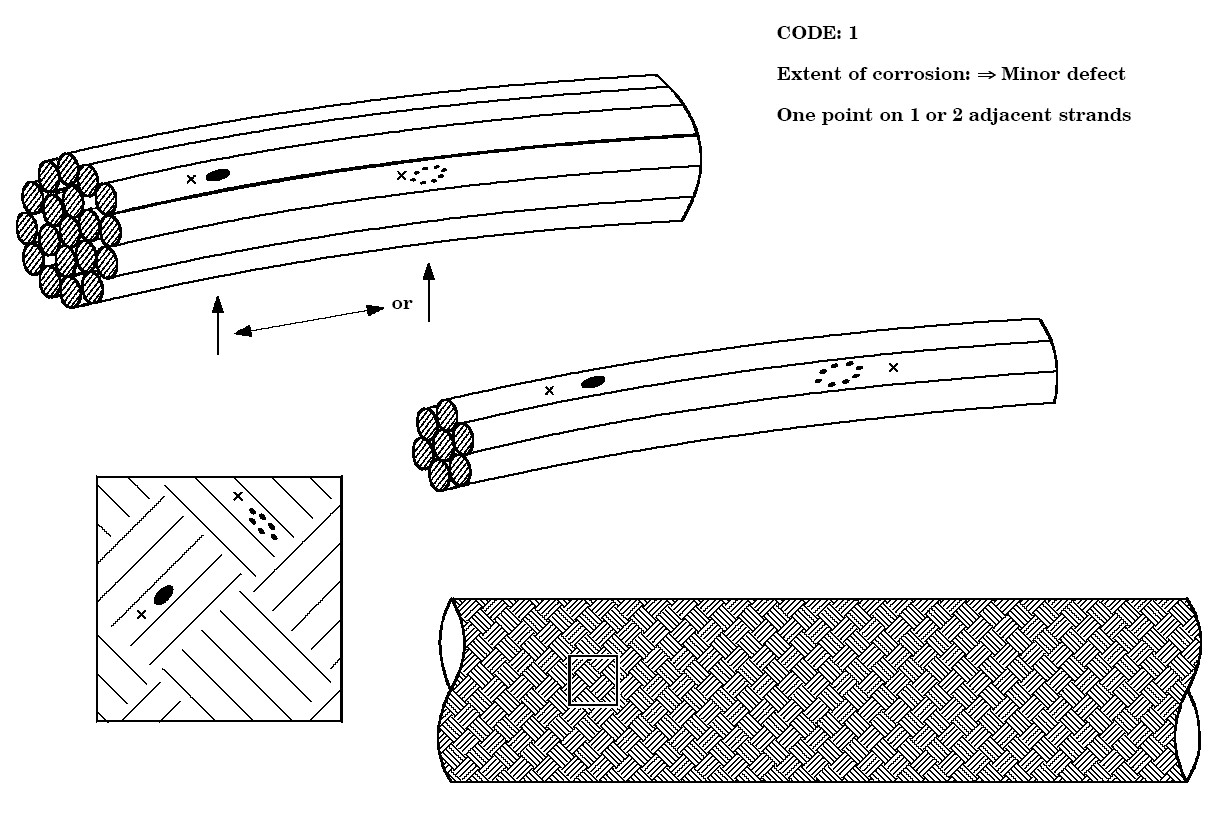

- For samples comprising 19 wire strands, classify the extent of corrosion (per 20 cm length) present on the tested samples, on the basis of subjective visual inspection results, in accordance with Table 51.

For further guidance, see also Annex C.

- For samples comprising 7 wire strands:

- Classify as a minor defect when 2 to 3 strands in one or more locations along the sample length are affected.

- Classify as major defect when corrosion affects 4 or more strands (more than 50 %) at the same sample length.

Visual inspection as means of quantifying the extent of corrosion is subjective owing to the possibility of widespread precipitation of corrosion product onto adjacent strands.

For conductors that have been designated a code of 4 or 5, the supplier shall quantify the number of strands that bear corrosion sites by metallography.

Acceptance and rejection criteria

For the cases when codes 4 and 5 are confirmed by additional investigation, as defined in 5.3.1b, the supplier shall reject the sample and associated batch of conductor material as unsuitable for space use.

The codes 0 to 3, as defined in 5.3.1a and in Table 51 are not cause for failure of the test sample.

Table 51: Corrosion classification

|

Code

|

Extent of corrosion (19strand wire)

| |

|

0

|

None

|

|

|

1

|

Minor defect:

|

One point on 1 or 2 adjacent strands.

|

|

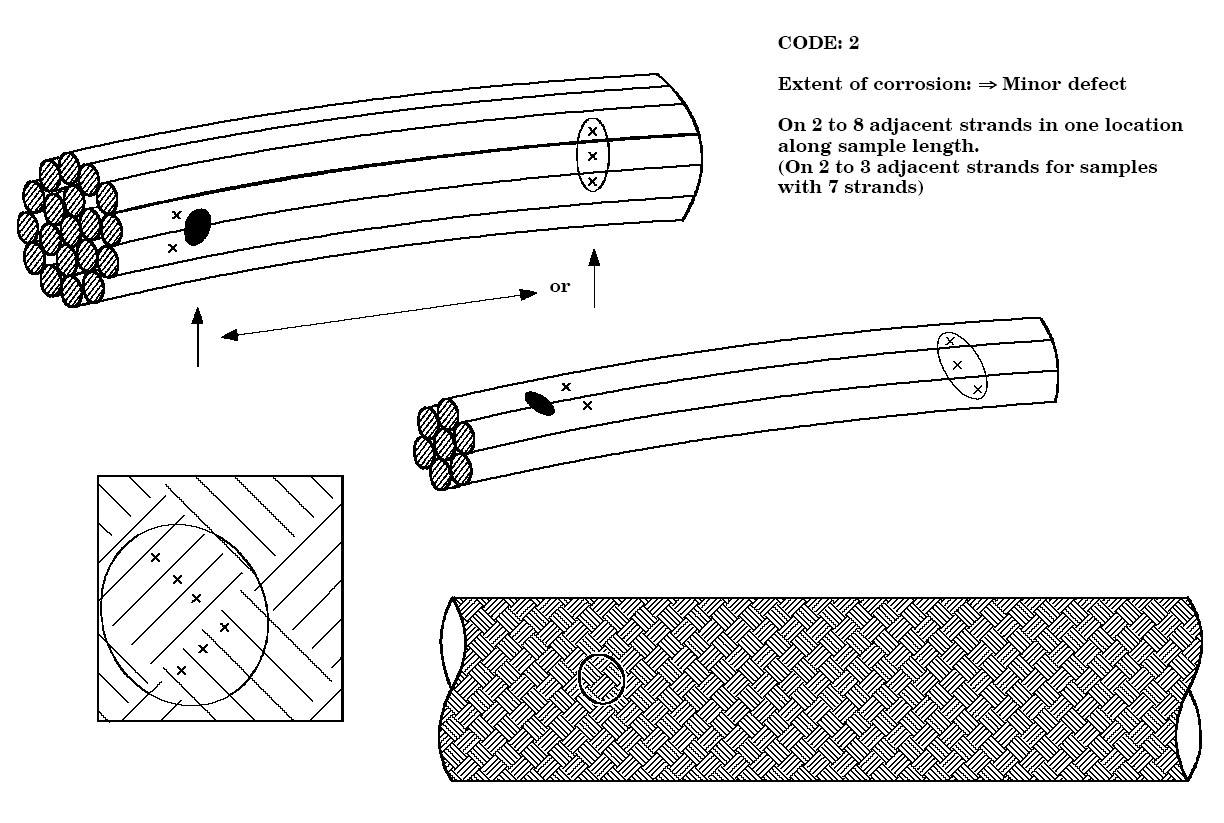

2

|

Minor defect:

|

On 2 to 8 adjacent strands in one location along sample length.

|

|

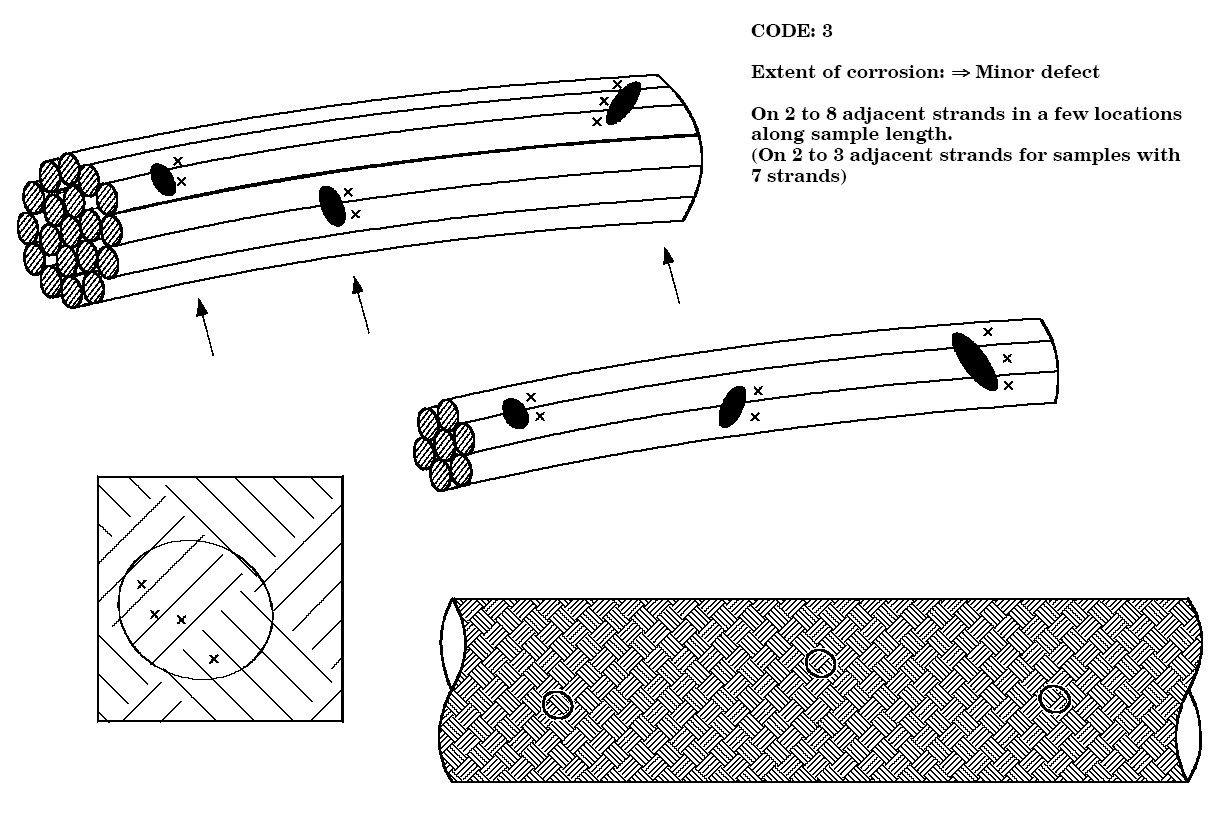

3

|

Minor defect:

|

On 2 to 8 adjacent strands in a few locations along sample length.

|

|

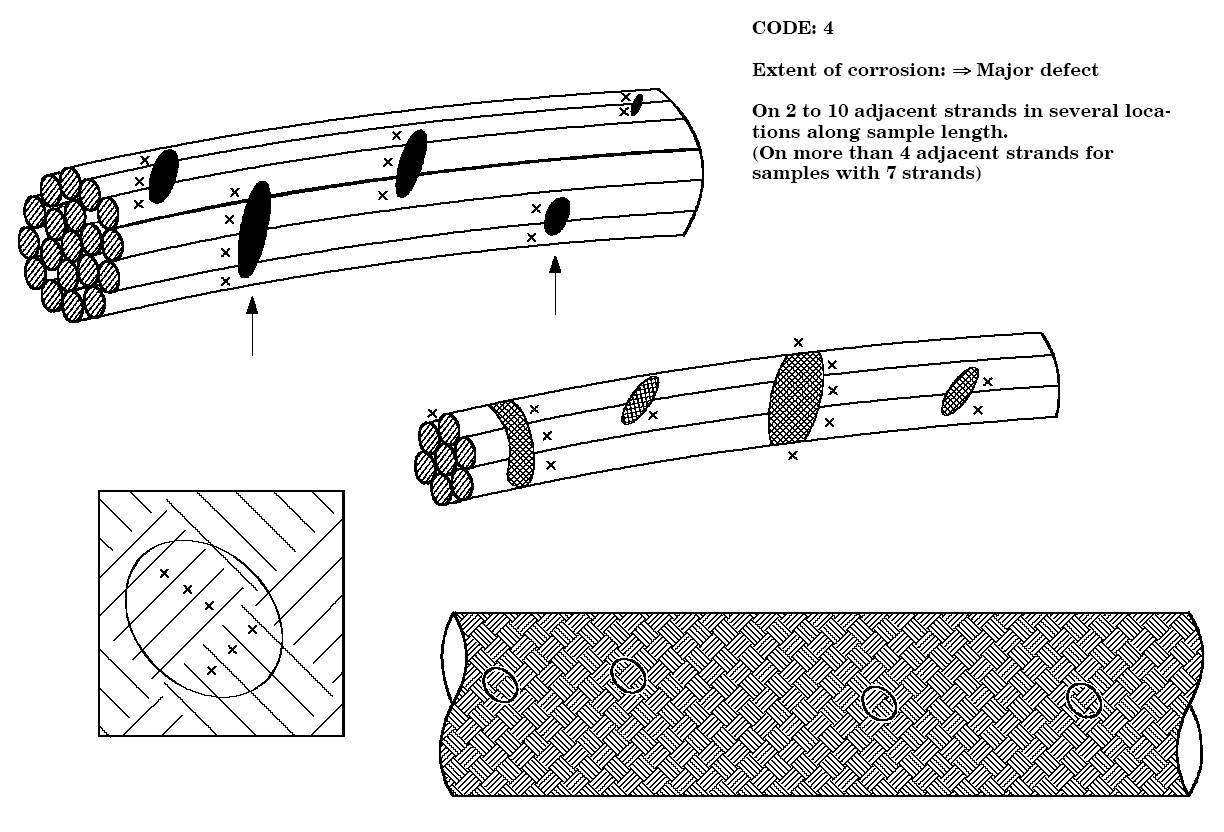

4

|

Major defect:

|

On 2 to 10 adjacent strands in several locations along sample length.

|

|

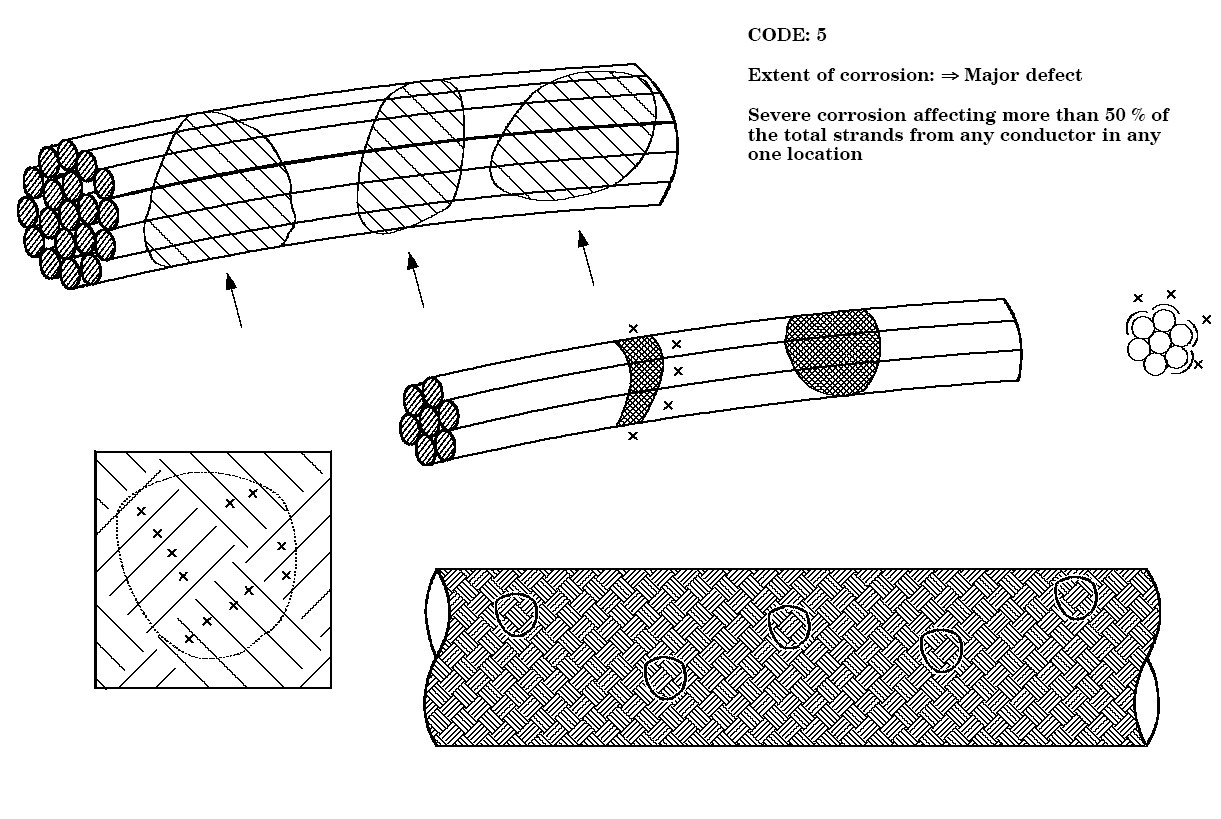

5

|

Major defect:

|

Severe corrosion affecting more than 50 % of the total strands from any conductor, in any location.

|

|

NOTE 1 Codes 0 to 3 are considered not to affect the electrical properties of the wire or cable.

| ||

|

NOTE 2 A graphical representation of this extent of corrosion code is given in Annex C.

| ||

Quality assurance

Data

The supplier shall establish an evaluation report in conformance with Annex A

The supplier shall retain the evaluation report for at least ten years, or in accordance with business agreement requirements.

Calibration and traceability

The supplier shall calibrate any measuring equipment to traceable reference standards

The supplier shall record any suspected or actual equipment failure as a project nonconformance report in conformance with NCR DRD in ECSSQST1009.

This is to ensure that previous results can be examined to ascertain whether or not reinspection and retesting is necessary.

The supplier shall maintain traceability throughout the process from incoming inspection to final test, including details of test equipment and personnel employed in performing the task.

ANNEX(normative)Red-plague evaluation report - DRD

DRD identification

Requirement identification and source document

This DRD is called from ECSS-Q-ST-70-20, requirement 5.4.1a.

Purpose and objective

The aim of this report is to provide relevant information about the test method to determine the suitability of silverplated wire and cable materials for use on spacecraft and associated equipment.

Expected response

Scope and content

The evaluation report shall uniquely identify the test.

The evaluation report shall identify the wire or cable as described in 5.1.2a.

The evaluation report shall list the inspection and test results as described in 5.3.1a6 and 5.3.1b.

The evaluation report shall refer to photomicrographs as described in 5.3.1a.4.

The evaluation report shall contain the date of test completion.

The evaluation report shall contain the signature of the inspector.

Special remarks

The supplier may use the template given in Annex B.

ANNEX(informative)Example of redplague evaluation report template

Figure B-1 presents an example of template that can be used to present the redplague evaluation report specified in Annex A.

|

Red�plague test report sheet

| |||||

|

Test number

|

Wire or cable designation

|

Inspection results

|

Date of text completion

|

Signature of inspector

| |

|

Sample 1

|

Sample 2

| ||||

Figure: Example of redplague test report sheet

ANNEX(informative)Codes for extent of corrosion

Figure C-1 to Figure C-6 are the graphical representations of the extent of corrosion codes of the acceptance criteria for requirement 5.3.1a.5 and Table 51.

Figure: Extent of Corrosion (per 20 cm length/test sample): Code 0

Figure: Extent of Corrosion (per 20 cm length/test sample): Code 0

Figure: Extent of Corrosion (per 20 cm length/test sample): Code 1

Figure: Extent of Corrosion (per 20 cm length/test sample): Code 1

Figure: Extent of Corrosion (per 20 cm length/test sample): Code 2

Figure: Extent of Corrosion (per 20 cm length/test sample): Code 2

Figure: Extent of Corrosion (per 20 cm length/test sample): Code 3

Figure: Extent of Corrosion (per 20 cm length/test sample): Code 3

Figure: Extent of Corrosion (per 20 cm length/test sample): Code 4

Figure: Extent of Corrosion (per 20 cm length/test sample): Code 4

Figure: Extent of Corrosion (per 20 cm length/test sample): Code 5

Figure: Extent of Corrosion (per 20 cm length/test sample): Code 5

Bibliography

|

ECSS-S-ST-00

|

ECSS system – Description, implementation and general requirements

|

|

Anthony and Brown (1965)

|

Mater. Prot Performance, March 1965 Vol. 4 No. 3 “Red plague corrosion on silver plated wire” by Anthony P.L. and Brown O.M.

|