Space engineering

CANbus extension protocol

Foreword

This Standard is one of the series of ECSS Standards intended to be applied together for the management, engineering and product assurance in space projects and applications. ECSS is a cooperative effort of the European Space Agency, national space agencies and European industry associations for the purpose of developing and maintaining common standards. Requirements in this Standard are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards.

This Standard has been prepared by the ECSS-E-ST-50-15C Working Group, reviewed by the ECSS Executive Secretariat and approved by the ECSS Technical Authority.

Disclaimer

ECSS does not provide any warranty whatsoever, whether expressed, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item are error-free. In no respect shall ECSS incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this Standard, whether or not based upon warranty, business agreement, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by ECSS.

Published by: ESA Requirements and Standards Division ESTEC, P.O. Box 299, 2200 AG Noordwijk The Copyright: 2015© by the European Space Agency for the members of ECSS## Change log

|

ECSS-E-ST-50-15C

|

First issue

|

Introduction

This standard specifies requirements for the use of the CAN (Controller Area Network) data bus in spacecraft onboard applications. These requirements extend the CAN Network specification to cover the aspects required to satisfy the particular needs of spacecraft data handling systems. This standard is one of a series of ECSS standards relating to data link interfaces and communication protocols e.g. MIL-STD-1553 and ECSS-E-ST-50-5x Space Wire.

In order to provide a uniform set of communication services across these standards the CCSDS Spacecraft Onboard Interface Services (SOIS) Subnetwork Recommendations have been applied as driving requirements for protocol specification.

The CAN Network has been successfully used for three decades in automotive and critical control industry. In particular, its use in applications that have demanding safety and reliability requirements, or operate in hostile environments have similarities to spacecraft onboard applications.

The CAN Network is being adopted for a variety of space applications and care has therefore been taken during the drafting of this standard to include existing experience and feedback from European Space industry.

In addition to the CAN Network data link specifications, this standard also specifies the optional use of the CANopen standard as an application layer protocol operating over CANbus.

The set of CANopen specifications comprises the application layer and communication profile as well as application, device, and interface profiles. CANopen provides very flexible configuration capabilities.

Scope

This standard is applicable to spacecraft projects that opt to use the CAN Network for spacecraft on-board communications and control. It also defines the optional use of the CANopen standard as an application layer protocol operating in conjunction with the CAN Network data link layer.

This standard does not modify the basic CAN Network specification and complies with ISO 11898-1/-2:2003. This standard does define protocol extensions needed to meet spacecraft specific requirements.

This standard covers the vast majority of the on-board data bus requirements for a broad range of different mission types. However, there can be some cases where a mission has particularly constraining requirements that are not fully in line with those specified in this standard. In those cases this standard is still applicable as the basis for the use of CAN Network, especially for physical layer and redundancy management.

This standard may be tailored for the specific characteristic and constrains of a space project in conformance with ECSS-S-ST-00.

Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this ECSS Standard. For dated references, subsequent amendments to, or revision of any of these publications do not apply. However, parties to agreements based on this ECSS Standard are encouraged to investigate the possibility of applying the more recent editions of the normative documents indicated below. For undated references, the latest edition of the publication referred to applies.

|

ECSS-E-ST-00-01

|

ECSS system – Glossary of terms

|

|

ECSS-E-ST-20

|

Space engineering - Electrical and electronic

|

|

ECSS-E-ST-20-07

|

Space engineering - Electromagnetic compatibility

|

|

ECSS-Q-ST-70-08

|

Space product assurance - Manual soldering of high-reliability electrical connections

|

|

ECSS-Q-ST-70-26

|

Space product assurance - Crimping of high-reliability electrical connections

|

|

ESCC 3401/029 Issue 1, October 2002

|

Connectors Electrical Rectangular Microminiature, based on type MDM

|

|

ESCC 3401/01 Issue 2, March 2010

|

Connectors, Electrical, Rectangular, Microminiature, Solder Bucket Contacts, with EMI Backshell, based on Type MDM

|

|

ANSI/TIA/EIA-485-A-1998 (reaffirmed 28 March 2003)

|

Electrical Characteristics of Balanced Voltage Digital Interface Circuits.

|

|

DIN 41652-1 (1990-06)

|

Rack and panel connectors, trapezoidal, round contacts ∅ 1 mm; common mounting features and dimensions; survey of types

|

|

ISO 11898-1:2003

|

Road vehicles – Controller Area Network (CAN) - Part 1: Data link layer and physical signalling

|

|

ISO 11898-2:2003

|

Road vehicles – Controller Area Network (CAN) - Part 2: High-speed medium access unit

|

|

CiA 102 v. 2.0

|

CAN physical layer for industrial applications

|

|

CiA 301 Version 4.2.0

|

CANopen Application Layer and Communication Profile, CAN in Automation

|

|

CiA 306 Version 1.3.0

|

CANopen electronic data sheet specification

|

|

iCC 2012

|

CAN in Automation - Computation of CAN Bit Timing Parameters Simplified - Meenanath Taralkar, OTIS ISRC PVT LTD, , India

|

|

MIL-DTL-38999 (formerly MIL-C D38999 Series 3)

|

Connectors, Electrical, Circular, Miniature, High Density, Quick Disconnect (Bayonet, Threaded, and Breech Coupling), Environment Resistant, Removable Crimp and Solder Contacts, General Specification for. U.S. Department of Defense. 30 May 2008.

|

|

RS-485

|

The current reference of this standard is ANSI/TIA/EIA-485-A-1998 (reaffirmed 28 March 2003)

|

Terms, definitions and abbreviated terms

Terms from other standards

For the purpose of this Standard, the terms and definitions from ECSS-S-ST-00-01 shall apply.

Terms specific to the present standard

asynchronous data transmission

data transmission from an originating source that is not synchronized to any clock pulse or external common event

- 1 The data frame is delimited with (e.g.) start and stop signals. Both communication terminals do not need to have local clocks synchronized.

- 2 Data transmission systems that foresee asynchronous data transfer can allow senders to attempt to transfer data at any time. If two or more senders send data at the same time then there is a conflict and an arbitration scheme is used to determine the order in which the senders can put their data on the bus. Priority is then used to differentiate between information to be delivered urgently, and data whose delivery is less time critical. When there is a conflict between two or more senders the one with highest priority is allowed to send its data first.

CAN-ID

11- or 29-bit identifier used in the arbitration and control field of the CAN frame

[CANopen – CiA Standard 301 V4.2.0]

cold redundant bus

redundancy scheme whereby data is only transmitted on one of the available busses

[CANopen – CiA Standard 301 V4.2.0]

communication bus system latency

time from the source sending a packet to the time when it is received by the intended destination

cross-strapping

two identical units that are interconnected with the remaining system in such a way that either unit can provide the required functionality

In an avionics system, where each unit appears with its identical backup, cross-strapped units provide all possible interconnections between them. For bus-connected systems all bus connected subsystems, components, and instruments are cross-strapped to their respective data buses. The overall system reliability of a space avionics system is significantly enhanced by cross strapping, as if one unit fails a redundant unit can take over without implying a complete switch-over to a redundant chain.

cyclic data transmission

see "isochronous data transmission"3.2.11.

dominant and recessive states of CANbus signals

CAN transmission based on differential signal transmission

In this case, the difference between the CAN (controller area network) high (CAN_H) and CAN low (CAN_L) signals are used. Bus operation is dependent on accurate interpretation of Dominant and Recessive data bits within a CAN frame. Signal levels are reported in Clause 5.3.2 of this standard.

dominant bit level

logical level that when applied to a bus forces the entire bus to the same logical level

[CANopen – CiA Standard 301 V4.2.0]

hard coded (or Hardcoded) data

embedding what can, perhaps only in retrospect, be regarded as input or configuration data directly into the source code/read only memory of a FPGA/device, or fixed formatting of the data, instead of obtaining that data from external sources

[CANopen – CiA Standard 301 V4.2.0]

hot redundant bus

redundancy scheme whereby data is transmitted simultaneously on all of the available busses

[CANopen – CiA Standard 301 V4.2.0]

isochronous data transmission

form of synchronous data transmission where similar (logically or in size) data frames are sent linked to a periodic clock pulse or external common event

- 1 In an Isochronous transmission the sender and the receiver are synchronized in such a way that they send/receive during the same time slots. This implies the existence of an implicit or explicit time schedule table that needs to be consistent over the entire network.

- 2 The term is synonymous to cyclic data transmission (3.2.6) or to Rate Monotonic Scheduling.

local SCET

time counter implemented and maintained in a node, that is correlated with the SCET

[CANopen – CiA Standard 301 V4.2.0]

multimaster-capable, event-oriented message transmission

transmission mode where each node of a communication network can initiate the transmission of a message as soon as the bus is free

- 1 (see 3.2.7 NOTE: 2). As every node can initiate a message transfer (multi-master), a direct message transfer between all nodes of the network is possible.

- 2 It is expected that each node of a Multi-master- network is able to autonomously contend the bus to initiate the transmission of a message. As it can happen that more than one network node begins transmission of a message at the same time, an arbitration process is necessary, which ensures only one node actually continues with the transmission of its message.

- 3 Compared to a cyclic message transfer, a considerably lower bus load or a reduction in the required data transmission rate results.

NMT master

node in a CANopen network, responsible for managing all other nodes on the bus using the NMT services

[CANopen – CiA Standard 301 V4.2.0]

NMT slave

node in a CANopen network that is managed by the NMT master using the NMT services

[CANopen – CiA Standard 301 V4.2.0]

propagation time

critical length of a bus line occurring at the point where the return propagation delay (tprop(total)) of a signal through a line, equals the transition time(tt) of a signal (the greater between rise and fall times)

Network Critical Length = tt = tprop(total)

typical ISO or RS-485 driver has a 50 ns transition time, and when considering a typical twisted-pair transmission line prop delay of 5 ns/m, the return delay for one meter becomes 10ns/m. The critical length becomes 5 m (50 ns / 10ns/m = 5 m), and the max un-terminated stub length for the network is 1/3rd of the critical length, or 5/3 m (1,67 m).

[CANopen – CiA Standard 301 V4.2.0]

recessive bit level

logical level that when applied to a bus only has effect on the level of the bus if there is no driver that simultaneously applies a dominant bit level

[CANopen – CiA Standard 301 V4.2.0]

redundancy master

dedicated node responsible for managing the bus redundancy

In particular, this includes controlling the switching from a nominal to a redundant bus in a cold redundant bus system.

[CANopen – CiA Standard 301 V4.2.0]

redundant bus

bus system that consists of two or more identical physical communication channels to increase the bus reliability or availability

[CANopen – CiA Standard 301 V4.2.0]

redundant node

node that provides identical functionality as another node connected on the same physical bus

[CANopen – CiA Standard 301 V4.2.0]

spacecraft elapsed time (SCET)

central time reference that is maintained on-board the spacecraft

The SCET can be correlated to the ground time, and may be distributed to other on-board nodes.

[CANopen – CiA Standard 301 V4.2.0]

synchronous data transmission

data transmission in which a clock defines transmission times for data

- 1 Data transmission from originating source is triggered (or happens in conjunction with) a clock pulse or external common event.

- 2 Since start and stop bits for each character are not needed, more of the transmission bandwidth is available for message bits.

- 3 See also isochronous data transmission (3.2.11).

Abbreviated terms

For the purpose of this Standard, the abbreviated terms from ECSS-S-ST-00-01 and the following apply:

|

Abbreviation

|

Meaning

|

|

CAN

|

controller area network

|

|

CCSDS

|

Consultative Committee for Space Data Systems

|

|

COB-ID

|

communication object identifier

|

|

ECSS

|

European Cooperation for Space Standardisation

|

|

EDS

|

electronic data sheet

|

|

EMC

|

electromagnetic compatibility

|

|

EMCY

|

Emergency Object

|

|

FIFO

|

first in first out

|

|

LDUT

|

large data unit transfer

|

|

LSB

|

least significant bit

|

|

MSB

|

most significant bit

|

|

NMT

|

network management

|

|

OSI

|

open systems interconnection

|

|

PCB

|

printed circuit board

|

|

PDU

|

protocol data unit

|

|

PDO

|

process data object

|

|

RPDO

|

receive PDO

|

|

RTR

|

remote transmission request

|

|

SAP

|

service access point

|

|

SCET

|

spacecraft elapsed time

|

|

SDO

|

service data object

|

|

SYNC

|

synchronisation object

|

|

TPDO

|

transmit PDO

|

Bit numbering convention

The most significant bit of an n-bit field is:

numbered bit n-1,

the first bit transmitted,

the leftmost bit on a format diagram.

The least significant bit of an n-bit field is:

numbered bit 0 (zero),

the last bit transmitted,

the rightmost bit on a format diagram.

This is illustrated in Figure 31.

This convention is the opposite of most ECSS and CCSDS documents. Its choice is dictated by the bit numbering convention used in the CAN Network specification.

Figure 31: Bit numbering convention

Nomenclature

The following nomenclature applies throughout this document:

The word “shall” is used in this Standard to express requirements. All the requirements are expressed with the word “shall”.

The word “should” is used in this Standard to express recommendations. All the recommendations are expressed with the word “should”.

NOTE: NOTE It is expected that, during tailoring, recommendations in this document are either converted into requirements or tailored out. The words “may” and “need not” are used in this Standard to express positive and negative permissions, respectively. All the positive permissions are expressed with the word “may”. All the negative permissions are expressed with the words “need not”.

The word “can” is used in this Standard to express capabilities or possibilities, and therefore, if not accompanied by one of the previous words, it implies descriptive text.

NOTE: NOTE In ECSS “may” and “can” have completely different meanings: “may” is normative (permission), and “can” is descriptive. The present and past tenses are used in this Standard to express statements of fact, and therefore they imply descriptive text.

Overview of the standard and principles

Document organization

The remainder of this document is organised as follows:

Clause 5 specifies the CAN Network physical layer;

Clause 6 specifies CANopen for use over a CAN Network in spacecraft applications;

Clause 7 specifies the Time distribution protocol to be used over CAN Network;

Clause 8 specifies the CAN Network redundancy management;

Clause 9 species a minimal protocol set for highly asymmetric implementations;

Clause 10 specifies connectors and pin assignments.

In addition to these normative clauses, annexes are provided describing:

Annex A: CANopen Standard Applicability Matrix

The remainder of clause 4 provides informative information on each of the normative clauses.

Relationship of CAN Bus Network to existing Architectures

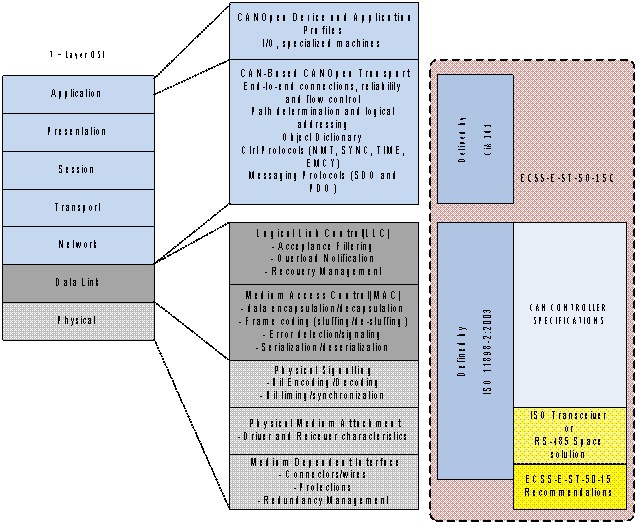

Figure 41 illustrates the relationship of the CAN Network to the ISO OSI model (as defined in [2]) and existing ECSS recommendations. The CAN Network specification covers the Physical and datalink layers of the ISO OSI model. The related ECSS-E-ST-50-15 standard covers only the physical layer.

Figure 41: Relationship between ISO layering, ISO 11898, CiA 301 and ECSS CAN standard definitions

Figure 41: Relationship between ISO layering, ISO 11898, CiA 301 and ECSS CAN standard definitions

CANbus network

The Controller Area Network (CAN) is a serial communications protocol which efficiently supports distributed real-time control with a very high level of security.

For a detailed and authoritative introduction to the CAN features and characteristics refer to:

Texas Instrument’s - Application Report SLOA101A – August 2002 – Revised July 2008 - Introduction to the Controller Area Network (CAN) by Steve Corrigan [4]

Extensive literature on use of CAN for high reliability command and control exists. Some of the most interesting articles are reported in the bibliography of this standard (see [9],[17],[18],[19],[20],[33],[34],[35],[36]).

Physical layer

Clause 5 lists the requirements related to the physical layer.

Communication model

The communication model is based on a CAN Network master connected to up to 126 slave nodes (the number of possible nodes depends on the physical layer capabilities).

The network is organized in a strict master/slave relationship (see Figure 42).

Figure 42: Example of minimal implementation topology

The CAN physical layer comprises the electrical, mechanical and performance characteristics of the cabling, connectors, termination resistors, CAN transceivers, and optional optical couplers.

The approach of this document is to make reference to ISO 11898-1:2003 and ISO 11898-2:2003 wherever possible; detailing only the specific restrictions where appropriate to satisfy the requirements for spacecraft applications.

For convenience, the Data Link layer description is included in this document within the physical layer clause. The Data Link conforms to ISO 11898-1:2003, which is based on the Bosch CAN 2.0B (1991) specification, [3].

CANopen higher layer protocol

The ISO 11898 standard specifies the CAN Network physical and data link layers. ISO 11898 provides fast, prioritized, reliable, broadcast message transmission with sophisticated error detection and error handling and can fulfil all requirements of small closed networks. However, it is not adapted to large, extendable, interconnected networks from different manufacturers

For this purpose this standard recommends the use of CANopen as a higher layer communication protocol operating over the CAN Network.

CANopen is a standard widely used in automation and industrial applications, including safety critical and maritime applications implementing redundant communication busses.

One of the strengths of CANopen is the simplicity of the redundancy management implementation. In addition, CANopen allows simple standardization of Electronic Data Sheets (EDS) making interoperability far more straightforward.

The description of a device's communication functionality and objects and its device-specific objects is provided in the form of an EDS), an ASCII or XML file with a strictly defined syntax. A description of the object configuration of an individual device with its default parameter values, as well as maximum and minimum ranges is called a Device Configuration File (DCF) and has the same structure as an EDS (see [28], [29], [30] for reference). Both file types are defined in the CANopen specification.

The CAN ISO 11898 standard defines only the layers 1 and 2; in practice these are completely handled by the CAN hardware, significantly reducing the implementation effort for node developers. However, a high level protocol is necessary in order to define how the CAN message frame's 11-bit identifier and 8 data bytes are used. Building CAN-based space systems guaranteeing interoperability and interchangeability of devices of different manufacturers requires a standardized application layer and 'profiles', standardizing the communication system, the device functionality and the system administration:

The application layer provides a set of services and protocols useful to every device on the network imaginable.

The communication profile provides the means to configure devices and communication data and defines how data is communicated between devices.

Device profiles (not foreseen in the present standard) may add device-specific behaviour for (classes of) devices (e.g. digital I/O, analogue I/O, motion controllers, encoders).

The CANopen communication model defines four types of messages (communication objects):

|

1

|

Administrative messages (Layer management, network management and identifier distribution services):

|

|

2

|

Service Data Object (SDO):

|

|

3

|

Process Data Object (PDO):

|

|

4

|

Predefined messages or Special Function Objects:

|

Clause 6 specifies requirements applicable to application layer protocol.

Reference is made to the CiA Standard 301 Version 4.2.0 (CANopen). Note that this standard also specifies additional details or constraints in addition to those specified by CANopen.

Time distribution

Overview

This standard defines a time distribution protocol based on the use of CANopen PDOs. The protocol may be used over a CAN Network and in conjunction with CANopen. The time distribution service defined as part of the CANopen is considered inadequate for spacecraft requirements.

The time distribution and synchronization protocols specified in this standard distribute a sample of the central time to devices maintaining a local time.

The time distribution protocol provides a mechanism to transfer and read back the time with no specific requirements on accuracy. The optional high-resolution time distribution protocol allows for the best possible time synchronization via the CAN Network. It is possible to use both protocols on the same CAN Network.

This standard makes no assumptions on the relationship or maximum time error between the central time and the local time. In particular, the frequency of local time updating and any associated mechanisms for adjusting the local time without loss or duplication of time codes are device and application specific and outside the scope of this standard.

The time distribution protocol is based on a single PDO transmission from the Time producer to one or more Time consumers. Read-back of the local time is facilitated by means of dedicated PDOs. There are no specific features in this protocol to control the accuracy of the time distribution.

The High-resolution time protocol uses the SYNC object to achieve the highest possible synchronization accuracy when distributing time over the CAN Network. Read-back of the local times is facilitated by means of dedicated PDOs. The actual accuracy of the time distribution is implementation dependent. Accuracy in the microsecond range can be achieved with a bit rate of 1 Mbps.

SYNC message and protocol

Synchronous network behaviour in CANopen networks can be achieved with the SYNC protocol. The cyclically transmitted SYNC message indicates to the consumers to start their application-specific behaviour, which is coupled to the reception of the SYNC message. Synchronous PDOs use the SYNC message as a triggering event for PDO transmission and as indication for sending the data valid, which has been received previously to the SYNC message.

The SYNC Message format is defined in CANopen CiA 301 V4.2.0 section 7.3.5.

The SYNC protocol uses a producer/consumer communication coherence. There is one SYNC producer and several SYNC consumers. In case a device supports the SYNC consumer capability, this functionality can be switched on in the COB-ID entry for the SYNC object (1005h). This entry also provides the CAN-Identifier for the SYNC message. All consumers need to assign the same CAN-Identifier to that COB-ID entry. Furthermore, they indicate the consumer functionality in bit 30.

Bit timing

Even if minor errors in the configuration of the CAN bit timing do not result in immediate failure, the performance of a CAN network can be reduced significantly. In most of the cases, the CAN bit synchronization amends a faulty configuration of the CAN bit timing so that only an occasional error frame is generated.

In the case of arbitration however, when two or more CAN nodes simultaneously try to transmit a frame, a misplaced sample point may cause one of the transmitters to become Error Passive.

The analysis of such sporadic errors requires a detailed knowledge of the CAN bit synchronization inside a CAN node and of the CAN nodes’ interaction on the CAN Network.

Further information about bit timing parameters are available in [11], [12], [21], [22], [23], [24].

Redundancy management and monitoring

Overview

Spacecraft on-board communication busses are typically implemented using a redundant physical media topology that is resilient to single point failure in cabling or connector faults.

Neither the CAN Network specification ISO 11898 nor the CANopen standard define redundancy management. However, both specifications define capabilities that are suitable for use when implementing a highly reliable bus system.

A redundant communication system requires redundant communication channels and also a redundancy management scheme. Components that can be redundant are the physical connection, the bus transceiver and the bus controller.

This standard specifies two alternative architectures for the implementation of the bus interfaces in the CAN nodes. The selective bus access architecture allows communication on one bus at a time, whereas the parallel bus access architecture allows simultaneous communication on both a nominal and a redundant bus. Both architectures can be used simultaneously in the same system

A redundancy management scheme for a cold redundant bus system is specified and consistent with the defined bus interface architectures.

Redundancy management for hot/warm redundant bus systems as well as node level redundancy management are application specific and therefore outside of the scope of this document. The redundancy management scheme defined in this standard uses the CANopen Heartbeat object as a means to monitor and control the bus system.

The redundancy management is specified in clause 8. This clause specifies the implementation and protocol requirements related to redundancy management at bus level. The redundancy management scheme is based on the assumption that there is always one dedicated node responsible for the bus redundancy management.

This standard specifies two alternative methods for the implementation of the CAN node transceivers: see clause 5.3.1a.

Node Monitoring via Node-Guarding or Heartbeat Messages

To ensure operability of network nodes, CANopen provides two alternatives:

Cyclic querying of the node state by a higher order instance, the so-called "NMT-Master" ("node guarding" principle) or

Automatic transmission of a "heartbeat message" by the network nodes ("heartbeat" principle).

With node guarding, a certain network node (the so-called NMT-master) requests the other nodes in the network (referred to as NMT-slaves) with a CAN remote frame one after the other at defined intervals ("guard time") to transmit a datagram with its current communication state (stopped, operational, pre-operational) together with a toggle-bit. If a node does not respond to the request of the NMT-master within a certain time ("node life time"), this is assessed as a failure of the node and indicated to the host controller of the NMT-master as a "node-guarding event". On the other hand, the NMT-slaves also monitor whether they have received a request from the NMT-master within their "life time". If such a request was absent for longer than the "life time" of a node, the NMT-slave assumes that the NMT-master itself has failed and indicates this event as "Life guarding event" to its host controller.

With node guarding, one CAN identifier per node is used to request the communication state. Low priority messages identifiers with a value of 1792 + NODE-ID are reserved for this.

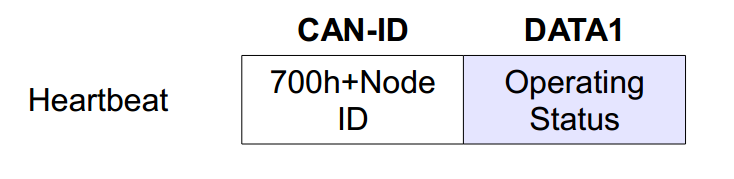

With node monitoring according to the heartbeat principle, a node automatically transmits its communication state (with format as in Figure 43) at regular intervals as evidence of its communication ability. The interval between two heartbeat messages ("heartbeat interval") of a heartbeat producer is configured via the object directory entry [1017]. A value of 0 disables the heartbeat mechanism. The so-called "heartbeat consumer time" of the up to 127 network nodes is given in the OD entry [1016]. This time interval describes the maximum time within which the arrival of a heartbeat message is expected by a particular node.

Figure 43: Format of hearthbeat message

Figure 43: Format of hearthbeat message

In a guarding or heartbeat message the communication status is transmitted in the form of a one-byte value.

The following state values are defined:

0x00 - Bootup;

0x04 - Stopped;

0x05 - Operational;

0x7F - Pre-Operational.

The highest value bit is assigned a special role - with guarding it toggles, with heartbeat it is constant 0.

Bus monitoring and reconfiguration management

The bus monitoring and reconfiguration management protocol defined in this standard make use of CANopen NMT objects (and in particular the CANopen Heartbeat message) to determine the active bus.

The Redundancy Master defines the bus to be considered active by periodic transmission of CANopen Heartbeat messages on the active bus. The slave nodes monitor the presence of the Heartbeat message from the master to determine the active bus.

In addition to the Master Heartbeat messages the slave nodes also detects if another CANopen NMT message is received from the master. If so, the bus on which the NMT message was received is considered the active one. Further information is given in Annex A.

Connectors and pin assignments

Clause 10 specifies the connector types and pin allocations to be used for connecting the CAN Network to the CAN nodes.

Minimal protocol set

In order to cater for applications with extremely simplistic needs, which cannot embed a high amount of computing power and do not have in-flight reconfiguration needs, a minimal protocol set is specified in clause 9.

This protocol is based on a restriction of the “pre-defined master/slave connection set” proposed by the CANopen.

With this minimal implementation, the CANopen object dictionary exists but objects are not necessarily defined as entries of a device and are not necessarily accessed with their index. Indexes, sub-indexes, data types, parameters, mapping parameters can be too complex and too bulky to manage relative to the available computing resources. It is therefore acceptable that the CANopen objects and their mapping are hard-coded.

To reduce the hardware and software required by devices, slave nodes may work autonomously with minimum intervention of the master, and without the need of Network Management (NMT).

The COB-ID assignment complies with the clause 6.10 of this standard.

Physical layer

Topology

Physical topology

General

A spacecraft system using a CAN Network shall use either of the following physical topologies:

- A Linear multi-drop topology as depicted in Figure 51.

- A Daisy chain topology as depicted in Figure 52.

For connector implementation see clause 10, all implementations are possible, if the pin-out for the main and redundant bus is maintained.

Figure 51: Linear multi-drop topology

For CAN Network devices connected in a daisy chain configuration, the connection between two subsequent trunks of the CAN Network shall be performed inside the connector as shown in Figure 52.

With this configuration the two topology options can be employed exclusively or in combination.

Figure 52: Daisy chain topology.

Equal cable lengths between devices shall be avoided.

Equal cable lengths for Drop (stub) cable shall be avoided.

The reason to avoid equal cable lengths between devices is to minimize standing waves. Similar reasons apply to drop (stub) cable lengths.

Terminators

Bus terminators shall be implemented according to ISO 11898-2:2003 clause 7.5.2.

Terminating resistors shall not be incorporated inside NMT slave equipment.

See Figure A-2 and Figure A-3 for examples.

For system configuration with all communications driven by a master/slave concept the terminating resistors may be incorporated inside the Master at the end of the bus.

Terminating resistors may be incorporated inside the CAN Network cable.

The terminator resistor(s) shall be installed at each end of the bus segment as shown in Figure 51 and Figure 52.

A 120 ohm terminating resistance shall be installed at each end of each bus segment.

Terminating resistors can consist of two 60 ohm resistors as shown in Figure A-5 (Split Termination).

Maximum bus length and drop length

The maximum bus length shall be implemented in accordance with ISO 11898-2:2003 clause 7.5.

The maximum stub drop lengths shall be implemented in accordance with ISO 11898-2:2003 clause 7.5.3.

Since stub-lines are un-terminated, signal reflections can develop in a stub that drives signal levels back and forth across a receiver's input thresholds, creating errors. Bit-sampling occurs near the end of a bit, so it is mandatory that all signal reflections in a CAN stub-line are attenuated before or during the propagation delay segment to provide an adequate margin of safety (see [5],[7],[8],[12] for detailed discussion).

To minimize reflections, stub-line length shall not exceed one-third (1/3) of the network critical length.

- 1 See definition 3.2.16.

- 2 Additional considerations and requirements are addressed in 5.4.3.

Number of network devices

The CAN physical layer interface of each node shall be designed such that it can be incorporated in a system with at least 64 network nodes.

The RS-485 physical layer interface of each node shall be designed to be incorporated into system with a maximum of 32 nodes.

- 1 The maximum number of network devices in a system is a function of the electrical properties of the devices and circuits of the CAN transceivers. Requirements for the CAN transceivers are specified in clause 5.3.

- 2 The maximum number of nodes main limit is the driving capability of a CAN transmitter. It’s usually specified in data sheets by the minimum allowed load resistance. The load of a transmitter in the CAN Network is composed of the termination resistors and the parallel combination of differential input resistances of all nodes.

- 3 The RS-485 implementation described in 5.3.5 cannot support more than 32 standard RS-485 Unit Load devices as described in [5].

Medium

Cable requirements

CAN primary bus

Each CAN node shall implement the provision to interface to at least one CAN Network in accordance with the physical medium specification of ISO 11898-2:2003 Table 9.

CAN redundant bus

If implemented, the second (redundant) CAN Network shall also be designed in accordance with the physical medium specification of ISO11898-2:2003 Table 9.

Redundancy management is addressed in clause 8.

CAN Network cable

The CAN Network cable shall be compliant with ISO 11898-2:2003, clause 7.5.

The application specific CAN Network cable selection is left to the system engineer. Guidelines can be found in [11],[13] [26].

Shield – system specific

All data cables shall use shielded twisted-pair cables.

Cable shielding shall comply with ECSS-E-ST-20-07 clause 4.2.13

A short pig-tail shall be crimped to the shield end at each connector end and then attached to connectors backshells and box chassis.

If individual shielding of the signal pairs is used, the same terminating technique as for the overall shield shall be used.

As described in ECSS-E-ST-20-07 4.2.13.2f network cabling should lie as close as possible to satellite structure and have intermediate overshield bonding points to minimize EMI pick up. This prevents parasitic currents from flowing in the shield between ground connections.

Connectors

Connector type

If connectors are selected from the ones described in clause 10, they shall comply with their associated requirements.

If connectors are not selected from the ones described in clause 10, then they shall comply with the naming convention defined in clause 10.2.

It is not practical to define a connector to suit all applications, systems and equipment. In particular, when several functions are grouped on a single connector for density reasons. Clause 10 specifies connectors for CAN Network standalone connections. Device-on-bus compatibility is maintained by implementing the configuration and signal pin-out for that connector.

Receptacles (Sockets)

Receptacles shall be used on board and unit assemblies.

Receptacles shall be equipped with male contacts.

Plugs

Plugs shall be used on cable assemblies.

Plugs shall be equipped with female contacts.

The conductors shall be directly soldered or crimped to the contacts.

Reserved pins

Pins designated as ‘Reserved’ in clause 10 of this standard shall not be used.

Reserved Pins are reserved for functions in future updates to this standard.

Transceiver characteristics

General

The physical layer specifications shall comply with either ISO11898-2:2003 as specified in 5.3.2 or EIA RS485 as specified in 5.3.5.

ISO11898-2:2003 should be used for transceiver electrical level compliance.

ISO 11898-2:2003 transceiver electrical characteristics

Transceivers shall comply with the physical medium attachment sub-layer specification of ISO 11898-2:2003 clause 7.2.

An excerpt of ISO 11898-2:2003 specification is illustrated in Table 51.

Table 51: CAN levels in ISO 11898-2:2003

|

Signal

|

Recessive

|

Dominant

| ||||

|

Min

|

Nom

|

Max

|

Min

|

Nom

|

Max

| |

|

CAN_High (V)

|

2,00

|

2,50

|

3,00

|

2,75

|

3,50

|

4,50

|

|

CAN_Low (V)

|

2,00

|

2,50

|

3,00

|

0,50

|

1,50

|

2,25

|

|

H-L (V)

|

-0,50

|

0,00

|

0,05

|

1,50

|

2,00

|

3,00

|

Resistance to electrical CAN Network faults

General

Transceivers shall withstand a voltage in the range between -10V and +15V on their bus pins w.r.t to chassis ground.

- 1 This requirement introduces a dedicated specification for ‘battery voltage’ as defined in ISO 11898-2:2003 that is relative to use of CAN in space equipment.

- 2 The rationale behind this choice is that those numbers envelope possible performances from present and future ISO and RS-485 transceivers (see for example absolute maximum ratings in [37]).

A robust system to manage babbling idiot nodes shall be present. - 1 Although unlikely, the theoretical presence of babbling idiots contending the bus cannot be ruled out. It is the System designer's duty to consider several possible ways to cope with this failure occurrence, including independent unit RESET/Power removal or low level CAN message for transceiver inhibit/reset.

- 2 This requirement does not impose an explicit independent reset/off signal per unit.

Unpowered nodes shall not disturb the bus.

This can be achieved by, for example, correct bus sizing, choice of bit timing, evaluation of added capacitance from OFF terminals (connector, transceiver, PCB).

Bus failure detection requirements

Overview

Clause 5.3.3.2.2 and 5.3.3.2.3 replace the requirements of ISO 11898-2:2003 clause 7.6 "Bus failure management".

Figure 19 of ISO 11898-2:2003 is a graphical representation of the failure modes (case 1 to case 9) covered in clause 5.3.3.2.3.

Table 52 is a summary of the requirements from clauses 5.3.3.2.2 and 5.3.3.2.3.

Disconnection, power off, loss of ground or shielding

If one node becomes disconnected from the bus, the remaining nodes shall continue communicating.

As an example for cold redundant units connected to the bus when the active one gets disconnected.

If one node loses power, the remaining nodes shall continue communicating.

As an example for cold redundant units connected to the bus.

If one node loses ground, the remaining nodes should continue communicating.

Ability for faulty bus to keep communicating depends on bus topology, data rate and physical implementation.

In case of loss of the shield connection at any node, all nodes should continue communicating.

- 1 This failure can happen only if a shielded cable is used. It can lead to common mode voltage induced between the shield and the two signal wires.

- 2 Ability for faulty bus to keep communicating depends on bus topology, data rate and physical implementation.

Open and short failures

If CAN_H or CAN_L are interrupted, the remaining nodes shall continue communicating with reduced signal-to-noise ratio.

Ability for faulty bus to keep communicating depends on bus topology, data rate and physical implementation.

If CAN_H or CAN_L are interrupted, the disconnected node may continue communicating.

If CAN_H shorted to Vfault <= +7V, the CAN bus should continue communicating with reduced signal-to-noise ratio.

- 1 Ability for faulty bus to keep communicating depends on bus topology, data rate and physical implementation.

- 2 Single event effect (SEE) resilience of the part is typically not guaranteed.

If CAN_H shorted to Vfault in the range as defined in 5.3.3a, upon fault removal the CAN network shall resume communication with no ill effects to CAN nodes.

If CAN_H is shorted to Vfault the CAN network cannot communicate.

In case a redundant bus is available, it should be possible to switch to the redundant CAN network if CAN_H is shorted to Vfault outside the range as defined in 5.3.3a.

This can cause irreversible fault to the transceivers.

If CAN_L is shorted to ground all nodes should continue communicating.

Ability for faulty bus to keep communicating depends on bus topology, data rate and physical implementation.

If CAN_H shorted to ground, upon fault removal the CAN network shall resume communication with no ill effects to CAN nodes.

If CAN_H is shorted to ground the CAN network cannot communicate.

If CAN_L is shorted to Vfault in the range as defined in 5.3.3a, upon fault removal the CAN network shall resume communication with no ill effects to CAN nodes.

- 1 If CAN_L is shorted to Vfault the CAN network cannot communicate.

- 2 Ability for faulty bus to keep communicating depends on bus topology, data rate and physical implementation.

- 3 Single event effect (SEE) resilience of the part is typically not guaranteed.

In case a redundant bus is available, it should be possible to switch to the redundant CAN network if CAN_L is shorted to Vfault outside the range as defined in 5.3.3a.

This can cause irreversible fault to the transceivers.

If CAN_L is shorted to CAN_H, upon fault removal the CAN network shall resume communication with no ill effects to CAN nodes.

If CAN_H and CAN_L wires are interrupted at the same location, CAN nodes upstream the break shall:

- remain communicating with reduced signal-to-noise ratio, and

- upon fault removal resume communication with no ill effects to CAN nodes. In case of loss of one connection to termination network all nodes shall continue communicating.

Ability for faulty bus to keep communicating depends on bus topology, data rate and physical implementation.

Table 52 – CAN failure modes and recommended FDIR actions.

|

Description of Bus Failure

|

Corresponding Network behaviour

|

Quality of specification

|

Comment

|

|

One node becomes disconnected from the bus

|

The remaining nodes continue communicating.

|

Mandatory

|

In a bus configuration where cold redundant units are connected to the same bus, any unit disconnection do not disturb the bus.

|

|

One node loses power

|

The remaining nodes continue communicating.

|

Mandatory

|

In a bus configuration where cold redundant units are connected to the same bus, any power loss does not disturb the bus.

|

|

One node loses ground

|

The remaining nodes continue communicating.

|

Recommended

|

Ability for faulty bus to keep communicating depends on bus topology, data rate and physical implementation.

|

|

Loss of the shield connection at any node

|

All nodes continue communicating.

|

Recommended

|

This failure can happen only if a shielded cable is used. In this case the loss of shield connection at one node can cause common mode voltage induced between the shield and the two signal wires.

Ability for faulty bus to keep communicating depends on bus topology, data rate and physical implementation. |

|

Open and short failures (The numbers 1 to 9 refer to Cases 1 to 9 in Figure 19 in ISO 11898-2:2003)

|

|||

|

1 CAN_H interrupted

|

The remaining nodes continue communicating with reduced signal-to-noise ratio.

Disconnected node continue communicating |

Mandatory Recommended |

Ability for faulty bus to keep communicating depends on bus topology, data rate and physical implementation.

|

|

2 CAN_L interrupted

|

The remaining nodes continue communicating with reduced signal-to-noise ratio.

Disconnected node continue communicating |

Mandatory Recommended |

Ability for faulty bus to keep communicating depends on bus topology, data rate and physical implementation.

|

|

3a CAN_H shorted to Vfault <= +7V

|

CAN bus continues communicating with reduced signal-to-noise ratio.

|

Recommended

|

Ability for faulty bus to keep communicating depends on bus topology, data rate, physical implementation.

Single event effect (SEE) resilience of the part is typically not be guaranteed. |

|

3b CAN_H shorted to Vfault in the range as defined in 5.3.3a

|

CAN network cannot communicate.

Upon fault removal CAN network resumes communication with no ill effects to CAN nodes. |

Acceptable.

Mandatory |

This assumes that the network is made with redundant buses, and each node is connected to both buses.

|

|

3c CAN_H shorted to Vfault outside the range defined in 5.3.3a

|

CAN network cannot communicate.

|

Acceptable.

|

This can cause irreversible fault to the transceivers.

Fault isolation through switch to redundant CAN network is still possible. |

|

4 CAN_L shorted to ground

|

All nodes continue communicating.

|

Recommended

|

Ability for faulty bus to keep communicating depends on bus topology, data rate, physical implementation.

|

|

5 CAN_H shorted to ground

|

CAN network cannot communicate.

Upon fault removal CAN network resumes communication with no ill effects to CAN nodes. |

Acceptable.

Mandatory |

This assumes that the network is made with redundant buses, and each node is connected to both buses.

|

|

6a CAN_L shorted to Vfault <= as defined in 5.3.3a

|

CAN network cannot communicate.

Upon fault removal CAN network resumes communication with no ill effects to CAN nodes. |

Acceptable.

Mandatory |

Ability for faulty bus to keep communicating depends on bus topology, data rate and physical implementation.

Single event effect (SEE) resilience of the part is not guaranteed. |

|

6b/6c CAN_L shorted to Vfault outside the range as defined in 5.3.3a

|

CAN network cannot not communicate.

|

Acceptable.

|

This can cause irreversible fault to the transceiver.

Fault isolation through switch to redundant CAN network is still possible. |

|

7 CAN_L shorted to CAN_H

|

CAN network cannot communicate.

Upon fault removal CAN network resumes communication with no ill effects to CAN nodes. |

Acceptable.

Mandatory |

|

|

8 CAN_H and CAN_L wires interrupted at the same location

|

CAN nodes upstream the break remain communicating with reduced signal-to-noise ratio

Upon fault removal CAN network resumes communication with no ill effects to CAN nodes. |

Mandatory

Mandatory |

|

|

9 Loss of one connection to termination network

|

All nodes continue communicating.

|

Mandatory

|

Ability for faulty bus to keep communicating depends on bus topology, data rate and physical implementation.

|

Transceiver isolation

Equipment implementing an isolated bus interface shall comply with the requirements of this standard, which uses an isolated Transceiver rather than isolated CAN signals.

Both the CAN Network signal lines and transceiver power supplies shall be isolated.

Electric ground support equipment (EGSE) designs for CAN bus shall use transceiver isolation as specified by this standard.

- 1 Isolators impose an additional propagation delay that can restrict the maximum possible bus length. It is the designer's duty to take into account that the maximum round trip interface delay time for a device is still compliant with the bit timing requirements of clause 5.4.

- 2 The isolation scheme proposed in this standard ensures that it is possible to connect both isolated and non-isolated nodes to the same network.

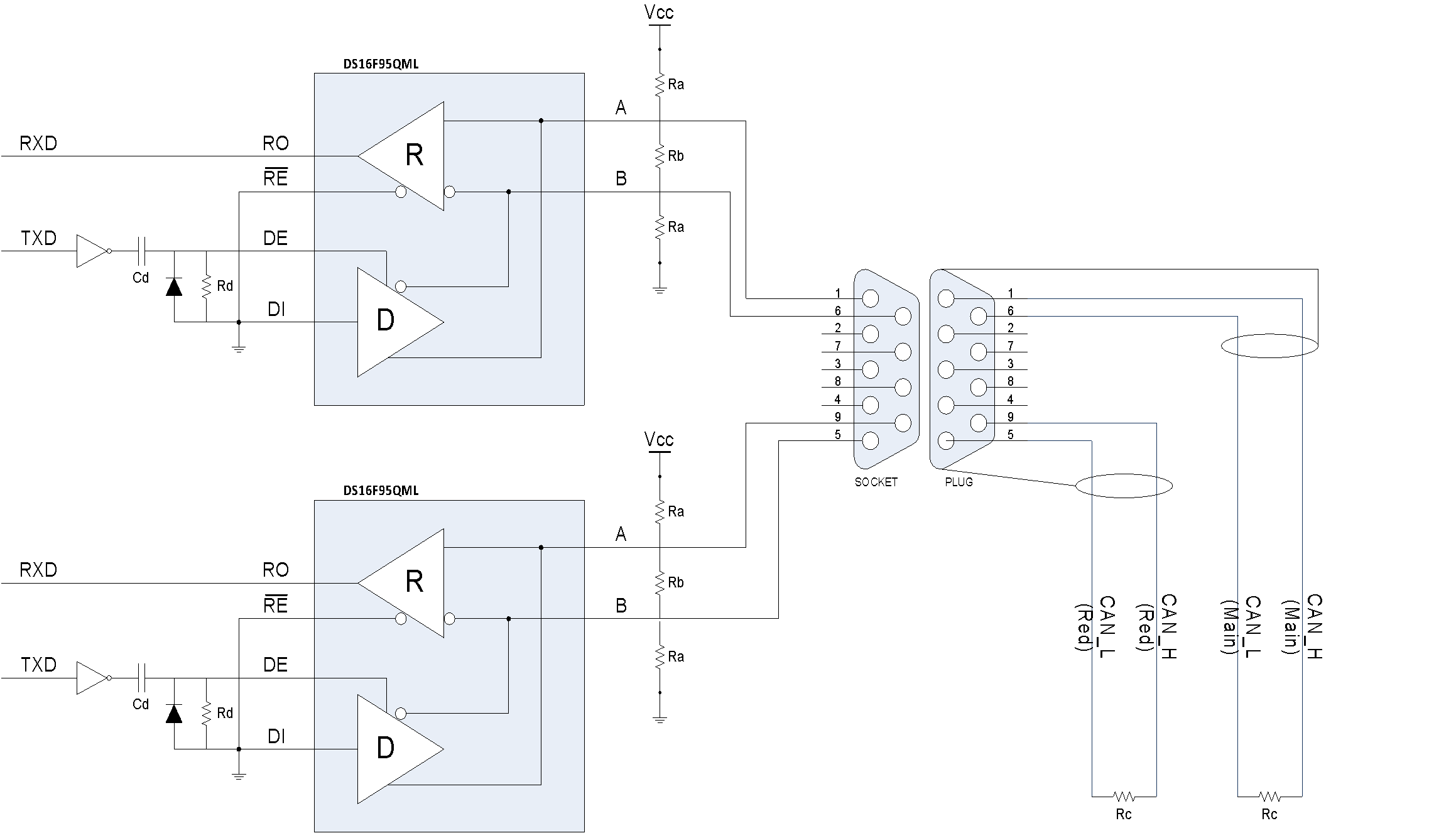

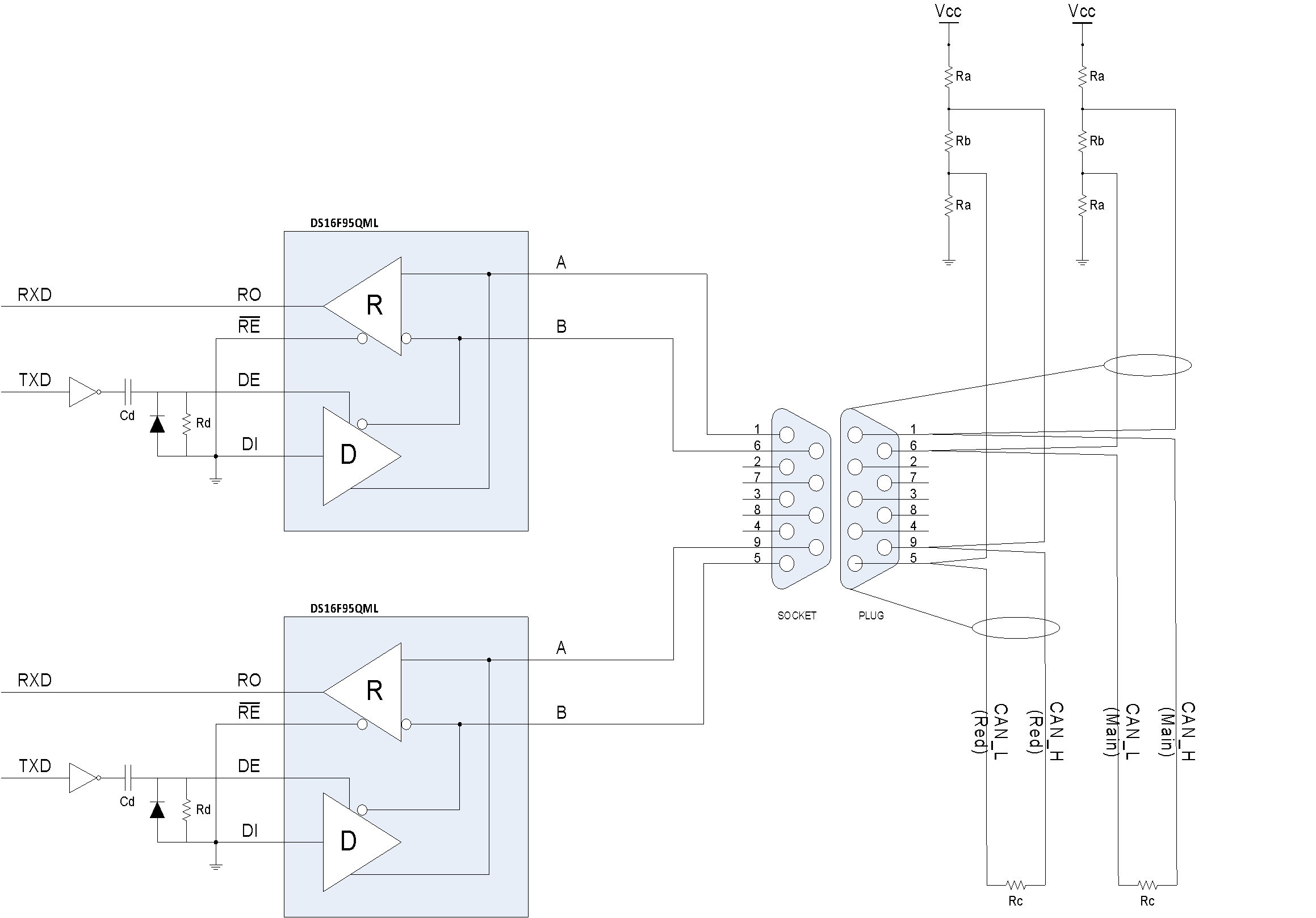

Physical layer implementation based on RS-485 transceivers

ISO11898-2:2003 and RS-485 devices shall never be used on the same bus.

Detailed implementation for RS-485 transceiver

Data Input (DI) and Drive Enable (DE) of the RS-485 transceiver shall be driven by the inverted CAN Transmit bit of the controller (TXD).

See Figure A-2 and Figure A-3 for examples.

A fail-safe mechanism shall be implemented to avoid that a faulty controller forces the bus into permanent dominant level and harms correct network operation.

An example of a fail-safe mechanism is an input filter. More details can be found in [6], [14] and [15].

Receive Enable (RE) pin shall be always active (enabled).

Receive Output (RO) shall be taken as the true value of the CAN signal.

Bit timing

Bit rate 1 Mbps

All transceivers shall support the 1 Mbps high-speed CAN bit rate.

ISO 11898-2:2003 specifies high-speed CAN as 125 kbps to 1 Mbps.

Other bit rates

If a device supports more bit rates than specified in requirement 5.4.1a it shall support one or more of the following rates:

- 500 kbps

- 250 kbps

- 125 kbps A device may implement additional bit rates only after complying to all the rates stated in 5.4.2a.

Bit timing

A CAN controller shall support configurable Time Quanta and Sample Point.

Bit timings and Sample Point used in systems compliant to this standard shall be calculated using the method explained in iCC 2012 CAN.

For each CAN system the option which allows the most propagation delay while still satisfying the oscillator tolerance requirement shall be chosen.

Resynchronization Jump Width (RJW), also referred to as Synchronization Jump Width (SJW) in some controllers, shall be configurable between 1 to MIN(4, Phase_Seg1) Time Quanta.

This parameter is used as a maximum limit of bit time adjustment in the case of re-synchronization when there is an edge phase error detected by the receiver CAN nodes.

Synchronisation shall be performed on ‘recessive to dominant’ edges only.

This standard does not define a limit for each device’s CAN interface round trip propagation time since the correct definition, at system level, of Bit timings Sample Point as per clause 5.4.3 ensures bus robustness.

Electromagnetic compatibility (EMC)

The CAN Network system shall comply with EMC requirements as defined in ECSS-E-ST-20 clause 6.

Data link layer

ISO 11898 compliance

The CAN Data Link layer shall comply with ISO 11898-1:2003.

- 1 The ISO 11898-1:2003 document inherits data link layer definitions from the Bosch specification, [3].

- 2 This implies also that both 11-bit and 29-bit identifiers can be used on the CAN Network.

Fault confinement

The Data Link layer shall implement fault confinement, as specified in ISO 11898-2:2003 clause 7.6, Fault Confinement.

- 1 The ISO 11898-2:2003 document inherits fault confinement definitions from the Bosch specification, [3]. It is left to the system engineer as how best to utilize the fault containment mechanisms provided for in clause 7.6 of the ISO reference for system FDIR purposes.

- 2 The ISO 11898-1:2003, specifies that only Bus Off and Normal Mode indications to be provided to the application.

The indication of Error Active and Error Passive should be provided to the application.

Non-intrusive read access at application SW level to the error counters shall be provided to allow assessment of the quality of the bus.

CANopen higher layer protocol

Service data objects

If Service data objects (SDOs) are implemented, the SDO shall be as specified in CANopen.

The implementation of Service Data Objects (SDO) is optional. This is used primarily to access to the device Object Dictionary. In systems only requiring configuration on ground, the Client SDO can be implemented in a PC or similar. SDOs can be used for configuration of the CAN nodes in-flight. This choice is left to the particular application and out of scope for this standard.

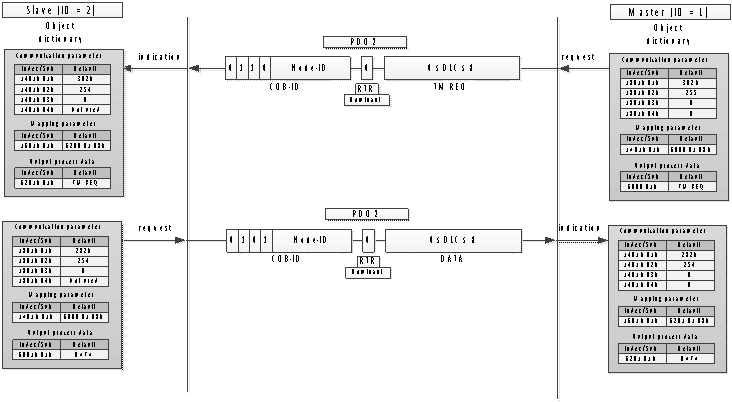

Process data objects

Process data objects (PDOs) shall be implemented according to the CANopen specification.

CANopen restricts the number of different PDOs to 512 Transmit PDOs and 512 Receive PDOs per node. A device can implement an arbitrary number of PDOs up to the limit defined by the CANopen standard.

Synchronisation object

All devices requiring synchronous communication shall implement a SYNC object.

A device can be a SYNC producer or SYNC consumer depending on its functionality.

The SYNC object shall be implemented according to CANopen CiA 301 V4.2.0 section 7.2.5.

Emergency object

If implemented, the Emergency object shall:

- be used only for Error reporting,

- have error codes as defined in CANopen standard. All CANopen defined Error codes shall be implemented.

The implementation of the Emergency object is optional.

Network management objects

Module control services

All devices, excluding the minimum configuration specified in clause 9.3, shall implement the following CANopen NMT Module Control Services:

- Start Remote Node

- Stop Remote Node

- Enter Pre-Operational

- Reset Node

- Reset Communication

Error control services

All devices shall implement the Heartbeat service as specified in CANopen CiA 301 V4.2.0 section 7.2.8.3.2.2.

All slave nodes shall consume the redundancy master Heartbeat message.

CANopen specifies that it is mandatory to implement either the Node/Life Guarding or the Heartbeat services and protocols. This standard is more restrictive and specifies only the Heartbeat service and protocol as mandatory.

Bootup service

All devices shall implement the minimum Bootup service as specified in CANopen CiA 301 V4.2.0 section 7.2.8.2.3.

Node state diagram

All devices shall implement the NMT state diagram as specified in CANopen CiA 301 V4.2.0 section 7.3.2.

Electronic data sheets

Each device in the network shall be accompanied by a Device Configuration File in accordance with the CANopen standard as per CiA DS306 Version 1.3.0.

The functions and properties of CANopen devices are largely described by objects and are managed in an object directory. The object directory is represented in electronic form by so-called EDS files. EDS files are a fixed component of standardization in the CANopen field (CiA DS306) and play a key role in configuring CANopen networks. The file format specified by CiA guarantees that device descriptions generated by tools of different software producers can be read and processed. All participants in the development of CANopen systems benefit from complete and correct EDS files for the CANopen devices available on the market.

Device and application profiles

The device profile designer shall coordinate the allocation and definition of the device profile with CAN in Automation (CiA) for inclusion in their database.

- 1 This is in order to ensure that any device profile defined within the space community is compatible with the CANopen device profile requirements.

- 2 In general, standardized profiles simplify system integration by means of off-the-shelf configuration tools. Devices compliant to the same profile are interoperable and partly or completely exchangeable.

- 3 The procedure for definition of a new Device Profile is established by CiA via definition of a Draft Standard proposal (DSP).

Each device implementing a built-in self-test functionality shall provide the means to start the test using an object in the device Object Dictionary.

The result of the test shall be accessible in a dedicated object.

Object dictionary

All devices shall implement an Object Dictionary (OD) according to CANopen.

- 1 Data Types implemented within the OD are application dependent and are built on basic data types.

- 2 For simple systems not using SDO, the object dictionary can be hardcoded.

Synchronous communications

Synchronous data transfers shall be performed using synchronous PDOs as defined in CANopen.

Synchronous PDOs transfer shall be synchronized by receipt of SYNC object as defined in 6.3.

The SYNC producer shall be capable of sending the SYNC object according to CANopen.

Only one device within the network shall act as SYNC producer by issuing periodically the SYNC object.

Bus redundancy management uses SYNC object exchange as described in 8.3.

SYNC consumers implementing the SYNC capability shall react on SYNC object’s reception according to CANopen.

COB-ID and NODE-ID assignment

All devices shall provide the capability of COB-ID assignment as specified by CANopen.

COB-IDs restricted for a specific purpose in CANopen shall not be used other than for that particular purpose.

The capability shall be provided to change any non-restricted COB-ID of a device at any time up to the completion of system level testing without need for a re-qualification of the device.

This implies that COB-ID reassignment capability can be implemented by using SDOs but also by other means such as PROM boxes, straps in connectors, S/W updates or similar can be considered if acceptable for the particular application.

No single point failure shall cause a terminal to validate a false COB-ID.

This implies a protection mechanism on COB-ID assignment.

The NODE-ID shall be hard-coded inside the node.

The Node shall not communicate until a valid NODE-ID has been activated.

The Node–ID shall be configurable when the node is in a specific maintenance mode only.

Each node connected on the CAN Network shall have at least one unique NODE-ID.

The NODE-ID shall be agreed by the customer and the supplier.

The capability shall be provided to change any NODE-ID of a node at any time up to completion of system level test without the need of a re-qualification of the node.

Node‐ID reassignment capability can be implemented by using internal configuration, but also by other means such as PROM boxes, straps in connectors. S/W updates or similar can be considered if acceptable for the particular application.

No single point failure shall cause a terminal to validate a false NODE-ID.

This implies that a protection mechanism on NODE-ID assignment is used.

Each hot redundant node connected to the same physical CAN Network shall use different COB-IDs.

In the case where two or more redundant nodes are connected and operating on the same physical CAN Network, the communication objects of each redundant node shall be uniquely identifiable.

For each device, the default COB-ID allocation to be implemented before delivery of the device shall be agreed between the customer and the supplier.

The COB-ID assignment upon device delivery is thus not restricted to the CANopen pre-defined connection set.

Time distribution

Time objects

Time code formats

Each device on the CAN network that maintains time information shall use Spacecraft Elapsed Time (SCET) as defined in clause 3.2 of CCSDS 301.0-B-4.

The time code format of the SCET is the CCSDS UNSEGMENTED TIME CODE (CUC) an unsegmented binary count of seconds and binary powers of sub-seconds. The SCET is thus a free running counter with a MSB of up to 232 seconds and LSB sub-second representations down to 2-8, 2-16 or 2-24.

Each device on the CAN network that maintains time information may use Spacecraft Universal Time Coordinated (UTC) as defined in ECSS-E-70-41 Annex C.

If the spacecraft provides the optional service of maintaining the UTC on board, the format of the UTC shall be that of the CCSDS Day Segmented time code (CDS).

The CDS is a 16 or 24 bit binary representation of number of days elapsed from a predefined epoch, 32 bits represent the number of ms and an optional 16 or 32 bit field represents the sub-milliseconds.

This standard allows for either of the time code formats to be used as long as all devices in the network support the selected time code format. There are however, some limitations in terms of resolution and size of the fields.

Network Devices shall use either the Spacecraft elapsed time object or the Spacecraft universal time coordinated (UTC) object.

Spacecraft elapsed time objects

The Spacecraft elapsed time objects (SCET) shall be implemented in all devices that maintain time information.

Each device shall implement one Local SCET Set and one Local SCET Get object in the device Object Dictionary.

The Local SCET Set object shall allow setting the local time of the node via the CAN Network.

The Local SCET Get object shall allow reading the local time of the node via the CAN Network.

The Local SCET Set and Local SCET Get objects shall be of a compound data type according to the following SCET definition:

struct { unsigned 32 Coarse Time unsigned 24 Fine Time (sub seconds) } SCET The Local SCET Set and Local SCET Get objects shall be mapped into the CAN frame according to Figure 71.

It is up to the designer to decide the implemented size of the Fine Time counter in a particular device.

Figure 71: Format for objects containing the SCET

If a device supports less than 24 bits of fine time, the unused least significant bits shall be set to zeroes whenever the SCET is transmitted from a device.

If a device supports less than 24 bits of fine time, the unused least significant bits shall be interpreted as don’t-care whenever a device receives the SCET.

Spacecraft universal time coordinated objects

Each device supporting UTC shall implement one Local UTC Set and one Local UTC Get object in the device Object Dictionary.

The Local UTC Set object shall provide the capability of setting the local time of the node via the CAN Network.

The Local UTC Get object shall provide the capability of reading the local time of the node via the CAN Network.

The Local UTC Set and Local UTC Get objects shall be of a compound data type according to the following UTC definition:

struct { Unsigned 16 Day Unsigned 32 ms of day Unsigned 16 submilliseconds of ms } UTC The Local UTC Set and Local UTC Get objects shall be mapped into the CAN frame according to Figure 72.

It is up to the designer to decide if the “submilliseconds of ms” field is used in a particular device.

Figure 72: Format for objects containing the Spacecraft UTC

If a device does not support the “submilliseconds of ms” field, the unused least significant bits shall be set to zeroes whenever the time object is transmitted from a device.

If a device does not support the “submilliseconds of ms” field, the unused least significant bits shall be interpreted as don’t-care whenever a device receives the time object.

Time distribution and synchronization protocols

General

Each device on the network that maintains time information shall be compliant to the Time distribution protocol specified in clause 7.2.2.

Time distribution protocol

The Time Producer shall map the Local SCET Get object (7.1.2) or the Local UTC Get object (7.1.3) to a dedicated Spacecraft Time PDO transmit PDO.

The Time Producer shall use the Spacecraft Time PDO to convey its local time to the time consumers.

The Time Consumers shall map the Local SCET Set or Local UTC Set objects to the Spacecraft Time PDO receive PDO.

There shall be only one Spacecraft Time PDO in a particular system.

Each Time consumer shall map the Local SCET Get object (7.1.2) or the Local UTC Get object (7.1.3) to a dedicated Local Time PDO.

The Time consumers shall use its Local Time PDO to convey its local time on the CAN Network.

There shall be one Local Time PDO for each node maintaining local time.

The various transmission types defined in CANopen allow to use a number of different methods to transmit the Spacecraft Time PDO and Local Time PDOs. However, the details are application specific and out of scope for this standard.

High-resolution time distribution protocol

The Time Producer shall map the Local SCET Get object (7.1.2) or the Local UTC Get object (7.1.3) to a dedicated Spacecraft Time PDO transmit PDO.

The Time Producer shall use the Spacecraft Time PDO to convey its local time to the time consumers.

The value of the Spacecraft Time PDO shall correspond to the spacecraft time when the last preceding SYNC object was successfully transmitted.

The SYNC Producer and the Time Producer shall be implemented as separate entities.

The Time Producer shall implement the Spacecraft Time PDO with a transmission type of 1-240.

Transmission types 1-240 imply that the Time Producer samples its local time on successful receipt of the SYNC object and thereafter send the Spacecraft Time PDO.

The Spacecraft Time PDO defined in 7.2.3a shall be used for conveying the time information.

This prevents the use of Time object as specified in CANopen.

The Time Consumers shall map the Local SCET Set or Local UTC Set objects to the Spacecraft Time PDO receive PDO.

Each Time consumer shall map the Local SCET Get object (7.1.2) or the Local UTC Get object (7.1.3) to a dedicated Local Time PDO transmit PDO.

Each Time consumer shall use its Local Time PDO to convey its local time on the CAN Network.

There shall be one Local Time PDO for each node maintaining local time.

The value of the Local Time PDO shall correspond to the local time when the last preceding SYNC object was successfully received.

- 1 The detailed mechanisms for transmission of the Local Time PDOs are out of scope in this standard.

- 2 It is left to the implementer to define if the sampling of the local time at the occurrence of the SYNC object are implemented in H/W or S/W in order to achieve the required accuracy. It is good practice that generic H/W implementations always provide the possibility to signal, e.g. by means of an interrupt, that the SYNC object has been successfully transmitted/received.

Redundancy management

General

In any system implementing bus redundancy there shall be only one active node at any given time assigned to be the Redundancy Master.

The Redundancy Master shall be identical to the CANopen NMT master.

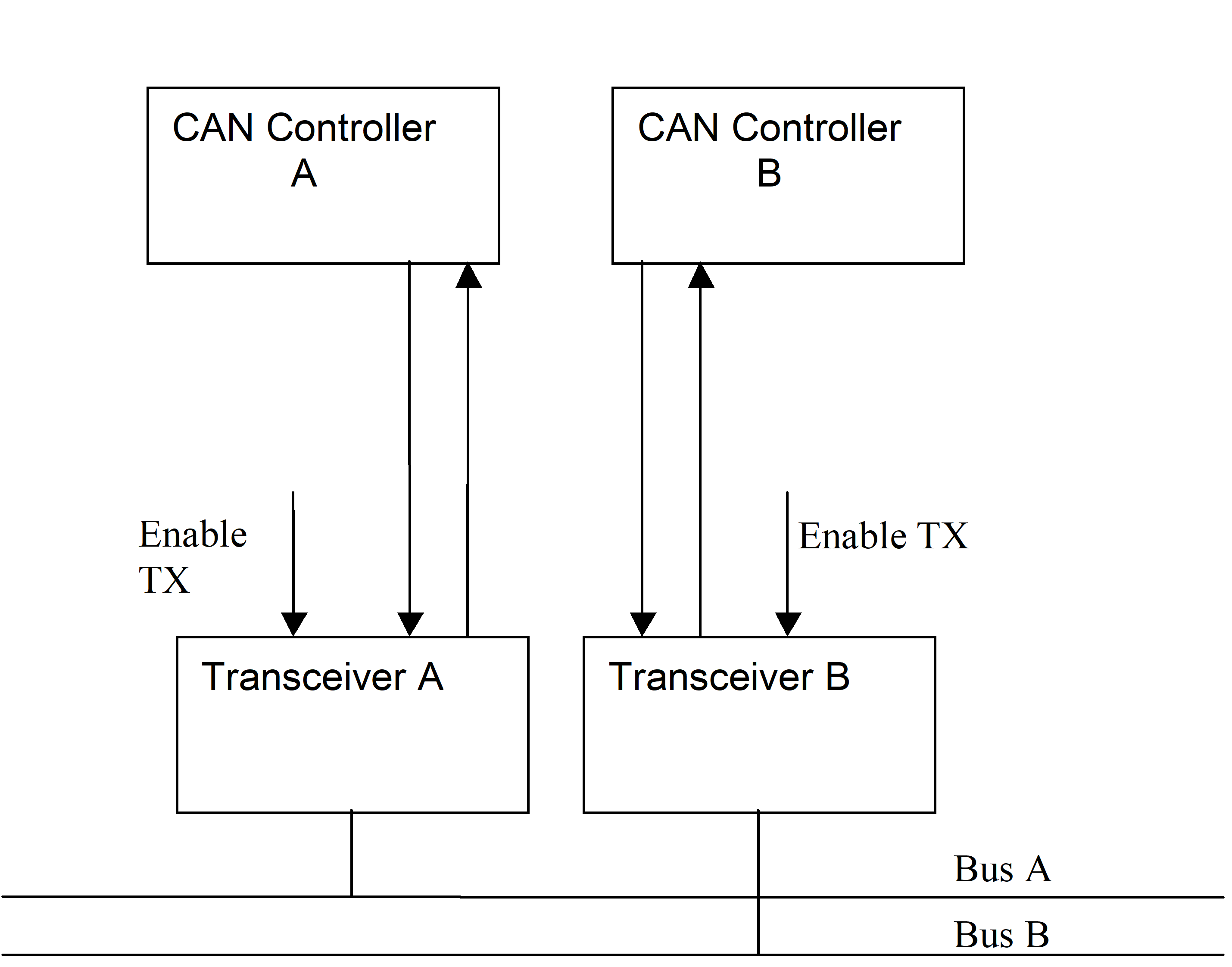

Node internal bus redundancy architectures

General

The redundancy bus architecture shall be based on only one of the following designs:

- a selective bus access architecture providing communication on only one bus at a time,

- a parallel bus access architecture providing simultaneous communication on both a nominal and a redundant bus.

Parallel bus access architecture

For a parallel bus architecture, the nodes shall implement a Redundancy Master such that each CAN Network is fully and independently accessible via a separate CAN controller.

- 1 See expanded information in A.4.2.

- 2 For bus monitoring protocol see 8.3.3.

- 3 This is to allow the bus Redundancy Master to passively listen for messages on the redundant (not active) bus.

Selective bus access architecture

Nodes implementing the selective bus access architecture shall provide a mechanism allowing the application to select which bus to use.

The details of this selection mechanism is implementation specific and out of scope for this standard.

Bus monitoring and reconfiguration management

Bus redundancy management parameters

Each slave node shall implement the objects listed in Table 81 in its Object Dictionary.

The Master Node shall implement the objects listed in Table 82 in its Object Dictionary.

The objects listed in Table 81and Table 82 shall be programmable by means of SDOs.

This allows variations in CANbus configurations of the object dictionaries as an outcome of failure investigations at data-handling sub-system level.

The objects listed in Table 81 and Table 82 shall be specified by the customer.

- 1 Clause 8.3.1 specifies the parameters that define the characteristics of the reconfiguration protocol.

- 2 Implementations of these objects is not strictly necessary for a minimum configuration as specified in clause 9.3.

Table 81: BUS redundancy management parameters for slaves

|

Parameter

|

Remark

|

|

Consumer Heartbeat Time

|

The Consumer Heartbeat Time parameter is specified by CANopen. The parameter specifies the maximum time allowed between two subsequent Heartbeat messages linked to that heartbeat consumer.

|

|

Producer Heartbeat Time

|

The Producer Heartbeat Time parameter is specified by CANopen. The parameter specifies the maximum time allowed between two subsequent Heartbeat message transmissions.

|

|

Bdefault

|

Bdefault specifies the bus to be considered active after a node power-on, node hardware reset.

|

|

Ttoggle

|

Ttoggle specifies the number of Consumer Heartbeat times during which the node is required to be listening for an NMT HB message on a particular bus before switching to the other bus.

|

|

Ntoggle

|

Ntoggle specifies the number of toggles between the Nominal and Redundant bus in case of no HB message being detected. If an even number is used the last toggle puts the system into Bdefault.

|

|

Ctoggle

|

The counter of Ntoggles (bus toggles) shows the count of the number of toggles that have already been performed by the device.

|

Table 82: BUS redundancy management parameters for master

|

Parameter

|

Remark

|

|

Consumer Heartbeat Time

|

The Consumer Heartbeat Time parameter is specified by CANopen. The parameter specifies the maximum time allowed between two subsequent Heartbeat messages linked to that heartbeat consumer.

|

|

Producer Heartbeat Time

|

The Producer Heartbeat Time parameter is specified by CANopen. The parameter specifies the maximum time allowed between two subsequent Heartbeat message transmissions.

|

|

Bdefault

|

Bdefault specifies the bus to be considered active after a master power-on or master hardware reset.

|

|

Ttoggle

|

Ttoggle specifies the number of Consumer Heartbeat times during which the node is required to be listening for an NMT HB message on a particular bus before switching to the other bus.

|

|

Ntoggle

|

Ntoggle specifies the number of toggles between the Nominal and Redundant bus in case of no HB message being detected. If an even number is used the last toggle puts the system into Bdefault.

|

|

Ctoggle

|

The counter of Ntoggles (bus toggles) shows the count of the number of toggles that have already been performed by the device.

|

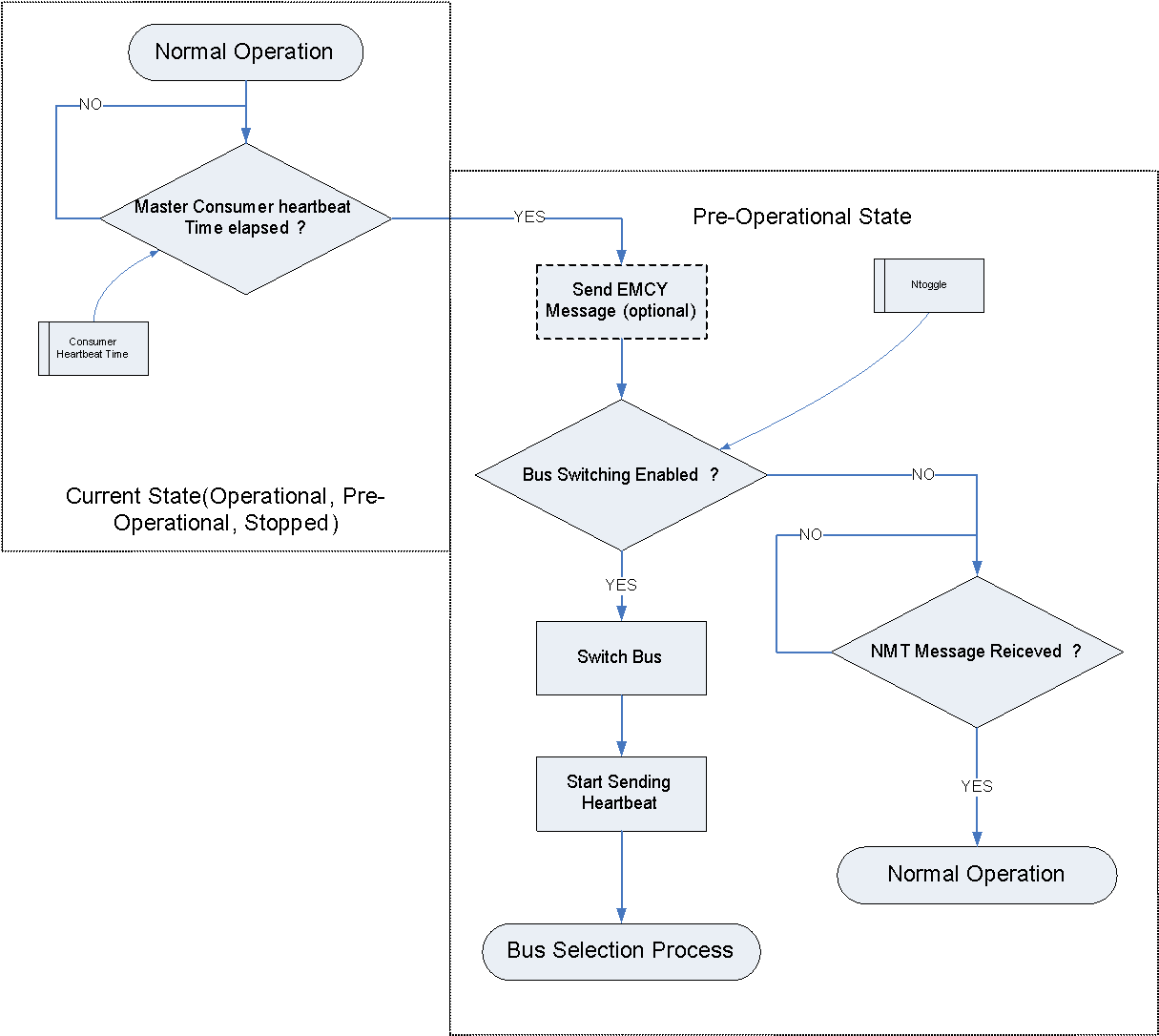

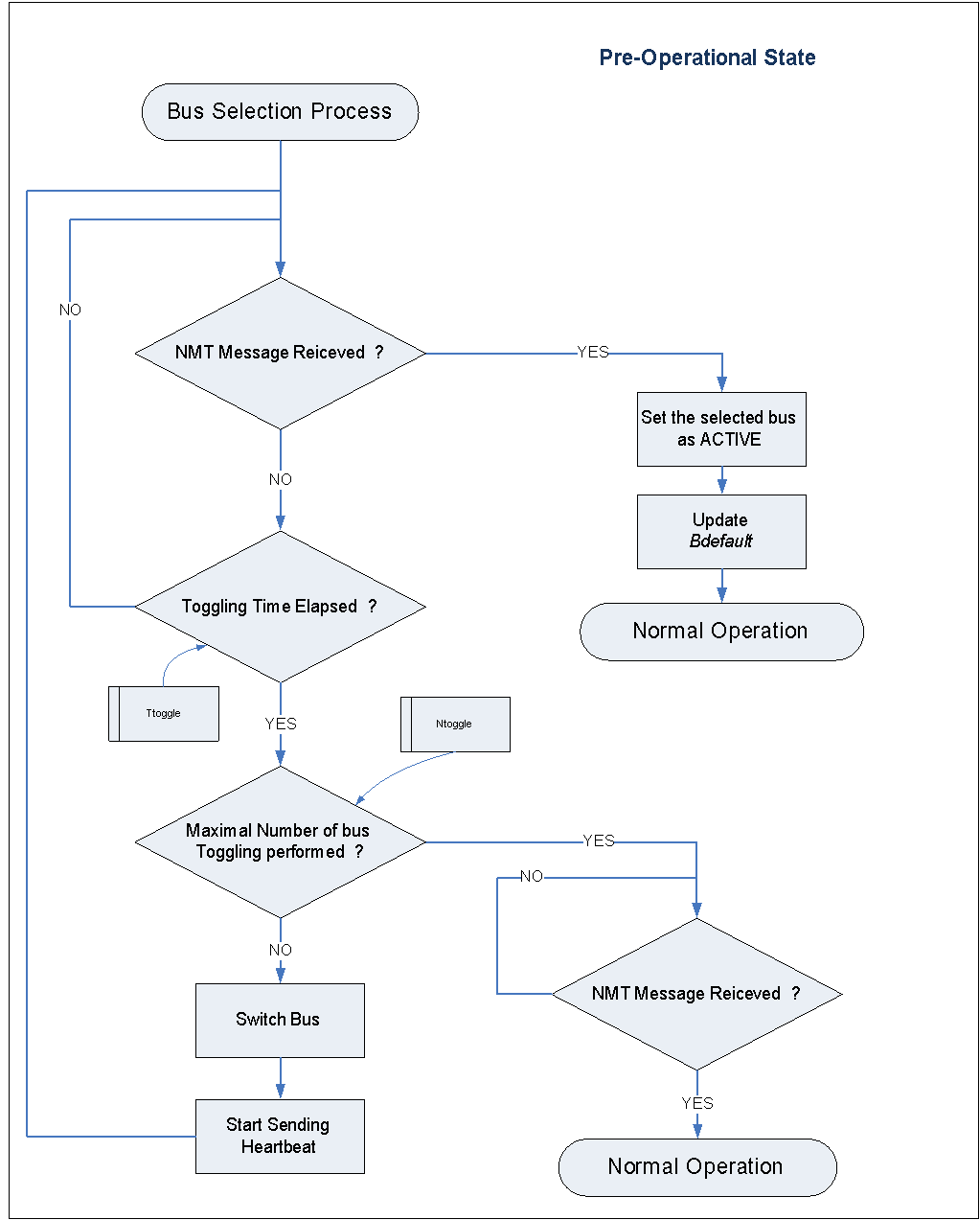

Start-up procedure

After a node power-on or after hardware reset, the node shall use the bus defined by the Bdefault parameter as the active bus.

This implies that the CANopen Boot-up message is transmitted on the default bus.

When in the CANopen Pre-operational state, each slave node shall listen for an NMT message, alternatively on the two busses according to the toggling mechanism specified in clause 8.3.3.

The nodes start-up procedure is illustrated in Figure 81. The start-up procedure ends with an entry to the bus selection process specified in clause 8.3.3.

Figure 81: Node start up procedure

Bus monitoring protocol

The Redundancy Master shall periodically produce CANopen Master Heartbeat messages on the active bus.

The Redundancy Master shall switch over and operate on the alternate bus by carrying out the following procedure:

- stopping transmission of the heartbeat messages on the active bus and

- starting transmission of heartbeat messages on the alternate bus.

This makes the alternate bus the active one.

Each Slave node shall be a consumer of the Master Heartbeat messages sent by the Redundancy Master.

Each Slave node shall periodically transmit CANopen Heartbeat messages on the bus it considers being the active.

When a Slave node misses the Master Heartbeat as defined by Ttoggle on the active bus, it shall perform the following:

- enter the CANopen Pre-operational state, then

- switch to the alternate bus.

- 1 The CANopen Pre-operational state affects the communication on the CAN Network in the sense that PDOs are no longer transmitted by the node. However, the mode of the application in the node is not necessarily affected.