Space engineering

Modal survey assessment

Foreword

This Standard is one of the series of ECSS Standards intended to be applied together for the management, engineering and product assurance in space projects and applications. ECSS is a cooperative effort of the European Space Agency, national space agencies and European industry associations for the purpose of developing and maintaining common standards. Requirements in this Standard are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards.

This Standard has been prepared by the ECSS-E-ST-32-11C Working Group, reviewed by the ECSS Executive Secretariat and approved by the ECSS Technical Authority.

Disclaimer

ECSS does not provide any warranty whatsoever, whether expressed, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item are error-free. In no respect shall ECSS incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this Standard, whether or not based upon warranty, business agreement, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by ECSS.

Published by: ESA Requirements and Standards Division

ESTEC, ,

2200 AG Noordwijk

The

Copyright: 2008 © by the European Space Agency for the members of ECSS

Change log

|

ECSS-E-30-11A

|

First issue

|

|

ECSS-E-30-11B

|

Never issued

|

|

ECSS-E-ST-32-11C

|

Second issue

|

Scope

This Standard specifies the basic requirements to be imposed on the performance and assessment of modal survey tests in space programmes. It defines the terminology for the activities involved and includes provisions for the requirement implementation.

This Standard specifies the tasks to be performed when preparing, executing and evaluating a modal survey test, in order to ensure that the objectives of the test are satisfied and valid data is obtained to identify the dynamic characteristics of the test article.

This standard may be tailored for the specific characteristics and constrains of a space project in conformance with ECSS-S-ST-00.

Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this ECSS Standard. For dated references, subsequent amendments to, or revision of any of these publications, do not apply. However, parties to agreements based on this ECSS Standard are encouraged to investigate the possibility of applying the more recent editions of the normative documents indicated below. For undated references, the latest edition of the publication referred to applies.

|

ECSS-S-ST-00-01

|

ECSS system — Glossary of terms

|

|

ECSSEST-1003

|

Space engineering — Testing

|

|

ECSS-E-ST-32

|

Space engineering — Structural general requirements

|

Terms, definitions and abbreviated terms

Terms from other standards

For the purpose of this Standard, the terms and definitions from ECSSSST0001 apply.

Terms specific to the present standard

accelerance

ratio of the output acceleration spectrum to the input force spectrum

- 1 Accelerance is computed as follows:

where

is the output acceleration spectrum;

is the input force spectrum.

-

2 The accelerance is also called “inertance” and it is the inverse of the apparent mass (see 3.2.2).

apparent mass

ratio of the input force spectrum to the output acceleration spectrum -

1 Apparent mass is computed as follows:

where

is the input force spectrum;

is the output acceleration spectrum.

-

2 The apparent mass is also called “dynamic mass”, and it is the inverse of the accelerance (see 3.2.1).

auto modal assurance criterion AutoMAC

measure of the degree of correlation between two mode shapes of the same mode shape set -

1 For example, test mode shapes or analysis mode shapes.

-

2 The AutoMAC is a specific case of the MAC (see 3.2.26); the AutoMAC matrix is symmetric.

-

3 The AutoMAC is particularly useful for assessing whether a given selection of DOFs is adequate for MAC evaluations employing two different sets of mode shapes (e.g. test and analysis).

coherence function

measure of the degree of linear, noisefree relationship between the measured system input and output signals at each frequency -

1 The coherence function is defined as

where

is the frequency;

Sff () is the power spectrum of the input signal;

Sxx () is the power spectrum of the output signal;

Sxf () is the inputoutput cross spectrum.

-

2 ()=1 indicates a linear, noisefree relationship between input and output.

-

2 ()=0 indicates a non causal relationship between input and output.

complex mode shape

modal vector of a nonproportionally damped system -

1 For complex mode shapes, any phase relationship can exits between different parts of the structure.

-

2 Complex mode shapes can be considered to be propagating waves with no stationary node lines.

complex mode indicator function

indicator of the existence of real or complex modes and their relative magnitudes

The complex mode indicator function has extended functionality to estimate approximate modal parameters.

co-ordinate modal assurance criterionCoMAC

measure of the correlation of the a given DOF of two different sets of mode shapes over a number of comparablepaired mode shapes

- 1 The coordinate modal assurance criterion for DOF j is defined as:

where

is the mode shape coefficient for DOF j for mode r of set A;

is the mode shape coefficient for DOF j for mode r of set X;

r is the index of the correlated mode pairs.

For example, mode shapes X and A are test and analysis mode shapes, respectively.

- 2 CoMAC = 1 indicates perfect correlation.

- 3 The results can be considered to be meaningful only when the CoMAC is applied to matched modes, i.e. for correlated mode pairs.

damping

dissipation of oscillatory or vibratory energy with motion or with time

damped natural frequency

frequency of free vibrations of a damped linear mechanical system

driving point residue

calculated quantity that defines the most appropriate exciter positions

The magnitude of the driving point residue for a location is defined as:

where

rjr is the driving point residue of DOF j for mode r;

vjr is the mode shape coefficient of DOF j for mode r;

mr is the modal mass for mode r;

dr is the damped natural frequency for mode r.

dynamic compliance

ratio of the output displacement spectrum to the input force spectrum

- 1 Dynamic compliance is computed as follows:

where

X() is the output displacement spectrum;

F() is the input force spectrum.

-

2 The dynamic compliance is also called dynamic flexibility, and it is the inverse of the dynamic stiffness (see 3.2.12).

dynamic stiffness

ratio of the input force spectrum to the output displacement spectrum -

1 Dynamic stiffness is computed as follows:

where

F() is the input force spectrum;

X() is the output displacement spectrum.

-

2 The dynamic stiffness is the inverse of the dynamic compliance (see 3.2.11).

effective modal mass

measure of the mass portion associated to the mode shape with respect to a reference support point -

1 The six effective masses for a normal mode, {}r, are the diagonal values of the modal mass matrix.

where

{L}r is the modal participation factor:

;

mr is the generalised mass:

;

{}r, is the elastic mode r;

{}, is the rigid body mode.

- 2 The sum of the effective masses provides an indication of the completeness of the measured modes, since the accumulated effective mass contributions from all modes equal the total structural mass and inertia for each of the six translatory and rotatory DOFs, respectively.

eigenfrequency

See natural frequency

finite element modelFEM

mathematical representation of a physical structure or system where the distributed physical properties are represented by a discrete model consisting of a finite number of idealized elements which are interconnected at a finite number of nodal points

The FEM contains only a finite number of degrees of freedom compared to the infinite number of degrees of freedom for the physical structure or system.

forced vibration

vibratory motion of a system that is caused by mechanical excitation

free vibration

vibratory motion of a system without forcing

frequency response assurance criterionFRAC

measure of the similarity between an analytical and experimental frequency response function

- 1 The frequency response assurance criterion is a degree of freedom correlation tool. It is the FRF equivalent to the CoMAC (see 3.2.7).

- 2 The frequency response assurance criterion is defined as

where

AHjk() is the analytical frequency response function of a response at DOF j due to an excitation at DOF k;

XHjk() is the corresponding experimental frequency response function.

-

3 FRAC = 1 indicates a perfect correlation of the two frequency response functions.

-

4 FRAC = 0 indicates a non correlation of the two frequency response functions.

frequency response function FRF

descriptor of a linear system in the frequency domain that relates the output motion spectrum (displacement, velocity or acceleration) to the input force spectrum -

1 The frequency response function is generally defined as:

-

2 H() is a complex function containing magnitude and phase information.

-

3 Common definitions of standard and inverse FRF are:

-

accelerance or inertance (see 3.2.1);

-

apparent or dynamic mass (see 3.2.2);

-

dynamic compliance or flexibility (see 3.2.11);

-

dynamic stiffness (see 3.2.12).

-

impedance (see 3.2.22);

-

mobility (see 3.2.24).

fundamental resonance

first major significant resonance as observed during the modal survey test -

1 For unconstrained mechanical systems, the fundamental resonance is the lowest natural frequency with motions of the whole test article.

-

2 For clamped mechanical systems, the fundamental resonance is the mode with the largest effective mass.

impact

single collision between masses where at least one of the masses is in motion

impedance

ratio of the input force spectrum to the output velocity spectrum

- 1 Impedance is computed as follows:

where

F() is the input force spectrum;

is the output velocity spectrum.

- 2 The impedance is the inverse of the mobility (see 3.2.24).

linear system

system whose response is directly proportional to the excitation for every part of the system

mobility

ratio of the output velocity spectrum to the input force spectrum

- 1 Mobility is computed as follows:

where

is the output velocity spectrum;

F() is the input force spectrum.

- 2 The mobility is the inverse of the impedance (see 3.2.22).

modal analysis

process of determining the modal parameters of a structure within the frequency range of interest

For the frequency range of interest, see 4.1.2.

modal assurance criterionMAC

measure of the degree of correlation between two mode shapes

-

1 The modal assurance criterion is defined as:

where

and

are the two mode shapes.

-

2 MAC = 1 indicates perfect correlation of the two mode shapes.

-

3 MAC = 0 indicates no correlation of the two mode shapes.

modal confidence factorMCF

indicator of computational noise modes in time domain parameter estimation methods -

1 The modal confidence factor for mode r is given as

where

is a computed mode;

r is a complex eigenvalue, or system pole for mode r;

is a massnormalized mode shape;

is the time interval.

-

2 MCFr 1 indicates a physical mode, and in such case:

-

3 MCFr << 1 indicates a computational noise mode.

modal identification

technique to determine the inherent modal properties of a mechanical system

modal parameters

collection of natural frequency, modal damping, mode shape and (generalized) modal mass for each mode of a mechanical system

-

1 The modal parameters of all modes, within the frequency range of interest (see 4.1.2), constitute a complete dynamic description of the structure.

-

2 Common definitions relating to modal parameters are:

-

damped equations of motion

;

-

inertia force

-

elastic force

-

damping force (proportional with velocity)

;

-

external dynamic force

-

undamped eigenvalue problem

-

natural or eigenfrequency

;

-

general mode shape

-

(generalized) modal mass

-

(generalized) modal damping

-

generalized stiffness

-

massnormalized mode shape

-

massnormalized modal mass

-

massnormalized modal damping

-

massnormalized modal stiffness

-

modal matrix

,

-

3 For nonproportional damping, the generalized damping matrix is not a diagonal matrix.

modal participation factor

measure of the efficiency of the excitation at each degree of freedom of the supporting point -

1 The modal participation factor is a measure of the reaction force at the supported reference point.

-

2 See also 3.2.13.

modal scale factorMSF

least squares difference of two mode shapes, where one mode shape is projected on the other and scaled to the length of the latter

The modal scale factor is given as

where

and

are the two mode shapes;

[W] is a weighting matrix (most often the unity matrix).

modal survey test MST

test that identifies a set of modal properties of a mechanical system

mode indicator functionMIF

measure for phase purity of the measured mode shapes using a single reference

-

1 The most common definitions applied by different modal analysis systems are:

-

Breitbach (1972):

-

Hunt (1984):

where xj is the complex valued response at the jth structural point:

,

- 2 MIF = 1 indicates a perfectly excited mode shape.

- 3 MIF << 1 indicates either no resonances in the frequency range or inappropriately excited modes.

- 4 The mass weighting is often neglected.

- 5 The MIF is a special case of the MMIF (see 3.2.35).

mode shape

characteristic shape of motion of an elastic structure when vibrating at its corresponding natural frequency

multivariate mode indicator functionMMIF

measure of the phase purity of the measured mode shapes using a multiple reference

- 1 The MMIF is given as a frequency dependent eigenvalue problem:

where:

[A] =

;

[B] =

;

is the real part of the FRF;

is the imaginary part of the FRF;

is the force eigenvector;

is the mass matrix;

is an eigenvalue.

-

2 The MMIF comprises the eigenvalues resulting from the solution of the eigenvalue problem for each frequency .

-

3 MMIF = 0 indicates a perfectly excited mode shape.

-

4 MMIF >> 0 indicates either no resonances in the frequency range or inappropriately excited modes.

-

5 The MMIF yields a set of exciter force patterns that can best excite the real normal modes. It is therefore a simple but effective method to check the adequacy of the selected exciter locations.

natural frequency

characteristic frequency of a linear mechanical system at which the system vibrates when all external excitations are removed or damped out -

1 This definition refers to both, damped or undamped natural frequencies.

-

2 The natural frequency is frequently referred to also as resonant frequency or eigenfrequency (see 3.2.14).

noise

total of all sources of interference in a measurement system, independent of the presence of a signal

For example, mechanical background noise, ambient excitation, electrical noise in the transducing system, data acquisition noise, computational noise, and nonlinearities.

normal mode shape

mode shapes where all parts of the structure are moving either in phase, or 180 out of phase with each other

-

1 Normal mode shapes can be considered to be standing waves with fixed node lines.

-

2 For proportionally damped systems, the normal mode shapes can be derived from the complex mode shapes by rescaling.

orthogonality check

measure of the mathematical orthogonality and linear independence of a set of mode shapes (analytical or measured) using the mass matrix of the mathematical model (FEM or TAM) as a weighting factor -

1 The following are common definitions of the orthogonality check:

-

Auto orthogonality check (AOC) Measure of the mathematical orthogonality of mode shapes r and s taken from the same set j of analytical or measured mode shapes.

Where 0 AOCrs 1.

-

Cross orthogonality check (COC) Measure of the mathematical orthogonality of mode shapes r and s taken from two different sets, j and k, of mode shapes (analytical and measured, respectively).

Where 0 COCrs 1.

-

2 The degree of orthogonality is usually assessed by the magnitude of the offdiagonal elements AOCrs and COCrs of the orthogonality matrices [AOC] and [COC], respectively.

-

3 The auto orthogonality check is an indicator of the accuracy of the assumed mass matrix and the acquired data. Ideally:

pickup

See transducer

pretest analysis

structural analysis activities to prepare for the modal survey test

Usually, the pretest analysis employs the structural mathematical model of the test article. The test setup is included if it has a significant influence on the results.

real mode shape

modal vector of a proportionally damped system where all parts of the structure vibrate in phase

Real mode shapes can be considered to be standing waves with stationary node lines.

reciprocity

structural response at a given point due to an input at another point equals the response at the input point due to an identical input at the given response point

This is known as Maxwell’s reciprocity principle: pq = qp.

resonance

maximum amplification of the response of a mechanical system in forced vibrations

resonance frequency

frequency of a mechanical system where any change, however small, in the frequency of excitation in either direction causes the system response to decrease

response

output of a structure at a given point due to an input at another point

For modal survey tests the structural responses are usually measured in terms of accelerations.

response vector assurance criterionRVAC

measure of the similarity between an analytical and experimental response vector at a particular frequency

- 1 The response vector assurance criterion is a vector correlation tool. It is the FRF equivalent to the MAC (see 3.2.26).

- 2 The response vector assurance criterion is defined as:

where

- is the analytical vector containing only the FRF values at all response points due to an excitation at DOF k for a particular frequency r;

- is the corresponding experimental response vector.

- 2 RVAC = 1 indicates perfect correlation of the two response vectors.

- 3 FRAC = 0 indicates no correlation of the two response vectors.

signal analysis

process of evaluating the input and output signals of mechanical systems to describe their characteristics in meaningful and easily interpretable terms in the time or frequency domain

signaltonoise ratio

ratio of the power of the desired signal to that of the coexistent noise at a specified point in a transmission channel under specified conditions

- 1 The signaltonoise ratio is a measure of the signal quality.

- 2 It is usually given as the ratio of voltage of a desired signal to the undesired noise component measured in corresponding units.

signal conditioner

amplifier placed between a transducer or pickup and succeeding devices to make the signal suitable for these devices

For example, succeeding devices can be amplifiers, transmitters or readout instruments.

spectrum control

capability to limit the excitation to the frequency range of interest

For the frequency range of interest, see 4.1.2.

steadystate vibration

vibration where the amplitude and frequency stay constant over the whole duration of the vibration

test analysis modelTAM

finite element model of the test setup in terms of stiffness and mass matrix, for test purposes reduced to excitation and measurement degrees of freedom

The test setup can include the test fixture.

test equipment

collection of hardware to support the test execution

For example, test adapters.

test setup

collection of the test article, the test equipment and the test instrumentation

transducer

device to convert a mechanical quantity into an electrical signal

- 1 For example, usually, these mechanical quantities are force and acceleration.

- 2 The transducer is frequently referred to as pickup.

transducer sensitivity

ratio between the electrical signal (output) and the mechanical quantity (input) of a mechanicaltoelectrical transducer or pickup

For example, transducer sensitivity is given in (mV)/(m/s2).

transient

finite duration change from one steadystate condition to another

Usually the initial and the final steadystate conditions are zero.

transmissibility

relative vibration levels of the same mechanical quantity at two points in terms of this quantity in the frequency domain

The transmissibility reaches its maximum at the resonance frequency.

Abbreviated terms

For the purpose of this Standard, the abbreviated terms from ECSS-S-ST-00-01 and the following apply:

|

Abbreviation

|

Meaning

|

|

AOC

|

auto orthogonality check

|

|

ARMA

|

autoregressive moving average

|

|

CMIF

|

complex mode indicator function

|

|

COC

|

cross orthogonality check

|

|

CoG

|

centre of gravity

|

|

CoMAC

|

coordinate modal assurance criterion

|

|

DAS

|

data acquisition system

|

|

DOF

|

degree of freedom

|

|

EI

|

effective independence

|

|

FEA

|

finite element analysis

|

|

FEM

|

finite element model

|

|

FRAC

|

frequency response assurance criterion

|

|

FRF

|

frequency response function

|

|

H/W

|

hardware

|

|

IRS

|

improved reduction system

|

|

KE

|

kinetic energy

|

|

MAC

|

modal assurance criterion

|

|

MCF

|

modal confidence factor

|

|

MDOF

|

multiple degree of freedom

|

|

MIF

|

mode indicator function

|

|

MMIF

|

multivariate MIF

|

|

MIMO

|

multiple input - multiple output system

|

|

MST

|

modal survey test

|

|

MPP

|

measurement point plan

|

|

POC

|

pseudo orthogonality check

|

|

PDR

|

point drive residue

|

|

RMS

|

root mean square

|

|

RVAC

|

response vector assurance criterion

|

|

SDOF

|

single degree of freedom

|

|

SEREP

|

system equivalent reduction expansion process

|

|

SISO

|

single input - single output system

|

|

S/W

|

software

|

|

TA

|

test article

|

|

TAM

|

test analysis model

|

|

TBD

|

to be defined

|

|

TF

|

test fixture

|

Notation

The following notation, compatible with Ewins, 2000 (see Annex D) is used within this document:

Matrices, vectors and scalars

|

[ ]

|

matrix

|

|

{ }

|

vector

|

|

[ ]T, { }T

|

transpose of a matrix, vector

|

|

| |

|

modulus of complex number

|

Spatial properties

|

[C]

|

viscous damping matrix

|

|

[D]

|

structural damping matrix

|

|

{f(t)}

|

force vector (time domain)

|

|

{F()}

|

force vector (frequency domain)

|

|

h(t)

|

impulse response function (IRF)

|

|

H()

|

frequency response function (FRF)

|

|

G()

|

estimated frequency response function

|

|

[K]

|

stiffness matrix

|

|

Mjj

|

mass connected with DOF j

|

|

[M]

|

mass matrix

|

|

S()

|

coherence function

|

|

{x(t)}

|

displacement vector (time domain)

|

|

|

velocity vector (time domain)

|

|

|

acceleration vector (time domain)

|

|

{X()}

|

displacement vector (frequency domain)

|

|

|

velocity vector (frequency domain)

|

|

|

acceleration vector (frequency domain)

|

|

xj

|

complex valued response of DOF j

|

|

xj

|

real part of xj

|

|

xj

|

imaginary part of xj

|

|

t

|

time increment

|

Modal properties

|

r

|

natural or eigenfrequency of rth mode (rad/s)

|

|

r

|

eigenvalue of rth mode

|

|

{}r

|

rth mode shape or eigenvector

|

|

{}r

|

rth normalized mode shape or eigenvector (normalised either to mass or maximum displacement)

|

|

{}

|

rigid body mode

|

|

r

|

modal viscous damping (damping ratio) of rth mode

|

|

mr

|

(generalized) modal mass of rth mode

|

|

|

effective modal mass of rth mode (j = 1,6)

|

|

|

modal participation factor of rth mode (j = 1,6)

|

|

[m]

|

(generalized) modal mass matrix

|

|

[c]

|

(generalized) modal viscous damping matrix

|

|

[d]

|

(generalized) modal structural damping matrix

|

|

[k]

|

(generalized) modal stiffness matrix

|

General objectives and requirements

Modal survey test objectives

Overview

As specified in ECSS-E-ST-32, modal survey tests are performed to identify dynamic characteristics such as the natural frequency, mode shapes, effective and generalized mass and modal damping.

The objective is to identify the majority of the test parameters to be acquired, and the accuracy of the test results.

General

Prior to the execution of the test, the frequencies of interest and the mode shapes of interest shall be identified.

- 1 The “frequencies of interest” and the “mode shapes of interest” are those identified as being relevant for achieving the modal survey test objectives.

- 2 Instead of specific frequencies of interest, a frequency range of interest can be identified.

- 3 In cases where the test article mathematical model is employed for accurate response predictions, the frequency range of interest is usually defined as being the frequency range in which major dynamic excitations from the launch vehicle are expected.

Verification of design frequency

The modal survey test shall demonstrate that the manufactured hardware conforms to the design frequency requirements listed in the test specification.

- 1 For the test specification, see ECSS-E-ST-10-03.

- 2 Frequency requirements are specified for a structure to avoid coupling with dynamic excitations during launch or operation which can result to structural damages or loss of the mission.

Mathematical model validation

The modal survey test shall demonstrate that the structural mathematical model correlates with the hardware characteristics.

Adequate correlation (see 5.8.2.1) enables the use of the structural mathematical model for load predictions.

The modal survey test shall provide to the structural analyst the information to localize medullisation errors and to update the stiffness and mass characteristics of the structural mathematical model in such a way that the correlation between the analytical predictions and the test results (specified in 5.8.2.1) is achieved.

The modal survey test shall provide the damping characteristics of the test item.

Measures shall be taken to ensure that the nonlinear behaviour is characterized with the objective of optimizing the structural mathematical model with respect to the expected operational load levels.

- 1 Structural mathematical models are usually established in the early design phase to support the product development.

- 2 Even in the case of best practice modelling, the predictions for the structural mathematical model (natural frequencies, mode shapes) can deviate from the hardware dynamic characteristics in the overall frequency range of interest (see 4.1.2) and are therefore not suitable for accurate flight load predictions.

Troubleshooting vibration problems

The level of modal testing and the number of measurement points shall be adjusted to clearly isolate the problem and to visualize the modal behaviour of the structure.

Modal survey tests can be performed to troubleshoot vibration problems which are detected for a structure in service or while undergoing vibration testing.

Verification of design modifications

After modifications have been made to the test item and modal testing is repeated in order to demonstrate the improvements in performance, it shall be verified that all other conditions applying to the predecessor are unchanged.

- 1 This is particularly relevant for the boundary conditions.

- 2 Poor repeatability can cause difficulties in interpreting the changes that are revealed. Otherwise, the improvements due to the structural modifications cannot be clearly identified.

Failure detection

Requirements for a modal survey test relevant to the objectives of error and failure detection shall be established.

The requirements specified in 4.1.7a shall be in accordance with

- the type of failure to be detected,

- the sensitivity of the modal data with respect to the failure, and

- the mathematical method applied for the failure detection analysis.

Modal testing techniques can be used to detect changes in structural behaviour that are caused by some forms of failure. These changes can be induced by any form of environmental test or by inservice loading.

Structural parts that are difficult to access, or critical structural members that are difficult to inspect, shall be identified for the purpose of requirement 4.1.7d.

Modal testing methods shall be used to check the structural integrity for the cases identified in requirement 4.1.7c.

Modal survey test general requirements

Test setup

The test article shall be representative with respect to the test objectives described in the test specification

- 1 For example, a test objective can be the verification of the flight hardware.

- 2 For the test specification, see “Test specification” DRD in ECSS-E-ST-10-03.

The test setup (including adapters and measurement devices) shall not influence the test results within the given limits and the frequency range of interest. - 1 For example, the masses of accelerometers mounted on lightweight test articles can have an undesired effect on the test results.

- 2 For the frequency range of interest, see 4.1.2.

If the test equipment influences the test results beyond the limits stated in the test specification in conformance with ECSS-E-ST-10-03, the effects shall be assessed and be represented in the FEM or TAM.

For the test specification, see “Test specification” DRD in ECSS-E-ST-10-03.

Boundary conditions

The boundary conditions shall be in conformance with the test objectives described in the test specification.

- 1 For example, boundary conditions close to the real conditions during flight and operation.

- 2 For the test specification, see “Test specification” DRD in ECSS-E-ST-10-03.

The influence of the boundary conditions shall be derived by analysis or measurements.

For boundary conditions, see 5.3.2.

Environmental conditions

The environmental conditions shall conform to the requirements listed in the test specification and be guaranteed for the whole test phase.

- 1 For example, environmental conditions are usually cleanliness, temperature and relative humidity.

- 2 For the test specification, see “Test specification” DRD in ECSS-E-ST-10-03.

The influence of air and gravity effects shall be assessed.

The influence of air and gravity effects should be obtained by analysis or test. - 1 These influences can be compensated for or represented in the FEM or TAM.

- 2 Air can act as mass, force and damping.

- 3 Prestress due to gravity can significantly influence the modal data.

Test facility certification

The staff at the test facility shall be qualified to execute the test activities and agreed upon with the customer.

For example, test manager and test operators.

The test facility shall have a valid (uptodate) calibration certificate.

- 1 The calibration certificate documents the results of the calibration of the measuring instruments or the measurement system. Usually the calibration is performed by an authorized external institution.

- 2 It is good practice for test facilities to provide calibration certificates that are less than one year old.

The accuracy of the measurement equipment shall be conform to the test objectives and requirements described in the test specification.

For the test specification, see “Test specification” DRD in ECSS-E-ST-10-03.

Functional checkouts (endtoend) of the test setup shall be performed including instrumentation calibration, data acquisition and processing units (software and hardware), amplifier settings according to the test range, input control, and monitoring devices.

The test facility shall have the capability to monitor, control and document the environmental conditions.

The test facility shall provide evidence that it has, at its disposal, a number of spare parts in conformance with 4.2.4g.

For example, accelerometers, exciters.

The number of spare parts shall be sufficient to replace malfunctioning hardware during the modal survey test.

Safety

Overview

In addition to the following safety requirements, the safety aspects covered in ECSS-Q-ST-40, apply.

Requirements

The test facility shall control the input and output loads (forces, accelerations, displacements, and velocities) and load cycles according to the values stated in the test specification.

For the test specification, see “Test specification” DRD in ECSS-E-ST-10-03.

Test operators shall be alerted by automatic facility procedures if there is overloading.

For example, acoustic or optical warnings, automatic shutdown.

The load introduction of the excitation signal shall not damage the test article.

Precautions shall be defined and adhered to in order to avoid any hazard in the test facility and in the test article that can endanger the safety of the personnel conducting the tests.

Outgassing and pollution by test equipment shall be controlled and kept within the limits stated in the test specification.

For the test specification, see “Test specification” DRD in ECSS-E-ST-10-03.

Test success criteria

The test shall result in modal parameters with the accuracy and completeness stated in the test specification.

- 1 The modal parameters can be measured directly, derived from measurements or derived from the mathematical model data combined with measured data.

- 2 For the test specification, see “Test specification” DRD in ECSS-E-ST-10-03.

The accuracy and completeness shall be verified by a combination of the procedures as given in 5.4 and 5.7.1. - 1 Usual specifications are as follows:

- Accuracy of natural frequencies: 0,5 %.

- accuracy of mode shapes: 5 % (to be verified by a modal assurance criterion (MAC) or an orthogonality check).

- Completeness of the identified mode shapes, e.g. sum of the effective masses of the measured modes greater than a percentage of the total test article mass or inertia to be defined on a case by case basis.

- 2 The accuracy of mode shapes and the completeness of identified mode shapes cannot be checked without a valid analytical mass matrix. This implies a quality assessment of the mass matrix of the TAM.

Modal survey test procedures

General

The modal survey test procedures shall include

- test planning, in conformance with 5.2,

- test setup, in conformance with 5.3,

- test performance, in conformance with 5.4,

- modal identification in conformance with 5.5, and parameter estimation, in conformance with 5.6,

- test data validation and visualization, in conformance with 5.7, and

- testanalysis correlation, in conformance with 5.8.

Test planning

Test planning

The test planning shall be broken down into

- pretest activities, in conformance with 5.2.2,

- test activities, in conformance with 5.2.3, and

- posttest activities, in conformance with 5.2.4.

Figure 51 shows the test planning activities.

Figure 51: Test planning activities

Pretest activities

The pretest activities shall include the following:

- Define the test objectives and the test success criteria.

- Define the test input and output in conformance with excitation and instrumentation (measurement point plan).

For the test activities, see 5.2.3a.

- Define the methods for deriving additional output from the test data.

- Select the test method.

- Select the test facility.

- Design the test setup.

- Predictions for the preliminary test.

Usually the prediction model includes the test article and test equipment (e.g. adapters). Important modes are determined by forcing function and load requirements, and the frequency range can be derived. For further details see Clause 6.

- Generate and validate the testanalysis model (TAM).

- Generate the test specification document (or alternatively a test plan and a test procedure) and submit it to the test facility and the customer.

- 1 The test specification document is used by the test facility to establish the stepbystep test procedure, and to define the technical support and logistics activities.

- 2 The test specification document is supplied to the customer for the purpose of assigning task responsibilities and further defining the technical contents of the test.

Test activities

The test activities shall include the following:

- Prepare the test article and the test setup.

- Install the instrumentation and the excitation system.

- Test system checkout.

- Test operations, including data acquisition and processing.

- Estimate or measure modal parameters depending on the test method.

The test activities can include real time correlation of test results with analytical predictions provided that skilled personnel and tools are available at the test facility.

- Preliminary test data quality control.

This can consist of real time plausibility checks. Plausibility checks can include the following:

- Early correlations of test and analysis results.

- Verification of correct accelerometer directions using dominating and simple to identify mode shapes (e.g. main lateral bending mode).

- Verification of signal magnitude by comparison with neighbouring measurements.

Posttest activities

The posttest activities shall include the following:

- Validate test data.

- Interpret the test results.

- Evaluate the accuracy of the test data.

- Correlate the test data with the analytical model.

- Update the dynamic model of the test article if the correlation requirements as specified in 5.8.2 are not satisfied.

Test setup

Definition of the test setup

The definition of the test setup shall include the following:

- The boundary conditions.

- The fixture certification.

- The excitation system.

- The measurement system.

- The data handling system.

Test boundary conditions

General

The boundary conditions for the test setup (in a laboratory environment) shall represent the boundary conditions for the launch, or any other configuration for which the modal characteristics are being determined.

Table 51 summarizes the most common modal survey test objectives and the associated requirements for the test boundary conditions.

When selecting the test boundary conditions, it should be taken into account that testing with “freefree” conditions results, in general, in the loading of other test article areas, stiffness and masses than when testing with “fixedfree” boundary conditions.

Table 51: Test objectives and associated requirements for the test boundary conditions

|

Test objective

|

Test boundary conditions to be satisfied

|

|

Verification of the structural mathematical model (usually FEM) on the basis of good correlation with test results.

|

To match the boundary conditions of the structural mathematical model.

|

|

Measurement of test structure dynamics under normal operating conditions.

|

To match as closely as possible the operating boundary conditions.

|

|

Measurement of test structure dynamics under specific boundary conditions.

|

To match the theoretically defined boundary conditions.

|

Free condition

The suspension system shall be defined such that it is flexible compared to the rigidity of the test article.

The suspension system shall be defined such that it has no significant influence on the frequencies and mode shapes of the test article to be measured.

The suspension system shall be defined such that the frequencies of the rigid body are much lower than the elastic frequencies of interest of the test article.

- 1 The following can be used for defining the suspension system:

- Attach the suspension system at the nodal points of the elastic mode shapes of interest (see 4.1.2).

- Define the suspension system such that the highest rigid body mode frequencies are less than 10 % to 20 % of the frequency of the lowest elastic mode.

- Measure the rigid body modes.

- Consider the influence of the suspension on the damping characteristics of the test article.

- 2 For the frequencies of interest, see 4.1.2.

- 3 A specific advantage of the “free” condition is that the rigid body modes and thus the mass and inertia properties of the test structure can be measured.

- 4 Due to gravity loads the “free” condition testing uses a suspension system. The “free” conditions can be approximated using the following suspension systems:

- elastic bands;

- very soft springs (e.g. rubber springs, or air springs);

- suspension wires.

Fixed condition

The test fixture for “fixed” boundary conditions shall be quasirigid compared to the test article stiffness.

The test fixture for “fixed” boundary conditions shall provide the inertia properties (“seismic block”) as described in the test specification

,For the test specification, see “Test specification” DRD in ECSS-E-ST-10-03.

The test fixture for “fixed” boundary conditions shall have lowest elastic frequencies (of the rigid test article mass on top of the test fixture) that are significantly higher than the elastic frequencies of interest of the test article, as agreed between the test facility and the customer.

For the frequencies of interest, see 4.1.2.

The influence of the test fixture on the fundamental modes shall be checked prior to the test, by analysis, and during the test execution.

The influence of the test fixture (TF) on the fundamental modes of the test article (TA) can be checked, for example, by FEA, or during the test, by using Dunkerley’s equation:

Test instrumentation

A measurement point plan (MPP) shall be defined for the modal survey test.

- 1 The structural dynamic responses can be measured by means of accelerometers. Different types of accelerometers can be applied.

- 2 For specific applications, other sensors can also be applied, for example: strain gauges, optical sensors, and displacement meters.

- 3 Depending the test requirements, the measurement direction can be either uniaxial, biaxial, or triaxial.

The number of sensor locations and measurement directions shall enable the mode shapes to be defined in the frequency range of interest.

Automated techniques, for example based on the linear independence criterion, provide the best means for selecting the optimum sensor locations. For the frequencies of interest, see 4.1.2.

For clamped structures, the number of sensors to be provided for the test fixture (as a minimum, at the interface) shall be such that the test boundary conditions specified in 5.3.2 can be verified.

Lightweight sensors and cables shall be used.

Transducers and the electric cables can have a significant influence on lightweight structures. Therefore minimization of the mass loading effect of the test instrumentation (transducers and the electric cables) on the test article is important.

The performance of the response sensors shall cover the frequency ranges and the expected response amplitudes of the modal survey test.

This is especially important for lowfrequency rigid body modes and elastic modes in the case of freefree boundary conditions.

The locations of all transducers shall be clearly identified.

Excitation plan

The test structure shall be dynamically excited by means of either:

a shaker table in the case of base driven excitation, or

electrodynamic shakers or an impact hammer in the case of single or multipoint excitation.

The applied excitation forces shall be measured to enable a complete modal analysis, including the determination of the generalized masses.

Forces are measured by force transducers or by means of the exciter voltage. Modal exciters are characterized by a free vibrating coil with low friction.

The mass loading effect of the test equipment, including the covibrating exciter coil, should have no significant influence on the test measurements.

If 5.3.4c is not met, the mass loading effect shall be taken into account in the test analysis correlation.

The test structure locations, selected as excitation points, shall provide a stiffness capable of carrying the applied excitation loads.

Driving point residues, calculated with the FEM of the test article, can be utilized to support the selection of appropriate excitation locations.

The suitability of the exciter locations to excite the number of modes described in the test specification shall be evaluated by using the single (MIF) and multivariate mode indicator function (MMIF).

For the test specification, see “Test specification” DRD in ECSS-E-ST-10-03.

Test hardware and software

The test equipment shall include a data acquisition system capable of recording and processing the measurement data.

This affects the technical features of the data acquisition system in terms of the number of channels, frequency range, speed and performance.

The measurement accuracy shall be traceable.

The applied modal analysis systems and software shall ensure that the modal parameters can be derived from the measured frequency response functions,

The applied modal analysis systems and software shall include graphical and numerical data presentation and output devices.

The analysis software shall provide for posttest data treatment to validate the test results and to correlate the test data with analytical predictions.

Test performance

Test

The modal survey test requirements in the test specification shall define the test performance with respect to the following:

- The frequency range of interest.

For the frequency range of interest, see 4.1.2.

- The target modes (global modes, local modes).

- The measurement point plan (MPP).

- The applicable exciter positions and allowable force levels.

- The dynamic response levels (including overload).

- The test success criteria.

For the test specification, see “Test specification” DRD in ECSS-E-ST-10-03.

Excitation system

The excitation system shall be either:

a base driven excitation, or

a single or multiple excitation.

- 1 Base driven excitation can be utilized for shaker modal identification on hydraulic or electrodynamic shakers. However, there is a limited excitability for, for example, modes with vanishing effective masses, or torsion modes in the most common case of translatory base movements.

- 2 Single or multiple excitation systems are usually applied at internal structure locations. These excitation systems can be either contacting or noncontacting.

In the case of contacting excitation, the exciter remains attached to the test article throughout the test providing continuous or transient excitation. The exciter itself can be suspended on some kind of hoist, or rigidly mounted on the floor or on stands.

Noncontacting excitation can be applied by, for example, using a noncontacting electromagnet or such that the exciter is in contact with the test article only for a short period during which the excitation is applied (such as a hammer impact).

The following potential problems for excitation systems attached to the test article shall be prevented:

- Excitation of low frequency suspension modes when using a suspended excitation system.

- Occurrence of ground transmission between the shakers when using a grounded excitation system. The excitation and maximum outputresponse levels shall be defined in the test specification document.

For the test specification, see “Test specification” DRD in ECSS-E-ST-10-03.

The stiffness of the connection of the excitation systems to the test structure shall be such that parasitical forces or vibrations are avoided.

- 1 Usually, pushpull rods with high axial and low lateral stiffness are applied for this purpose.

- 2 The excitation systems can be fixed to the structural surface by gluing or screwing using small adapter plates.

The excitation systems shall generate acoustic or optical warning signals in the case of a maximum acceleration overload.

The maximum acceleration overload specified in 5.4.2e shall be defined prior to starting the tests.

The dynamic characteristics of the excitation systems shall be evaluated without the test structure.

Excitation signal

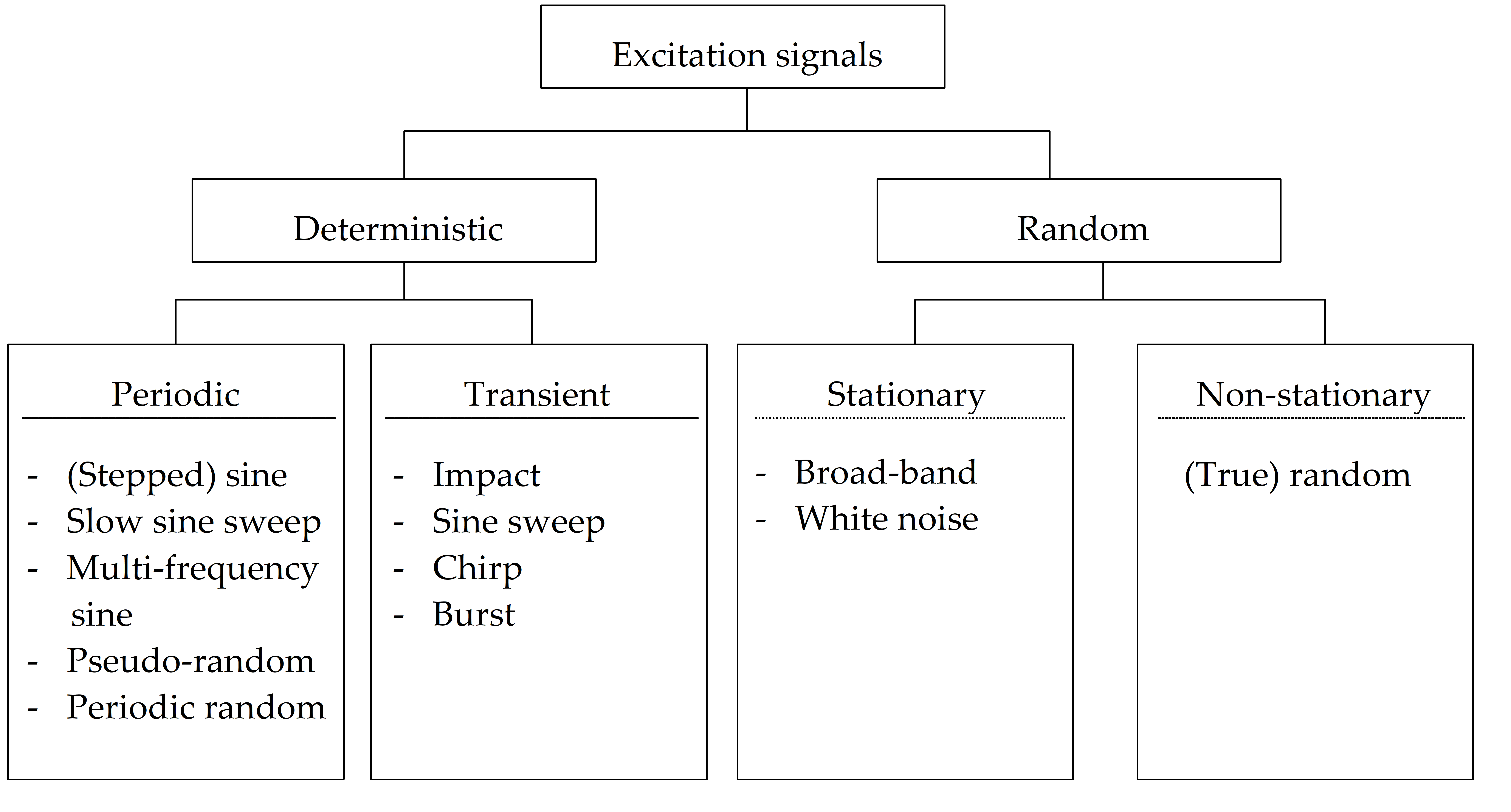

The type of the excitation signal shall be defined.

The most commonly applied excitation signals are given in Annex A.

The excitation signal shall be selected such that the modes in the frequency range of interest are excited with sufficient energy input in conformance with the requirements listed in the test specification.

- 1 Strength and fatigue aspects can become relevant in cases where the excitation load levels have approximately the same order of magnitude as the flight limit loads or the design loads. For the frequency range of interest, see 4.1.2.

- 2 For the test specification, see “Test specification” DRD in ECSS-E-ST-10-03.

Linearity and structural integrity

Measurements shall be performed to check the structurally linear behaviour of the test article.

For example, measuring the frequency response functions or tuning the mode shapes at different excitation levels.

Stiffness and damping nonlinearities shall be determined by measuring the variation of natural frequencies and damping factors versus different input levels.

Nonlinearity curves shall be provided for each normal mode investigated, for both the frequency and damping variation.

The distortion of the mode shapes shall be checked.

Distortions of the frequency response functions are an indicator of the nonlinear structural characteristics.

The structural integrity shall be checked by pretest and posttest frequency response measurements.

Modal analysis and finite element theory are based on the assumption of linear structural behaviour. Knowledge of the structurally linear behaviour of the test article is therefore a fundamental issue for the modal analysis of the test data, as well as for the validation and updating of the mathematical model.

Measurement errors

The effects of measurement errors on the frequency response estimators shall be assessed.

In case of random errors, averaging shall be applied.

This usually improves the accuracy of the estimator.

To minimize the effect of bias errors, an equivalent alternative estimator shall be selected.

Mobility measurements can be affected by random and bias errors. Random errors are observed as random scatter in the measurement data and caused by noise. Bias errors are systematic errors appearing with the same magnitude and phase at each observation.

Modal identification methods

A modal identification method to enable the modal parameters to be identified from the test measurements shall be selected.

-

1 The methods available for modal identification purposes can generally be divided into two classes:

-

methods with tuned sinusoids and force appropriation (phase resonance technique);

-

methods without force appropriation (phase separation technique).

-

2 Within the phase resonance method a single vibration mode is excited by the use of multiple shakers with an appropriated force and exciter configuration. The applicable excitation methods are limited to sine excitation at suitable locations.

The specific characteristics of this method are: -

damping forces are compensated;

-

normal modes and natural frequencies are directly measured;

-

structural nonlinearities can be easily investigated.

The utilization of the modal indicator function (MIF) in the tuning process can considerably reduce the duration of the test.

The phase resonance method provides highly accurate and dependable results. However, the phase purity to be used for force appropriation can be aggravated in cases of limited accessibility to the structure.

- 3 Within the phase separation method, several modes excited simultaneously are separated analytically by estimating the modal parameters from the measured frequency response functions.

The phase separation method provides more flexibility with respect to the excitation types (sine, transient or random excitation) and the excitation location.

The phase separation method exhibits significant deficiencies when closely spaced modes and significant nonlinearities are present in the test structure. Therefore successful modal identification cannot be performed using the phase separation method, without sufficient knowledge and experience.

Modal parameter estimation methods

Modal parameters shall be estimated from the measured frequency responses or measured time histories, to determine the modal characteristics (including natural frequencies, mode shapes, modal damping ratios, generalized and effective masses).

-

1 For the purpose of the modal parameter estimation, the parameters of an appropriate modal model are selected such that the measured frequency responses or time histories are sufficiently approximated by the modal model.

In general, the structure undergoing the modal survey testing is assumed to be linear, timeinvariant, viscously damped, and free of gyroscopic effects. -

2 An overview of available modal parameter estimation methods is provided in Annex B; this can be used as a guideline for making an appropriate choice.

Test data

Quality checks

Introduction

Preliminary test data quality control is performed as part of the realtime test activities (see 5.2.3a.6). The methods presented in 5.7.1.2 to 5.7.1.6 are proposed to support the detailed and comprehensive test data validation as part of the posttest activities.

Analytical methods

The analytical quality checks performed shall encompass the following:

- Mode indicator function (MIF).

- Autoorthogonality.

- Modal assurance criterion (MAC).

Mode indicator function (MIF)

A definition of the MIF applied should be given with the test results to indicate whether a mass weighting is used for the MIF.

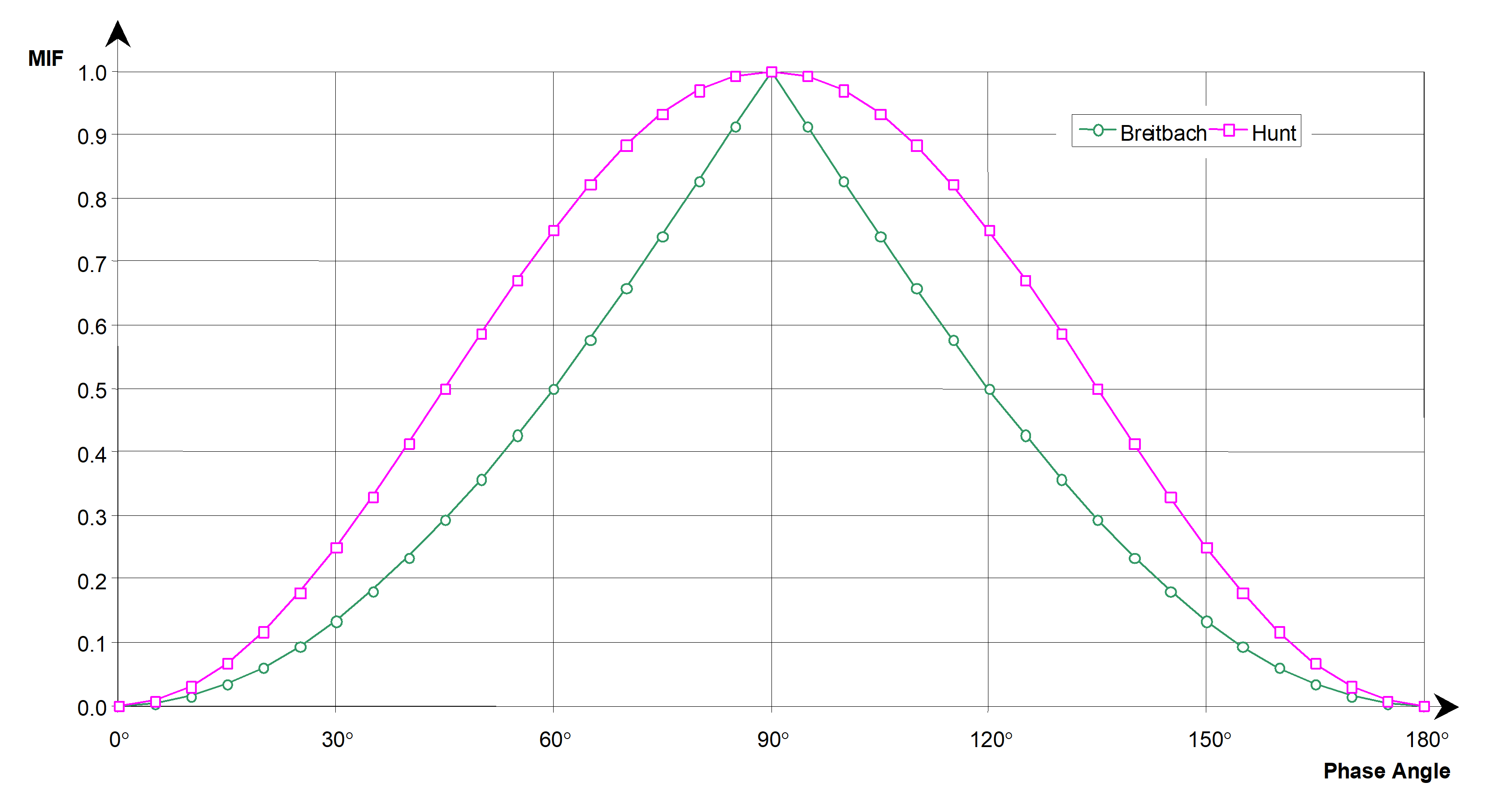

For tuned modes, the MIF values should not be less than 0,9 (Breitbach) and 0,98 (Hunt).

- 1 The MIF can be used to assess the phase purity of the measured mode shapes by a MIF.

- 2 The Breitbach and Hunt MIFs are defined in clause 3.2.33 and the difference between them is illustrated in Figure 52.

Figure 52: Comparison of mode indicator functions (MIF) according to Breitbach and Hunt

Figure 52: Comparison of mode indicator functions (MIF) according to Breitbach and Hunt

Autoorthogonality

To perform the autoorthogonality check, the measured mode shapes shall be transformed to the number of the analytical degrees of freedom.

This transformation can be facilitated if the measurement locations coincide as closely as possible with the finite element nodal points. The remaining nodal points can be conveniently determined by numerical interpolation. Consequently, a good measurement point plan takes into account the necessity of a reliable interpolation.

The offdiagonal elements shall be less than 10 %.

- 1 High offdiagonal values can indicate an inadequate isolation of the respective modes, especially if they are closely spaced in the frequency band, or if they are not very well tuned.

- 2 The degree of orthogonality of two measured modes with respect to the analytical mass matrix can be used as a criterion for the validity of the test results, for example to check the accuracy of the measurements and to detect duplicate modes.

- 3 The orthogonality can be highly dependent on the validity of the mass matrix (accuracy of TAM).

Modal assurance criterion

The modal assurance criterion compares the mode shape pattern directly without taking into account the mass distribution.

Two orthogonal modes do not always result in a zero MAC value.

Visual methods

The test setup shall include hardware and software to enable the mode shapes to be visualized and animated.

A wireframe model of the test article is frequently used for this purpose. The wireframe model can be constructed by connecting the measurement points by line elements such that the contour of the test article is closely represented.

Generalized parameters

For each normal mode identified, the following parameters shall be determined:

- generalized mass;

- modal damping.

- 1 Since the generalized mass and the modal damping are related to each other via the latter, this cannot be done without measuring the exciter forces.

- 2 For the phase resonance method, modal damping can be determined from narrowband frequency response measurements near the resonance. Proven evaluation methods are, for example,

- Nyquist circle curve fit,

- evaluation of real part slopes,

- complex power method, and

- forces in quadrate method.

- 3 The generalized parameters can be identified from the measured frequency response functions using suitable phase separation methods.

- 4 With the knowledge of the generalized parameters (natural frequencies, mode shapes, generalized masses and modal damping factors), the dynamic behaviour of the test article can be described using generalized coordinates.

Effective masses

For each normal mode identified, the effective masses related to the support point DOFs shall be determined.

-

1 Effective masses can be determined by adequate measurement of interface forces or by using the analytical mass matrix (see 3.2.13). However, measurement of the interface forces gives better results due to potential errors present in the analytical mass matrix.

-

2 The summation of all effective masses in each translatory and rotational direction yields the total structural mass and inertia, respectively. Therefore, the sum of the effective masses provides an indication of the completeness of the measured modes.

-

3 For structures with freefree boundary conditions, the following apply:

-

the effective masses of the rigid body modes are equal to the total mass and inertia;

-

the effective masses of the elastic modes are equal to zero.

This criterion can be used to verify the quality of the elastic suspension. -

4 The effective masses of clamped structures with fixedfree boundary conditions are related to the interface forces and moments.

Data storage and delivery

General aspects

The data exchange shall conform to the requirements specified in the test specification

For the test specification, see “Test specification” DRD in ECSS-E-ST-10-03.

Electronic data exchange should be used, employing established exchange formats.

- 1 For product exchange data, see ECSS-E-TM1020.

- 2 Usual data exchange formats are:

- For natural frequencies, mode shapes and modal damping: Universal File Format 55.

- For frequency response functions: Universal File Format 58.

All data, regardless of the format, shall be accompanied by documentation containing a detailed description of the data, including the following: - the format;

- date and status of data;

- the format of media (e.g. tape, backup and operating system);

- the version of exchange format standard.

Test data storage

The modal survey test data shall be stored by the test facility for a period agreed with the customer.

The minimum storage time for test data in the European coordinated test facilities is 10 years.

Testanalysis correlation

Purpose

General

The experimental test modal data shall be compared with the analytical modal data, for the following purposes:

- To validate the mathematical model.

- To validate the test data.

- To select reliable test data for the mathematical model update.

- For taking corrective measures in a running test campaign.

- To detect erroneous areas in the mathematical model (error localization).

The correlation methods are given in Table 52.

Techniques identified as mandatory in Table 52 shall be applied.

Table 52: Most commonly used correlation techniques

|

Type

|

Techniques

|

|

Vector based techniques

|

- Modal assurance criterion (MAC) a - Orthogonality or cross-orthogonality a |

|

DOF based techniques

|

- Coordinate modal assurance criterion (CoMAC) - Modulus difference a - Coordinate orthogonality check |

|

Frequency based techniques

|

- Frequency difference a - Frequency response assurance criterion (FRAC) - Response vector assurance criterion (RVAC) |

|

a Mandatory (see 5.8.1.1b)

| |

Mathematical model

The mathematical model shall describe the dynamic behaviour of the hardware in the frequency range of interest;

The mathematical model shall be applicable for coupling with other models for coupled static (with respect to I/F loads) and dynamic analysis;

The mathematical model shall describe the dynamic response in the frequency range of interest.

For the frequency range of interest, see 4.1.2.

Application of baseline correlation methods

As a minimum, the following steps shall be performed during the test analysis correlation:

- Selection of analysis DOFs: reduce the number of analysis mode shapes such that they are compatible with the experimental DOFs (number of accelerometers).

In general, the test modes have significantly fewer DOFs than the analysis mode shapes.

- Mode pairing: differentiate the mode pairs between analysis and test in order of the highest MAC or crossorthogonality values, and calculate the eigenfrequency differences for these pairs.

For mode pairs not in the same order as the eigenfrequency sequence, the MAC can incorrectly indicate corresponding pairs.

- Crossorthogonality: perform a general quality check of the FEM by means of the crossorthogonality check. To perform the crossorthogonality check specified in 5.8.1.3a.3, either the mass matrix shall be reduced to the number of the experimental DOFs, or the experimental mode shapes shall be expanded to the number of the DOFs of the FEM.

Criteria for mathematical model quality

Criteria for dynamic response predictions

The quality criteria for the testanalysis correlation shall ensure that the dynamic response predictions employing the test validated mathematical model conform to the accuracy requirements established by the customer.

Examples of testanalysis correlation quality criteria are given in Table 53.

Criteria for reduced mathematical models

Reduced mathematical models to be employed in dynamic response predictions shall represent the detailed FEM in conformance to the model quality criteria.

The usual reduced mathematical model quality criteria are given in Table 54 .

Conformance shall be demonstrated by comparing the dynamic behaviour of the reduced mathematical model with the dynamic analysis results obtained from the detailed FEM.

Table 53: Test-analysis correlation quality criteria

|

Item

|

Quality criterion a

| |

|

Fundamental bending modes of a spacecraft

|

MAC:Eigenfrequency deviation:

|

> 0,9< 3 %

|

|

Modes with effective masses > 10 % of the total mass

|

MAC:Eigenfrequency deviation:

|

> 0,85< 5 %

|

|

For other modes in the relevant frequency range b

|

MAC:Eigenfrequency deviation:

|

> 0,8< 10 %

|

|

Crossorthogonality check

|

Diagonal terms:Offdiagonal terms:

|

> 0,90< 0,10

|

|

Damping

|

To take measured values as input for the response analysis.To use realistic test inputs for this purpose.

|

|

|

Interface force and moment measurements

|

For modes with effective masses > 10 %: deviations of interface forces and moments < 10 %.

|

|

|

a The quality criteria given are not normative and are given as examples for achieving a satisfactory test–analysis correlation.

| ||

Table 54: Reduced mathematical model quality criteria

|

Item

|

Quality criterion

| |

|

Frequencies and modal masses of fundamental lateral, longitudinal and torsional modes

|

Effective mass: Eigenfrequency deviation:

|

< 5 %< 3 %

|

|

For other modes up to 100 Hz

|

Effective mass:Eigenfrequency deviation:

|

< 10 %< 5 %

|

|

Modes of reduced FEM (within frequency range of interest, see 4.1.2)

|

Total effective mass > 90 % of the rigid body mass.

|

|

Pretest analysis

Purpose

Pretest analyses shall be performed to support the modal survey test with respect to test planning and test execution.

- 1 The modal survey test is strongly supported by dynamic finite element analysis (FEA), for example modal analysis, response analyses and reduction of mathematical models, in order to optimize the output from the modal survey test.

- 2 The pretest analysis requirements defined provide a general approach to FEA and improve the quality of modal survey test results. In particular, requirements for the following areas are given:

- Modal survey test FEM: complete FEM; test fixture participation.

- Test Analysis Model (TAM): measurement point plan; test predictions; test fixture participation.

- 3 The pretest analysis activities are shown in Figure 61.

Modal survey test FEM

Purpose

The modal survey test FEM shall represent the dynamic behaviour of the test article.

-

1 The FEM is applied to predict the modal survey test results (natural frequencies, vibration modes), to support the optimization of the exciter locations and the measurement point plan, and to assess the influence of adjacent structures (e.g. test fixtures).

This FEM is often called the reference FEM and is a full (detailed) FEM. -

2 For a detailed description of the reference FEM and the representation of the test article to be provided in the test prediction document, see clause 6.4.2.

Figure 61: Modal survey pretest analysis activities

Reduction of the detailed FEM

The reduced FEM shall represent the reference FEM in conformance with the criteria given in clause 5.8.2.2.

- 1 Usually the number of measurement points is (much) less than the total number of DOFs in the reference FEM. Therefore the size of the reference FEM is consistently reduced to match the number of measurement DOFs. The latter is equal to the number of measurement locations and the corresponding measurement directions (accelerometers).

- 2 The number, location and directions of the installed accelerometers define the size of the reduced FEM (number of retained or so-called dynamic DOFs). The remaining DOFs are mathematically eliminated from the total set of DOFs in the reference FEM.

- 3 In practice, the measurement point plan (number, locations, and directions of excitation and instrumentation) is usually defined with the aid of the reference or baseline FEM, where the predicted kinetic energy (KE) fraction is often used as an “accelerometer” location selector. DOFs with a relatively large KE are expected to dominantly influence the cross orthogonality matrix. Alternatively, the maximum linear independence criterion can be applied.

- 4 The reduced model is frequently called the test analysis model (TAM).

The reduced FEM shall consist of a mass and stiffness matrix reduced to the number of measurement DOFs.

In general, the reduced mass and stiffness matrix are generated by applying a model reduction technique to the reference FEM. However, the TAM can also be a simplified FEM that adequately represents the reference model for test correlation and evaluation purposes.

The reduction of the reference FEM should be performed by employing one of the following techniques:

static reduction (Guyan);

dynamic reduction;

improved reduced system (IRS);

system equivalent reduction expansion process (SEREP).

- 1 The advantages and disadvantages of the most common model reduction techniques are summarized in Table 61.

- 2 The applicability of modal reduction techniques is limited because the physical DOFs are not preserved in the TAM. Model reduction based upon such techniques results in reduced mathematical models to be used for component mode synthesis (CMS) methods.

Table 61: Advantages and disadvantages of model reduction techniques

|

Model reduction technique

|

Advantages

|

Disadvantages

|

|

Guyan (static) reduction

|

- Easy to use and computationally efficient. - Works well if Aset is properly defined. - Available in most commercial FEA software. |

- Limited accuracy. - Bad if Aset is badly defined. - Unacceptable for high mass or stiffness ratio. - Neglect of mass effects at omitted DOFs. |

|

IRS

|

- Better performance than Guyan (static) reduction. - Takes into account the mass inertia effects associated with deleted DOFs. |

- No standard implementation into FEA software (e.g. Nastran). - Errors if Aset is badly defined. |

|

Dynamic reduction

|

- Better performance than Guyan (static) reduction. - Nearly exact structural response at any frequency. |

- No standard implementation into FEM software (e.g. Nastran). - No obvious choice of eigenfrequency estimates. - Limited experience. |

|

SEREP

|

- Exact reproduction of the lower natural frequencies of the full model. - Possible to select specific modes to be included in reduction process. |

- No standard implementation into FEM software (e.g. Nastran). - Limited experience. |

Test analysis model (TAM)

Purpose

The TAM shall be used to scale measured vibration modes and to calculate the mass weighted cross orthogonality matrix between measured and analytical vibration modes.

For a detailed description of the TAM to be provided in the test prediction document, see clause 6.4.2.

The DOFs retained in the TAM shall:

- correspond one to one with accelerometers in the modal survey test configuration (location and measurement direction);

- coincide geometrically with the accelerometer locations for the modal survey test in the MPP in order to facilitate the correlation task.

- 1 For the MPP, see clause 6.3.3.

- 2 The TAM provides the basis for the testanalysis comparison.

- 3 The TAM has several major functions:

- The selection of the TAM DOFs supports the optimization of the test measurement and excitation locations.

- The reduced mass matrix provides a mean for performing onsite orthogonality checks of the test modes.

- The accuracy of the FEM during posttest correlation activities can be assessed and quantified in the form of orthogonality and crossorthogonality checks.

- 4 The TAM is not considered to be suitable for the derivation of frequencies and mode shapes. As specified in 6.2.1, the FEM is used for this purpose.

TAM accuracy

The difference between the natural frequencies of the TAM and the “reference” model should be minimized in conformance with the quality criteria specified in Table 54.

The diagonal and offdiagonal terms of the cross orthogonality check between the TAM and “reference” model shall conform to the criteria given in Table 53.

The cross orthogonality check employs the mass matrix of the reduced model.

Measurement point plan (MPP)

The number of accelerometer locations (experimental DOFs) shall be chosen such that the modal characteristics of the test article (including natural frequencies, mode shapes, modal damping ratios, generalized and effective masses) in the frequency range of interest can be determined in conformance with the requirements listed in the test specification.

For the frequency range of interest, see 4.1.2. For the test specification, see “Test specification” DRD in ECSS-E-ST-10-03.

The accelerometer locations should be selected to ensure linear independence of the mode shapes of interest while retaining information about selected modal responses in the measurement data.

- 1 For the mode shapes of interest, see 4.1.2.

- 2 The following criteria can be applied in selecting the accelerometer locations:

- Retain DOFs with a large kinetic energy.

- Retain DOFs with a high massstiffness ratio.

- Retain DOFs that maximize the observability of mode shapes (effective independence).

- Remove only one DOF per iteration when optimizing the accelerometer locations with respect to kinetic energy and massstiffness ratio.

- 3 The suitability of the measurement locations can be assessed by evaluating the sensitivity of the predicted dynamic characteristics of the TAM with respect to the sensor locations. This can be done by using one of the following:

- The single (MIF) and multivariate mode indicator function (MMIF) calculated from the reference FEM (not the TAM) response at the measurement DOFs.

- The AutoMAC calculated from the reference FEM modes at the measurement DOFs.

Test predictions

The test predictions shall be based upon both the reference FEM and the TAM.